Makita DLS714 User manual

Other Makita Saw manuals

Makita

Makita M4500 Manual

Makita

Makita HS7101J User manual

Makita

Makita JR002G User manual

Makita

Makita 5143R User manual

Makita

Makita 5603R User manual

Makita

Makita BPB180 User manual

Makita

Makita DSS610RFE User manual

Makita

Makita DLS713 User manual

Makita

Makita 2414NB User manual

Makita

Makita MLT100 User manual

Makita

Makita 5057KB User manual

Makita

Makita LH1201FL User manual

Makita

Makita XBP01T User manual

Makita

Makita MLS100 User manual

Makita

Makita JR3061T User manual

Makita

Makita 5104S User manual

Makita

Makita 5037NB User manual

Makita

Makita JR103D User manual

Makita

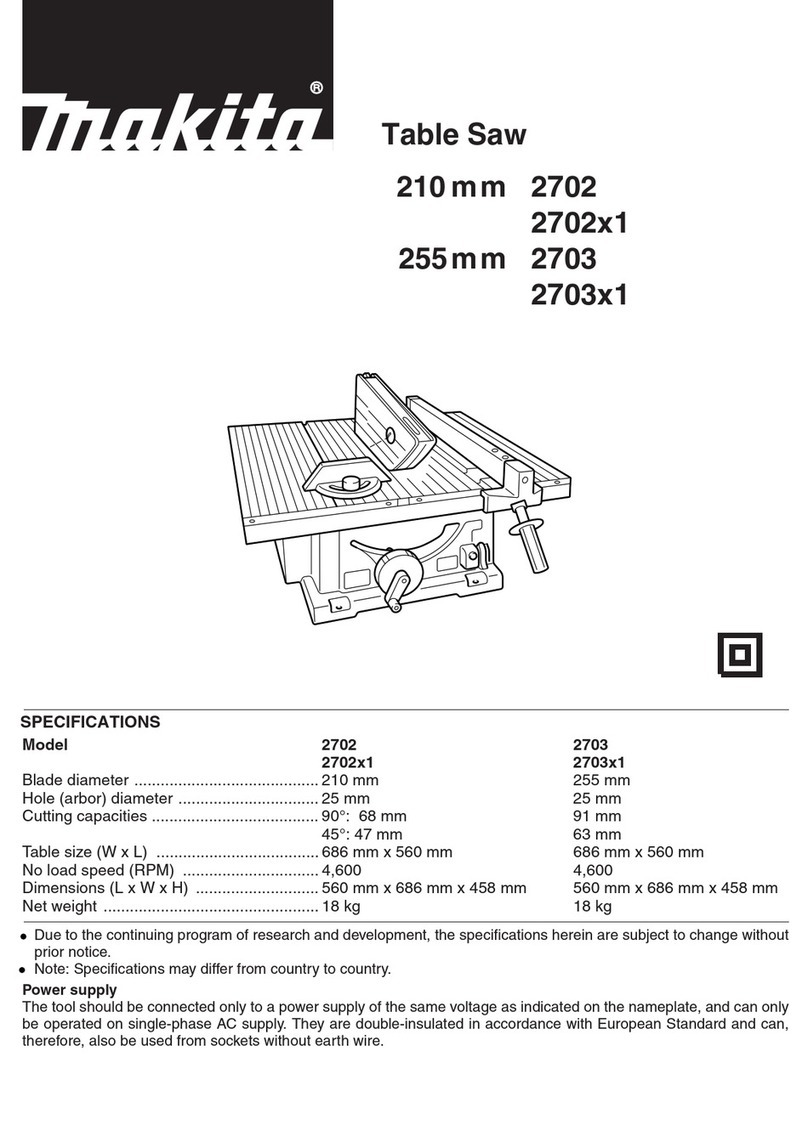

Makita 2702 User manual

Makita

Makita LW1400 Manual