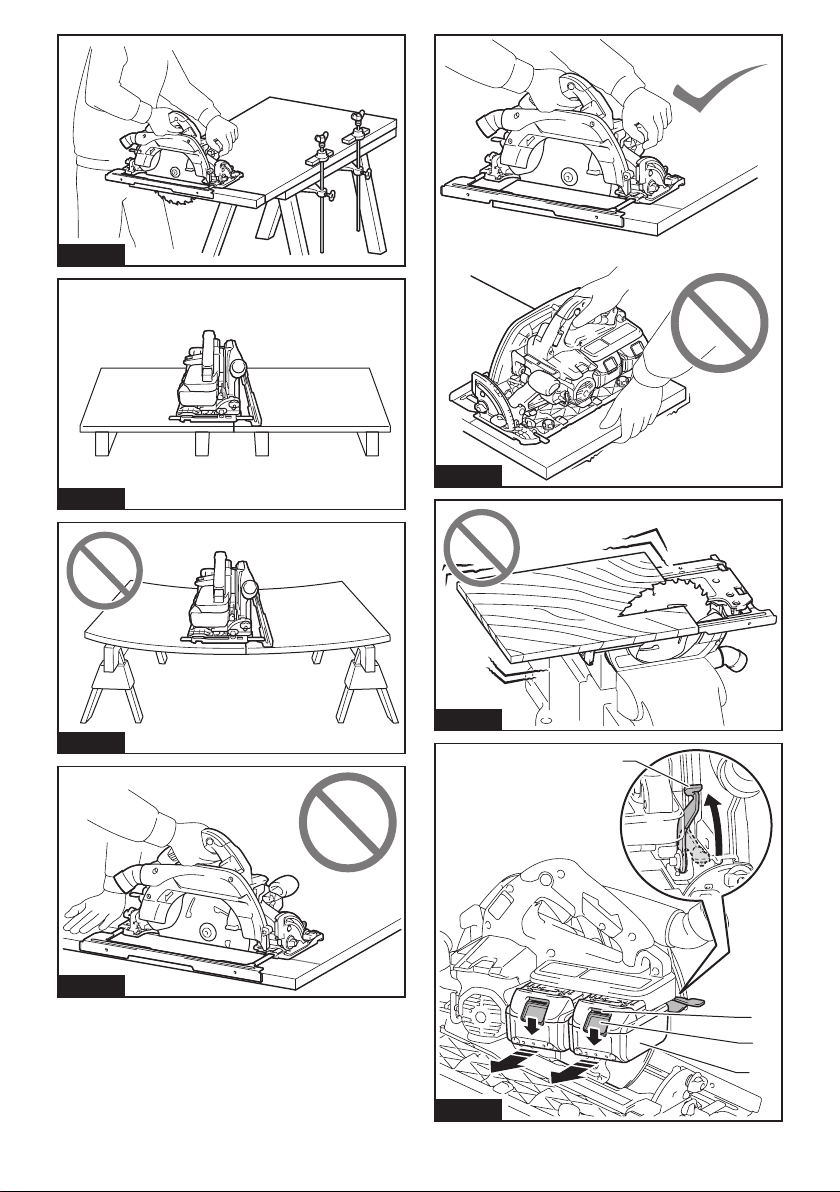

Makita DHS900ZU User manual

Other Makita Saw manuals

Makita

Makita JR3000V User manual

Makita

Makita LB1200F User manual

Makita

Makita LS1016 User manual

Makita

Makita LH1040 User manual

Makita

Makita JR3061T User manual

Makita

Makita DPC6430 Instruction Manual

Makita

Makita JR3000VT User manual

Makita

Makita 5603R User manual

Makita

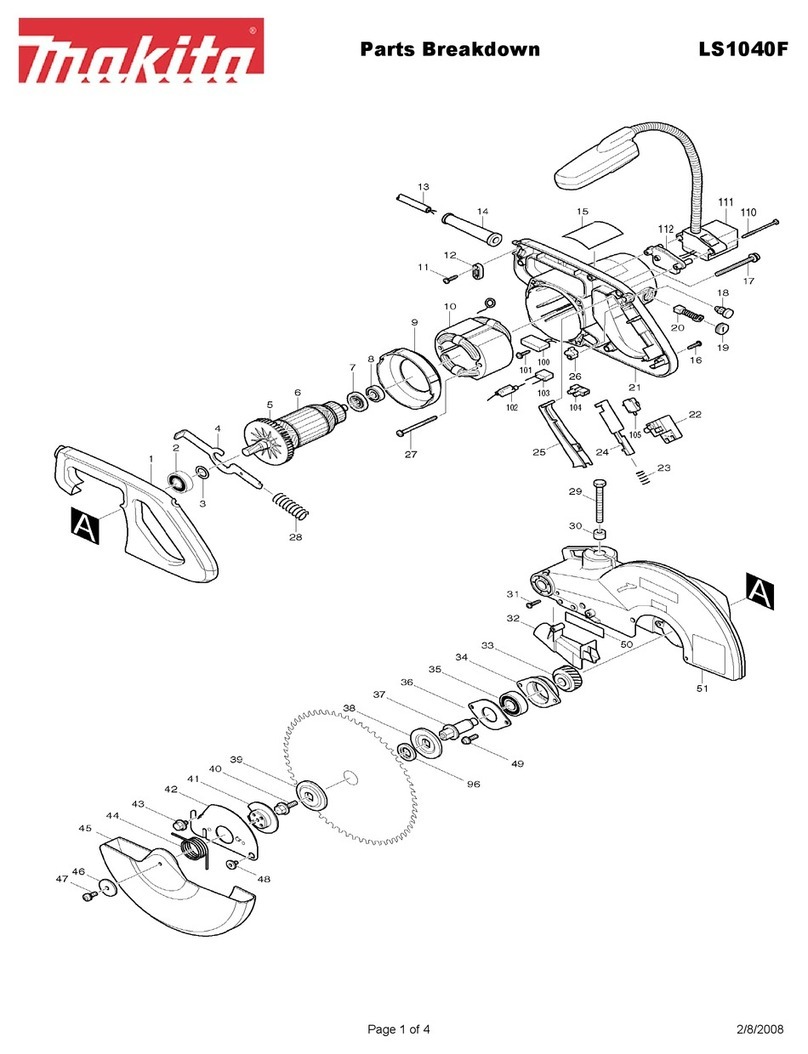

Makita LS1040 User manual

Makita

Makita LS1040F Quick start guide

Makita

Makita LS1040S User manual

Makita

Makita XBP01T User manual

Makita

Makita LF1000 User manual

Makita

Makita DLS714 User manual

Makita

Makita 5143R User manual

Makita

Makita 5621RD User manual

Makita

Makita SP001G User manual

Makita

Makita LS0714 User manual

Makita

Makita SD100D User manual

Makita

Makita HS7601 User manual