Makita BFT040F Manual

Other Makita Power Screwdriver manuals

Makita

Makita BFL080F User manual

Makita

Makita BFL060F Manual

Makita

Makita DFL650F User manual

Makita

Makita FS2700 User manual

Makita

Makita HP331DSMJ User manual

Makita

Makita DFL061F User manual

Makita

Makita AR411HR User manual

Makita

Makita XT262T User manual

Makita

Makita DFS250 User manual

Makita

Makita BFL061F User manual

Makita

Makita FS4000 User manual

Makita

Makita FS4000 User manual

Makita

Makita BFT022F User manual

Makita

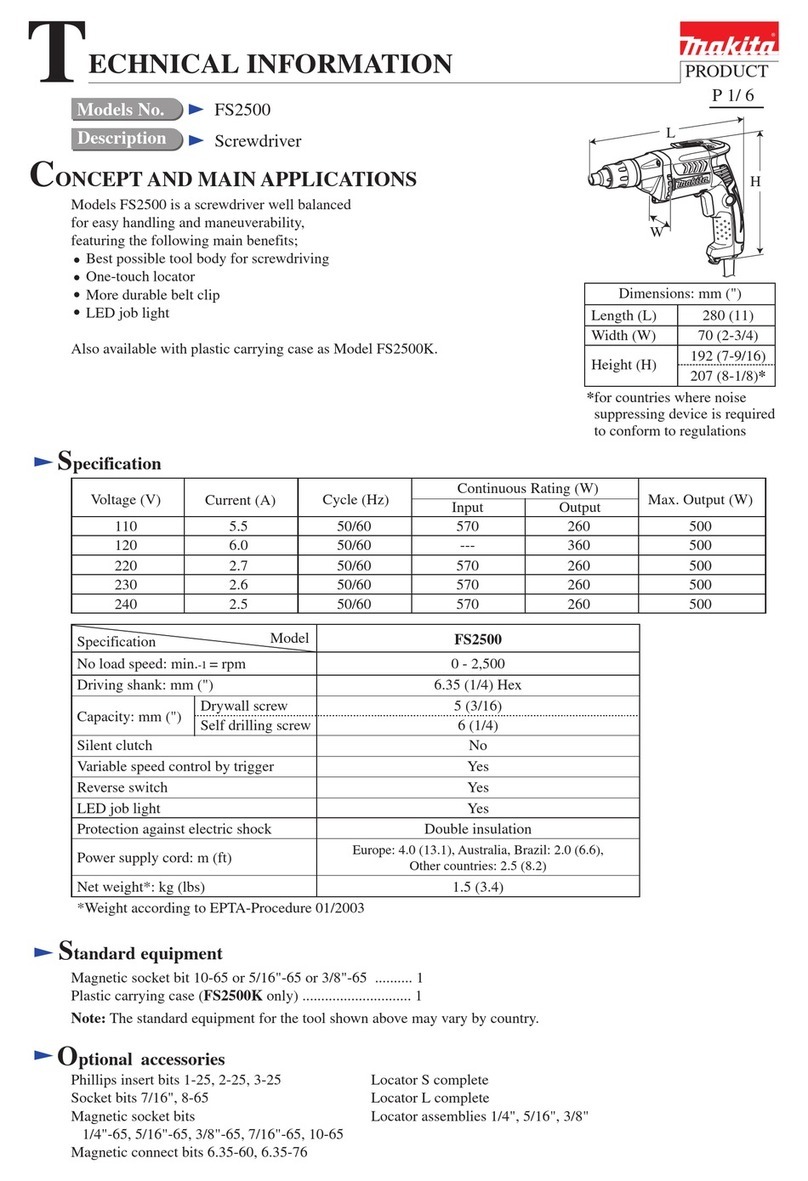

Makita FS2500 Manual

Makita

Makita DFS452 User manual

Makita

Makita 6823N User manual

Makita

Makita 6805BV User manual

Makita

Makita DDA460 User manual

Makita

Makita 6796D User manual

Makita

Makita XSF01 User manual

Popular Power Screwdriver manuals by other brands

Festool

Festool TI 15 operating manual

Matatakitoyo Torque Tools

Matatakitoyo Torque Tools MTD Operation manual

Skil

Skil 2346 Operating/safety instructions

DeWalt

DeWalt XR LI-ION DCD931 user manual

Festool

Festool DWC 18-2500 operating manual

EINHELL

EINHELL TE-CD 12/1 Li Series Original operating instructions