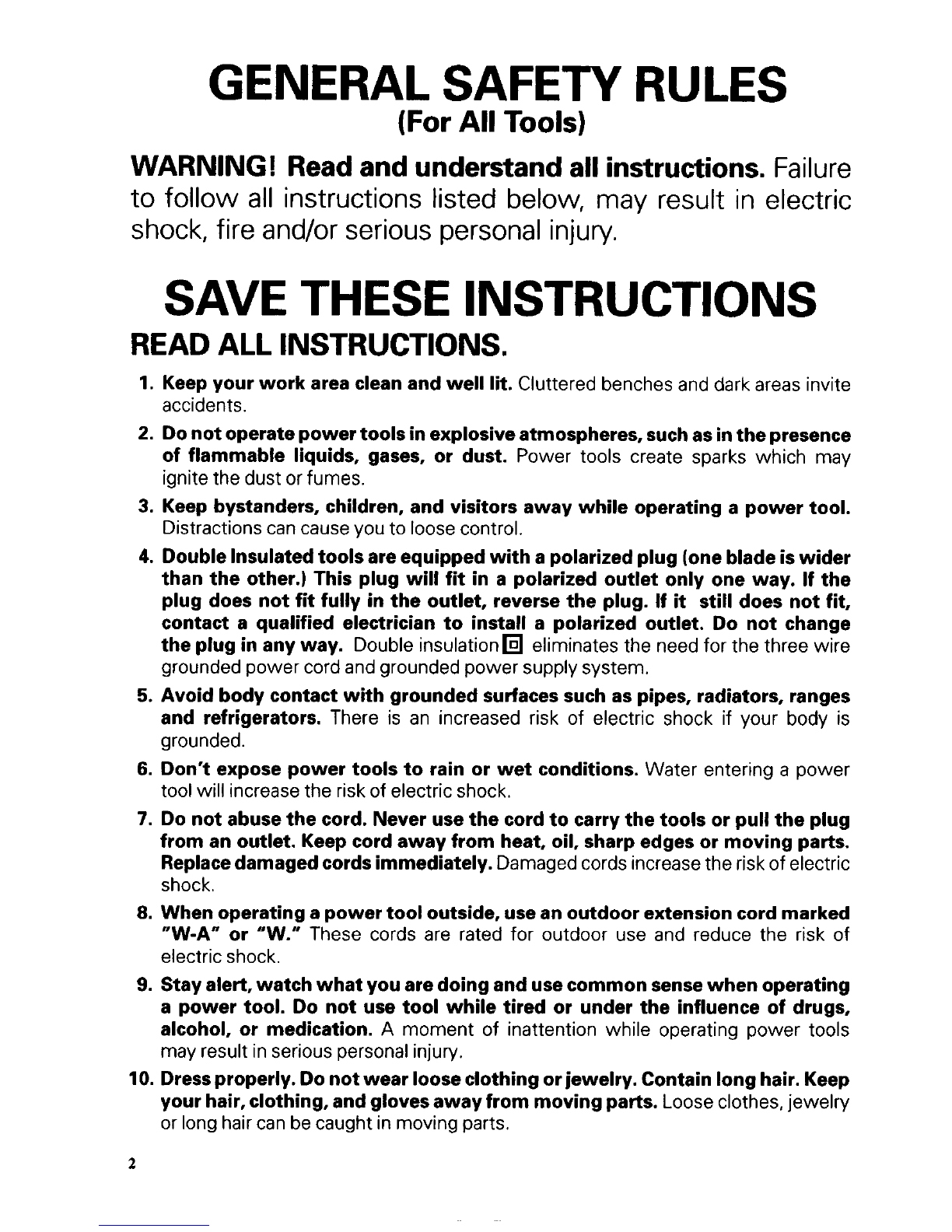

SpecificSafetyRules

1.

DANGER! Keep hands away from cuttingarea and blade. Keep your second

handon auxiliary handle,

or

motor housing. If both handsare holdingthe saw,

they cannotbecut bythe blade.

Keep your body positioned to either side of the saw blade,

but

not

in

line

with the saw blade. KICKBACK could cause the

saw

to jump backwards. (See

"Causes and Operator Prevention of Kickback")

Do notreach underneath thework while blade is rotating. The guard can not

protectyou from the blade below the work. Don't attempt to removecut material

when blade

is

moving

CAUTION: Blades coast after turn off.

2.

Check lower guardfor proper closing before each use. Donot operate saw if

lower guard does notmovefreely and closeinstantly. Never clamp

or

tiethe

lower guard intothe open position. If saw

is

accidentally dropped, lower guard

may be bent. Raise the lower guard with the RetractingHandle and make sure it

movesfreelyanddoesnottouchthe blade

or

any otherpart, in

all

anglesanddepths

of cut.

3.

Checktheoperationandconditionof thelowerguardspring.

If

theguard and

thespringarenotoperatingproperly,theymustbeservicedbeforeuse. Lower

guardmayoperatesluggishlydueto damagedpartsgummydeposits,or

a

buildupof

debris.

4.

Lower guard should be retracted manually only for special cuts such as

"Pocket Cuts." and "Compound Cuts." Raise lower guard by Retracting

Handle.As soon as bladeentersthe material, lower guard must bereleased.

For

all

other sawing, the lower guardshould operateautomatically.

5.

Alwaysobservethatthelowerguardiscoveringthebladebeforeplacingsaw

downonbench

or

floor. An unprotected,coastingbladewill causethe sawto

walk

backwards,cuttingwhatever

is

initspath.Beawareof thetimeittakesfor theblade

to stopafterswitchis released.

6.

NEVER

holdpiecebeingcut

in

your hands

or

acrossyour leg. Itis importantto

supportthe work properly to minimizebodyexposure, bladebinding,or

loss

of con-

trol.

7.

Holdtoolbyinsulatedgripping surfaceswhenperforminganoperation where

the cutting tool may contact hidden

wiring

or

its own cord. Contact with

a

"live" wirewillalsomakeexposedmetalpartsof thetool "live" andshockthe oper-

ator.

8.

When rippingalwaysusea

rip

fence

or

straight edgeguide. This improvesthe

accuracyof cutandreducesthe chancefor blade binding.

9.

Always use blades

with

correct size and shape (diamond vs. round) arbor

holes. Bladesthat do not matchthe mountinghardware of the saw will runeccen-

trically, causing

loss

of control.

10.

Neverusedamaged

or

incorrectbladewashers

or

bolts.The bladewashers and

boltwere specially designed for your saw, for optimum performanceand safety

or

operation.

4