4

For Model 5903R

ENG005-2

For European countries only

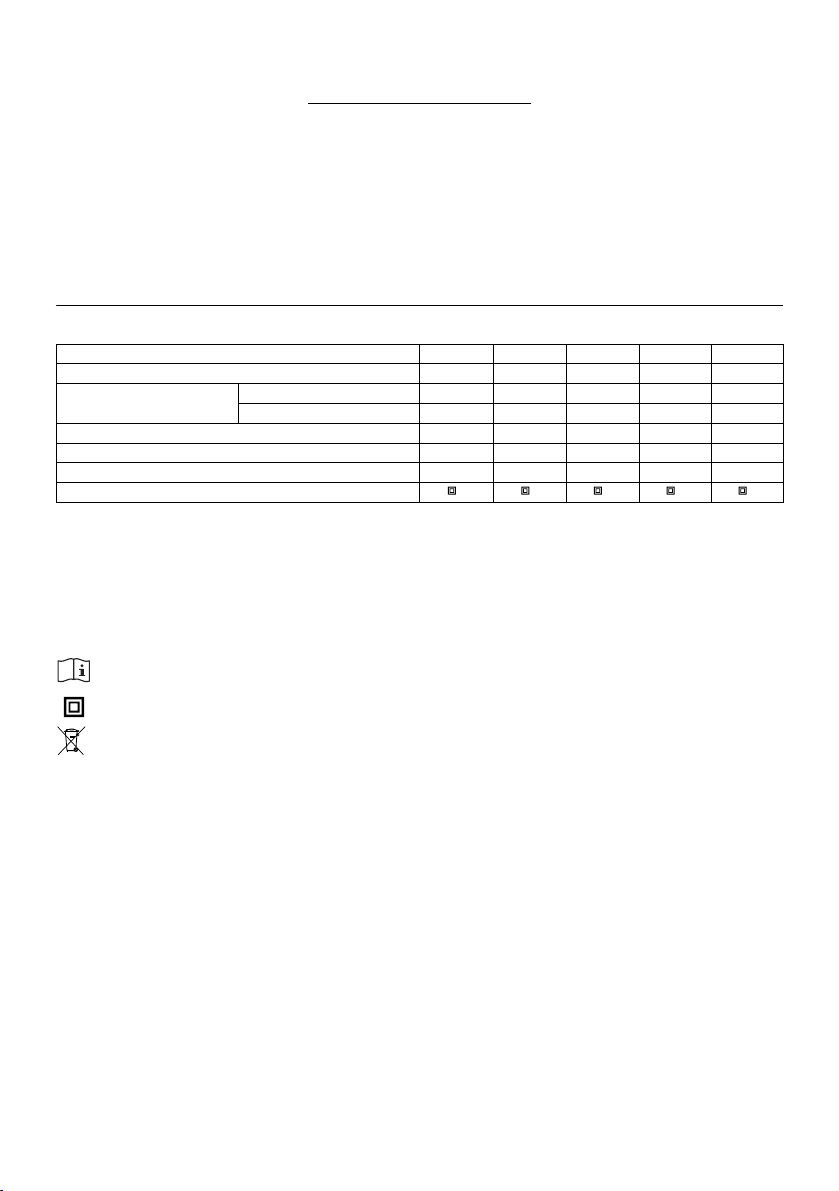

Noise and Vibration

The typical A-weighted noise levels are

sound pressure level: 95 dB (A)

sound power level: 106 dB (A)

Uncertainty: 3 dB(A)

Wear ear protection.

The typical weighted root mean square acceleration

value is not more than 2.5 m/s2.

These values have been obtained according to

EN60745.

For Model 5103R/5143R

ENG005-2

For European countries only

Noise and Vibration

The typical A-weighted noise levels are

sound pressure level: 94 dB (A)

sound power level: 105 dB (A)

Uncertainty: 3 dB(A)

Wear ear protection.

The typical weighted root mean square acceleration

value is not more than 2.5 m/s2.

These values have been obtained according to

EN60745.

ENH101-5

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this

product is in compliance with the following standards of

standardized documents;

EN60745, EN55014, EN61000 in accordance with

Council Directives, 89/336/EEC, 98/37/EC.

Yasuhiko Kanzaki CE2005

000087

Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15

8JD, ENGLAND

Responsible manufacturer:

Makita Corporation Anjo Aichi Japan

GEB029-1

SPECIFIC SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to circular saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious

personal injury.

Danger:

1. Keep hands away from cutting area and the

blade. Keep your second hand on auxiliary

handle, or motor housing. If both hands are

holding the saw, they cannot be cut by the blade.

2. Do not reach underneath the workpiece. The

guard cannot protect you from the blade below the

workpiece. Do not attempt to remove cut material

when blade is moving.

CAUTION: Blades coast after turn off. Wait until

blade stops before grasping cut material.

3. Adjust the cutting depth to the thickness of

the workpiece. Less than a full tooth of the blade

teeth should be visible below the workpiece.

4. Never hold piece being cut in your hands or

across your leg. Secure the workpiece to

stable platform. It is important to support the

work properly to minimize body exposure, blade

binding, or loss of control.

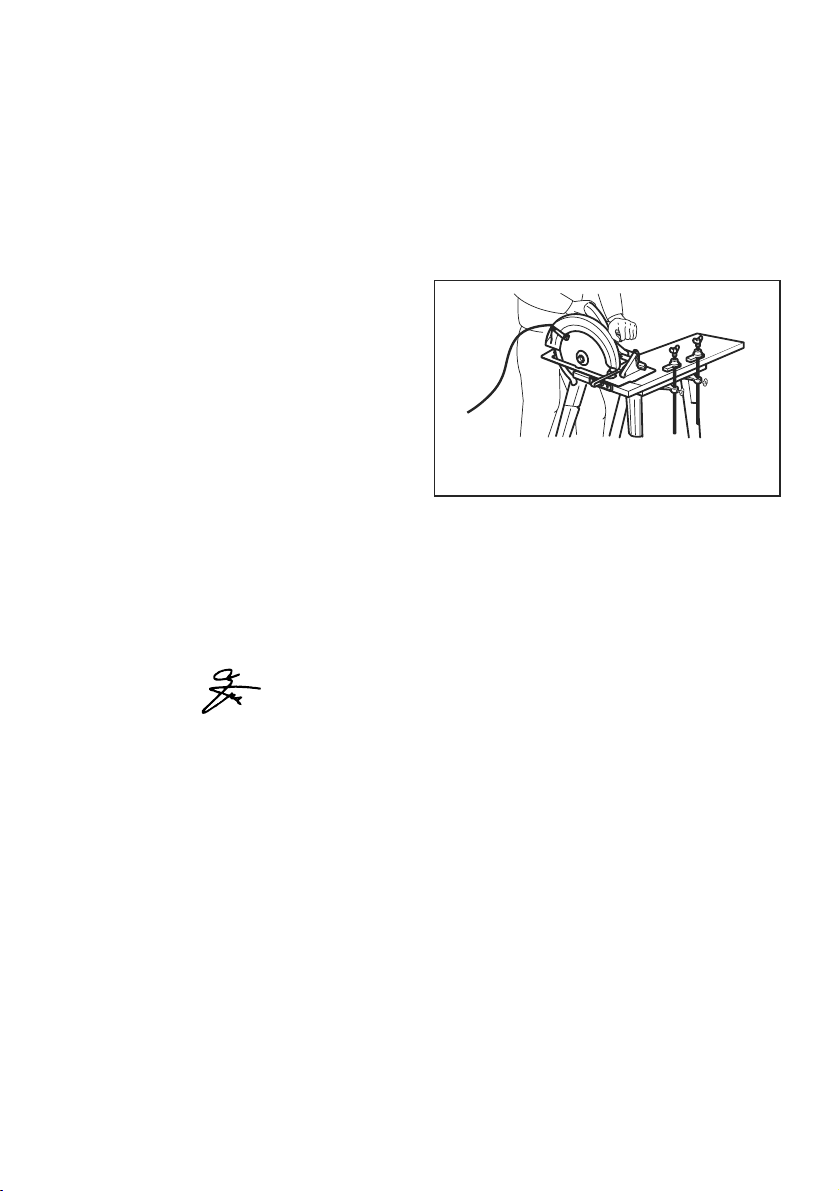

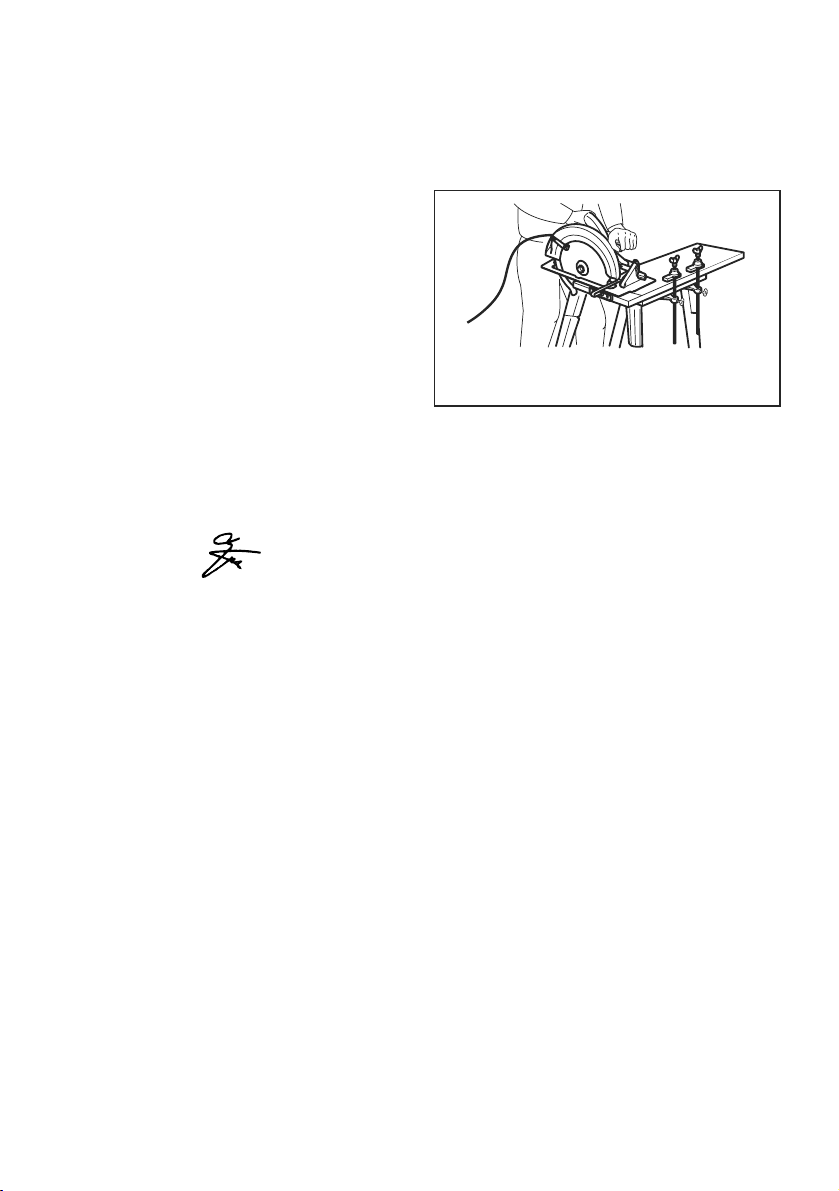

A typical illustration of proper hand support, workpiece

support, and supply cord routing (if applicable).

000157

5. Hold power tool by insulated gripping

surfaces when performing an operation where

the cutting tool may contact hidden wiring or

its own cord. Contact with a "live" wire will also

make exposed metal parts of the power tool "live"

and shock the operator.

6. When ripping always use a rip fence or

straight edge guide. This improves the accuracy

cut and reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond versus round) of arbour holes.

Blades that do not match the mounting hardware

of the saw will run eccentrically, causing loss of

control.

8. Never use damaged or incorrect blade

washers or bolt. The blade washers and bolt

were specially designed for your saw, for optimum

performance and safety of operation.

9. Causes and Operator Prevention of Kickback:

−kickback is a sudden reaction to a pinched,

bound or misaligned saw blade, causing an

uncontrolled saw to lift up and out of the

workpiece toward the operator;

−when the blade is pinched or bound tightly by

the kerf closing down, the blade stalls and the

motor reaction drives the unit rapidly back

toward the operator;

−if the blade becomes twisted or misaligned in

the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood

causing the blade to climb out of the kerf and