1CONTENTS

1CONTENTS.................................................................................................................................................................................2

2CAUTION....................................................................................................................................................................................3

3NECESSARY REPAIRING TOOLS ...........................................................................................................................................3

4LUBRICANT AND ADHESIVE APPLICATION ......................................................................................................................3

5TIGHTENING TORQUE SPECIFICATIONS............................................................................................................................3

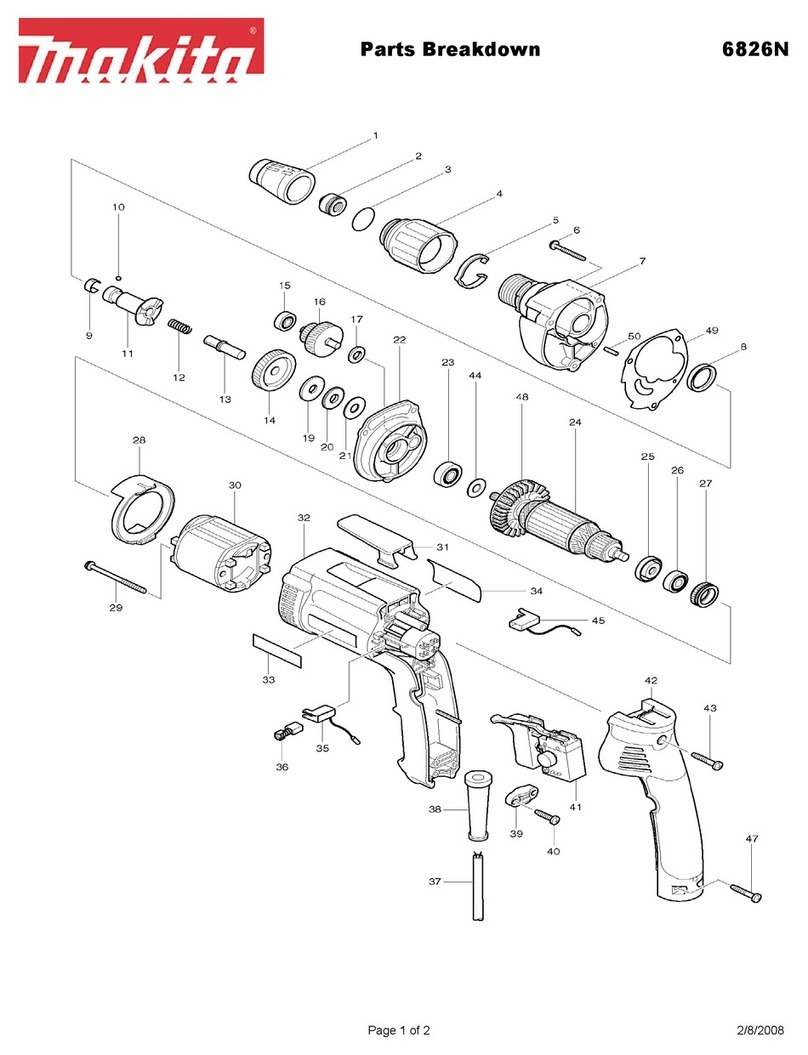

6REPAIR ........................................................................................................................................................................................4

6-1 Bit sleeve section..................................................................................................................................................................4

6-1-1 Disassembling .............................................................................................................................................................4

6-1-2 Assembling..................................................................................................................................................................4

6-2 Electrical parts section..........................................................................................................................................................5

6-2-1 Disassembling .............................................................................................................................................................5

6-2-2 Assembling..................................................................................................................................................................7

6-3 Clutch assembly section.....................................................................................................................................................10

6-3-1 Disassembling ...........................................................................................................................................................10

6-3-2 Assembling................................................................................................................................................................ 11

6-4 Gear assembly section........................................................................................................................................................13

6-4-1 Disassembling ...........................................................................................................................................................13

6-4-2 Assembling................................................................................................................................................................13

7CIRCUIT DIAGRAM................................................................................................................................................................15

8WIRING DIAGRAM.................................................................................................................................................................16

8-1 LED circuit section ............................................................................................................................................................16

8-2 Electrical parts section........................................................................................................................................................17

9-1 Models those Housing L with Opening A..........................................................................................................................18

10 TROUBLESHOOTING.............................................................................................................................................................19

10-1 Note for Repairing .............................................................................................................................................................19

10-2 Test for checking the short-circuit in FET (Field Effect Transistor) of controller ..............................................................19

12 CHECK LIST FOR TROUBLESHOOTING ............................................................................................................................20

13 APPROXIMATE ENDURANCE TIME OF EACH PART.......................................................................................................31

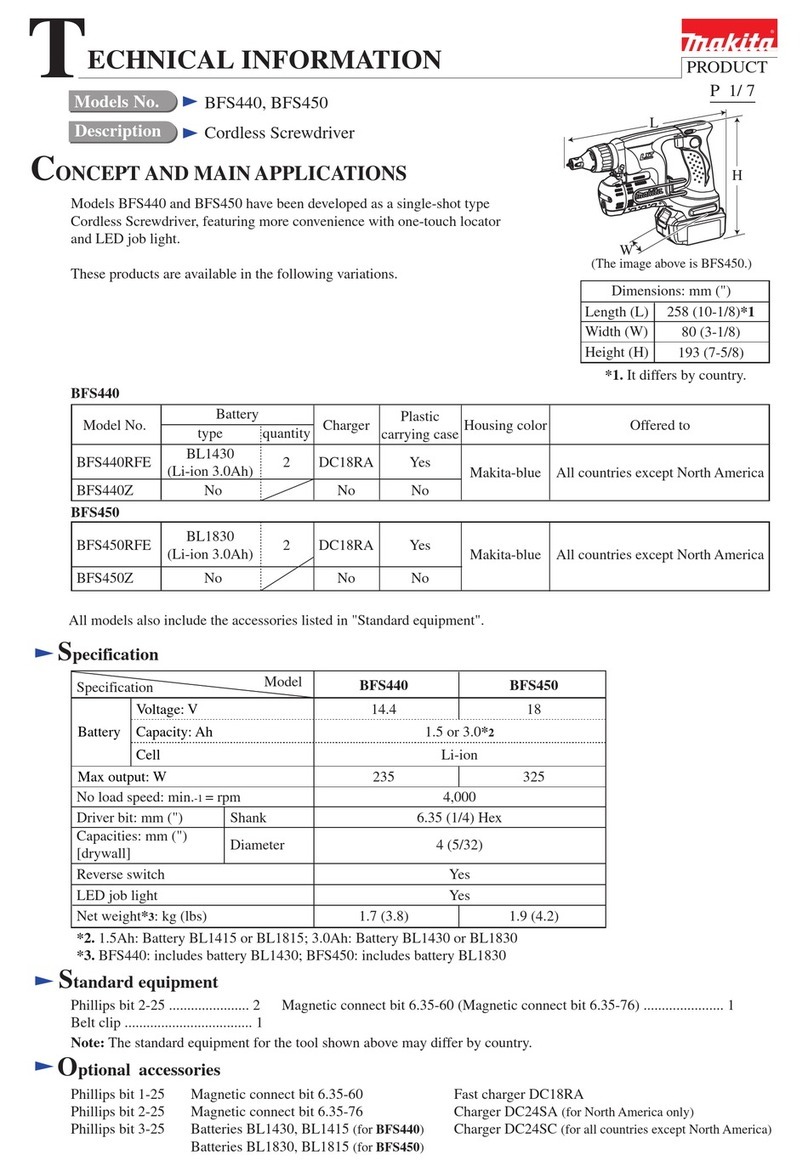

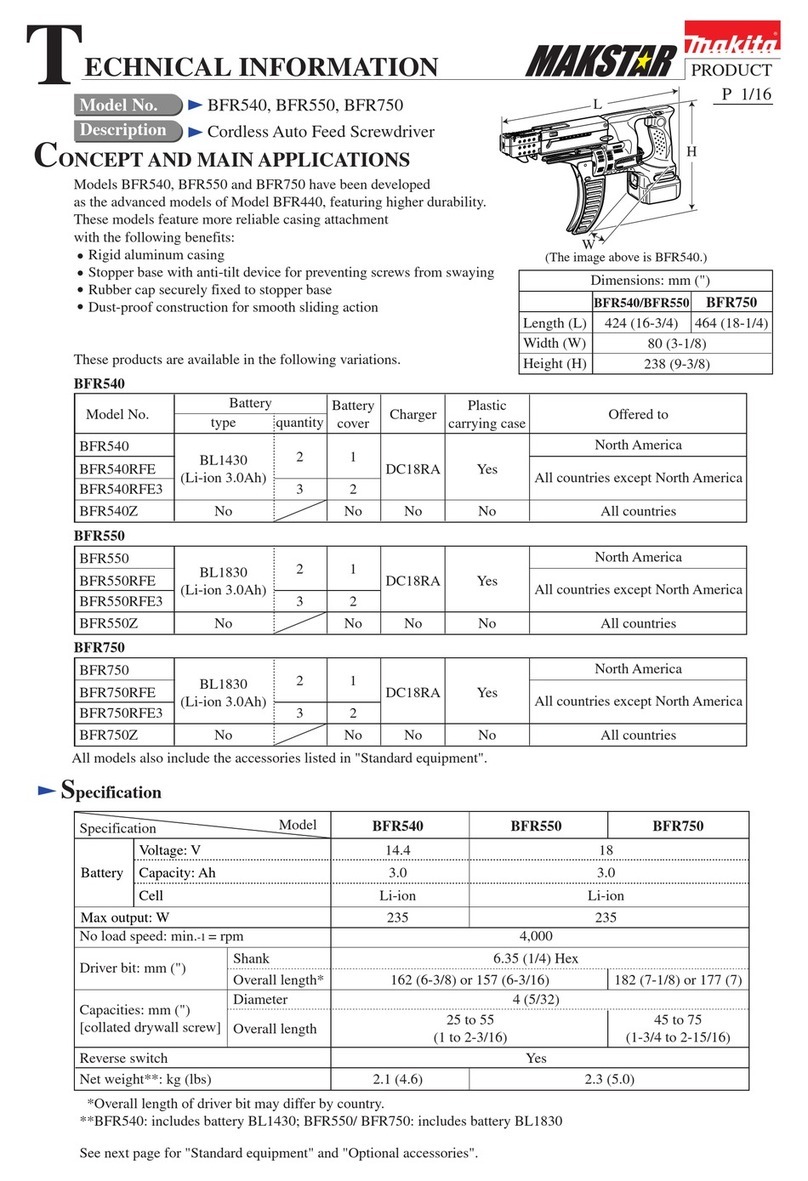

14 MAIN FEATURES OF THE MACHINE..................................................................................................................................32

15 SPECIFICATIONS OD BATTERY...........................................................................................................................................32

16 LISTS OF THE ELECTRONIC FUNCTIONS AND REMAINDERS ....................................................................................33

16-1 When a screw is tightened completely or when there is no trouble with the machine: ......................................................33

16-2 When a screw is tightened incompletely or when there is some trouble with the machine:...............................................33

16-3 When tightening the tightened screw again: ......................................................................................................................34

16-4 During USB communication..............................................................................................................................................34

17 TORQUE CHECK MODE ........................................................................................................................................................34

17-1 How to use “Torque check mode”. ....................................................................................................................................34

17-2 How to cancel “Torque check mode”.................................................................................................................................35

18 USING THE DEDICATED APP (MAKITA INDUSTRY TOOL SETTINGS) ........................................................................35