Makita LS1019 User manual

Other Makita Saw manuals

Makita

Makita LS1219 User manual

Makita

Makita JR103D User manual

Makita

Makita 2704 User manual

Makita

Makita LS1219/1 User manual

Makita

Makita HS7610 User manual

Makita

Makita XWL01 User manual

Makita

Makita DJR187 User manual

Makita

Makita DPC 7001 Quick start guide

Makita

Makita 2708 Manual

Makita

Makita DJR186ZK User manual

Makita

Makita 5104S User manual

Makita

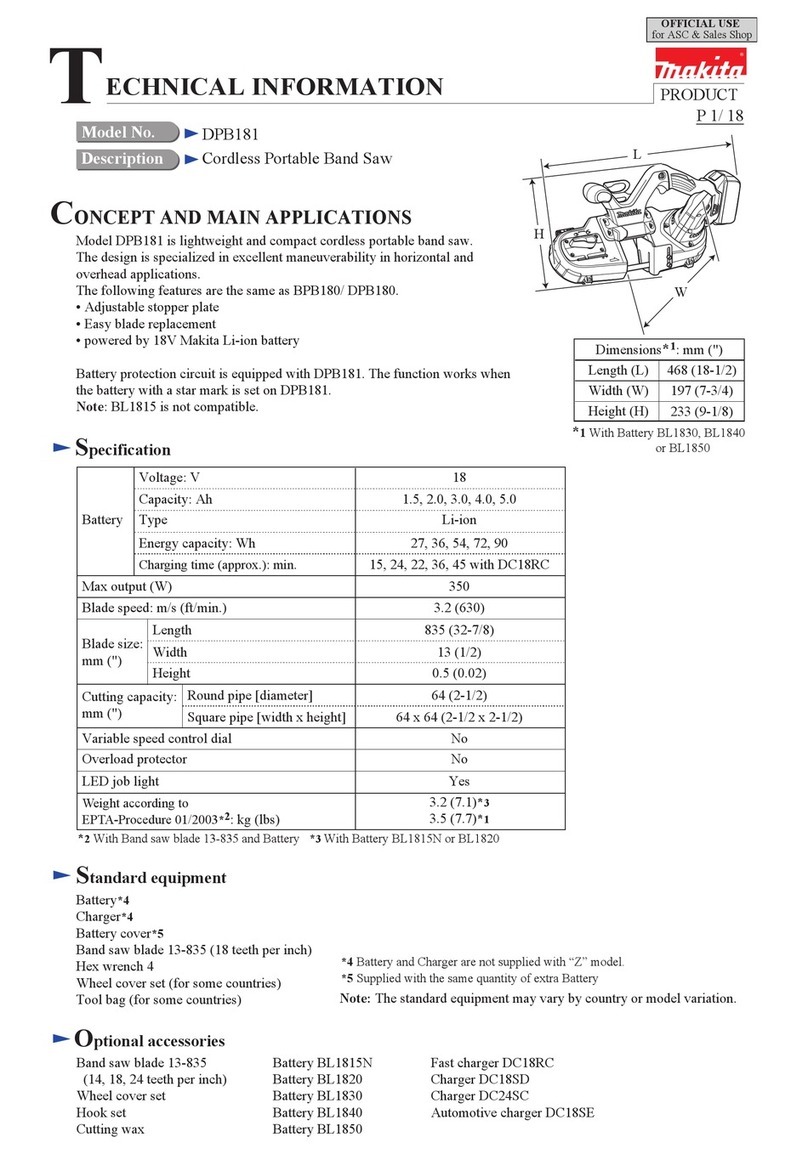

Makita DPB181 Manual

Makita

Makita DPB181 User manual

Makita

Makita 2704N User manual

Makita

Makita 5057KB User manual

Makita

Makita 5603R User manual

Makita

Makita 2414NB User manual

Makita

Makita LS1018LNX4 User manual

Makita

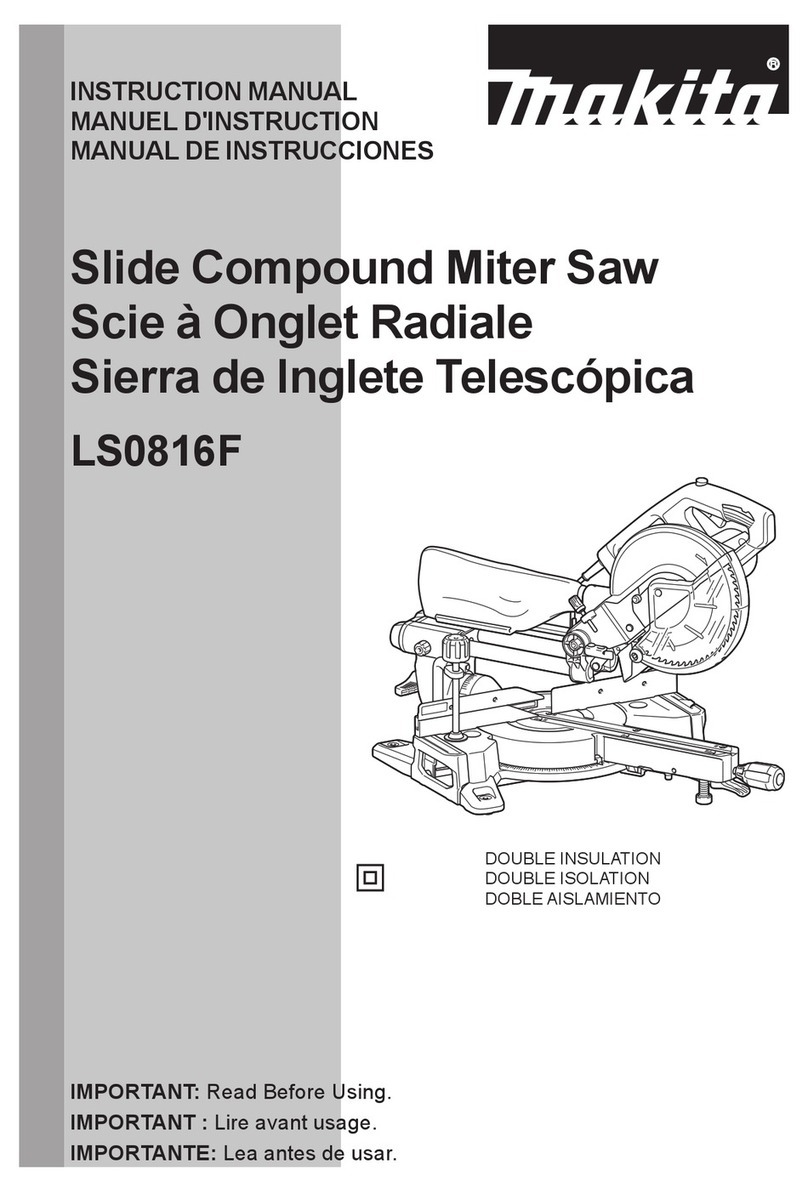

Makita LS0816F User manual

Makita

Makita LS1216 User manual