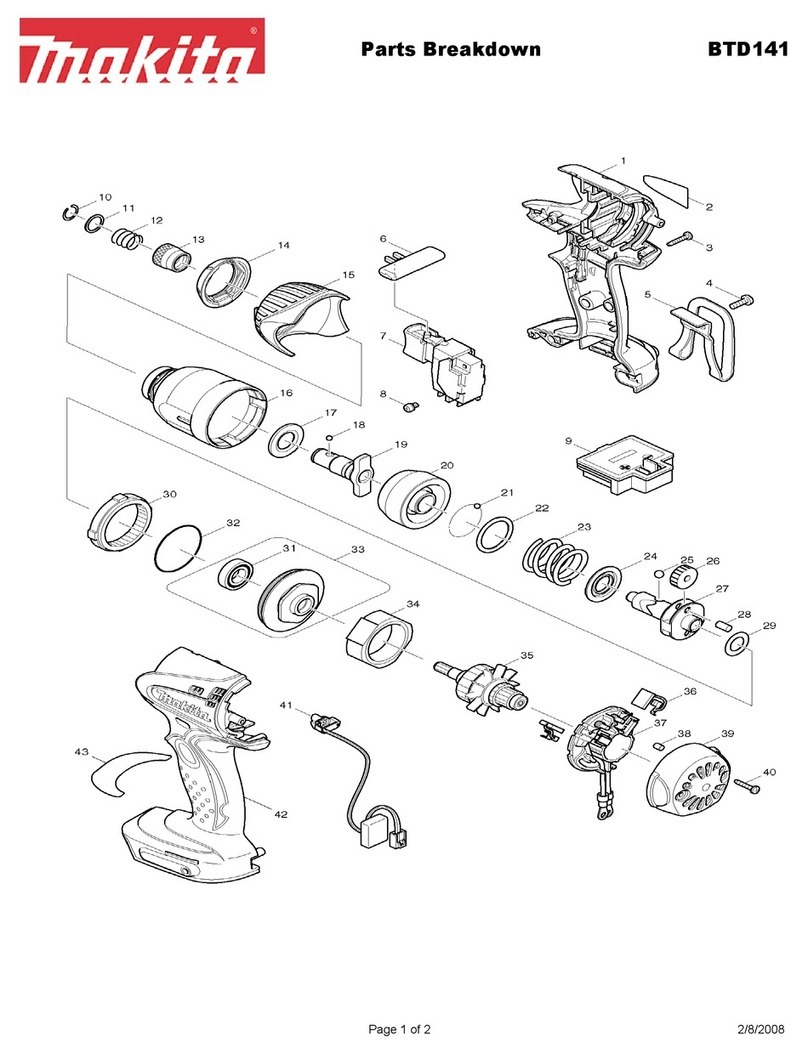

Repair P 2/ 8

< 1 > Lubrication

Apply MAKITA grease N. No.1 to the following portions designated by black triangle to protect

parts and product from unusual abrasion.

Sleeve 18

8

8

10 13

10

13

19

19

7

Hammer case

Anvil

Hammer

Spindle

Spring holder

Spur gear 19-41

* The surface which contacts sleeve 18.

* The outer surface which contacts the inner surface of 8 Hammer

* The inner surface where contacts 10 Spring holder.

* The inner surface where contacts 13 Spindle.

* The wing portion which is percussed by cam portion of 8 Hammer.

* The cam portion which transmits the percussion to 7 Anvil.

* The edge portion where 19 pcs.of steel ball 4 roll.

* The groove where 2 pcs. of steel ball 6.4 roll.

* The gear portion

* The teeth portion

* The surface where flat washer 8 contacts.

* The joining hole in which 13 Spindle is inserted.

19 cps. of

steel ball 4 Steel ball 6.4

Compression

spring 28

Position

No. Parts item Portion

to be lubricated Amount : g

( oz )

7

Flat

washer 8

0.5 (0.02)

0.5 (0.02)

0.5 (0.02)

1.0 (0.04)

0.1 (0.01)

10 .0 (0.35)

10 .0 (0.35)

2.0 (0.08)

3.5 (0.13)

3.5 (0.13)

3.0 (0.12)

3.0 (0.12)

Fig. 1

< 2 > Removing armature

Fig. 2

Cup washer

Motor housing

Hammer case cover

Urethane ring 5

Hex socket

head bolt M5x50

Hammer case

Armature

Mechanical section

( 1 ) Remove brush holder cap and carbon brush.

See Fig. 2.

( 2 ) Remove hex socket head bolt M5x50, cup

washer and urethane ring 5 each 4 pcs.

See Fig. 2.

( 3 ) Separate mechanical section (hammer case

and hammer case cover) from motor

housing. Then, armature can be separated

from motor housing together with

mechanical section. See Fig. 2.

< Note >

If the armature remains in the motor housing

at the step (3), it can be removed by knocking

the edge of motor housing with plastic hammer.