Makita DCU602 User manual

Other Makita Outdoor Cart manuals

Makita

Makita DCU602 User manual

Makita

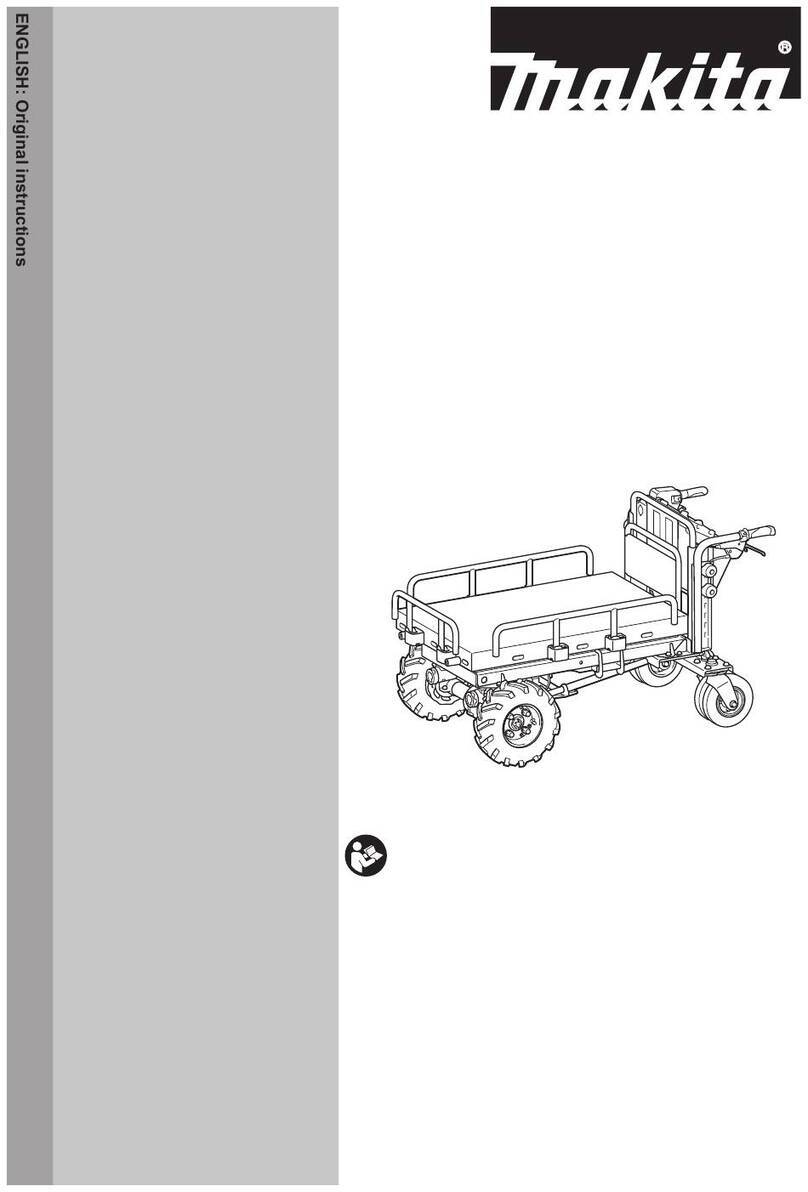

Makita DCU180 User manual

Makita

Makita DCU601 User manual

Makita

Makita DCU602 User manual

Makita

Makita DCU604 User manual

Makita

Makita DCU180 User manual

Makita

Makita DCU602 User manual

Makita

Makita DCU180 User manual

Makita

Makita DCU601 User manual

Makita

Makita DCU603 User manual