P 7 /15

Repair

[3] -1. Disassembling/ Assembling Blade Clamp Section (cont.)

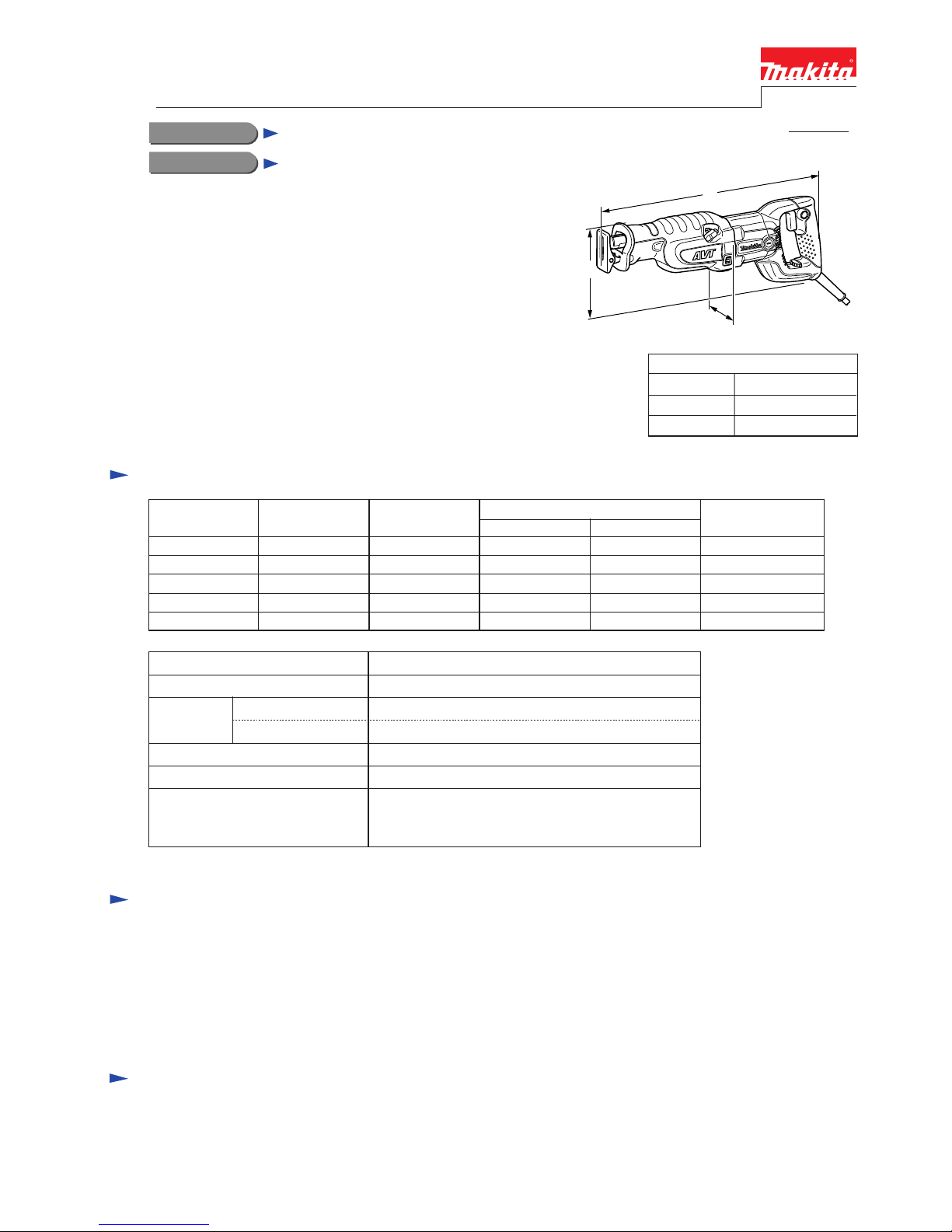

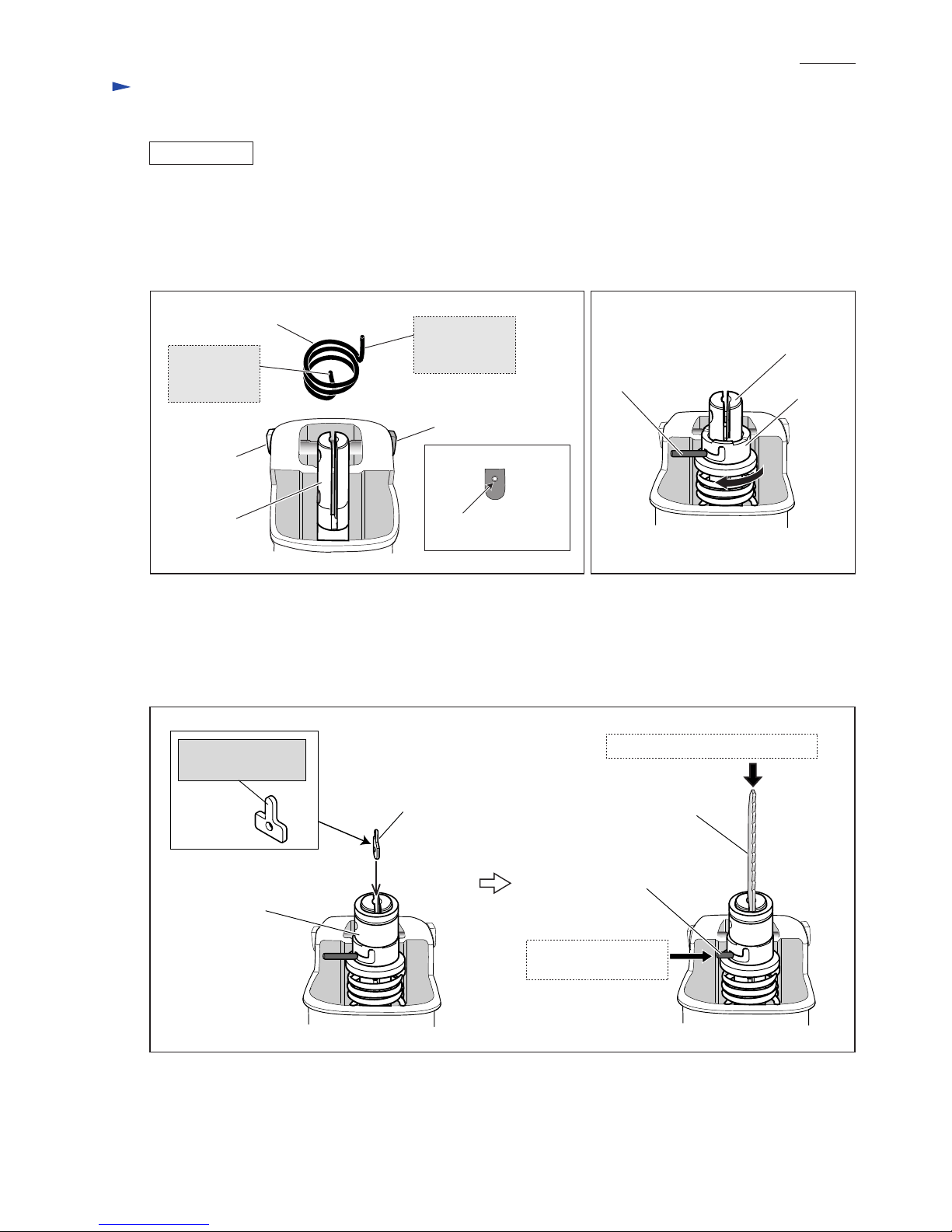

Fig. 12

5) While fitting the two projections of driving sleeve in the concavities of sleeve, push driving sleeve into gear housing.

At this time, turn driving sleeve clockwise so that the protruding portion of driving sleeve cannot be interfered by

gear housing. After driving sleeve is pushed into gear housing to the full, turn driving sleeve clockwise to lock pin 3

in place. (Fig. 12)

Note: Driving sleeve is used as a jig to lock pin 3 in place, not assembled to slider in this step.

6) Remove driving sleeve.

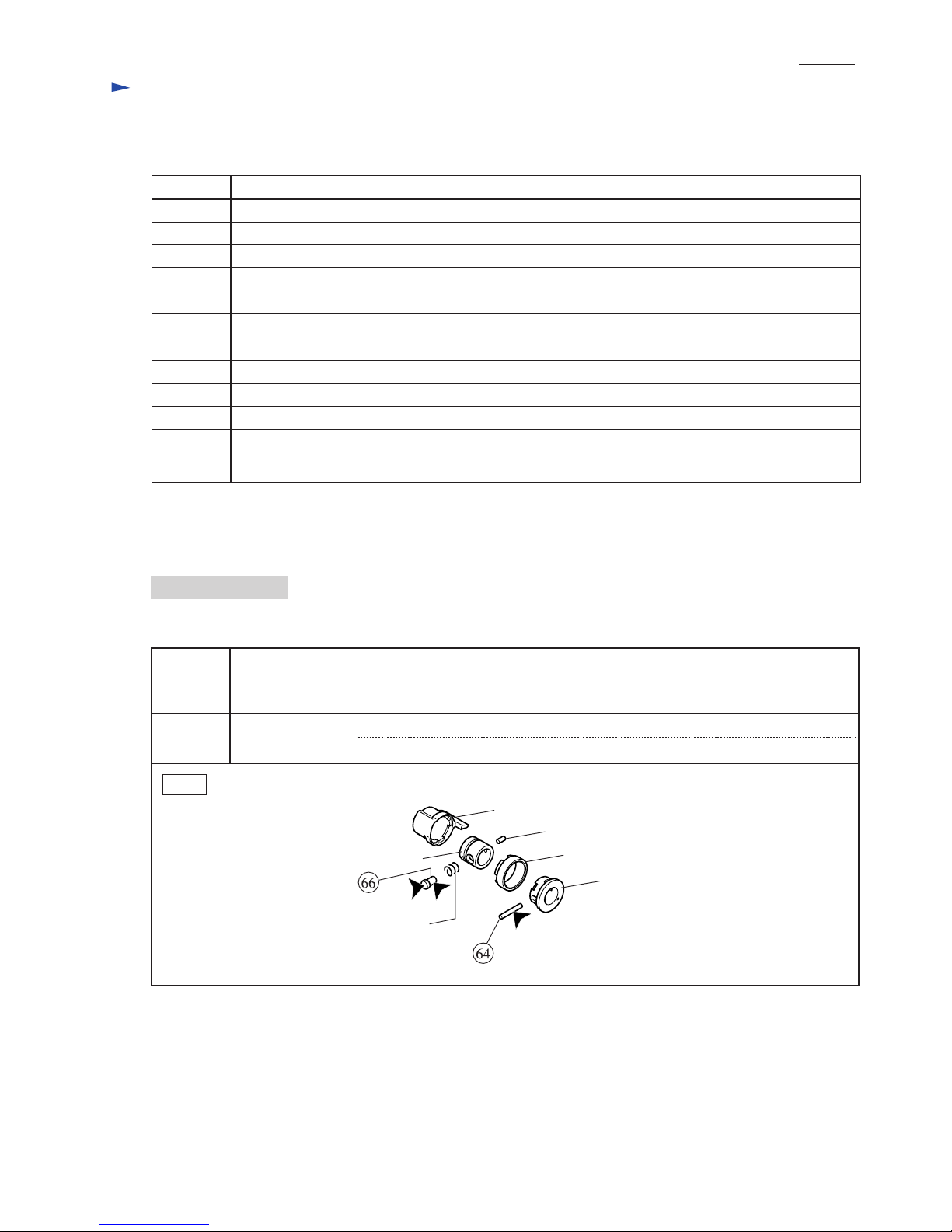

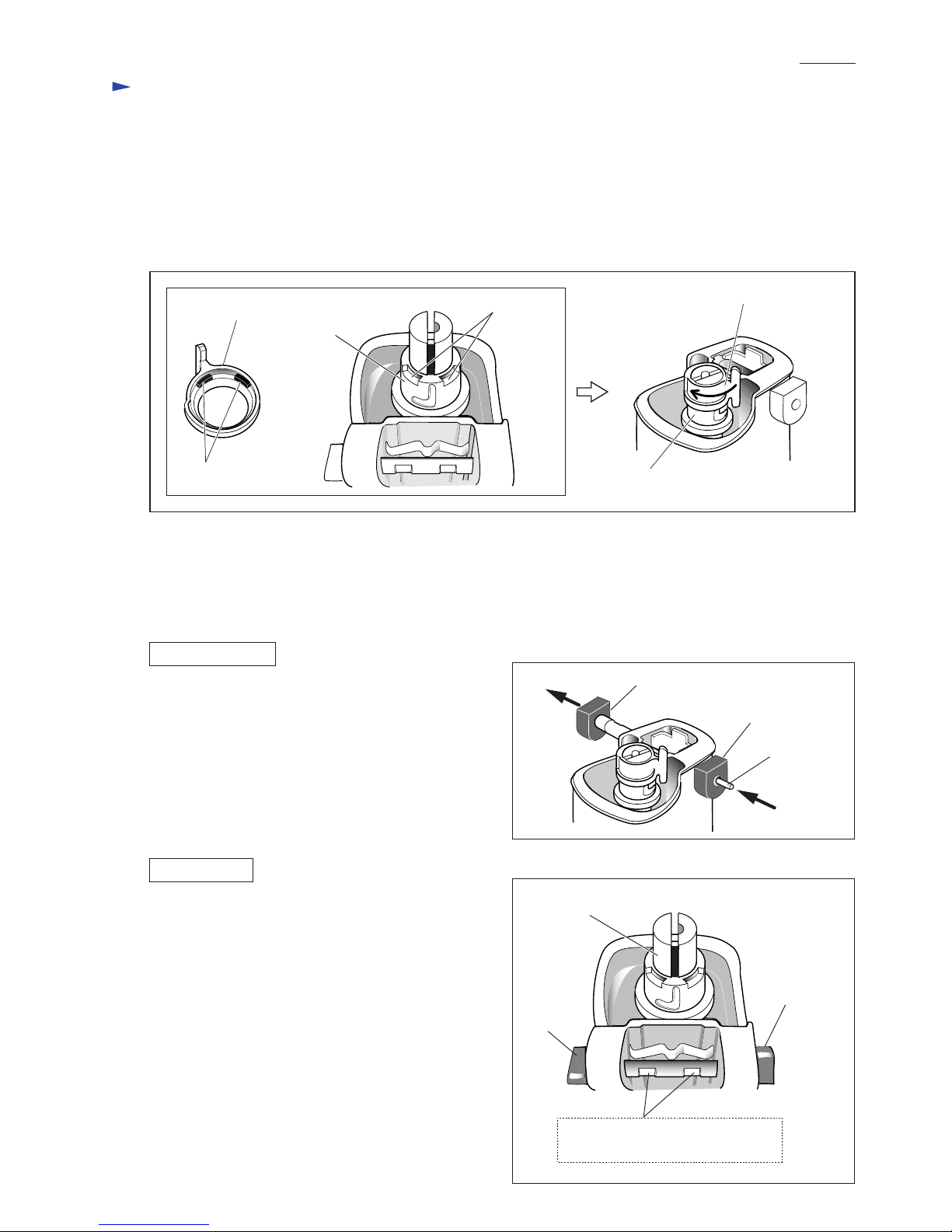

7) Assemble the following parts to slider (Refer to Fig. 5.):

Driving sleeve guide, Guide sleeve, Pin 3 (of 6mm length), Shoulder pin 5, Compression spring 6

8) Put driving sleeve over guide sleeve and secure it with retaining ring S-18 using 1R291. Then cover driving sleeve

with protector. (When installing driving sleeve, fit its projections in the concavities of sleeve and driving sleeve guide.)

Projections

Concavities

Driving sleeve Driving sleeve

Sleeve

Sleeve

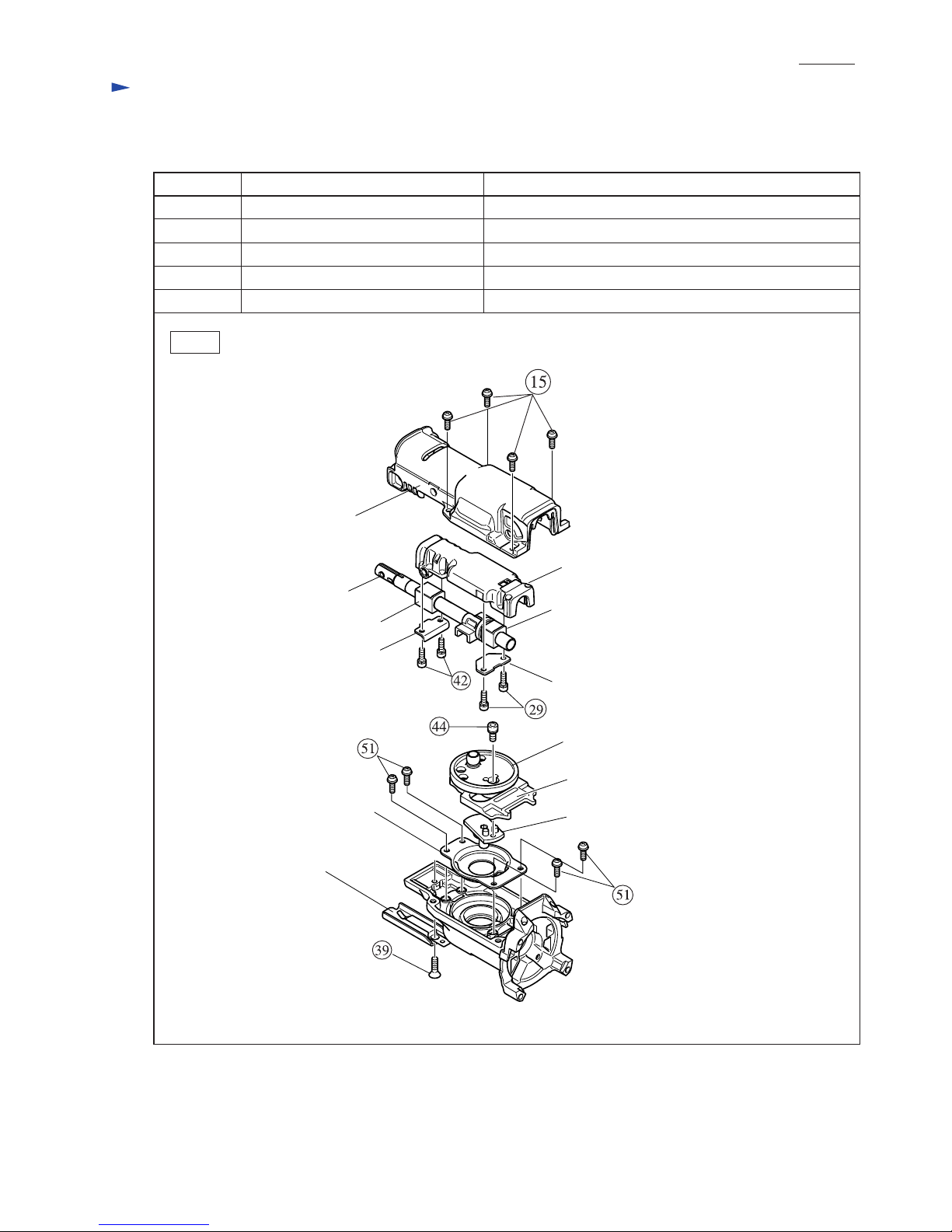

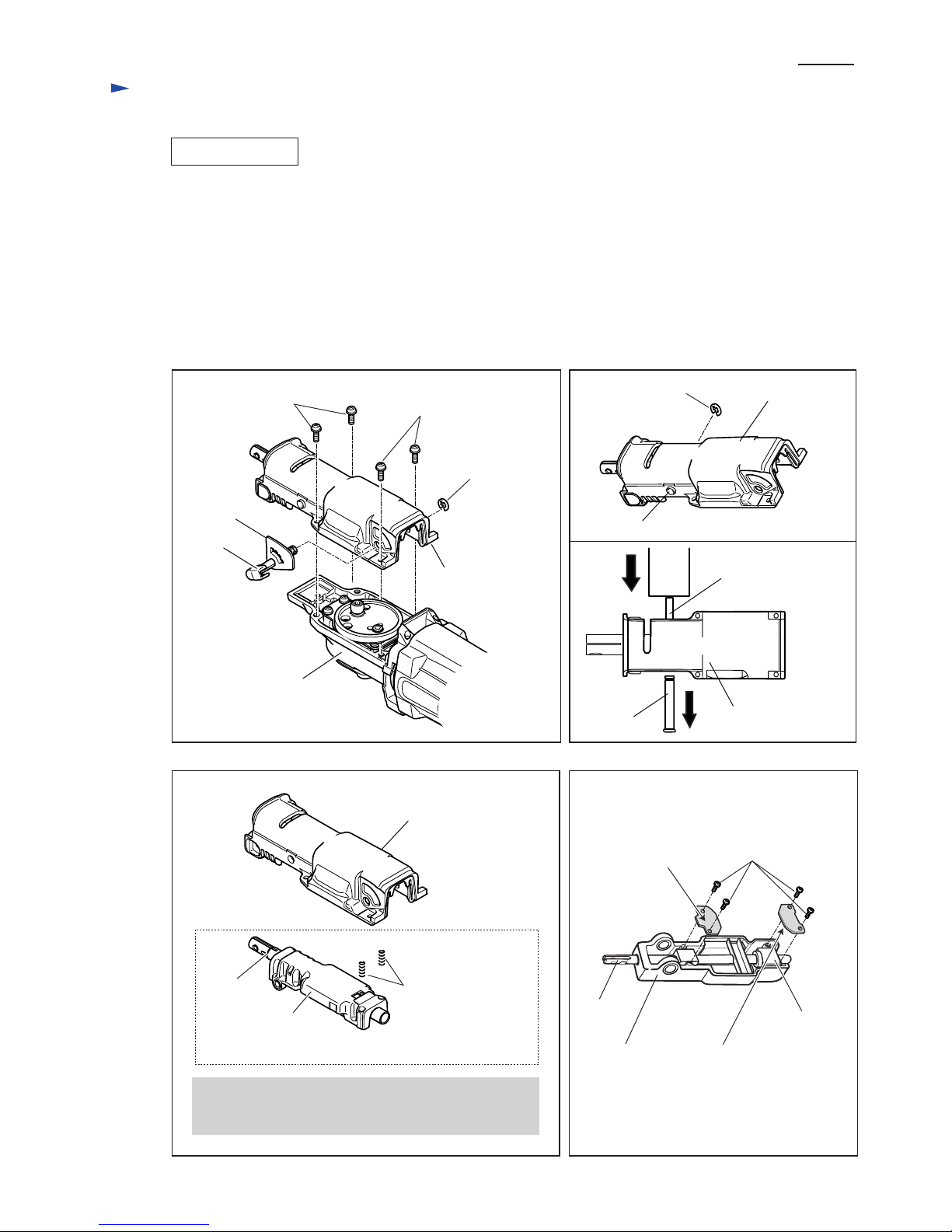

[3] -2. Replacing Shift Button and Cap

Shift button can be removed from gear housing cover by

inserting a thin bar into the hole of cap and push the bar.

(Fig. 13)

DISASSEMBLING

ASSEMBLING

Fig. 13

Shift button

thin bar

Cap

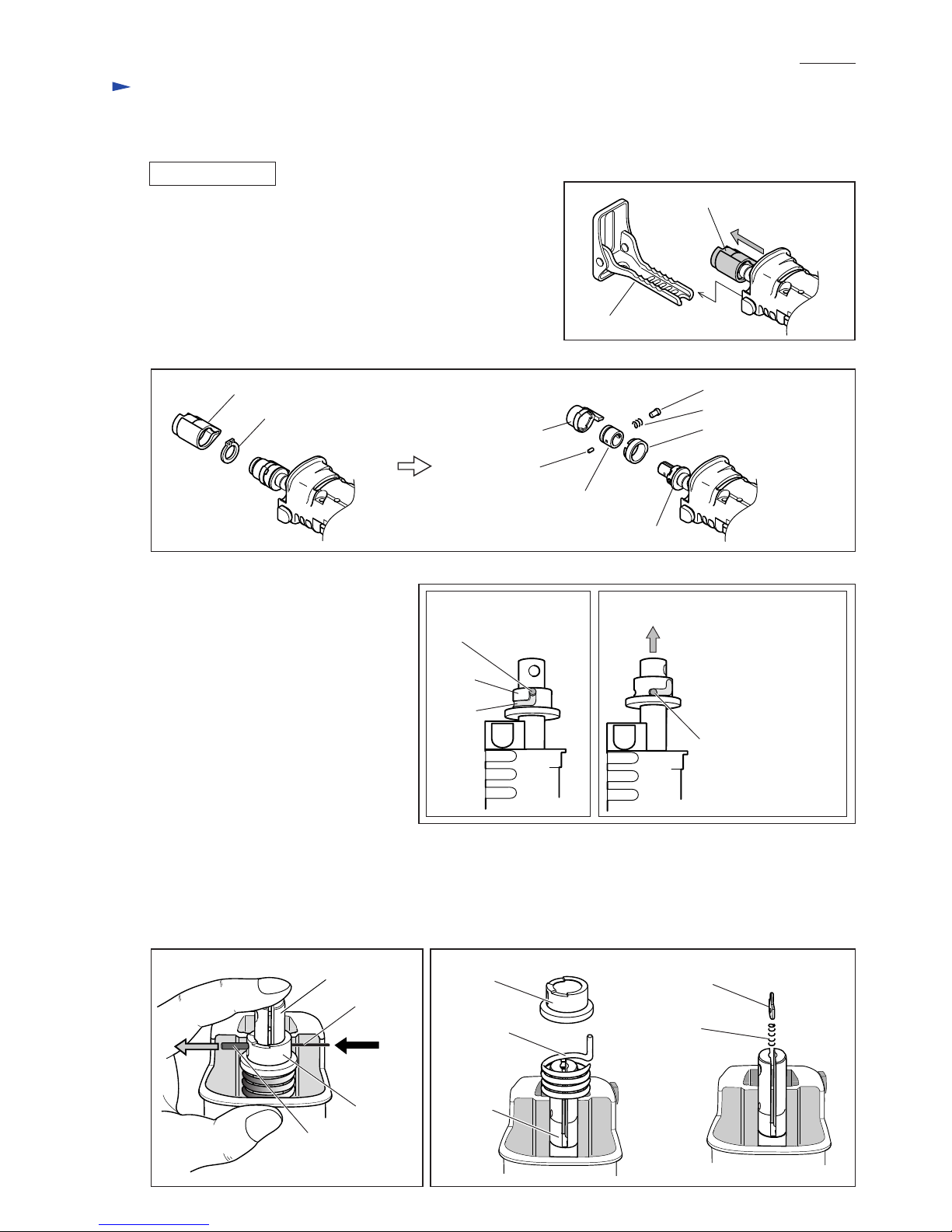

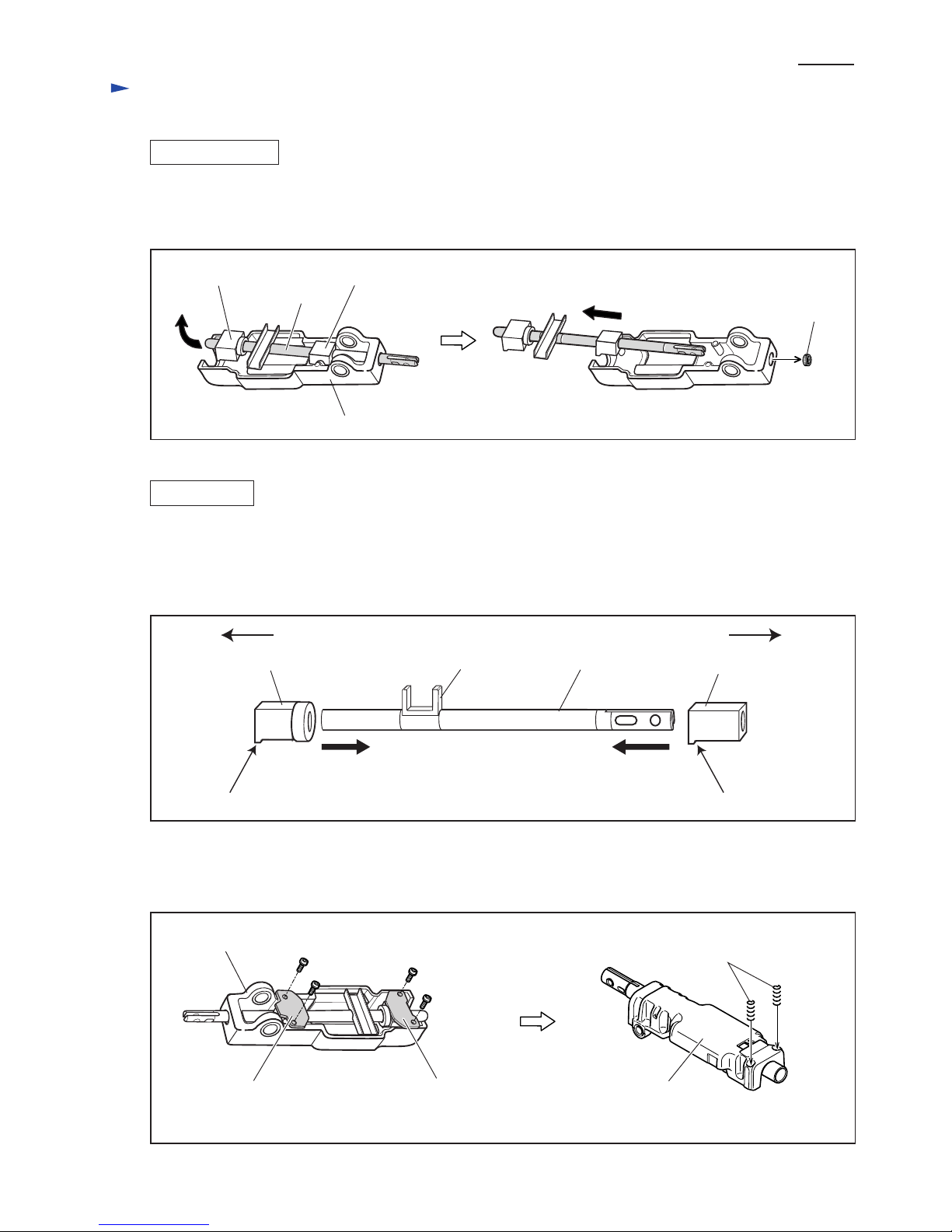

Fig. 14

1) Replace cap by new one because removal of shift button

damages the inside surface of cap.

2) From shift button, remove all the plastic dust scraped off

the removed cap. Insert shift button through the holes in

the both sides of gear housing cover.

And then press-fit shift button in the new cap by hand.

Important:

Be sure to assemble shift button to gear housing cover

so that the two notches of shift button face the side

opposite to slider as illustrated in Fig. 14.

These notches of shift button must

face the side opposite to slider.

Slider

Shift button

Cap