MAKOT UMS-04 Series User manual

Controllers of UMS-04 series are universal, programmable timing controllers. Main purpose of these

controllers is to control the external devices during process of milk cooling containers and milking

device.

Controllers default settings enables direct applicate of him in the most of the standard devices, intends

for washing of milking device and milk cooling containers.

Controllers also have a great opportunities of individual programming, or configuring work by the

installer, which installs the controller for a specific device. This creates the possibility of controller to be

wide use in various devices.

A characteristic feature of these controllers is the possibility of entering by the installer his own work

program or the edition of the program factory entered.

CONTROLLER’S FUNCTIONS

1. Washing programs.

The controller has 8 washing programs. Factory settings include 2 milking device washing

programs and 2 programs to wash the cooling containers. The remaining programs are to be

programmed by the installer

2. Programs setting and modification function.

The controller enables (the installer) to individually set the programs. Each program can

include up to 50 steps and can last up to 99 minutes. The programming is very simple and

intuitive. It is shown in detail in the manual in the form of pictures. The factory set programs

can also be modified according to specific needs

3. Function allowing to control water heating .

The controller is equipped with a built-in temperature regulator enabling to control the water

heating. For this function to work it is required to install a temperature sensor and to set the

heating temperature (factory set to 40oC). Controllers which include this function have a

letter ‘T’ at the end of the symbol description

4. Safety function in case of power outage.

In case of power outage the set program is stopped. When the power is back, the program

will be restarted at the same point it was at the moment the outage occurred

5. Service function enabling to test the correctness of work of the controller set.

This function allows to go to the next sequences of a program without waiting for the time to

pass. Skipping the stages is done by means of pressing a special button. This function is only

available for the installer

6. Function allowing to return to factory settings.

In case an error occurs when setting the controller’s work program, there is always a

possibility to return to factory settings

7. Function enabling to manually switch on the subpressure pump or the stirrer

8. Function enabling to start a program.

The program starts when a button located on the face of the controller is pressed manually or

when an external button attached to the controller is pressed. It is also possible to start the

program in an automatic way through an external device

9. Pause function (suspension) the execution of the program during his lifetime.

This function enables to stop the running of a program at any time until it is restarted. The

restart causes the program to start operating at the same point when it stopped. The pause

function can be enabled by pressing a button, located on the face of the controller or by

pressing an external button attached to the controller

10. Function switching the program work off.

The controller is equipped with a button which enables to switch the program off without the

possibility to restart it at the same point. When the program is restarted it will start the

program from the very beginning

11. Function which displays number of the running program and the time for its

completion.

When the program is running, on the controller display there is alternately shown number of

the running program and time to its completion. The time presented doesn’t include the time

required to pour the water in

PRZEDSIĘBIORSTWO

PRODUKCYJNO HANDLOWE

MANUAL

CONTROLLER

SERIES

UMS-04

30-716 KRAKÓW ul.Przewóz 34/304

tel 012 657 91 44

12. Function of finished the process of pouring the water in.

Depending on the signal from the hydrostat or the water feeder MPC-05 type

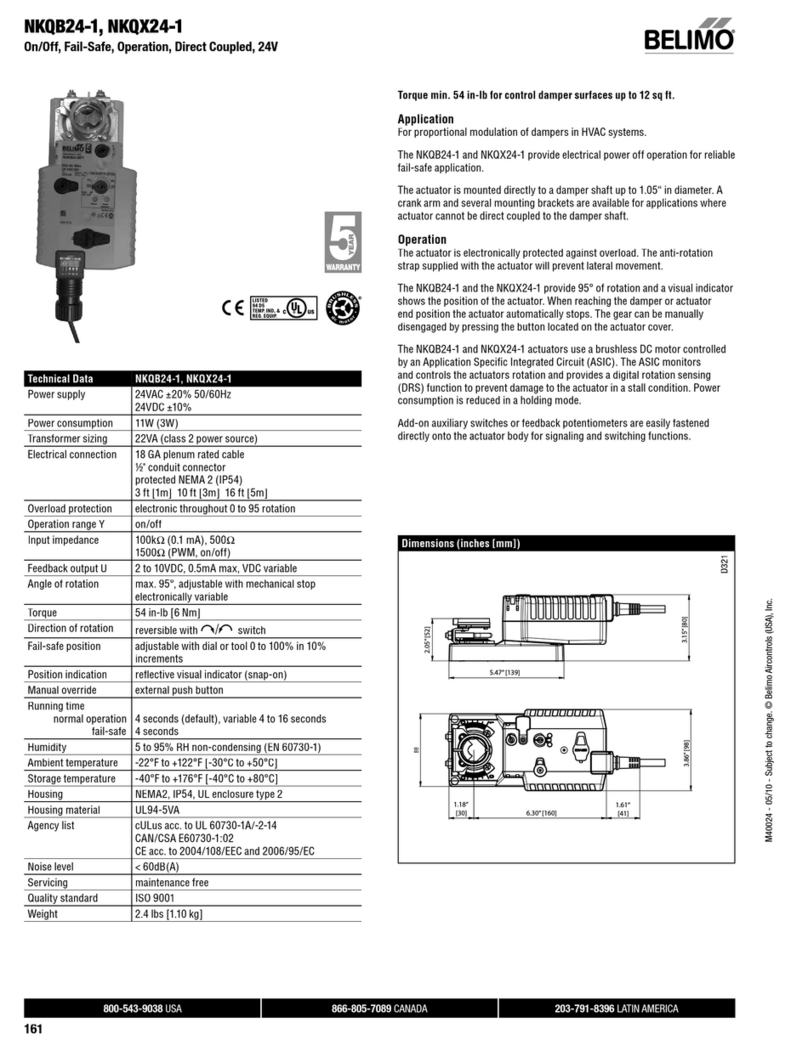

UMS-04 Controller is equipped with:

8 controller leads:

- one lead (relay No. 5) is equipped with contacts: normal close and normal open;

- leads (relay 1 –7) have normal open contacts;

-switched power input is conducted to enable providing any kind of power between 6 and

380 V

- relay lead: free contacts, which can be individually connected to any of voltage signals.

- lead PKD has normal close contacts. This output is designed to disable other equipment at

the time the washing program

hydrostat input

the input for connecting a temperature sensor (controllers with the T symbol, equipment

there's a temperature sensor)

input allowing to connect an external program starting button;

The controller is equipped with:

LED display indicating the remaining program time during its realization [1]

Light emitting diodes designed to inform which relay is currently on during realization of a

given program[2];

A light emitting diode showing when the hydrostat is working [3];

A light emitting diode showing the device is in test mode [4];

A switch turning the washing program on. This switch also allows to manually stop a

program in progress [5];

A switch turning the washing program off [6];

UMS-04 controllers are placed in a casing for rail mounting. There are derived two main

buttons , the other buttons available after face removing

TECHNICAL INFORMATION

number of programs 8

number of factory set programs 4

maximum number of stages in each program 50

maximum time of one stage 99 min

minimum time of one stage 1 second

number of relay leads 8

load capacity of relay contacts 10A 250V AC

number of controller inputs max. 3

ohydrostat

oexternal „Start Program” button

display type LED

casing size 105 x 90 x 65 mm

power supply 230 V AC 50 Hz

safeguard IP30

safety class B

STRUCTURE

UMS-04 controllers are placed in a casing for rail mounting.

SERVICING BY THE IMMEDIATE USER

A characteristic feature of the controller is the simple servicing by the user. Servicing requires to use

only two or three keys. All the other buttons are inactive for the immediate user disabling him from

accidentally interfering with the factory or installer settings.

ACTIVATION OF THE CONTROLLER

When power is connected to the controller it remains on stand-by. It is signalized by for bars being

lit up on the display panel.

The washing program can be enabled by pressing the green start button [5].

The controller allows to connect an external button which doubles the function of [5] button located

on the face of the controller.

When the start button is pressed the earlier set washing program is being executed.

During the execution of the program the display show the time remaining until the washing process

is over.

ATTENTION:

The time show by the display does not include the time required to pour in water when the controller

operates with a hydrostat

ACTIVATING THE WASHING PROGRAM

The washing program is activated by pressing the start button (green), this way a previously set program

is activated.

PAUSING THE WASHING PROGRAM

When the program is active it can be paused at any time. It is done by pressing the green start button

again. When the program is paused all the active relays are deactivated. It can be restarted again by

pressing the green start button once more. The program will continue from the moment it was paused.

DEACTIVATING THE WASHING PROGRAM

Whenever it is necessary the currently realized program can be stopped. It can be done by pressing the

OFF button (red).

When this button is pressed the program stops and deactivated completely and the controller switches to

stand-by mode. At this point, if the program is activated again it will start from the very beginning.

SERVICING BY THE INSTALLER

The controller is factory set for standard working conditions and it is designed for washing

the milk cooler –2 programs, and to control the washing of the milking room –2 programs.

Nonetheless, in order to provide optimized work of the controller in specific conditions, the

settings can be corrected to choose an appropriate program. The factory set washing programs can be

modified according to needs or a personalized program can be set.

When the controller is installed, the correctness of work of the entire washing system can be

checked in a fast mode.

SETTINGS CHART

Function

Symbol

Settings

Factory

settings

1

Entering the settings mode

U000

Access Code

121

2

Programs edition

EdPr

Editing the factory presets

and creating personalized

programs. Described

elsewhere within this

manual.

8 programs

See

Programs

Chart

3

Setting the program number

dPro

Pro1

Pro2

Pro3

Pro 4

Pro5

Pro6

Pro7

Pro8

Pro1

Setting heating (only for UMS-04T)

OHA

0 –no function

1 –heating with maximum

active time

2 –without maximum active

time

2

5

Setting the test program

UEL

0 –no function

1 –test function activated

0

8

Setting the maximum time without

Power supply after which the power is

restarted.

UAP

0 –no function (unlimited

time)

1 –9 h

9

9

Returning to factory settings when the

controller is next activated.

PdOd

0 –no function

1 –back to factory settings

0

ENTERING THE SETTINGS AND PROGRAMMING MODE

The controller is secured against accidentally entering the service settings mode that is available to

service and maintenance personnel only.

This includes:

- There are derived two main buttons , the other buttons available after face removing

- having to press and hold the settings and programming mode button [8] for approximately 15 sec.

- having to enter the access code, which is given in the Settings Table.

- entering the access code is effected in several steps.

ATTENTION.

You are requested not to make the access code available to end users.

Below is the graphic representation of the procedure for entering the accdess code which enables to

enter the settings and programming mode.

SELECTING THE FUNCTION TO BE EDITED

In the Settings Table are all the functions available with the description and the list of possible values to

be set. If it is necessary to change any parameter within the settings, enter the settings mode (see above).

Next select a particular function to be modified. Below is graphic representation of a change to the

factory settings for the washing program No 1.

EDITING THE PROGRAMS –EdPr Function

The controller is equipped with:

- 4 pre-programmed washing programs which can be edited according to needs by the

installer.

- 4 washing programs to be programmed by the installer and not pre-programmed.

Each program can consist of the maximum of 50 steps.

The following parameters are ascribed to each step:

- status of 7 relays;

- status of the hydrostat input;

- duration of the step;

- temperature of heating water (for UMS-04T with active OHA= 1 or 2 function)

RETURNING TO THE DEFAULT SETTINGS

In order to return to the default settings enter the controller settings mode. Select the PdOd option with

buttons ▲,▼. Confirm the selection by pressing button SChange the value from „0” to „1” using

button ▲. Then confirm the selection by pressing button S. again. Subsequently disconnect the power

from the controller and connect it again.

ATTENTION!

1. Returning to default settings will result in deleting all the settings from the controller’s

memory and simultaneously bringing back the default settings. Therefore this option

should be applied with proper care and awareness.

2. Returning to default settings is only effected once the controller’s power supply is

disconnected and connected again.

CONTROLLER OPERATING IN THE TEST MODE

The test mode function is designed for testing the correct operation of the washing system controlled by

UMS-02 controller.

Operating in test mode enables to manually speed up the particular steps of the program.

In order to set the test mode enter the settings mode and set the UEL function to 1.

Then confirm it by pressing S. To exit the setting mode press the red button.

The test mode operation is signaled by the flashing green light marked A.

Having switched on the program you can pass on to the following steps by pressing ▲. You can also go

back to the previous steps by pressing ▼.

Exiting the test mode:

- enter the access code;

- select the UEL function;

- set the value to 0

- confirm by pressing S;

- exit the settings by pressing the red button

ATTENTION

Having finished the tests of the washing system it is absolutely essential to remember to return to the

regular operation. During the regular operation the green light must not be on.

PRE-SET PROGRAMS

The controller contains 4 pre-set programs presented below. The remaining 4 programs are empty..

Program No 1

LED diode No

1

2

3

4

5

6

7

REMARKS

STEP

TIME

CW

ZW

PP

PML

ZZ

PMY

H

1

15:00

0

1

0

0

0

1

1

Max. time

2

03:00

0

0

1

0

0

1

0

3

00:30

0

0

1

1

0

1

0

4

15:00

1

0

0

0

1

1

1

Max. time

5

07:30

0

0

1

0

1

1

0

6

03:30

0

0

1

0

0

1

0

7

00:30

0

0

1

1

0

1

0

8

15:00

0

1

0

0

0

1

1

Max. time

9

05:00

0

0

1

0

0

1

0

10

00:30

0

0

1

1

0

1

0

01:05:30

Program No 2

Relay No

1

2

3

4

5

6

REMARKS

STEP

TIME

CW

ZW

PP

PML

ZZ

PMY

H

1

15:00

0

1

0

0

0

1

1

Max. time

2

04:00

0

0

1

0

0

1

0

3

00:30

0

0

1

1

0

1

0

4

15:00

1

0

0

0

1

1

1

Max. time

5

11:30

0

0

1

0

1

1

0

6

02:30

0

0

1

0

0

1

0

7

00:30

0

0

1

1

0

1

0

8

15:00

0

1

0

0

0

1

1

Max. time

9

06:00

0

0

1

0

0

1

0

10

00:30

0

0

1

1

0

1

0

01:10:30

Program No 3

LED diode No

1

2

3

4

5

6

7

STEP

TIME

CW

ZW

PM

PPR

ZZ

PMY

H

1

02:00

0

1

0

0

0

1

0

2

00:30

0

1

1

1

0

1

0

3

02:00

0

0

1

1

0

1

0

4

02:30

0

0

0

0

1

1

0

5

02:30

1

0

0

0

0

1

0

6

00:30

1

0

1

1

0

1

0

7

05:00

0

0

1

1

0

1

0

8

03:00

0

0

0

0

1

1

0

9

02:00

0

1

0

0

0

1

0

10

00:30

0

1

1

1

0

1

0

11

03:30

0

0

1

1

0

1

0

12

04:00

0

0

0

0

1

1

0

28:00

Program No 4

LED diode No

1

2

3

4

5

6

7

STEP

TIME

CW

ZW

PM

PPR

ZZ

PMY

H

T

1

02:30

0

1

0

0

0

1

0

40

2

01:00

0

1

1

1

0

1

0

40

3

01:00

0

0

1

1

0

1

0

4

02:30

0

0

0

0

1

1

0

5

02:30

1

0

0

0

0

1

0

45

40

6

01:00

1

0

1

1

0

1

0

45

40

7

04:30

0

0

1

1

0

1

0

8

03:00

0

0

0

0

1

1

0

9

02:30

0

1

0

0

0

1

0

40

10

01:00

0

1

1

1

0

1

0

40

11

02:30

0

0

1

1

0

1

0

12

04:00

0

0

0

0

1

1

0

28:00

Total time

CW –warm water relay ZW –cold water relay

PP –subpressure pump relay PML –milk pump relay

ZZ –dump valve relay PMY –washing relay

H- hydrostat T –water heating

D –dispensing

CW –warm water relay ZW –cold water relay

PM –washing pump relay PPR –mixer relay

ZZ –dump valve relay PMY –washing relay

H- hydrostat T –water heating

D –dispensing

CONNECTING THE CONTROLLER

Attention

1. Signal L of 230 VAC should be given to the external start button and the hydrostat input;

2. Relay No 5 has normally closed input NC and normally opened input NO

Table of contents

Other MAKOT Controllers manuals

Popular Controllers manuals by other brands

TOPP

TOPP C25 Installation and use instructions

Titus

Titus TA1 Installation, operation and maintenance manual

Becker

Becker Centronic SunWindSet SWS42 Assembly and operating instructions

Frigidaire

Frigidaire 318200138 (0610) instruction manual

EuroLite

EuroLite LED CB-8 user manual

Honeywell

Honeywell S9200U1000 installation instructions