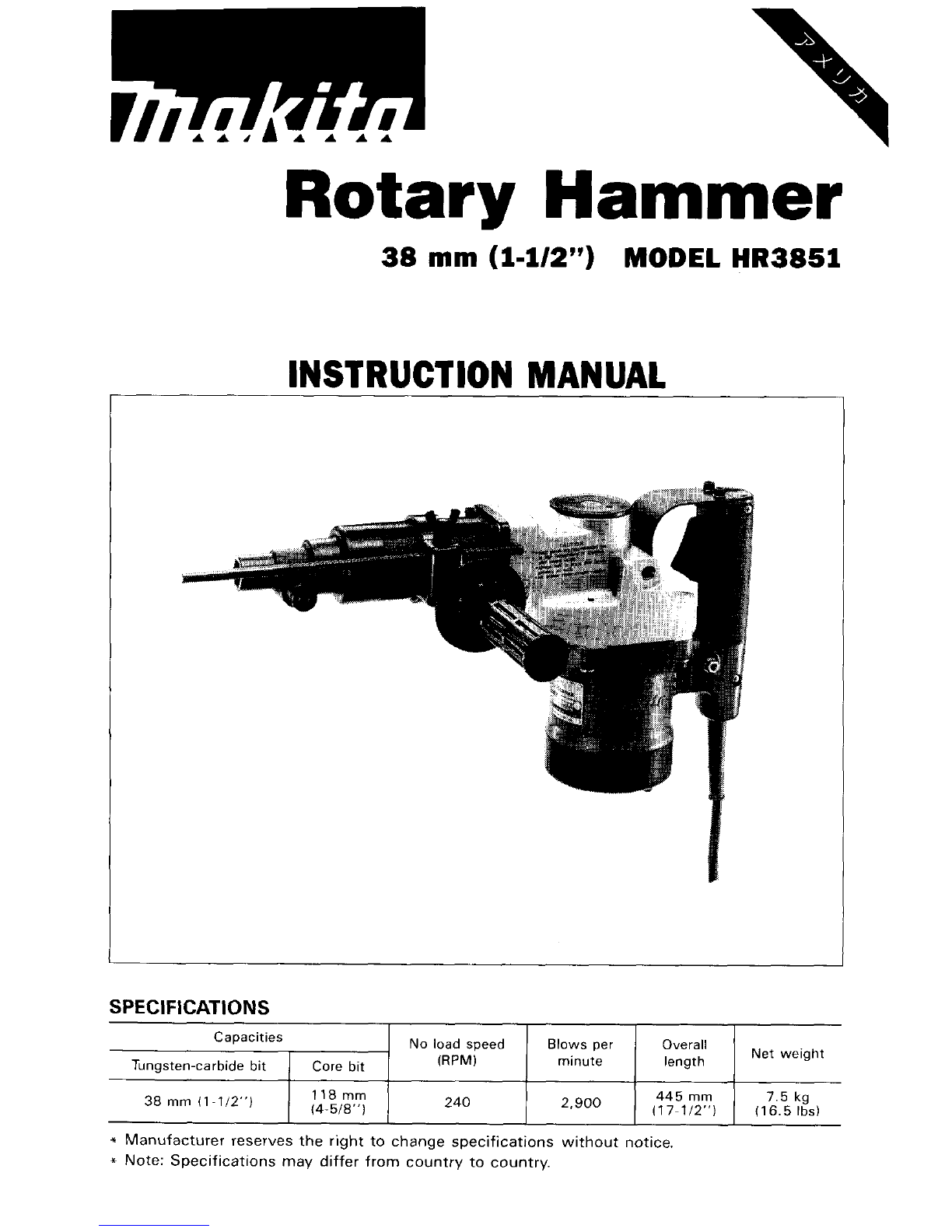

Makita HR3851 User manual

Other Makita Rotary Hammer manuals

Makita

Makita HR2230 User manual

Makita

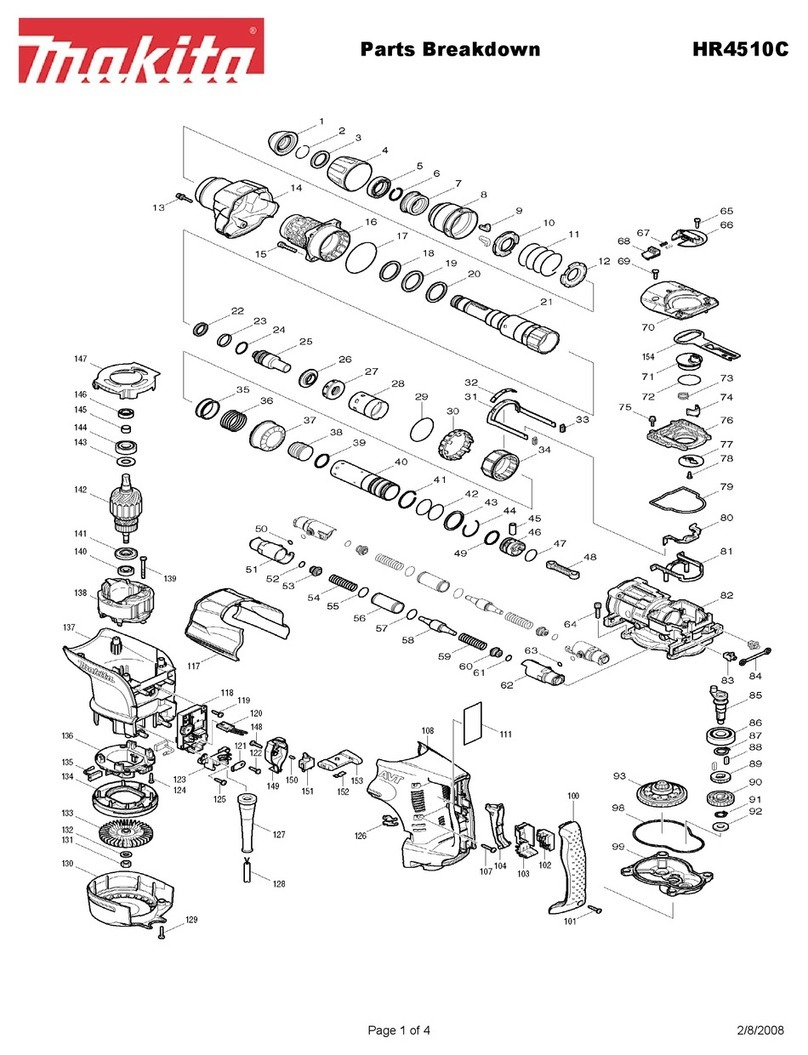

Makita HR4510C User manual

Makita

Makita HR2800 User manual

Makita

Makita Rotary Hammer User manual

Makita

Makita HR2400 User manual

Makita

Makita HR2800 User manual

Makita

Makita HR4510C Quick start guide

Makita

Makita HR006GD203 User manual

Makita

Makita HR4001C Quick start guide

Makita

Makita HR4001C User manual

Makita

Makita HR2460 User manual

Makita

Makita HR2470 User manual

Makita

Makita DHR400 User manual

Makita

Makita HR1840 User manual

Makita

Makita DHR164 User manual

Makita

Makita HR2800 User manual

Makita

Makita HR166D User manual

Makita

Makita HR2230 User manual

Makita

Makita HR5201C User manual

Makita

Makita HR3200C User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

BTI

BTI Profiline BTI-BH 24 VE operating instructions