Makita HR2430 Manual

Other Makita Rotary Hammer manuals

Makita

Makita HR140D User manual

Makita

Makita BHR200S Manual

Makita

Makita HR4003C User manual

Makita

Makita BHR162 User manual

Makita

Makita HR2440 User manual

Makita

Makita HR2470 User manual

Makita

Makita HR2440 User manual

Makita

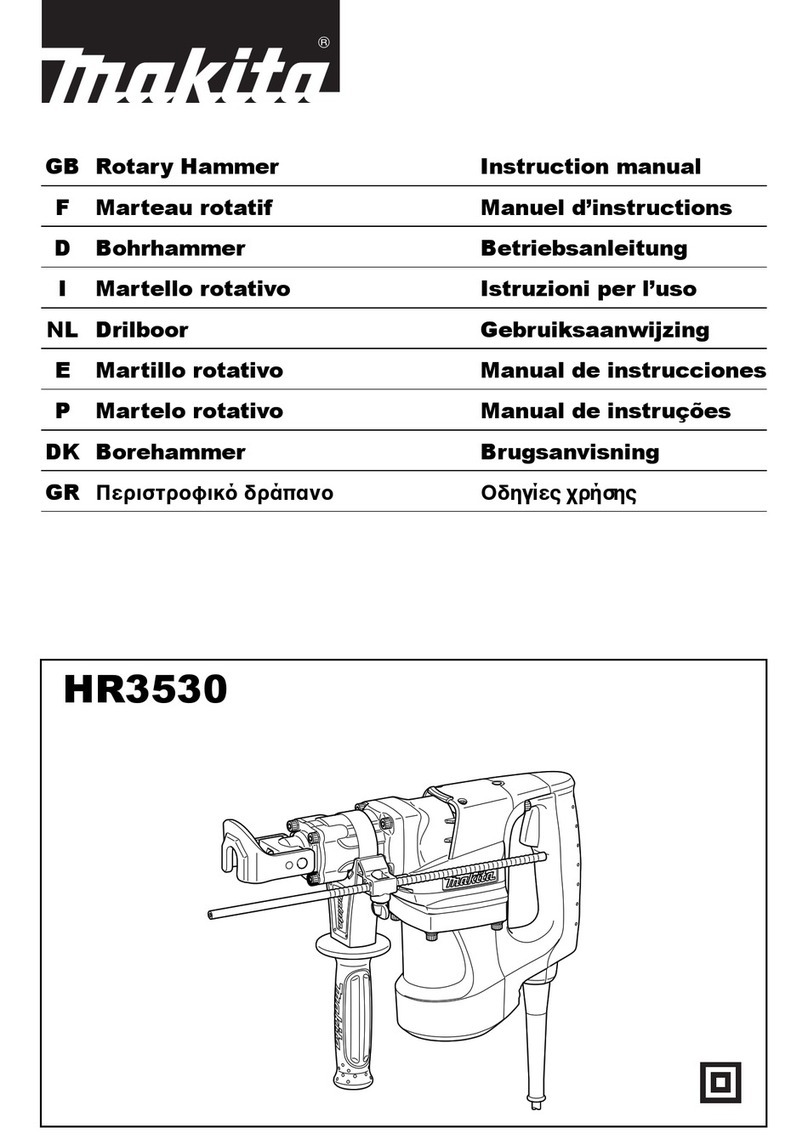

Makita HR3530 User manual

Makita

Makita HR3851 User manual

Makita

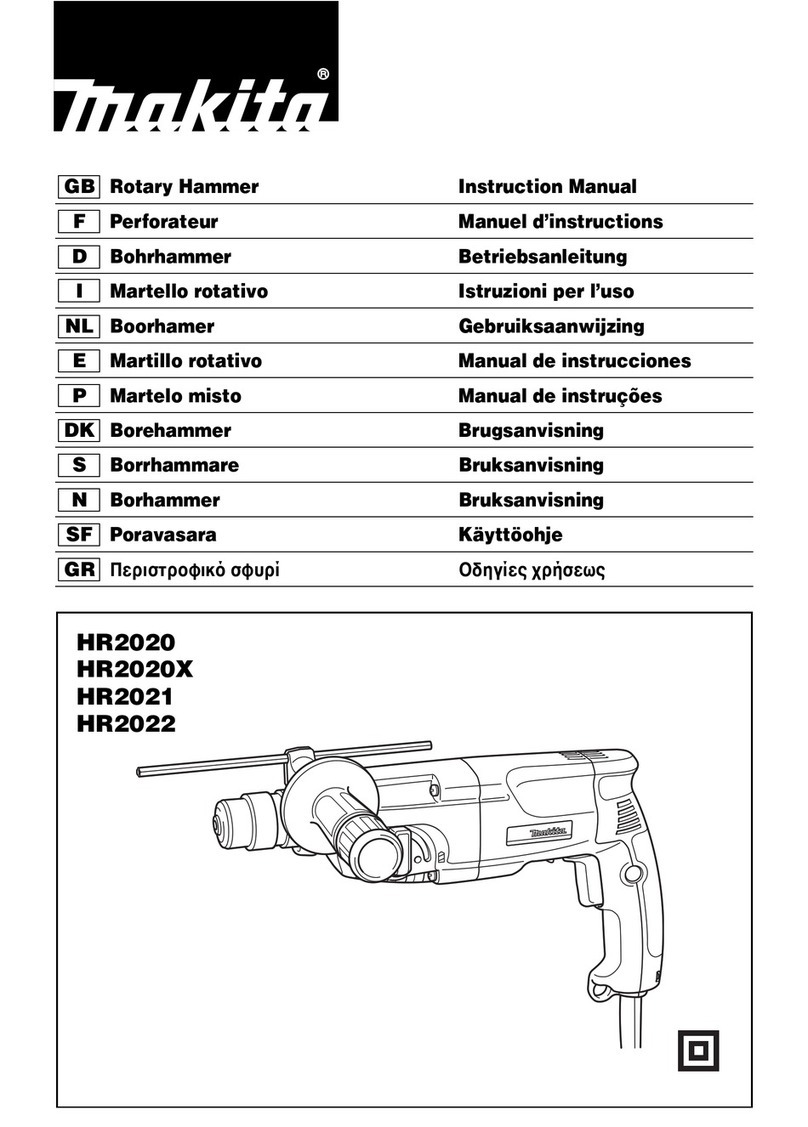

Makita HR2020 User manual

Makita

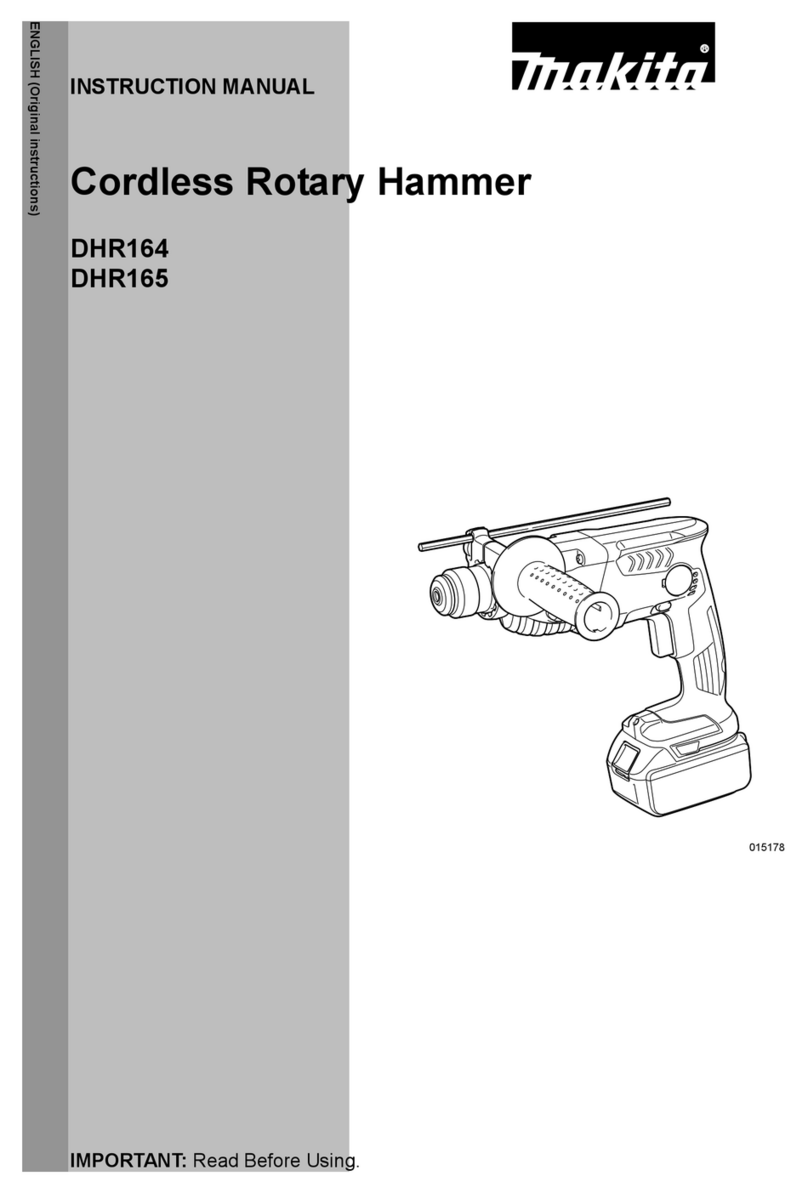

Makita DHR164 User manual

Makita

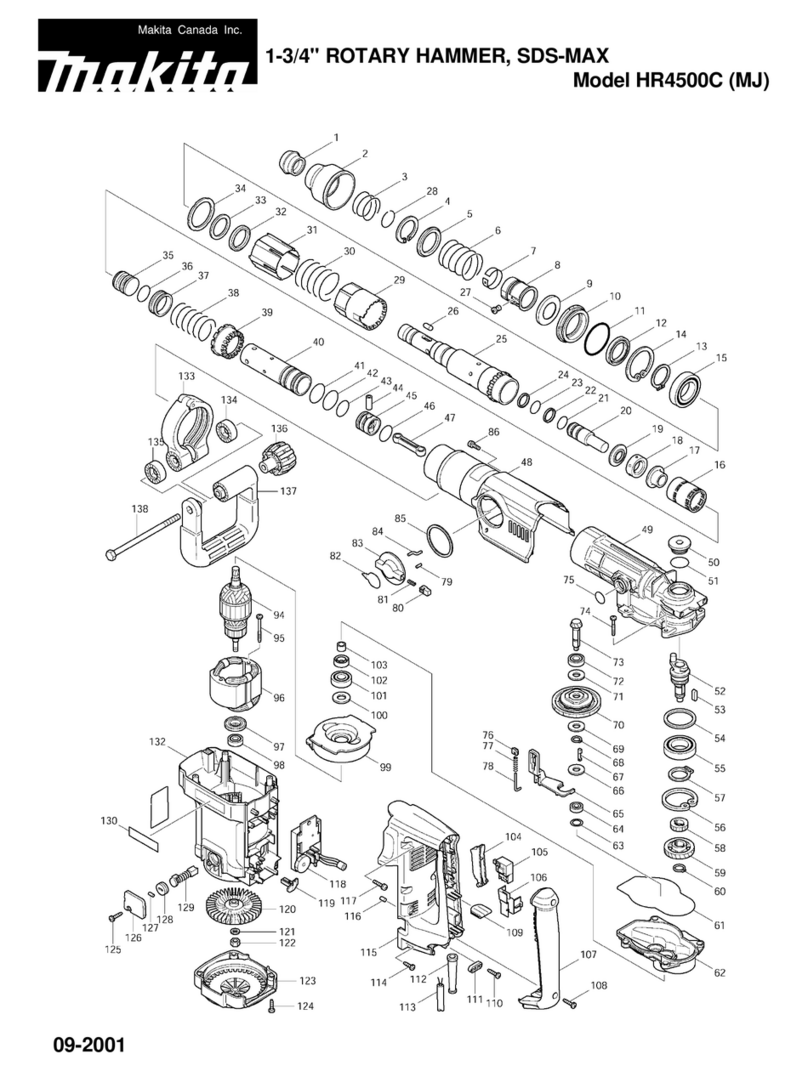

Makita HR4500C User manual

Makita

Makita HR2450F User manual

Makita

Makita HR2450 Series User manual

Makita

Makita HR4002 User manual

Makita

Makita HR1821 User manual

Makita

Makita HR4000C User manual

Makita

Makita HR5000K User manual

Makita

Makita BHR162 User manual

Makita

Makita HR3000C User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

BTI

BTI Profiline BTI-BH 24 VE operating instructions