Makita GD0603 Manual

Other Makita Grinder manuals

Makita

Makita 9067 User manual

Makita

Makita 9527PB Quick start guide

Makita

Makita DGD800 User manual

Makita

Makita GD0602 User manual

Makita

Makita DGA404 User manual

Makita

Makita GA7061 User manual

Makita

Makita M9509 User manual

Makita

Makita 9526NB User manual

Makita

Makita DGD800 User manual

Makita

Makita GA7020 User manual

Makita

Makita GA7071 User manual

Makita

Makita GA7030 User manual

Makita

Makita 9556HN User manual

Makita

Makita DGA405 User manual

Makita

Makita GA048G User manual

Makita

Makita 9558NBR User manual

Makita

Makita GA7001L User manual

Makita

Makita GA7010C User manual

Makita

Makita GA037G User manual

Makita

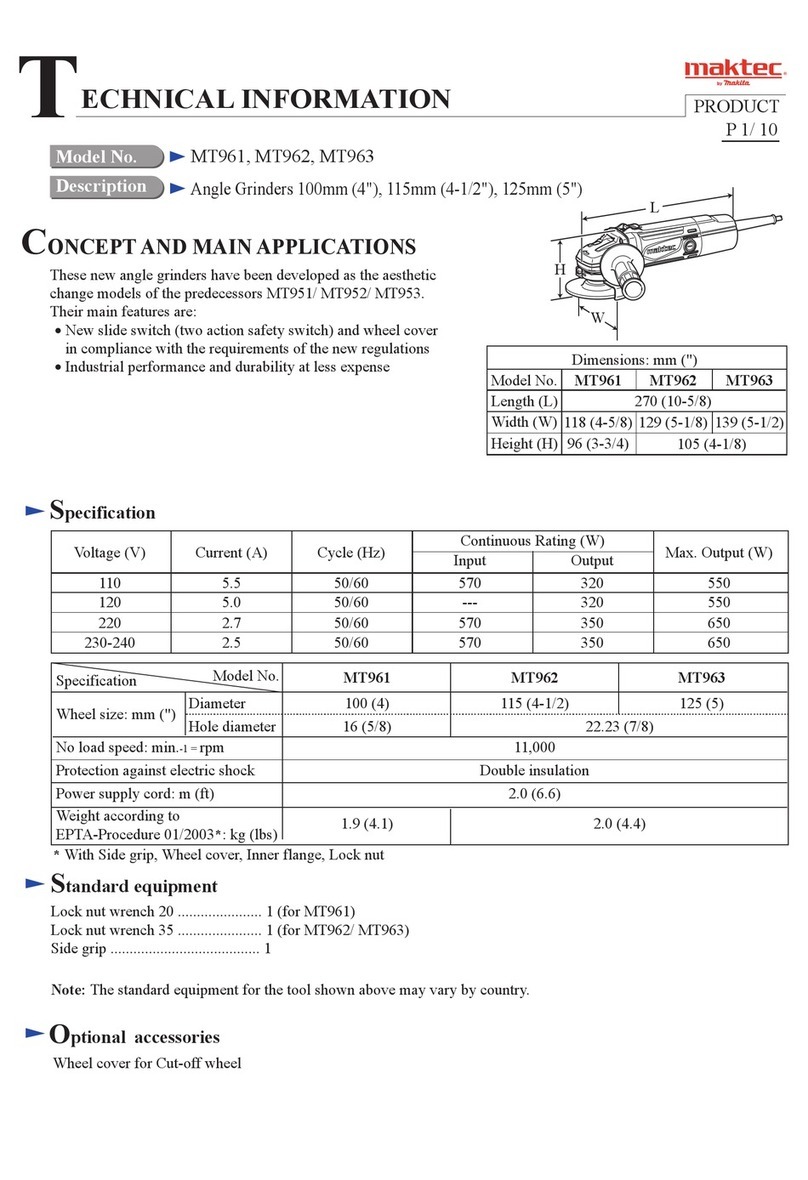

Makita Maktec MT961 Manual