P 7/ 8

[6] DISASSEMBLY/ASSEMBLY OF ARMATURE SECTION (Cont.)

Repair

ASSEMBLING

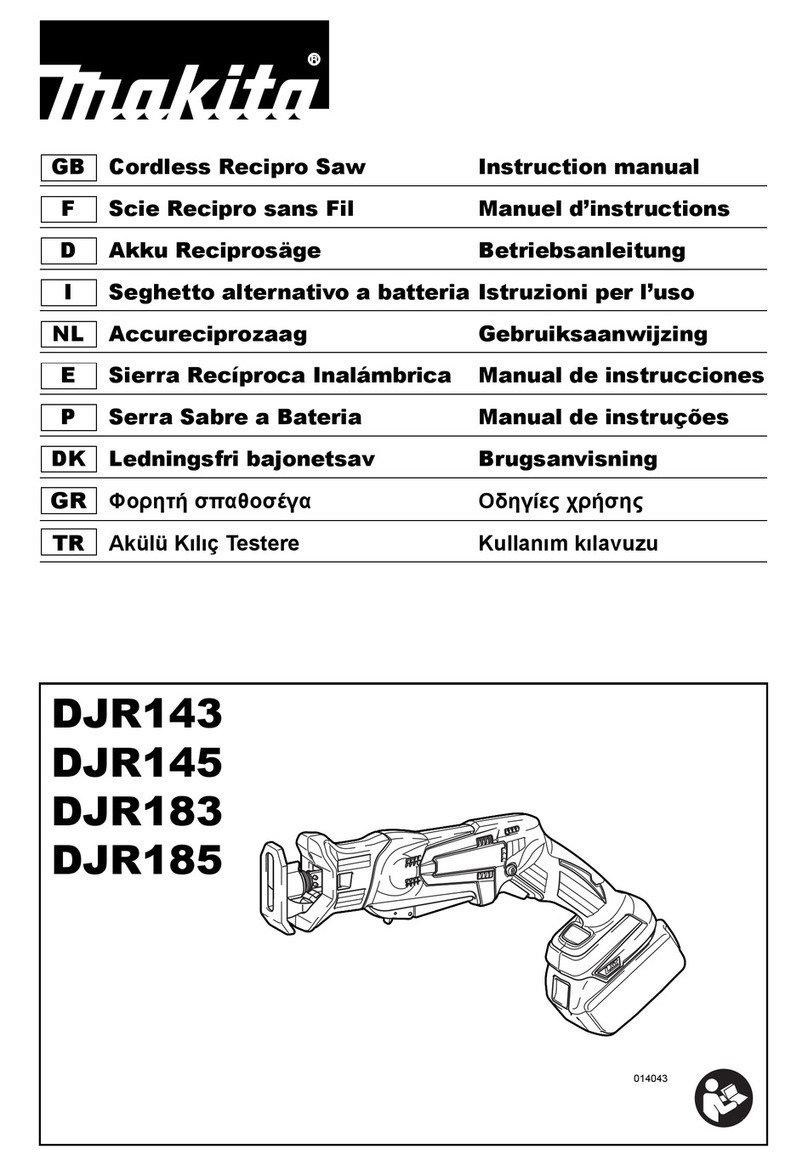

1) Mount Bearing retainer to Armature. Press-fit Ball bearing 6003LLB into Armature shaft.

2) Push new O ring 16 by hand until it contacts to the inner ring of Ball bearing 6003LLB as illustrated in Fig. 24.

3) Press-fit Ring 17 as illustrated in Fig.25. Pay attention to the direction of Ring 17.

4) Secure the their assembled parts by installing Retaining ring S-17 into the groove of Armature shaft.

5) Assemble the armature section while holding gear housing complete as illustrated in Fig. 20L.

Ball bearing 6003LLB

Bearing retainer

Inner ring of Ball bearing 6003LLB

O ring 16

Armature shaft Armature shaft

Ring 17

Groove for O ring 16

Groove for Retaining ring S-17

O ring 16

Fig. 24 Fig. 25

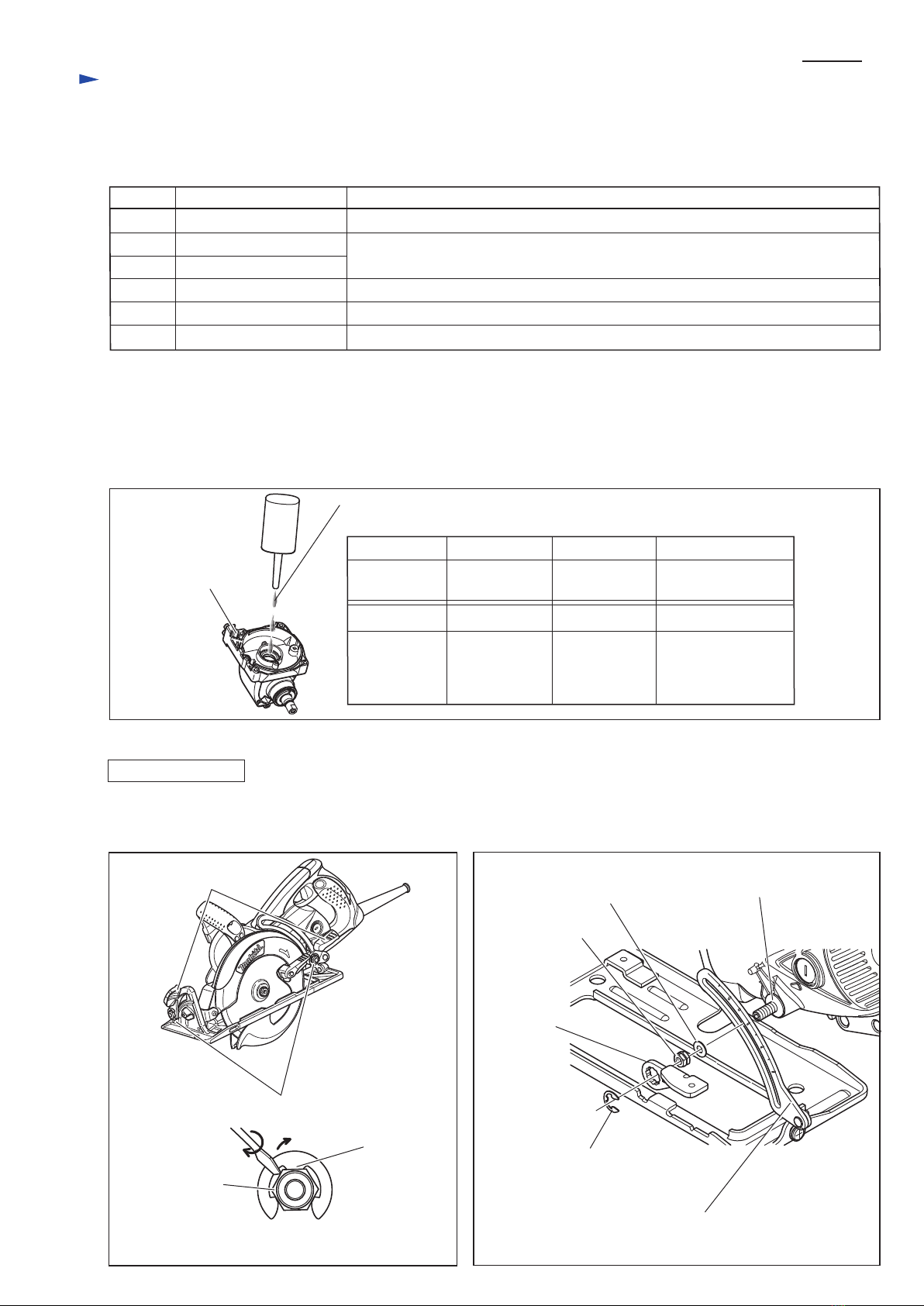

[7] ASSEMBLY OF OIL SEAL 22 IN GEAR HOUSING COMPLETE

0.5mm deeper than the rim

Rim

( Armature's Ball bearing 6003LLB

is accepted by this rim.)

Gear housing complete

When assembling Oil seal 22 to Gear housing complete, press-fit it for 0.5mm deeper than the rim for accepting Ball

bearing 6003LLB using 0.5mm thickness flat washer. Be sure to remove the 0.5mm thickness flat washer from Bearing

box after setting Oil seal 22 in place. (Fig. 26)

Oil seal 22

Bearing box part

Fig. 26

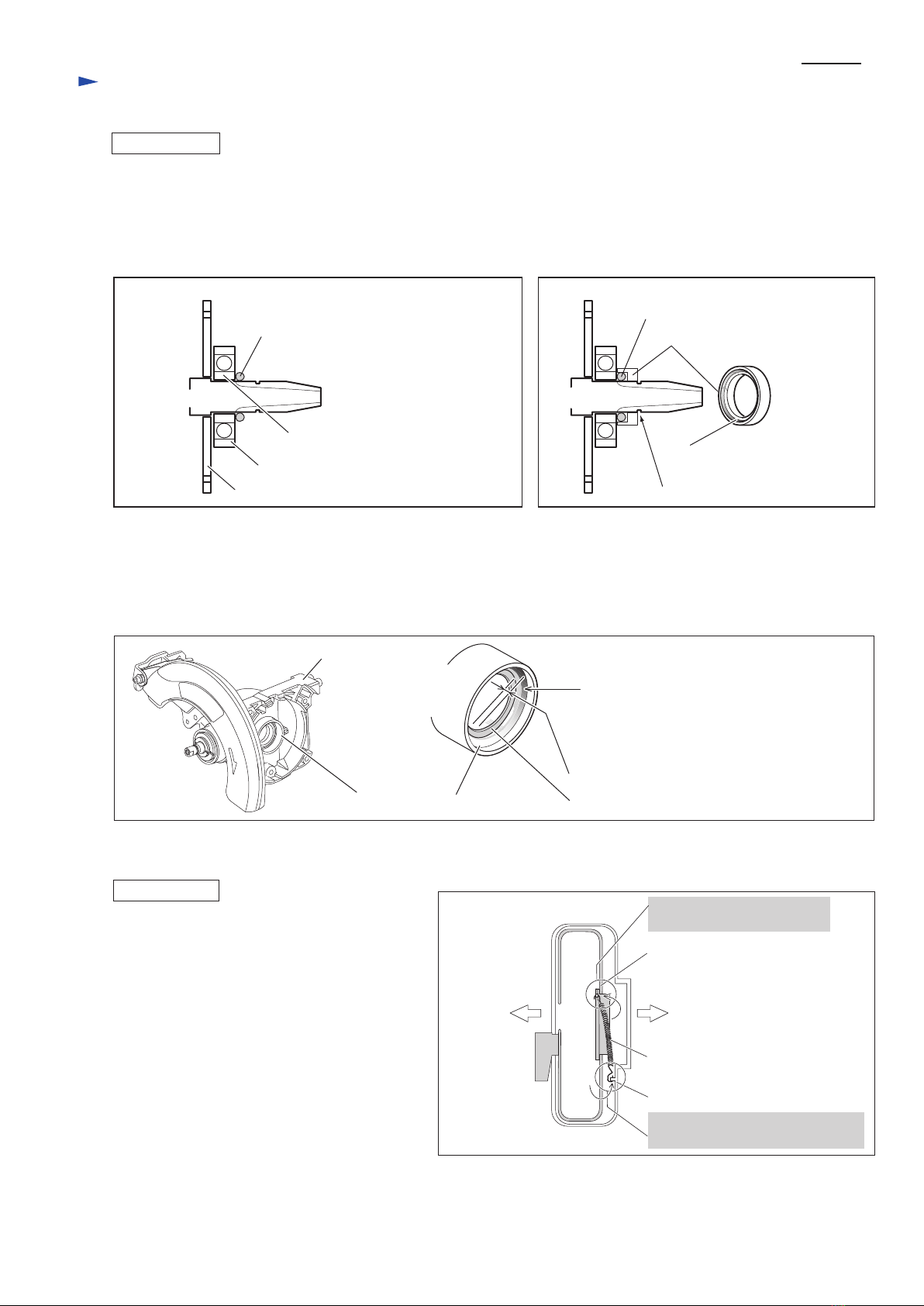

[8] ASSEMBLY OF TENSION SPRING 4 FOR SAFETY COVER

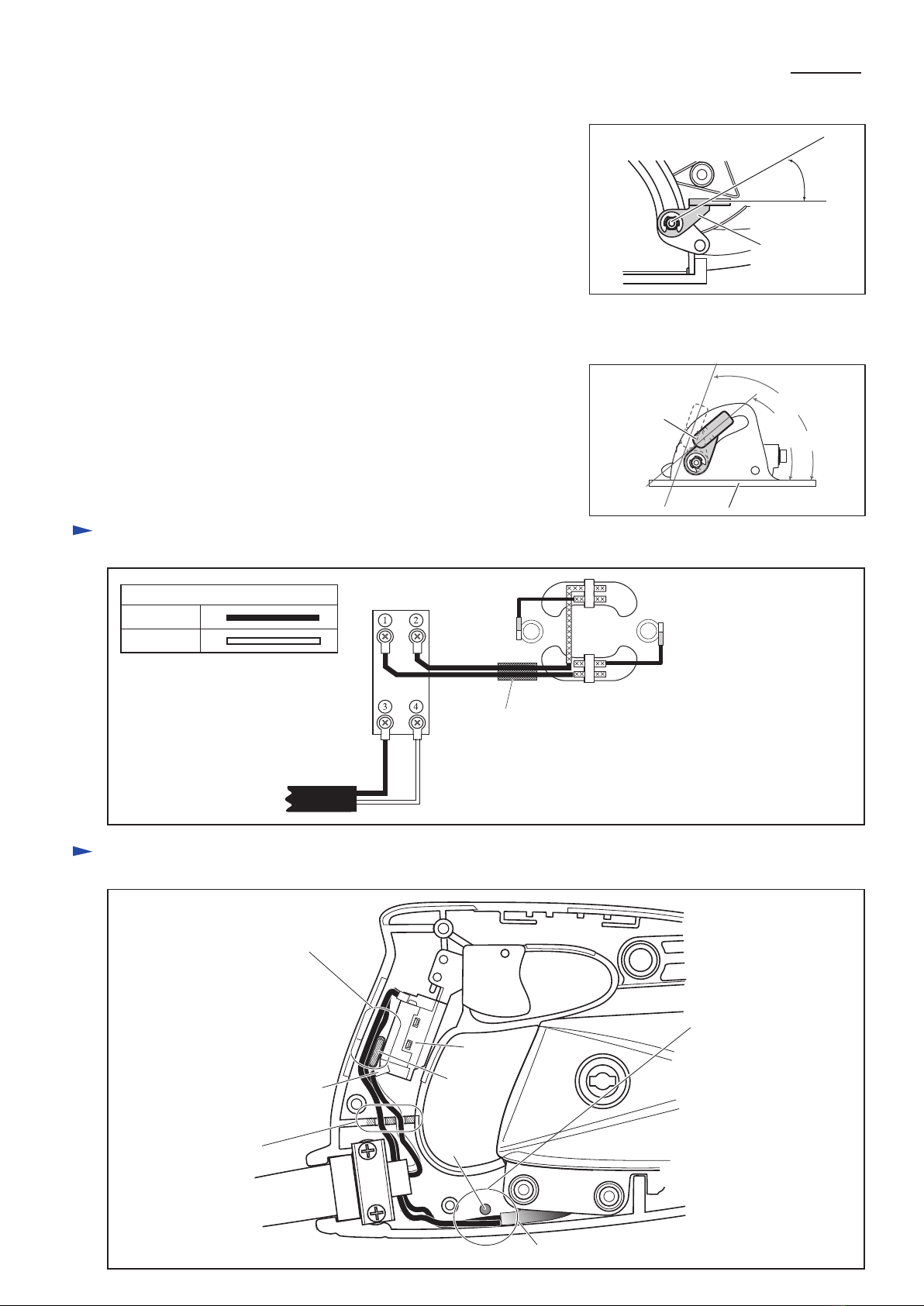

[9] FINE ADJUSTMENT OF BASE TO SAW BLADE AT 90 DEGREES

ASSEMBLING

When connecting Safety cover to Blade case with

Tension spring 4, hook the end of Tension spring 4

as illustrated in Fig. 27.

Adjust the angular deviation by loosening/tightening M5x8 Hex. socket set screw for adjusting bevel angle and by using

1R208. See the instruction manual for the details.

Blade side

Safety cover

Tension spring 4

Blade case

Gear housing Side

Pass the hook from Gear

housing side to Blade side.

Pass the hook from blade side to

Gear housing side.

Fig. 27