Makita 5104 User manual

Other Makita Saw manuals

Makita

Makita JR3020 User manual

Makita

Makita DJR189 User manual

Makita

Makita 5007NB User manual

Makita

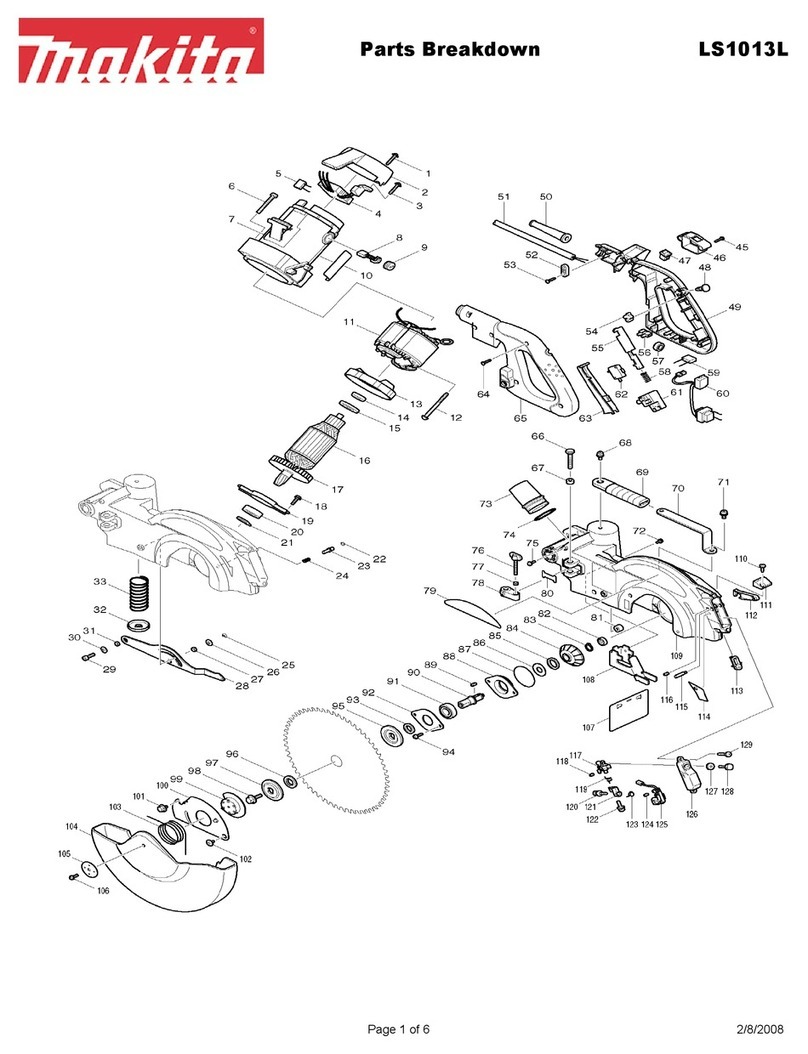

Makita LS1013L Quick start guide

Makita

Makita 2704 User manual

Makita

Makita LH1201FL User manual

Makita

Makita 5901B User manual

Makita

Makita 5603R User manual

Makita

Makita LC1230 User manual

Makita

Makita HS7601 User manual

Makita

Makita SP001G User manual

Makita

Makita RS001G User manual

Makita

Makita N5900B User manual

Makita

Makita 2704N User manual

Makita

Makita DPB182 User manual

Makita

Makita 5603R User manual

Makita

Makita DJR143 User manual

Makita

Makita XSS03 User manual

Makita

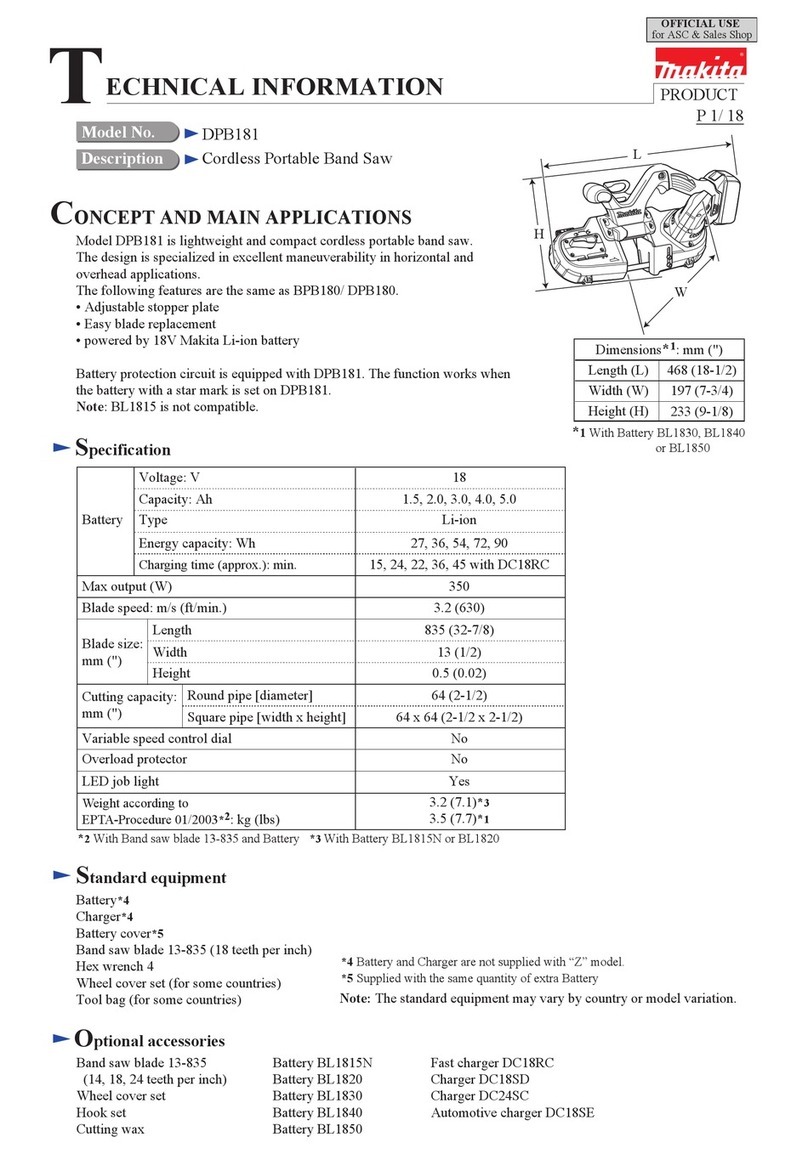

Makita DPB181 Manual

Makita

Makita DSD180 User manual