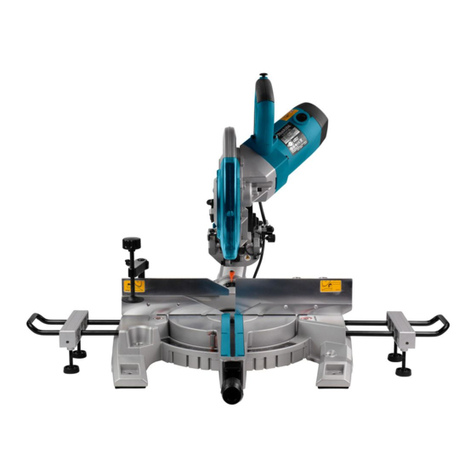

Makita LS1219 User manual

Other Makita Saw manuals

Makita

Makita SP001G User manual

Makita

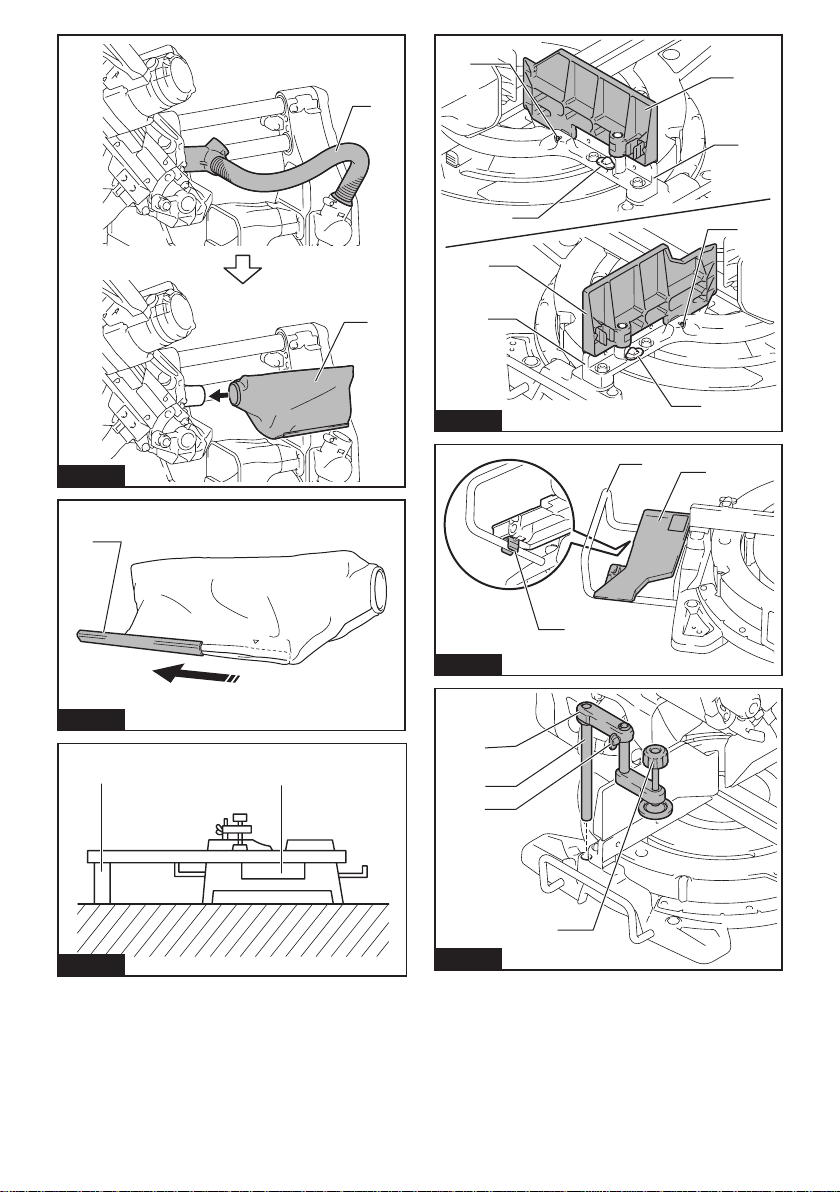

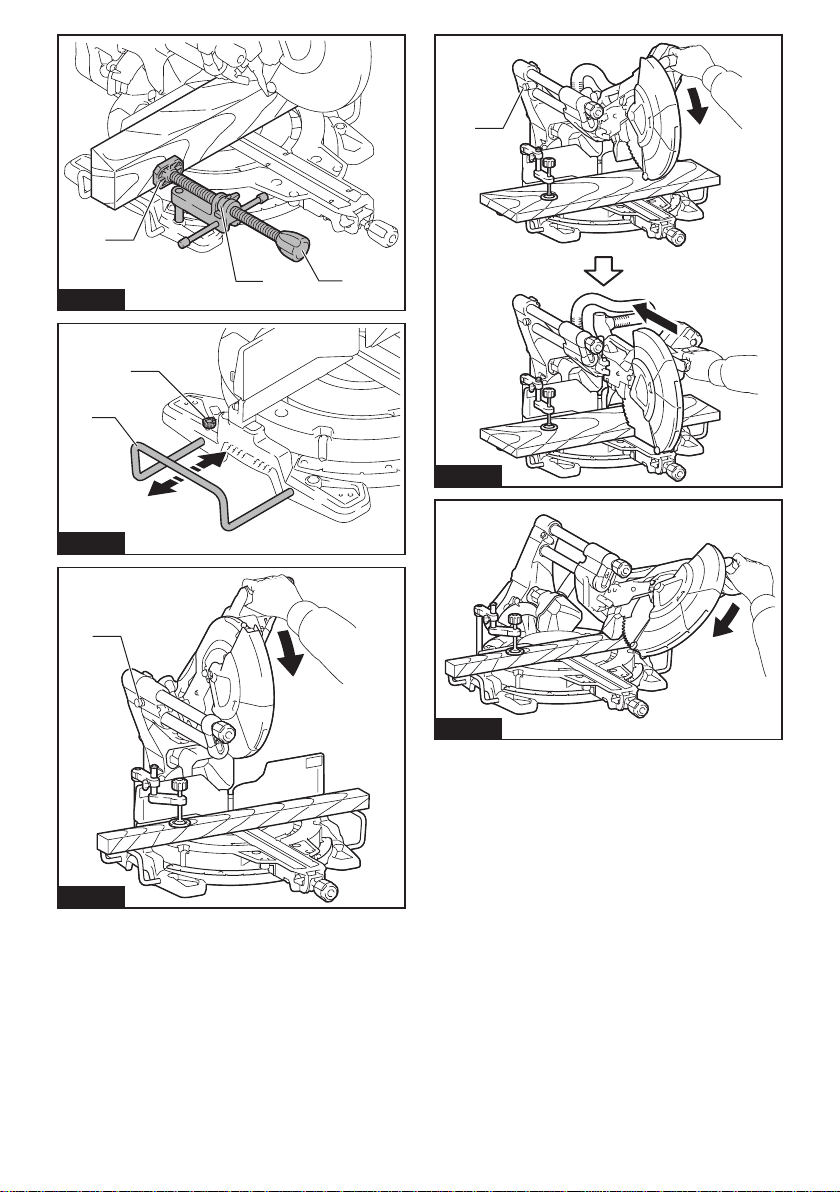

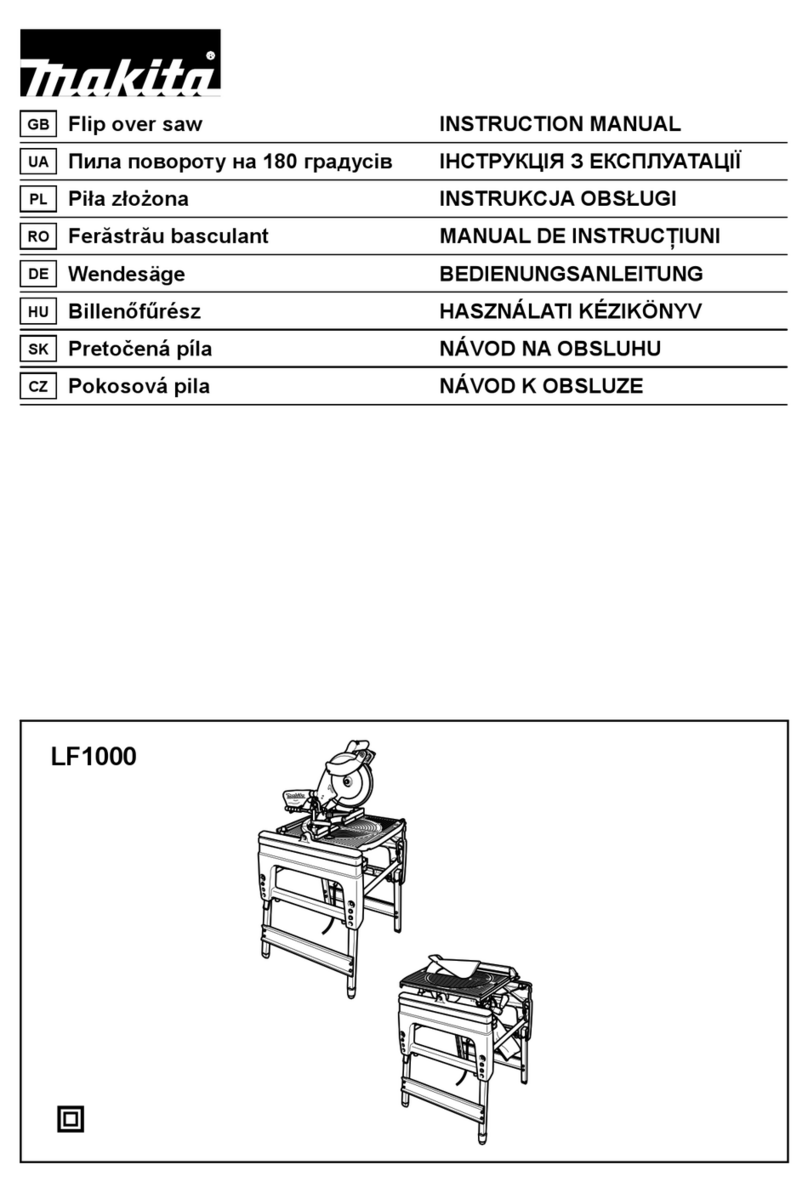

Makita LF1000 User manual

Makita

Makita LH1040 User manual

Makita

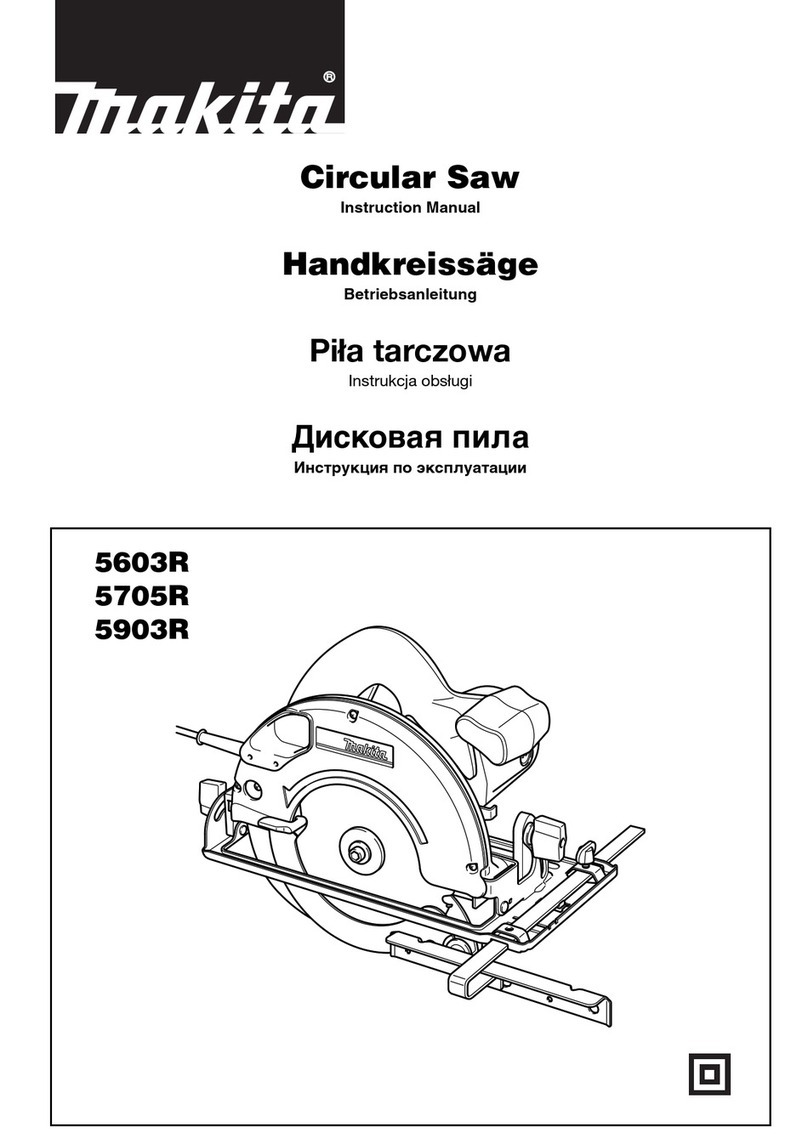

Makita 5603R User manual

Makita

Makita HS7611 User manual

Makita

Makita JR1000FT User manual

Makita

Makita HS6601 User manual

Makita

Makita MLT100N User manual

Makita

Makita LC1230 User manual

Makita

Makita LS1040 User manual

Makita

Makita JR3061T User manual

Makita

Makita DRS780 User manual

Makita

Makita 5092D User manual

Makita

Makita 2712 User manual

Makita

Makita LS1040 User manual

Makita

Makita JR3000VT User manual

Makita

Makita DPB183 User manual

Makita

Makita BPB180 User manual

Makita

Makita LS1018LN User manual

Makita

Makita MLS100 User manual