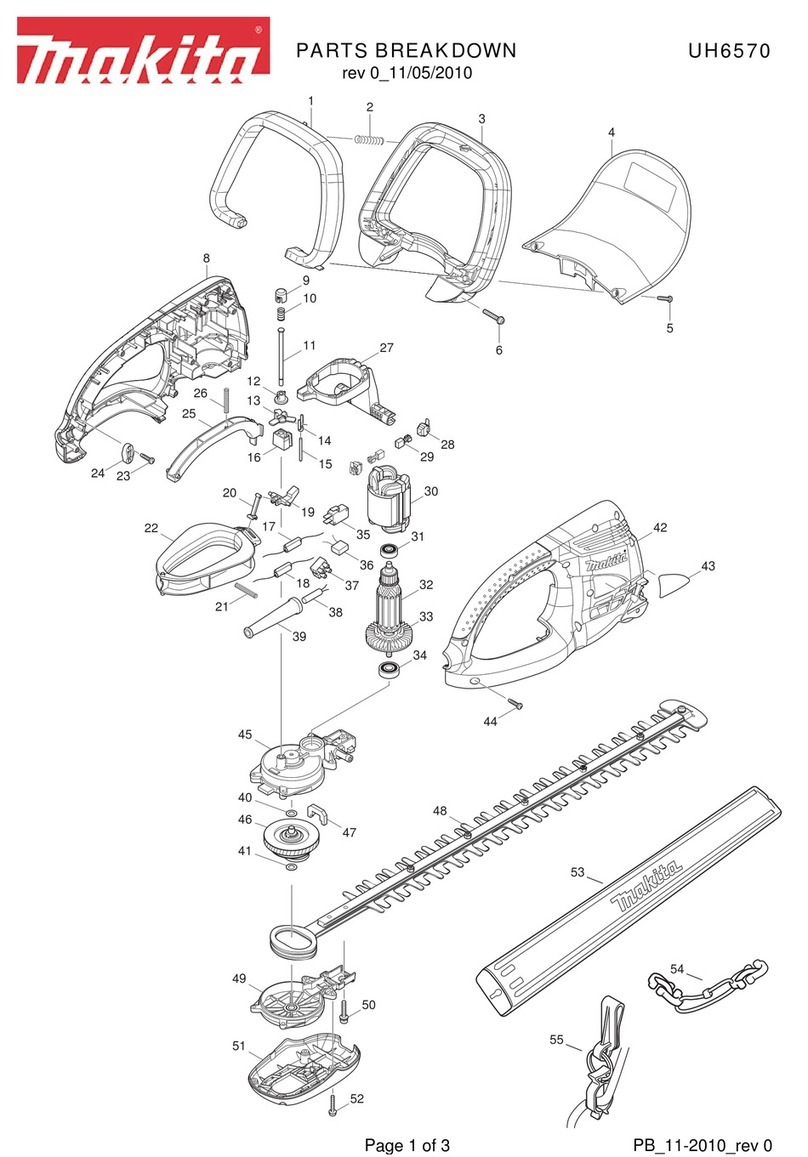

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Shear blade ass’y and Gear ass’y (cont.)

[3] -3. Motor, Switch and Power supply cord

P 3/ 7

ASSEMBLING

Fig. 9Fig. 8

Fig. 11

Fig. 10

DISASSEMBLING

DISASSEMBLING

slotted screwdriverShear blades

Gear housing complete

Dust guard

Flat shape

Guide plate

Take the disassembling step in reverse.

Note: Regarding the new Shear blade ass’y;

- make sure that the routes for the two M5x25 Pan head screws are secured.

- pass two M5x25 Pan head screws through the holes for Shear blade ass’y in advance.

The flat shape of Dust guard has to be inserted into the groove of Gear housing before putting Shear blade ass’y on

Gear housing. (Fig. 8)

Pass the two M5x25 Pan head screws through Shear blade ass’y to align the holes of Shear blade ass’y with

Sleeves, and tighten the two M5x25 Pan head screws. (Refer to Fig. 6.)

When reusing two M5x25 Pan head screws, apply adhesive to the threads.

When the holes and Sleeves for two M5x25 Pan head screws are not aligned, slide only Guide plate back and forth.

(Fig. 9)

After tightening M5x25 Pan head screws, make sure that Shear blades reciprocates smoothly with turning Crank

with slotted screwdriver. (Fig. 6)

5) Loosen two M5x25 Pan head screws (threadlocker type) and separate Shear blade ass’y from the machine. (Fig. 6)

Note: 1. Leave the two M5x25 Pan head screws in their holes of Shear blade ass’y when setting Shear blade ass’y in place

without disassembly.

Removing two M5x25 Pan head screws may cause misalignment between two sleeves and holes of Shear blade ass’y.

2. Leave Dust guard in the groove of Gear housing.

6) Pull out Gear ass’y from Gear housing using two 1R263 or slotted screwdrivers. (Fig. 7)

Fig. 6 Fig. 7

Blade cover

Sleeve (2pcs.)

in the holes of

Shear blade ass’y

Dust guard

M5x25 Pan head screw (2pcs.) 1R263 or slotted screwdriver (2pcs.)

Shear blade ass’y

Gear room

Gear ass’y

Gear ass’y

Gear housing

1) Remove Shear blade ass’y. (Refer to Fig. 6.)

2) Remove Top cover and Carbon brushes. (Figs. 1 and 2)

3) Remove two M5x30 Pan head screws, and then slide

the following parts together the forward direction. (Fig. 10)

*Switch lever B *Front grip *Protector complete

The above parts can be pulled out from Housing set.

4) Remove ten 4x18 Tapping screws and separate Housing R

from Housing L. (Fig. 11)

M5x30 Pan head

screw (2pcs.)

Switch lever B

Front grip

Protector

complete

4x18 Tapping screw

(10pcs.)

Housing R