9

• Do not place hand or fingers close to the blade.

• Ne pas placer les mains ou les doigts près de la lame.

• Halten Sie Hände oder Finger vom Sägeblatt fern.

• Non avvicinare le mani o le dita alla lama.

• Kom met uw handen of vingers niet te dicht bij het zaagblad.

• No ponga la mano ni los dedos cerca del disco.

• Não coloque a sua mão ou dedos perto da lâmina.

• Hold hænder og fingre på god afstand af klingen.

• Μη βάζετε το χέρι ή τα δάκτυλα κοντά στην λάμα.

• For your safety, remove chips, small pieces, etc. from the table top before operation.

• Pour votre sécurité, retirez les copeaux et autres petites pièces présentes sur la table avant de com-

mencer le travail.

• Zur Sicherheit sollte die Tischplatte vor dem Betrieb von Spänen, Kleinteilen usw. gesäubert werden.

• Per la propria sicurezza, togliere i trucioli, frammenti, ecc., dalla superficie superiore del piano di

taglio prima di procedere.

• Verwijder voor uw eigen veiligheid zaagafval, stukjes hout e.d. van de werktafel alvorens te gaan

zagen.

• Por su propia seguridad, retire las virutas, trozos pequeños, etc., de encima de la mesa de trabajo

antes de iniciar la tarea.

• Para sua segurança, retire aparas, peças pequenas, etc., de cima da bancada antes da operação.

• Af sikkerhedsårsager skal spåner, små stykker etc. fjernes fra bordtoppen inden anvendelsen.

• Για την ασφάλειά σας, αφαιρέστε τα αποκοπίδια, μικρά κομμάτια, κλπ. απ το τραπέζι πριν

απ την λειτουργία.

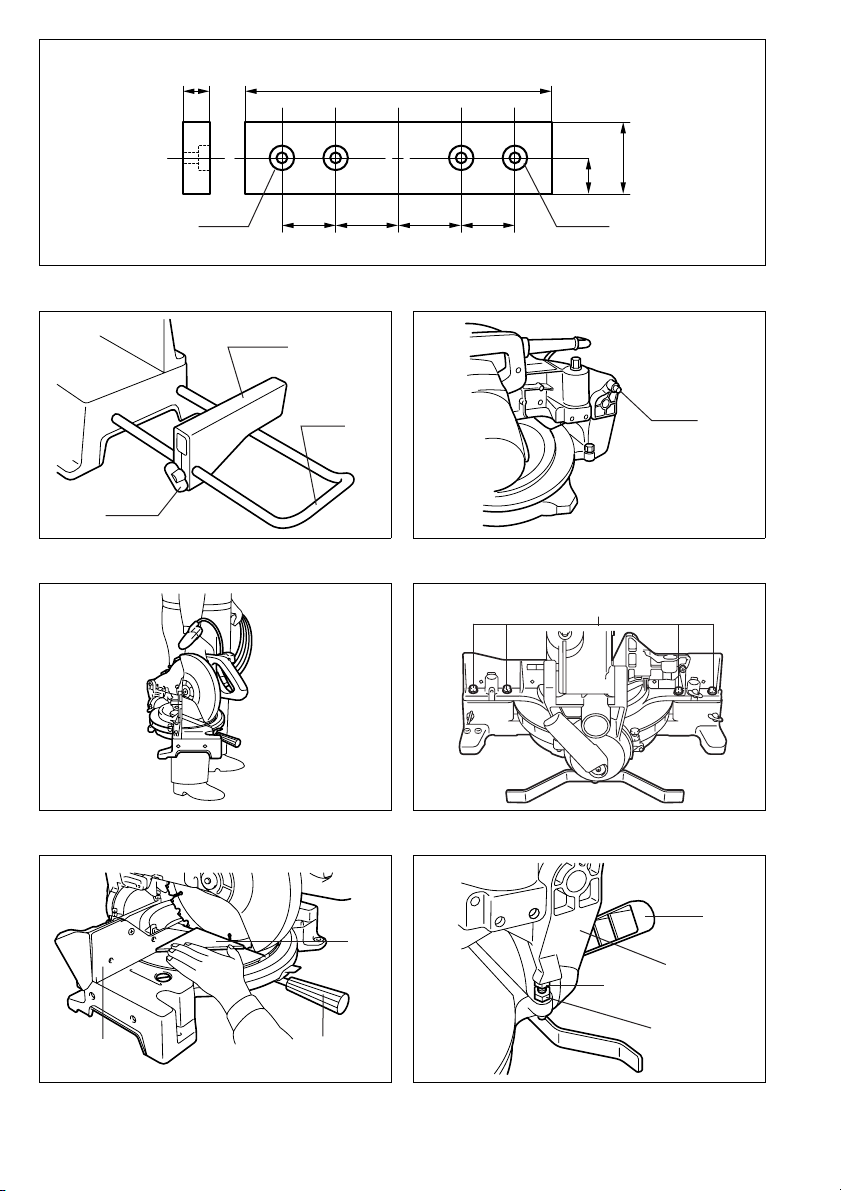

• Always set SUB-FENCE to left position when performing left bevel cuts. Failure to do so may cause

serious injury to operator.

• Lorsque vous effectuez des coupes en biseau sur la gauche, placez toujours la BUTÉE PARE-

ÉCLATS ROTATIVE à gauche. Sinon, il y a risque de blessure grave.

• Stellen Sie den ZUSATZANSCHLAG bei der Durchführung von Neigungsschnitten immer auf die

linke Position. Anderenfalls kann die Bedienungsperson ernsthaft verletzt werden.

• Posizionare sempre la guida pezzo secondaria a sinistra prima di eseguire i tagli a unghia. In caso

contrario, c’è pericolo di lesioni serie all’operatore.

• Zet de HULPGELEIDER altijd in de linkse positie wanneer u linkse schuine sneden wilt zagen. Als u

dit niet doet, kan de gebruiker ernstige verwonding oplopen.

• Ponga siempre la GUÍA AUXILIAR en la posición izquierda cuando realice cortes en bisel izquierdo.

De lo contrario, podrá sufrir graves heridas.

• Coloque sempre a GUIA AUXILIAR no lado esquerdo quando executa cortes de bisel à esquerda. Se

não o fizer pode ferir o operador.

• Anbing altid hjælpeanslaget (SUB-FENCE) i venstre position, når der laves skråsnit. Forsømmelse af

dette kan bevirke, at operatøren kommer alvorligt til skade.

• Πάντοτε ρυθμίζετε το SUB-FENCE (ΥΠΟ-ΦΡΑΚΤΗ) στην αριστερή θέση ταν εκτελείτε

αριστερές λοξές κοπές. Αμέλεια να το κάνετε μπορεί να προκαλέσει σοβαρ τραυματισμ

στον χρήστη.

• To loosen the bolt, turn it clockwise.

• Pour desserrer le boulon, tournez-le vers la droite.

• Drehen Sie die Schraube zum Lösen im Uhrzeigersinn.

• Per allentare il bullone, girarlo in senso orario.

• Draai de bout rechtsom los.

• Para aflojar el perno, gírelo hacia la derecha.

• Para desapertar o perno, rode-o no sentido dos ponteiros do relógio.

• Bolten løsnes ved at den drejes i retningen med uret.

• Για να ξεσφίξετε τον κοχλία, περιστρέψτε δεξιστροφα.