Makita LS0714 User manual

Other Makita Saw manuals

Makita

Makita SSP MSS703 User manual

Makita

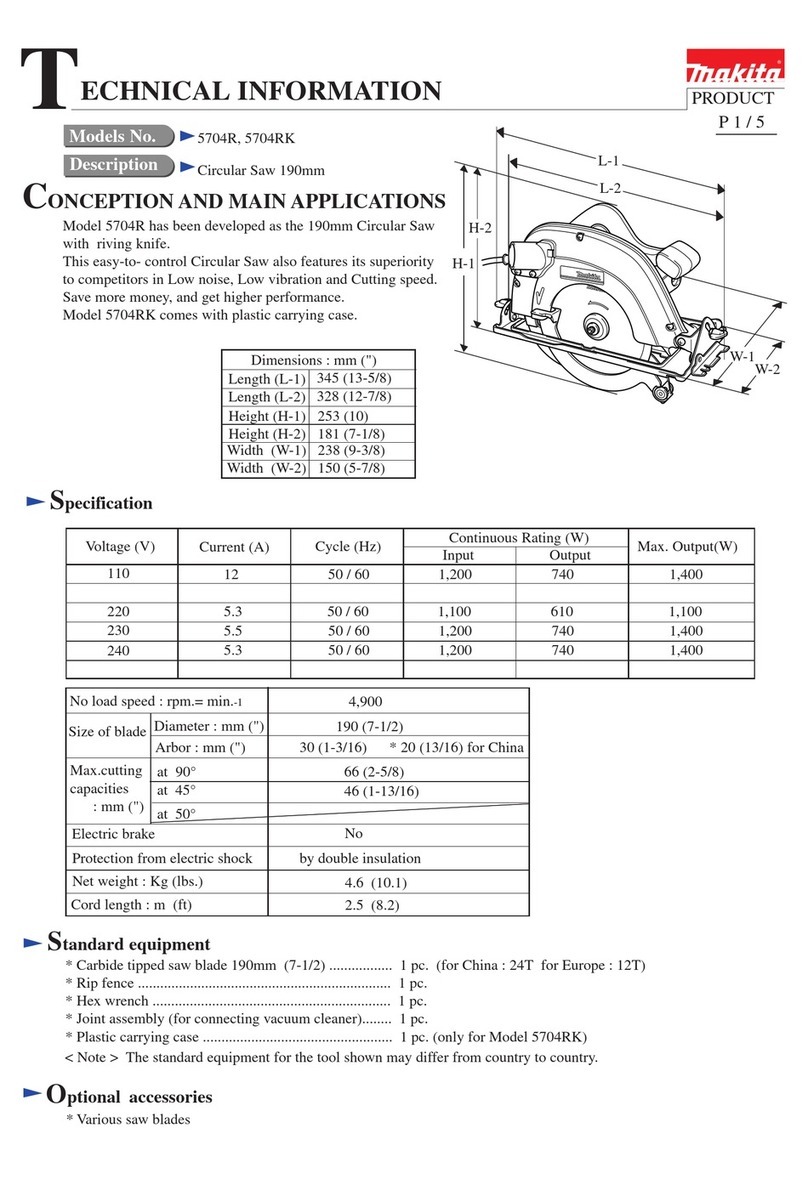

Makita 5704R Manual

Makita

Makita LH1201FL User manual

Makita

Makita 5008MG User manual

Makita

Makita BPB180 User manual

Makita

Makita 2414NB User manual

Makita

Makita HS6601 User manual

Makita

Makita SR1800 User manual

Makita

Makita LS1013 User manual

Makita

Makita 2107FK User manual

Makita

Makita LS1013 User manual

Makita

Makita 5603R User manual

Makita

Makita HS6601 User manual

Makita

Makita JR103D User manual

Makita

Makita JR3061T User manual

Makita

Makita EK7651HX1 User guide

Makita

Makita 2712 User manual

Makita

Makita MLT100 User manual

Makita

Makita MLT100 User manual

Makita

Makita BLS820 User manual