14.

15.

16.

17.

18.

19.

20.

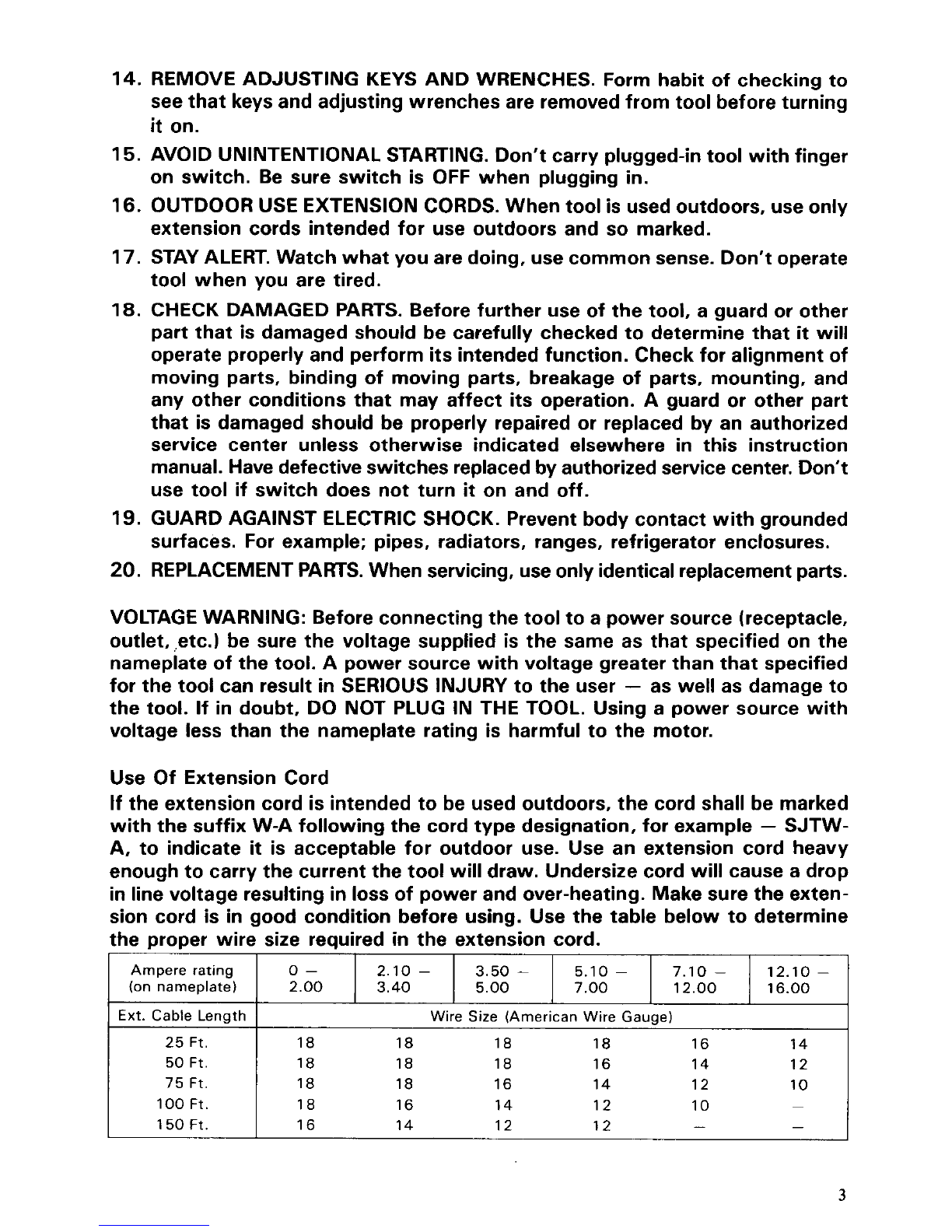

Ampere rating

(on nameplate)

Ext. Cable Length

25 Ft.

50 Ft.

75 Ft.

100Ft.

150Ft.

REMOVEADJUSTING KEYS AND WRENCHES. Form habit of checking to

seethat keysand adjusting wrenches are removed from tool beforeturning

it

on.

AVOID UNINTENTIONALSTARTING. Don’t carry plugged-in tool withfinger

on switch. Be sure switch is OFF when plugging in.

OUTDOOR USE EXTENSIONCORDS. Whentool is used outdoors, use only

extension cords intended for use outdoors and

so

marked.

STAY ALERT. Watch what youare doing, use commonsense. Don’t operate

tool when you are tired.

CHECK DAMAGED PARTS. Beforefurther use of the tool, a guard or other

part that is damaged should be carefully checked to determine that

it

will

operate properly and perform itsintended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or other part

that is damaged should be properly repaired or replaced by an authorized

service center unless otherwise indicated elsewhere

in

this instruction

manual. Havedefective switchesreplacedbyauthorized service center. Don’t

use tool if switch does not turn

it

on and off.

GUARD AGAINST ELECTRIC SHOCK. Prevent body contact withgrounded

surfaces. For example; pipes, radiators, ranges, refrigerator enclosures.

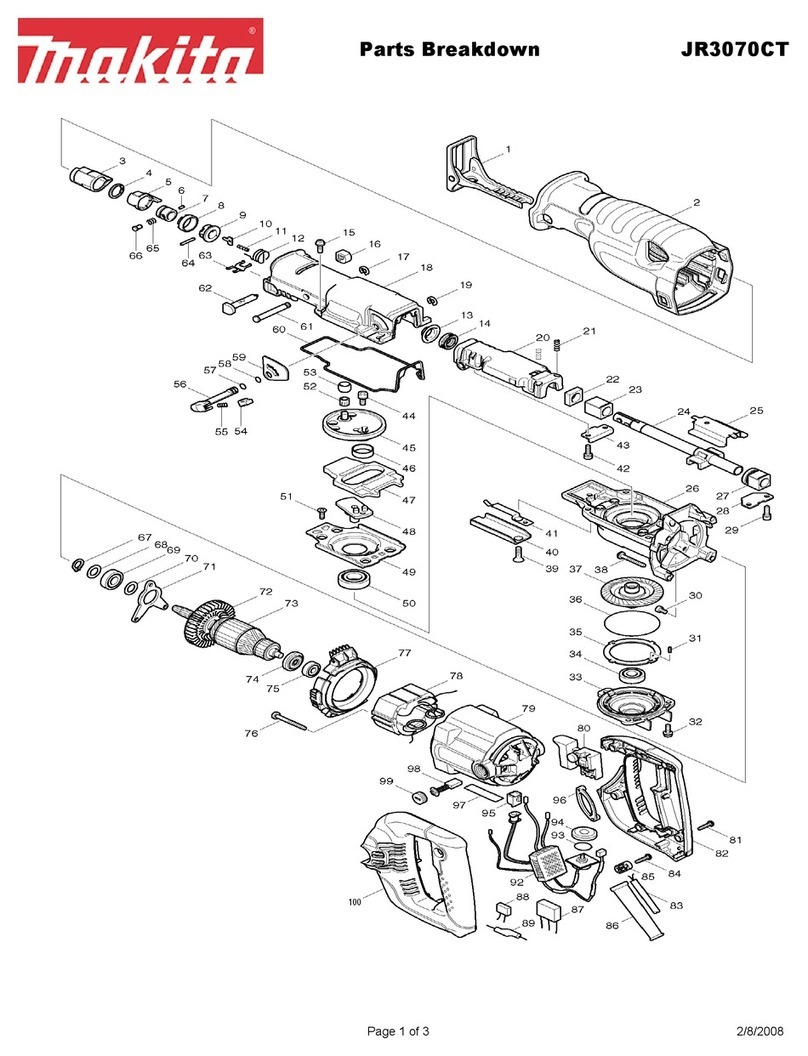

REPLACEMENTPARTS. When servicing, useonly identicalreplacement parts.

0-

2.10

-

3.50

-

5.10

-

7.10

-

12.10

-

2.00 3.40 5.00

7.00

12.00 16.00

Wire

Size

(AmericanWire Gauge)

18 18 18 18 16 14

18 18 18 16 14 12

18 18 16 14 12 10

18 16 14 12 10

~

16 14 12 12

- -

VOLTAGE WARNING: Before connectingthe tooltoa power source (receptacle,

outlet, etc.) be sure the voltage supplied is the same as that specified on the

nameplateof the tool. A power source with voltage greater than that specified

for the tool can result

in

SERIOUS INJURY to the user

-

as well as damage to

the tool.

If

in doubt, DO NOT PLUG INTHE TOOL. Using a power source with

voltage less than the nameplate rating is harmful to the motor.

Use Of Extension Cord

If the extension cord isintended to be used outdoors, the cord shall be marked

withthe suffix W-A following the cord type designation, for example

-

SJTW-

A, to indicate

it

is acceptable for outdoor use. Use an extension cord heavy

enoughto carry the current the toolwill draw. Undersize cord will cause a drop

in

line voltage resulting

in

loss

of power and over-heating. Makesure the exten-

sion cord is in good condition before using. Use the table below to determine

the proper wire size required

in

the extension cord.