Original Instruction Manual

Instructions d’emploi d’origine

Originalbetriebsanleitung

Manuale di istruzioni originale

Originele gebruiksaanwijzing

Instrucciones de manejo originales

Instruções de serviço original

Original brugsanvisning

Πρωτότυπο εγχειρίδιο οδηγιών

Orijinal Kullanım Kılavuzu

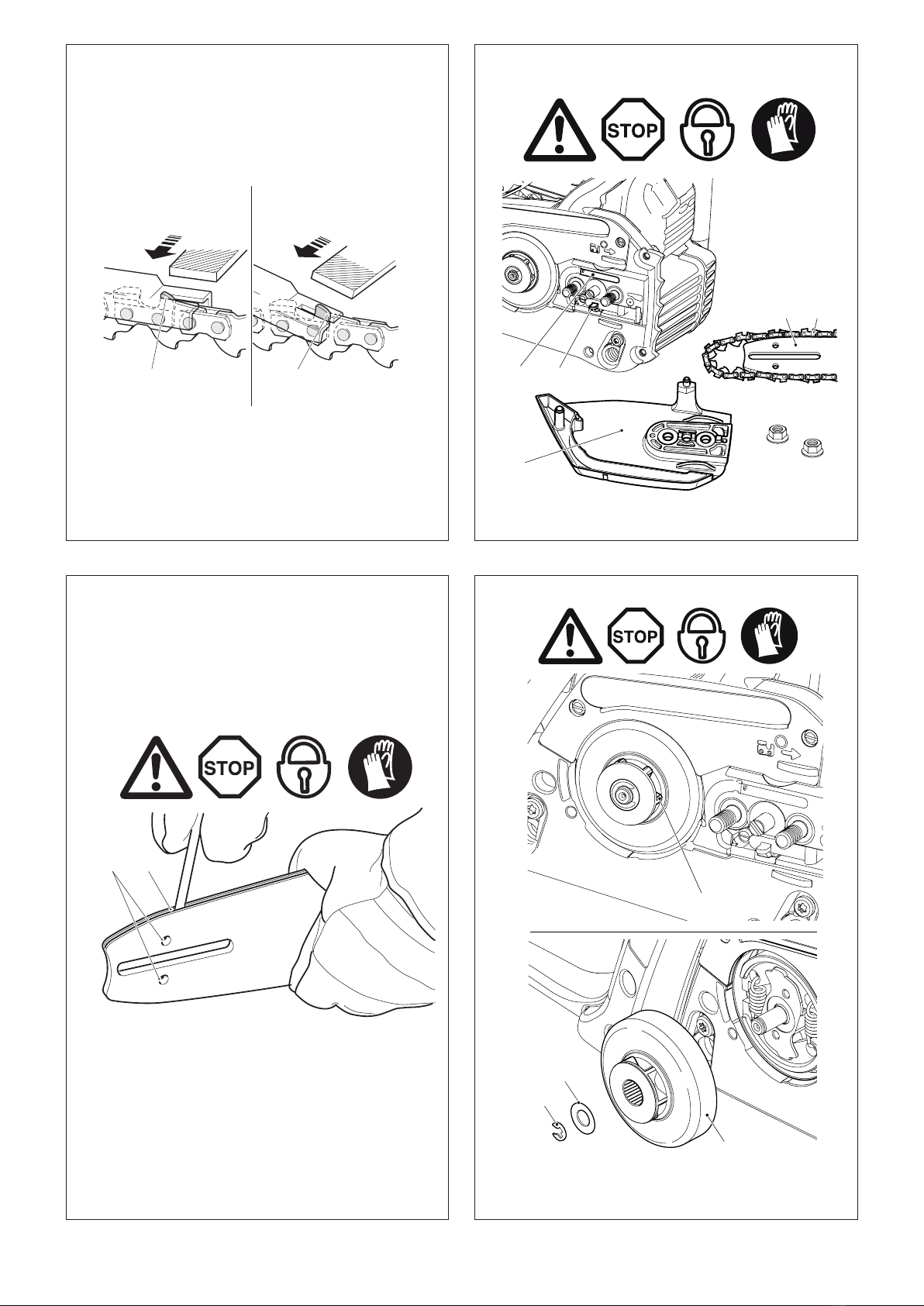

Important: Read this instruction manual carefully before putting the petrol chain saw into operation and strictly observe

the safety regulations! Keep this instruction manual!

Important : Veuillez lire attentivement ce mode d’emploi avant d’utiliser la tronçonneuse à chaîne et à essence et

respectez strictement les consignes de sécurité ! Conservez ce mode d’emploi !

Wichtig: Lesen Sie vor Verwendung der Benzin-Motorsäge diese Betriebsanleitung aufmerksam durch, und halten Sie die

Sicherheitsbestimmungen strikt ein! Bewahren Sie diese Betriebsanleitung auf!

Importante: leggere attentamente il presente manuale di istruzioni prima di mettere in funzione la motosega a benzina e

rispettare scrupolosamente le norme per la sicurezza. Conservare il manuale di istruzioni.

Belangrijk: Lees deze gebruiksaanwijzing aandachtig door voordat u de benzinekettingzaag in gebruik neemt en houd u

te allen tijde aan de veiligheidsinstructies! Bewaar deze gebruiksaanwijzing!

Importante: Lea atentamente este manual de instrucciones antes de utilizar la motosierra y cumpla estrictamente la

normativa de seguridad. Conserve este manual de instrucciones.

Importante: Leia cuidadosamente este manual de instruções antes de utilizar a moto-serra a gasolina e cumpra todas as

normas de segurança! Guarde este manual de instruções.

Vigtigt: Læs denne brugsanvisning omhyggeligt igennem inden du anvender den benzindrevne motorsav og overhold

sikkerhedsbestemmelserne til mindste detalje! Gem denne brugsanvisning!

Σημαντικό: Πριν θέσετε σε λειτουργία το βενζινοκίνητο μηχανοκίνητο πριόνι διαβάσετε προσεχτικά το παρόν εγχειρίδιο

οδηγιών και εφαρμόσετε αυστηρά τους κανονισμούς ασφαλείας! Κρατήστε αυτό το εγχειρίδιο χρήσης!

Önemli: Benzinli zincir testereyi kullanmaya başlamadan önce bu kullanım kılavuzunu dikkatlice okuyun ve güvenlik

talimatlarını haryen takip edin! Bu kullanım kılavuzunu saklayın!

EA3500S

EA3501S

EA3502S

EA3503S