ADDITIONAL SAFETY RULES

1.

Wear eye protection.

2.

Don't use the tool

in

presence of flammable liquids or gases.

3.

Never use the tool with an abrasive cut-off wheel installed.

4.

Check the blade carefully for cracks or damage before operation. Replace

cracked or damaged blade immediately.

5.

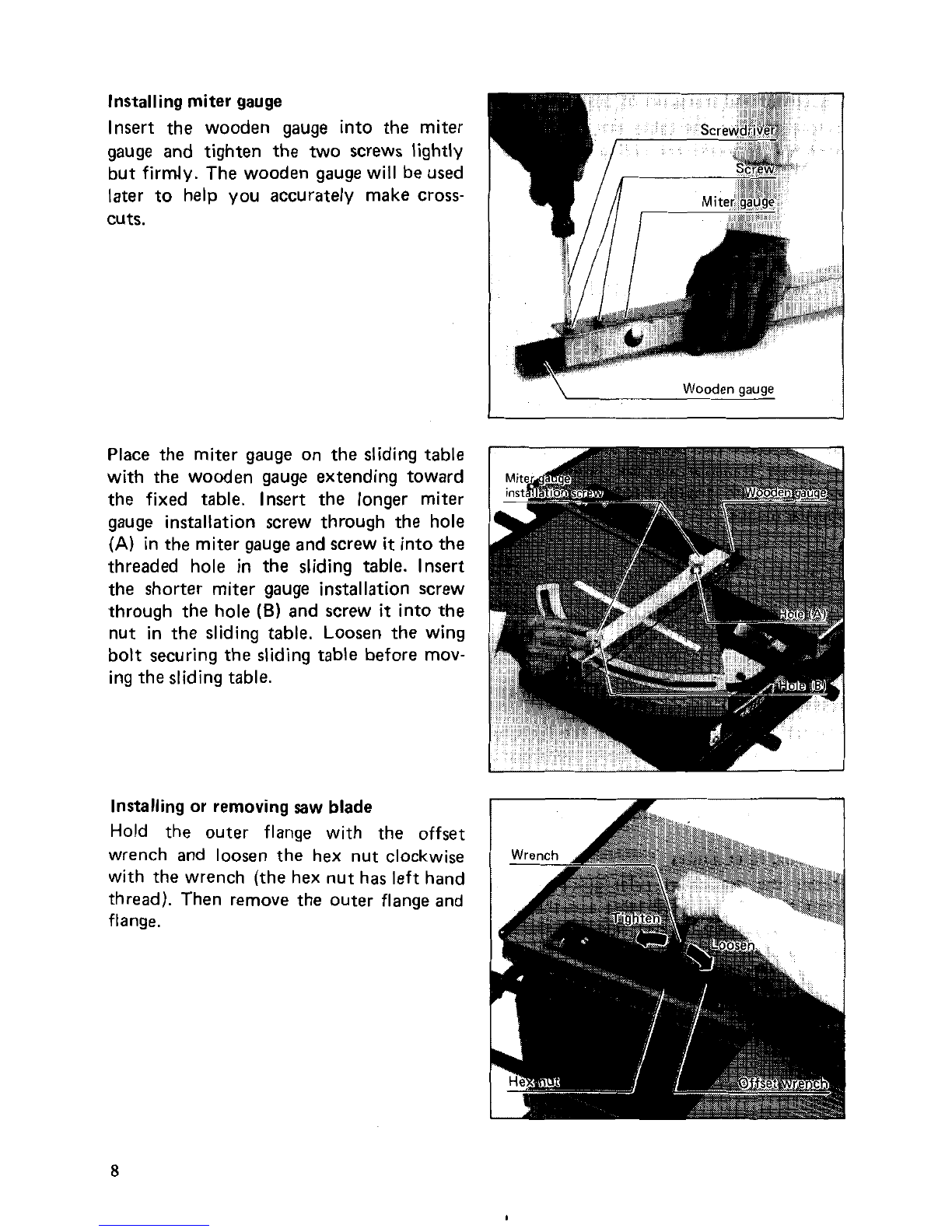

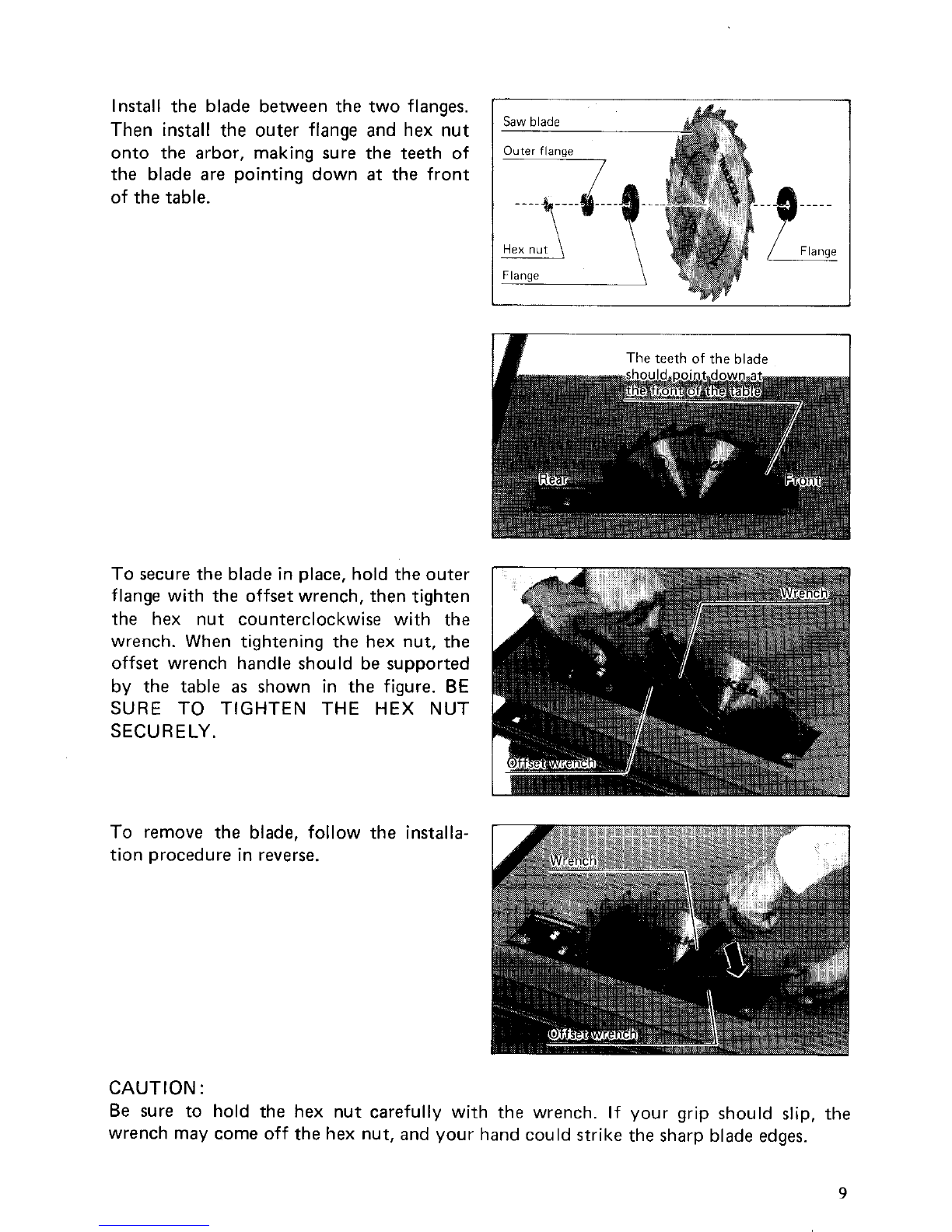

Clean the spindle, flanges (especially the installing surface) and hex

nut

before installingthe blade. Poor installation may cause vibration/wobbling

or slippage of the blade.

6.

Use saw-blade guard and spreader for every operation for which

it

can be

used, includingall through sawing operations. Through sawing operations

are those

in

which the blade cuts completely through the workpiece as in

ripping or cross cutting. Never use the tool with a faulty blade guard or

secure the blade guard with a rope, string, etc. Any irregular operation of

the blade guard should be corrected immediately.

7.

Avoid cutting nails, screws, etc. Inspectfor and remove all nails, screws and

other foreign matter from the workpiece before operation.

8.

Remove wrenches, cut-off pieces, etc. from the table before the switch is

turned on.

9.

Never wear gloves during operation.

IO.

Keep hands out of the line of saw blade.

Do

not stand or permit anyone else

to stand

in

line with the path of the saw blade.

11.

Make sure the bladeisnotcontactingthe spreader or workpiece beforethe

switch is turned on.

12.

Before cutting an actual workpiece, let the tool run for a while. Watch for

vibration or wobblingthat couldindicate poor installation or a poorly balanced

blade.

13.

Use a push stick when required. Push sticks should be used for ripping

narrow workpiecesto keep your hands and fingers well away from the blade.

14.

Pay particular attention to instructions for reducing risk of KICKBACK.

KICKBACK isthe ejectionof the workpiece from the tool back towards the

operator. Avoid KICKBACKS by keeping the blade sharp, by keepingthe rip

fence paralleltothe blade, by keeping the spreader, antikickback fingers and

blade guard

in

placeand operating properly, by not releasing the workpiece

until

youhavepushed

it

allthe way pastthe blade, andbynotripping a work-

piece that is twisted or warped or does not have a straight edge to guide

along the fence.

15.

Do not perform any operation freehand. Freehand means using your hands

to support or guide the workpiece.

16.

Never reach around or over saw blade.

17.

Avoid abrupt, fast feeding. Feed as slowly as possible when cutting hard

workpieces. Do not bend or twist workpiece while feeding. If you stall or

5