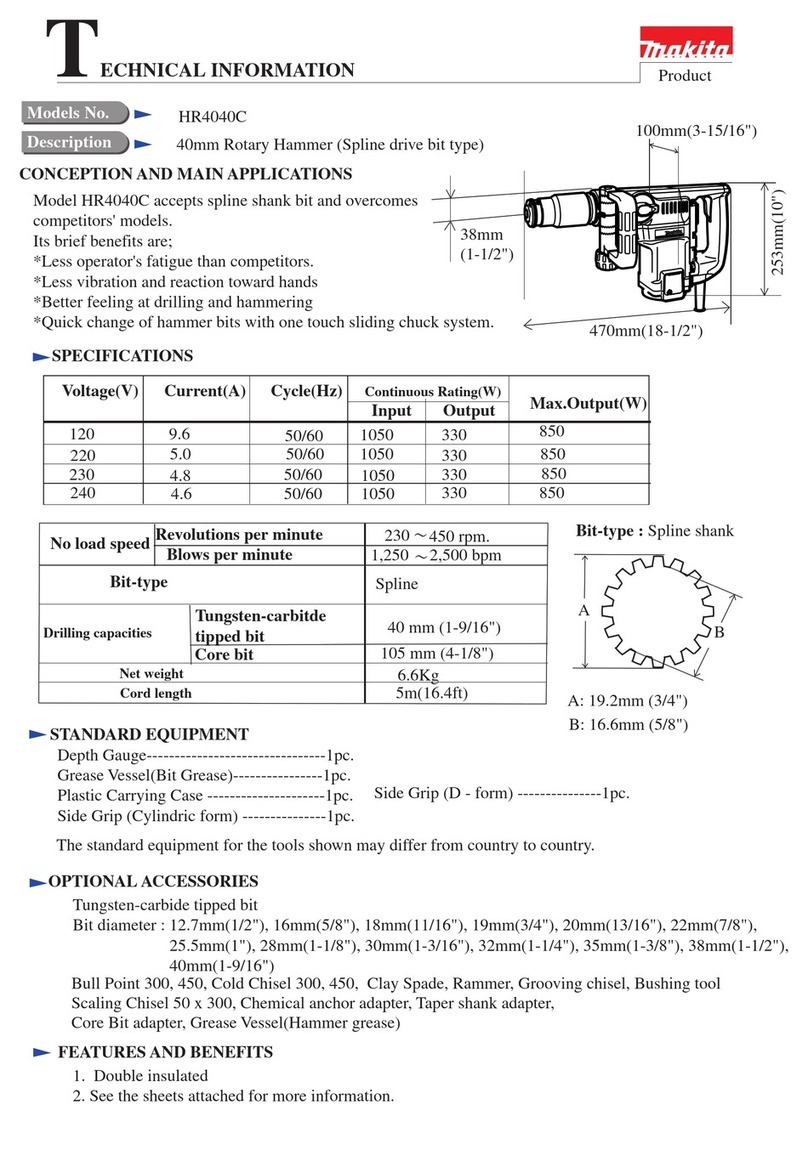

Models No.

Description

NEW TOOL

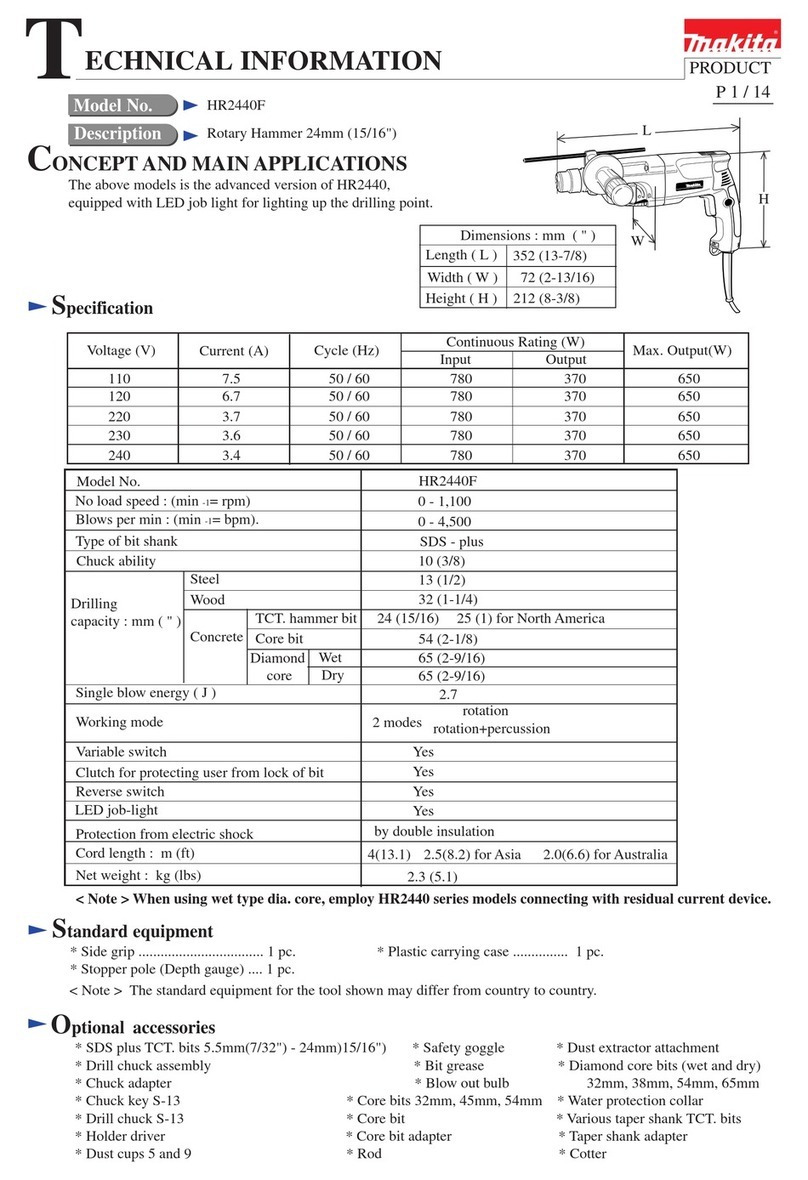

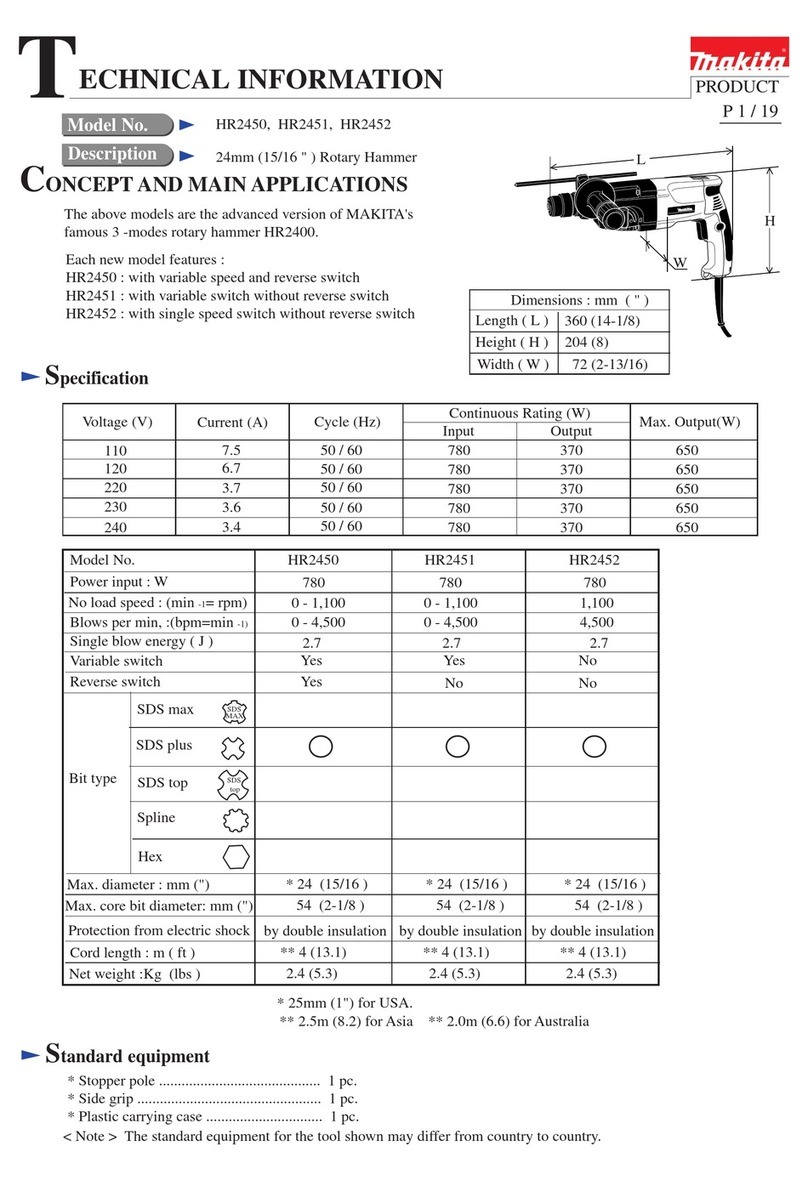

TECHNICAL INFORMATION

CONCEPTION AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 / 23

BHR200S

Cordless Rotary Hammer 20mm (3/16")

The above mentioned model is 20 mm (13/16") cordless

rotary hammer. Its brief benefits and features are as follows.

* Equipped with newly developed 24V/3.0Ah Ni-MH battery.

* 3 working modes, they are "rotation with percussion",

"percussion only" and "rotation only".

* SDS-plus bit can be used

Below listed standard type model is only available.

L

CH

H

W

Model No. Battery Charger Plastic case

BHR200SF B2430, Ni-MH 24V/3.0Ah DC24SA Yes Dimensions : mm ( " )

Width ( W )

*Height ( H )

86 (3-3/8)

235 (9-1/4)

Length ( L ) 316 (12-1/2)

Center height (CH) 35 (1-3/8)

*Height ( H ) : 210mm (8-1/4") when battery

B2417 is attached.

Voltage (V)

*Capacity (Ah)

*Energy (Wh)

24

3.0

72

0 - 1,100

0 - 4,700

SDS-plus

10 (3/8)

20 (13/16)

13 (1/2)

27 (1-1/16)

Yes

Yes

Battery

Electric brake

Yes

Reverse switch

Clutch

Concrete

Steel

Wood

No load speed : (min-1= rpm)

Blows per min : (min-1= bpm).

Bit type

Diameter of bit shank : mm ( " )

Capacity : mm ( " )

*Capacity (Ah): 1.7Ah when battery B2417 is attached.

*Energy (Wh) : 40.8Wh when battery B2417 is attached.

* Depth gauge (Stopper pole) ............................... 1 pc.

* Grease for bit .................................................... 1 pc.

* SDS-plus type TCT. hammer bit

4.0mm(5/32") - 20mm(13/16")

* Bull point

* Cold chisel

* Scaling chisel

* Grooving chisel

* Drill chuck assembly

* Chuck key S13

* Grease for bit

* Dust cup 5

* Dust cup 9

* Blow out bulb

* Chuck adapter assembly

* Battery B2430

* Battery B2417

* Charger DC24SA

* Dust extractor attachment

* Foot for battery B2417