Makita DLS111ZU User manual

Other Makita Saw manuals

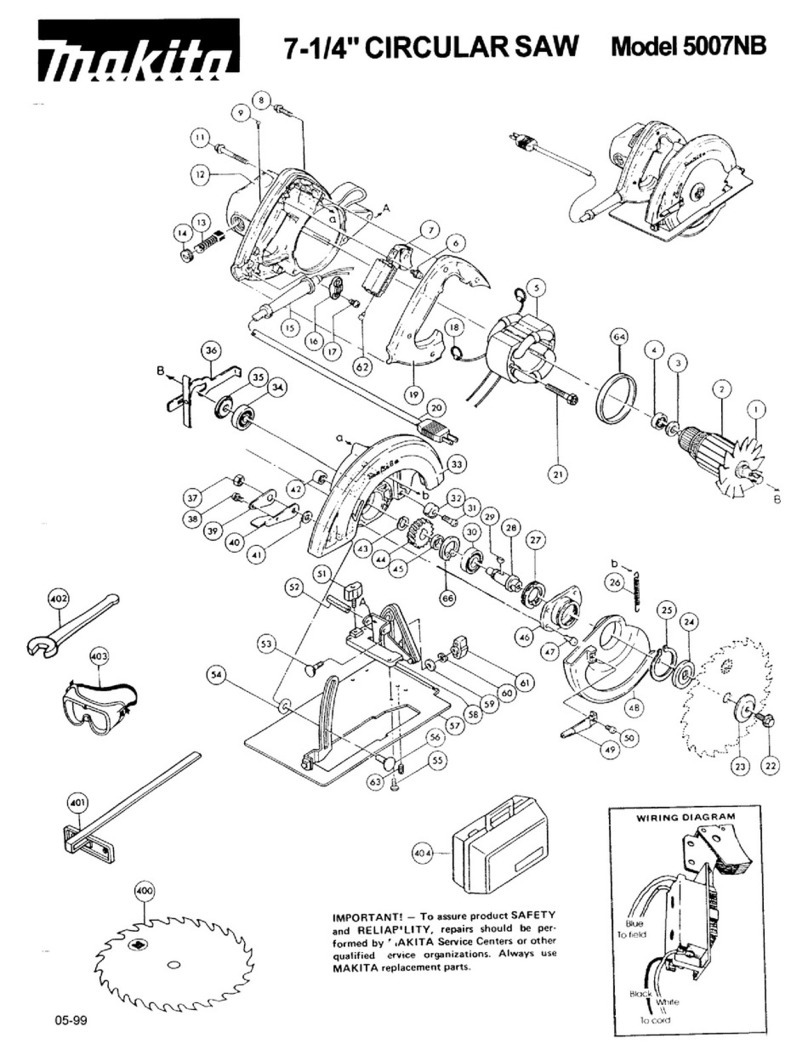

Makita

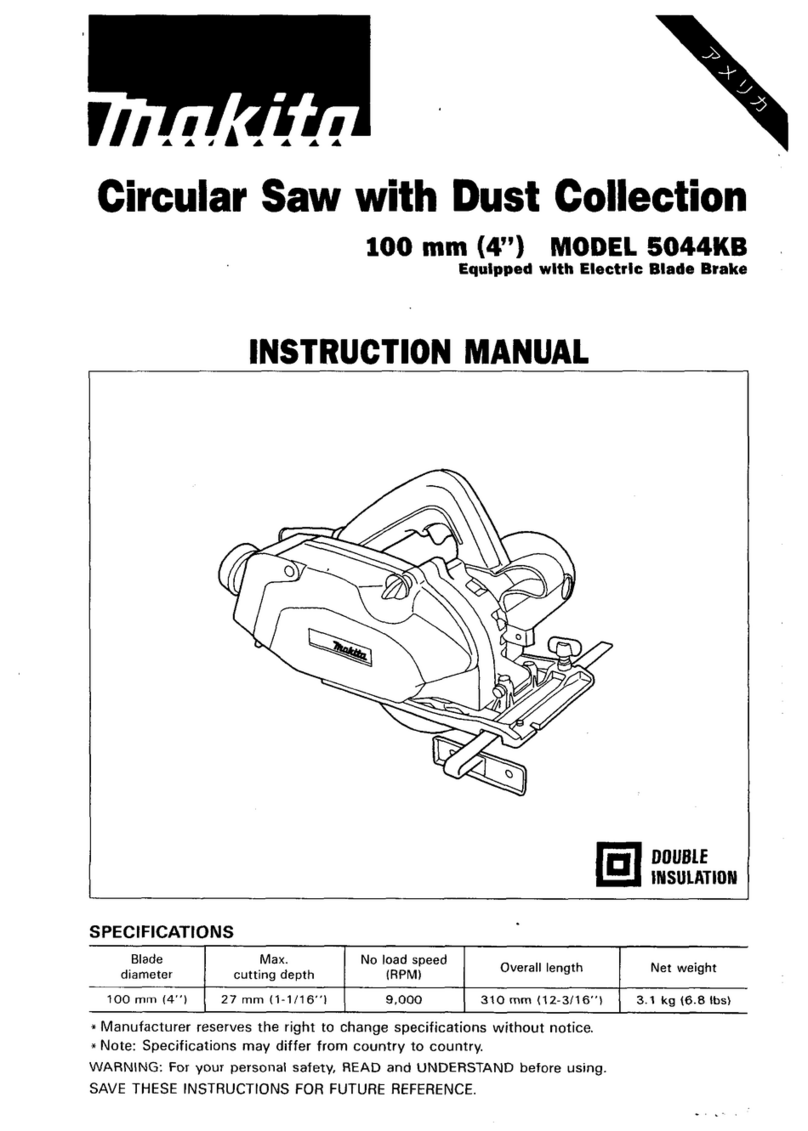

Makita 5044KB User manual

Makita

Makita HS0600 User manual

Makita

Makita LS1045 User manual

Makita

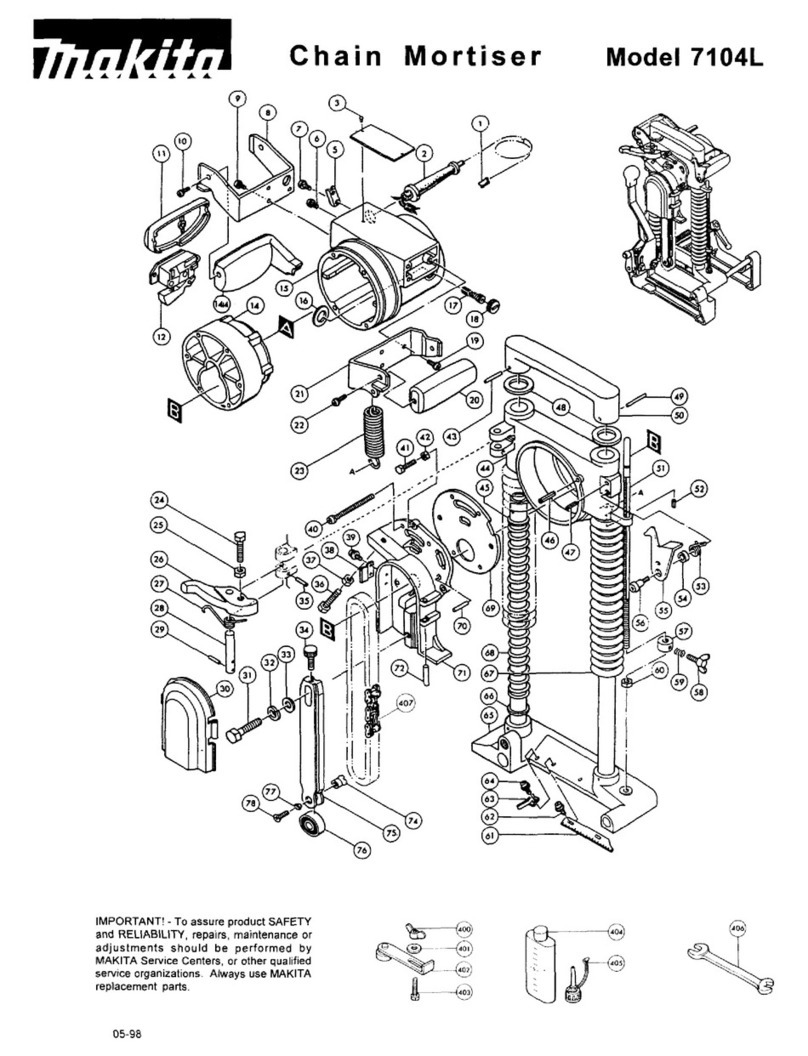

Makita 7104L User manual

Makita

Makita LS001G User manual

Makita

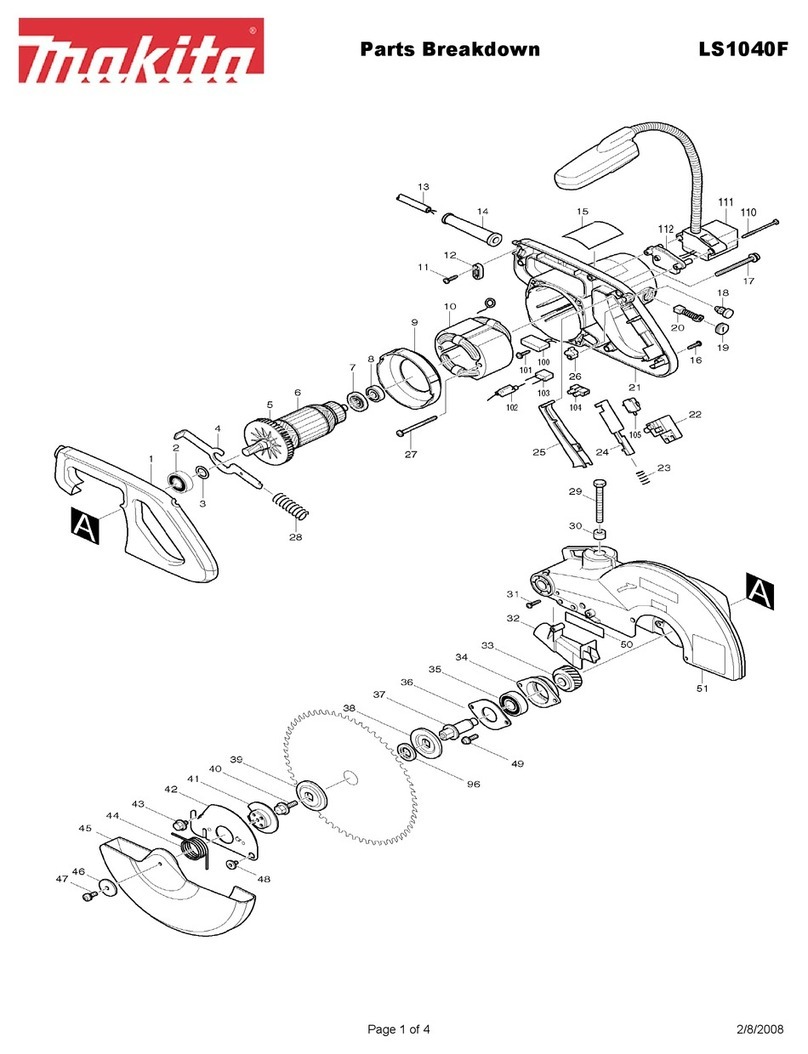

Makita LS1040F Quick start guide

Makita

Makita DJR183RTJ User manual

Makita

Makita LS1017L Manual

Makita

Makita 2704 User manual

Makita

Makita Makstar BSS610 User manual

Makita

Makita JR3051TK User manual

Makita

Makita MLS100 User manual

Makita

Makita LS0810 User manual

Makita

Makita DSD180 User manual

Makita

Makita LS800D User manual

Makita

Makita 5606B User manual

Makita

Makita 4200H User manual

Makita

Makita DJR186 User manual

Makita

Makita LS1018LN User manual

Makita

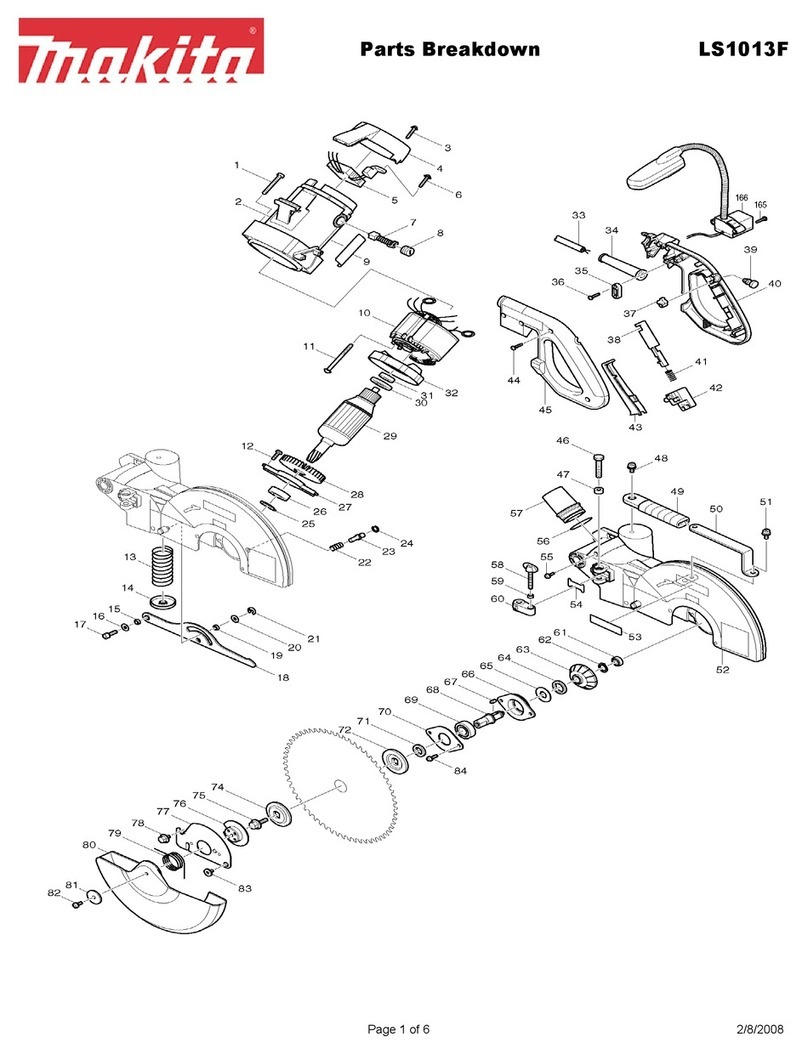

Makita LS1013F Quick start guide