Makita LS1013 User manual

Other Makita Saw manuals

Makita

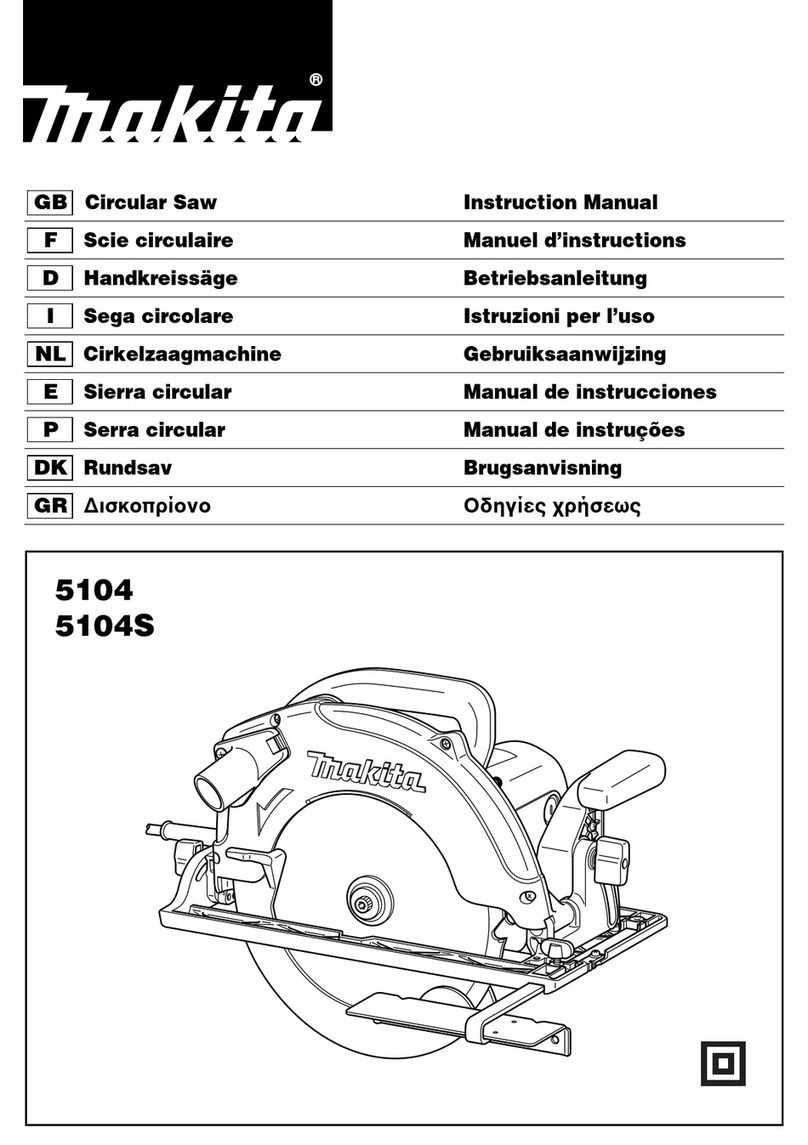

Makita 5104 User manual

Makita

Makita LS002G User manual

Makita

Makita DLS713RTE User manual

Makita

Makita DPB181 User manual

Makita

Makita DSP600 User manual

Makita

Makita LS1013 User manual

Makita

Makita RS002G User manual

Makita

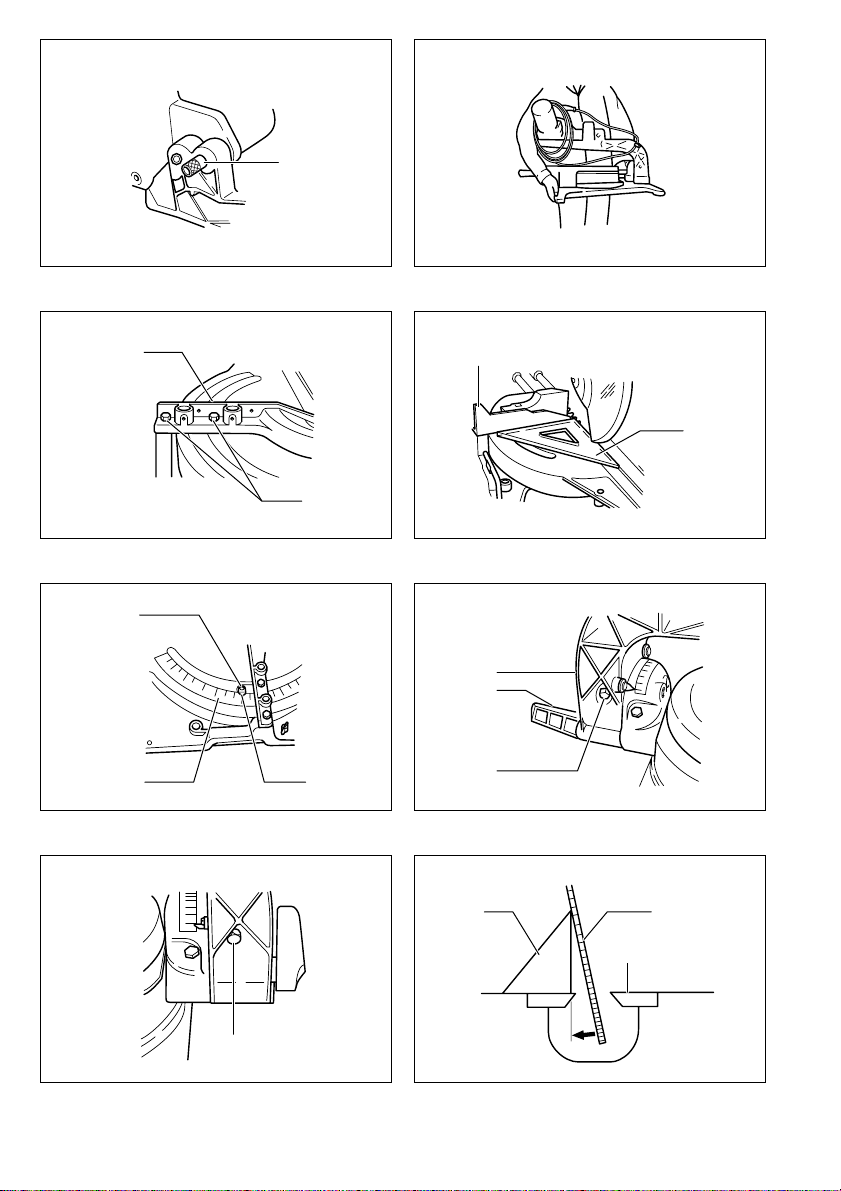

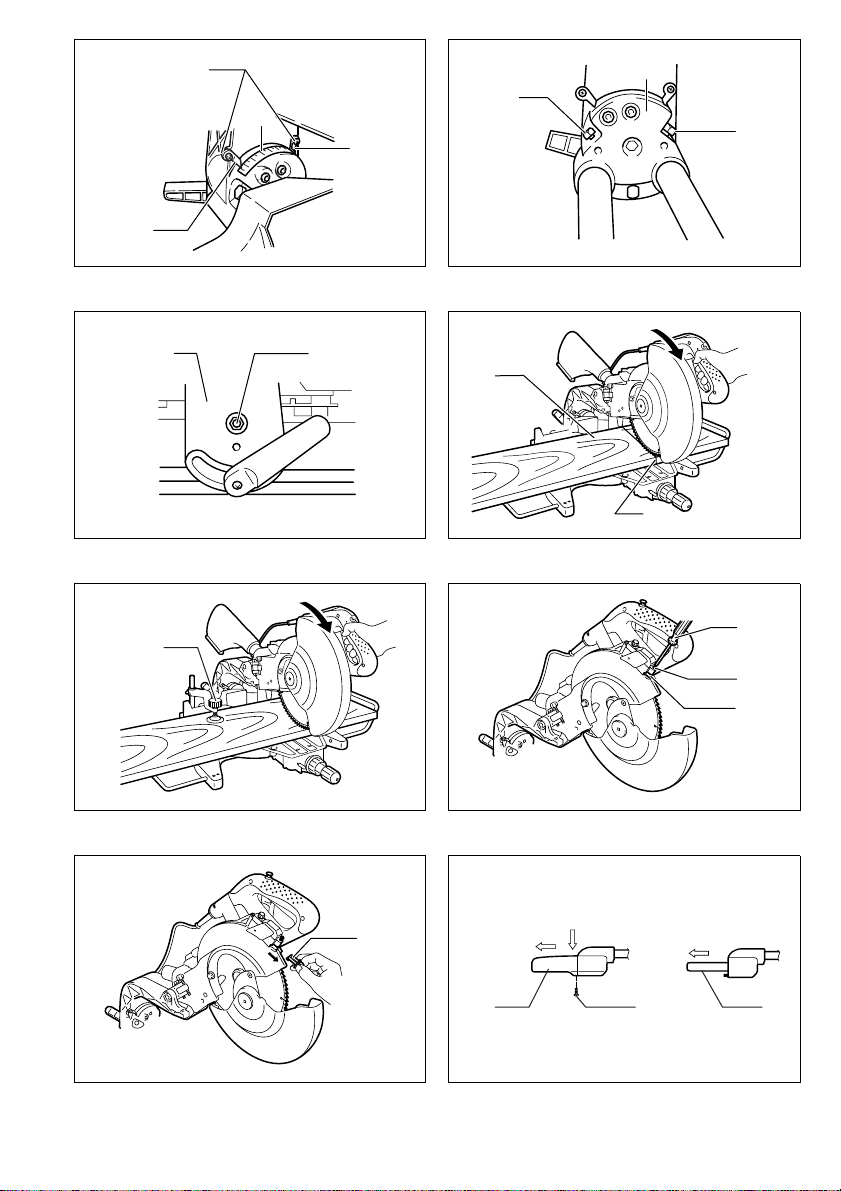

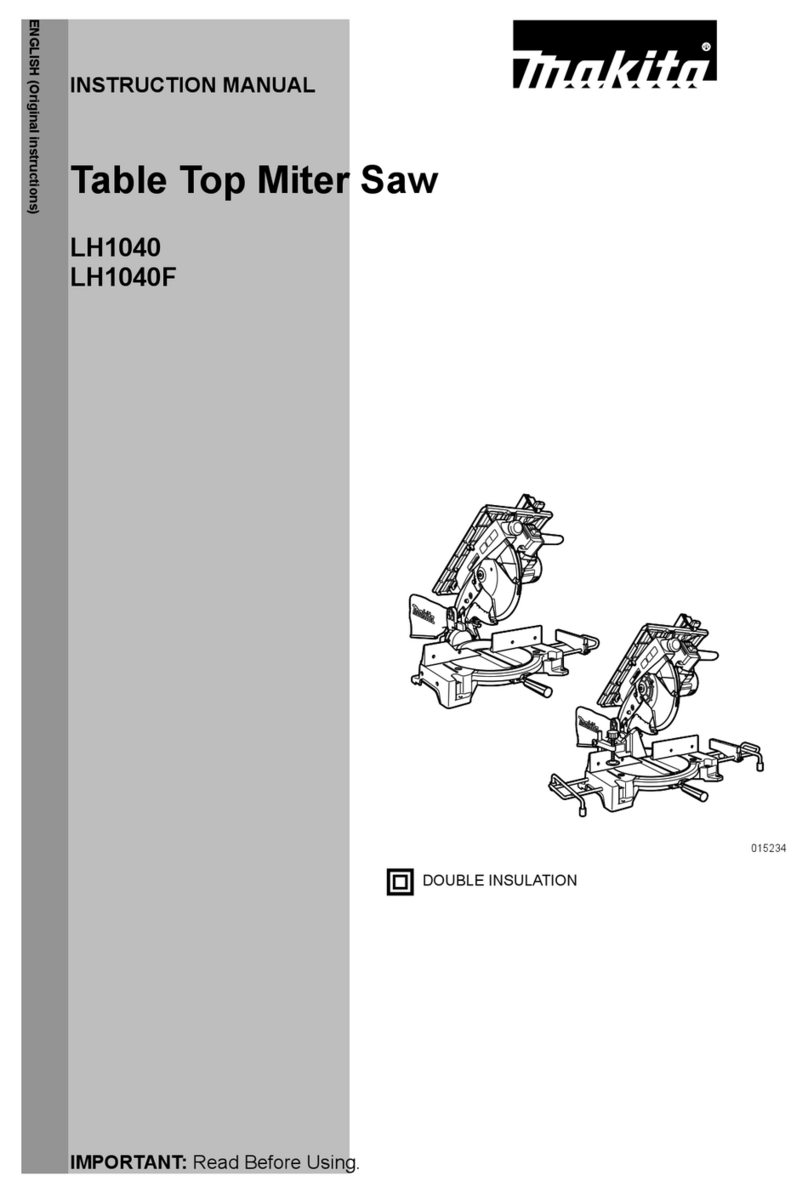

Makita LH1040F User manual

Makita

Makita 5007F User manual

Makita

Makita JR3060T User manual

Makita

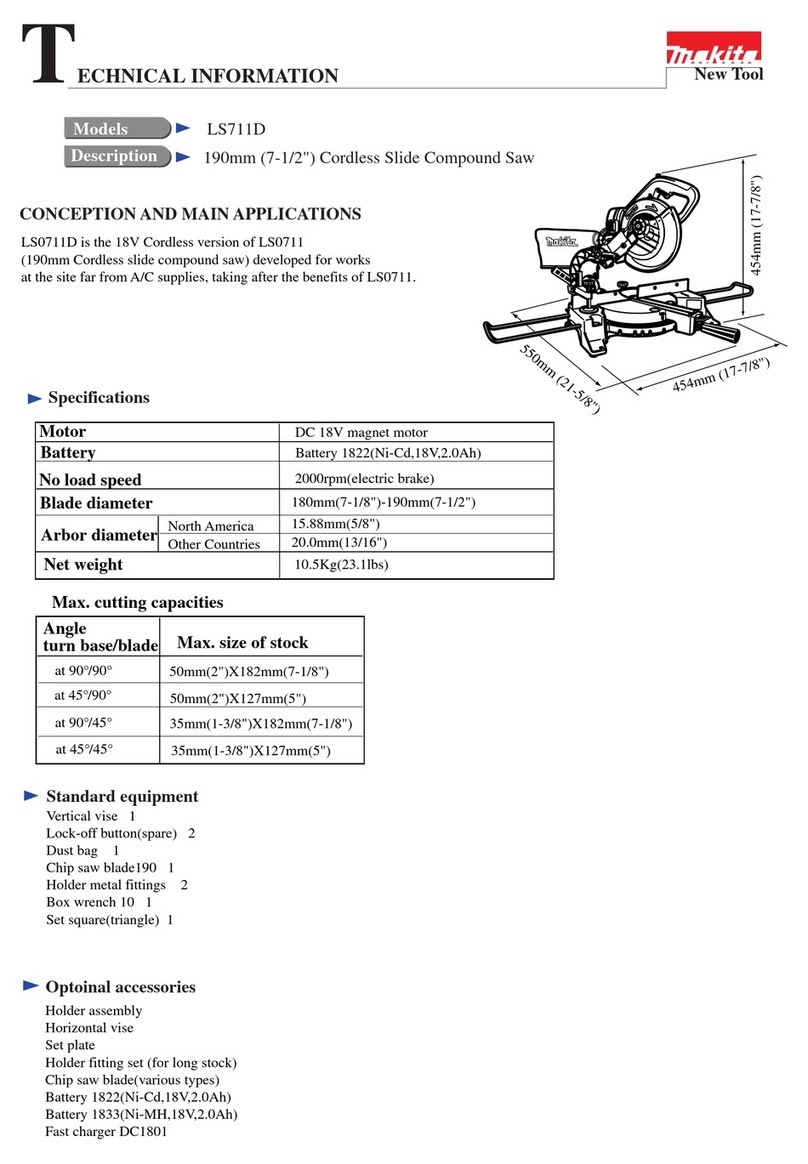

Makita LS711D Manual

Makita

Makita LF1000 User manual

Makita

Makita JR3050T User manual

Makita

Makita JR3000VT User manual

Makita

Makita CXT JR103D User manual

Makita

Makita LS001G User manual

Makita

Makita LS1019 User manual

Makita

Makita LS1219 User manual

Makita

Makita HS6600 User manual

Makita

Makita DLS211 User manual