Malema BCV-980 User manual

malema.com

Corporate Headquarters West Coast Headquarters Asia Pacic Headquarters

1060 S Rogers Circle

Boca Raton, FL 33487

P: (561) 995-0595 F: (561) 995-0622

2329 Zanker Road

San Jose, CA 95131

P: (408) 970-3419 F: (408) 970-3426

35, Marsiling Industrial Estate Road 3,

02-06, Singapore 739257

P: (65) 6482-3533 F: (65) 6484-4231

INSTRUCTION MANUAL

FOR

BCV-980

Bio-Pharmaceucal Proporonal

Pinch Control Valve

malema.com

INTRODUCTION:

The BCV-980 is an intelligent, Proporonal Control Valve intended for BioPharmacucal applicaons. The BCV is an electrically

operated Pinch Valve with built-in, sophiscated control capabilies. Electrically operated Pinch valves oer several advantages

over other valve construcons. For BioPharama applicaons these advantages include:

• No added materials in contact with the media; only the tube-manifold contacts the media

• No crevasses, cracks, clogging or dead spots

• Unaected by parculates in the stream

• Simple, robust & straight through design

• No Pneumac complicaons or facilies required for operaon

• Self-cleaning

• Tight shuto

• Minimal turbulence & fricon

• Minimal maintenance required. No bearings, seals or packings

• Low Total Cost of Ownership; other than the single use manifold there are no other consumables

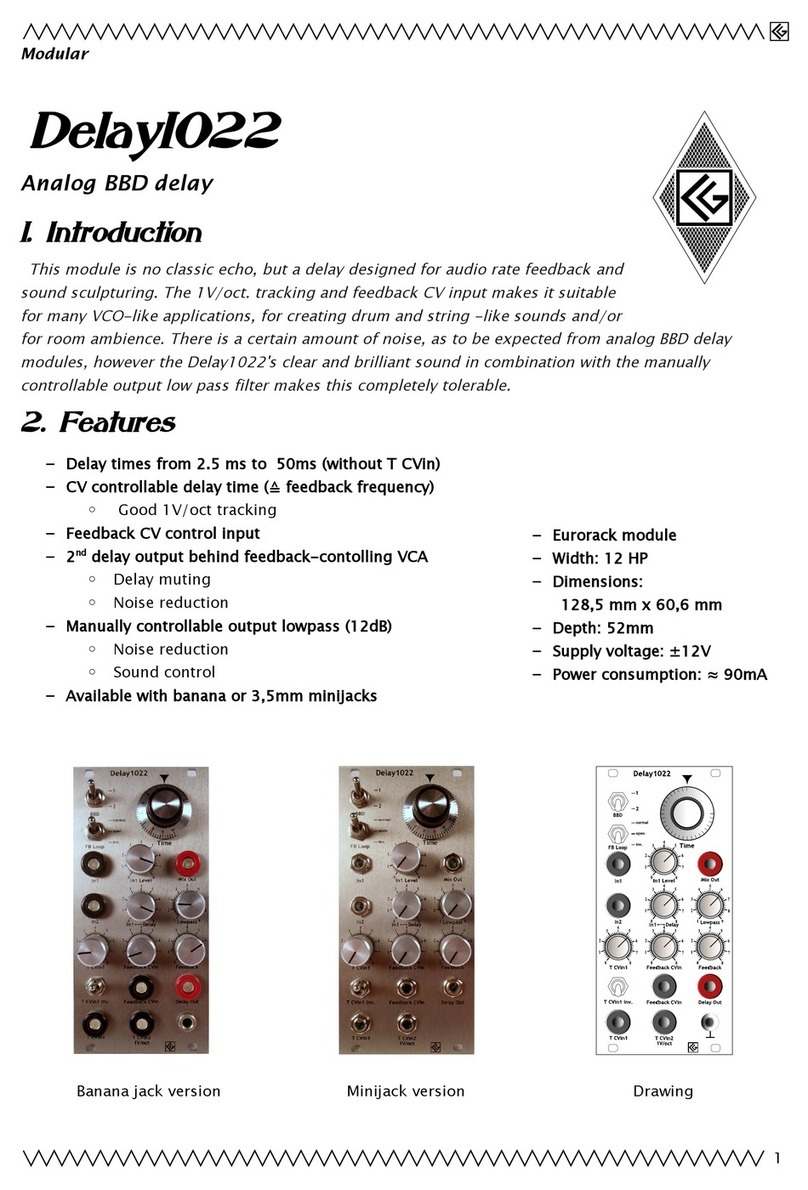

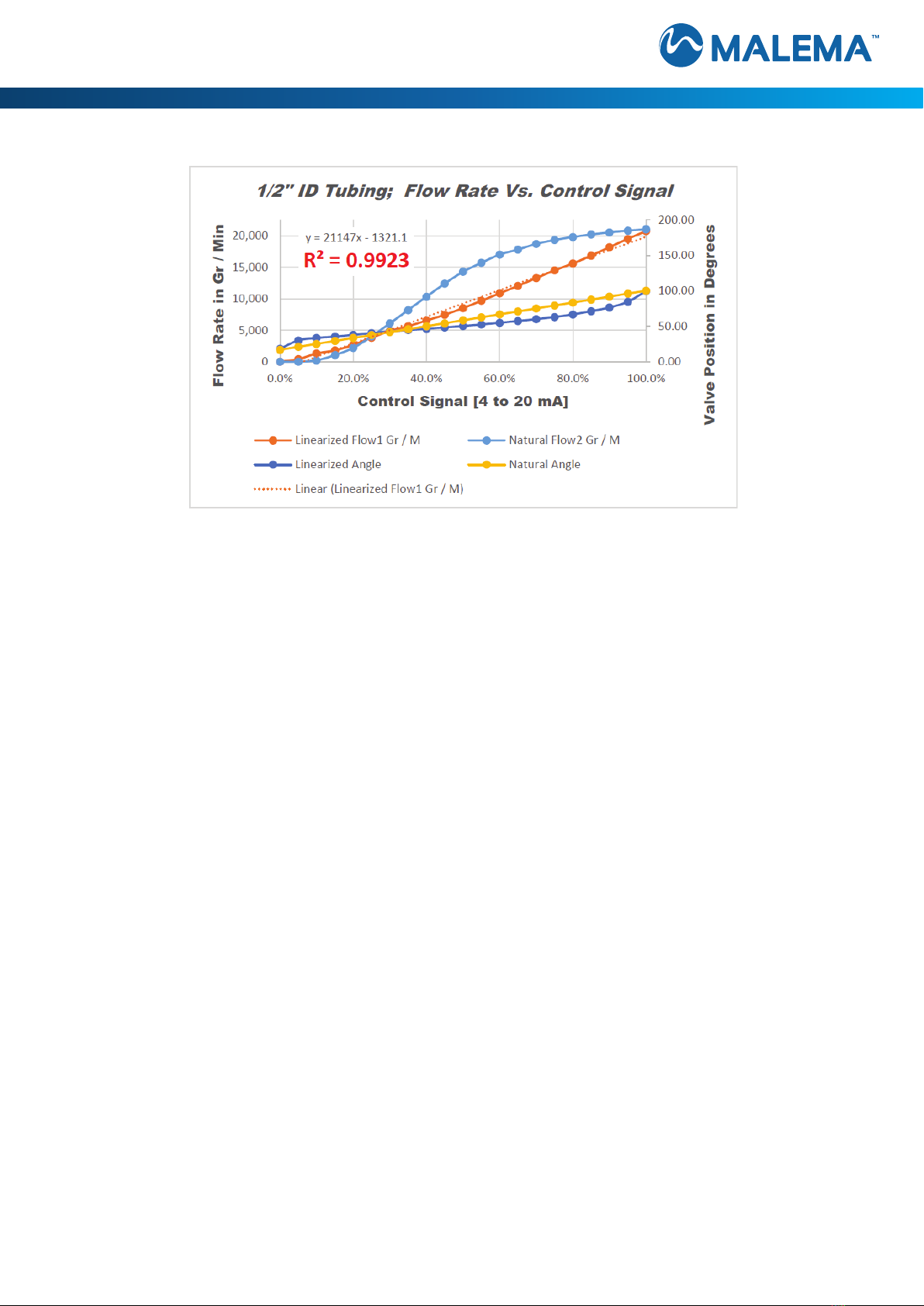

Classic pinch valves provide minimal throling control capabilies; most of the control occurs during the rst 1/4 to 1/3 of the

control range [Coecient of Determinaon, i.e.: R2 values around 66%]. Malema ulizes a complex polynomial algorithm

expanding upon the classic performance

of pinch valves. By linearizing valve perfor-

mance [ow rate] Vs. control signal rather

than linearizing valve posion Vs. control

signal. While using Malema’s linearizaon

scheme a slight change in control signal re-

sults in a similar [linear] change in ow rate

[Coecient of Determinaon, i.e.: R2 >95%].

This proprietary linearizaon scheme can be

disabled from Malema’s GUI.

Control Resoluon: The BCV-980 ulizes a ten(10) pitch [i.e.: ten(10) threads per inch] Acme screw and an eight thousand

(8,000) count per revoluon opcal encoder monitoring valve posion. A sixteen(16) bit ADC converts the command setpoint

signal into 65K steps between fully OPEN and fully CLOSED posions. Assuming one hundred LPM is the max ow through a

1” ID tube, individual step resoluon is about 5 ccm or ≈ 0.5% of Full Scale.

Resoluon varies with tube size. Smaller sized tubes may have fewer total steps available. Malema oers a high resoluon ver-

sion for these applicaons.

2

malema.com

Table of Contents

INTRODUCTION 2

OPERATING MODES 4

SAFETY, CAUTIONS 5

DIMENSIONAL DRAWINGS 5

PRODUCT SPECIFICATIONS 6

GETTING STARTED 7

TUBING INSTALLATION 8

REMOTE MANIFOLD INSTALL COMMAND 8

PANEL MOUNTING 9

CALIBRATION, LINEARIZATION 10

PINOUT, WIRING Diagrams 12

CIRCUIT DIAGRAMS 14

CABEL DETAILS 17

FRONT PANEL DISPLAY 16

TYPICAL, STAND-A-LONE TFF APPLICATION 17

CONTROL STRATEGY 18

MALEMA GUI 18

GUI CONTROL WINDOW 20

WARRANTY 21

CERTIFICATE OF COMPLIANCE 23

APENDIX of SELECTED DATA 24

3

© 2020 Malema Engineering Corporaon. All rights reserved.

Malema, Malema Sensors, and Malema Engineering Corporaon are service marks of Malema Engineering Corporaon. All other trademarks are property of their respecve owners.

Malema supplies this publicaon for informaonal purposes only. While every eort has been made to ensure accuracy, this publicaon is not intended to make performance claims or

process recommendaons. Malema does not warrant, guarantee, or assume any legal liability for the accuracy, completeness, meliness, reliability, or usefulness of any informaon, product,

or process described herein. We reserve the right to modify or improve the designs or specicaons of our products at any me without noce. For actual product informaon and recom-

mendaons, please contact your local Malema representave.

malema.com

INTRODUCTION (CONTINUED)

OPERATING MODES:

The BVC-980 is an intelligent, proporonal, pinch, control valve.

1. The BCV-980 – Supports 1/8” through 1”I.D. tubing

2. The BCV-980 supports virtually any biopharma tube construcon including:

a. Unreinforced tubing

b. Braid Reinforced tubing, or

c. Double Braid Reinforced tubing

The product has two(2) operang modes:

1. REMOTE Mode: In this mode, the device responds to an external 4 to 20 mA signal generated by a remote

operator or control system [i.e.: 4 mA = FULLY CLOSED; 20 mA = FULLY OPEN]. Valve posion is soware adjusted to

approximately linearize ow rate Vs. signal [I.e.: 12 mA ~= 50% FLOW]

2. TFF Mode: Based on an analog Setpoint signal, the device monitors up to three(3), external analog transducer

signals, adjusng valve posion based on the TFF Equaon. On applicaon, other algorithms can be supported.Conrm

that you have the following items:

When panel mounted in a standard 1/4 DIN panel cut-out [88 mm X 88 mm], the BCV-980 provides IP65 (protecon against

water jets) NOTE: Care must be taken in a panel layout as the exible tube running through a BCV-980 may obscure adjacent

panel cut-out locaons. The BCV-980 supports mounng in any orientaon.

The BCV-980 accepts tubing of virtually any size between 0.125” ID through 1.000” ID. Factory pre-conguraon for any size

or tube conguraon is available and recommended. One(1) nger guard is supplied with each BCV-980. Several nger guards

are available depending on tube OD

4

STORAGE AND HANDLING

Storage condions

Store the product under packed condions in an an-stac bag. The storage place shall be free from moisture, mechanical shock

and vibraon. The ambient temperature shall be between 3°C and 60°C and the humidity between 5% and 80% R.H. without

condensaon

Unpacking and Product Inspecon

On delivery, check the product for damage. Conrm that the model code on the label matches the specicaon in the purchase

order.

malema.com

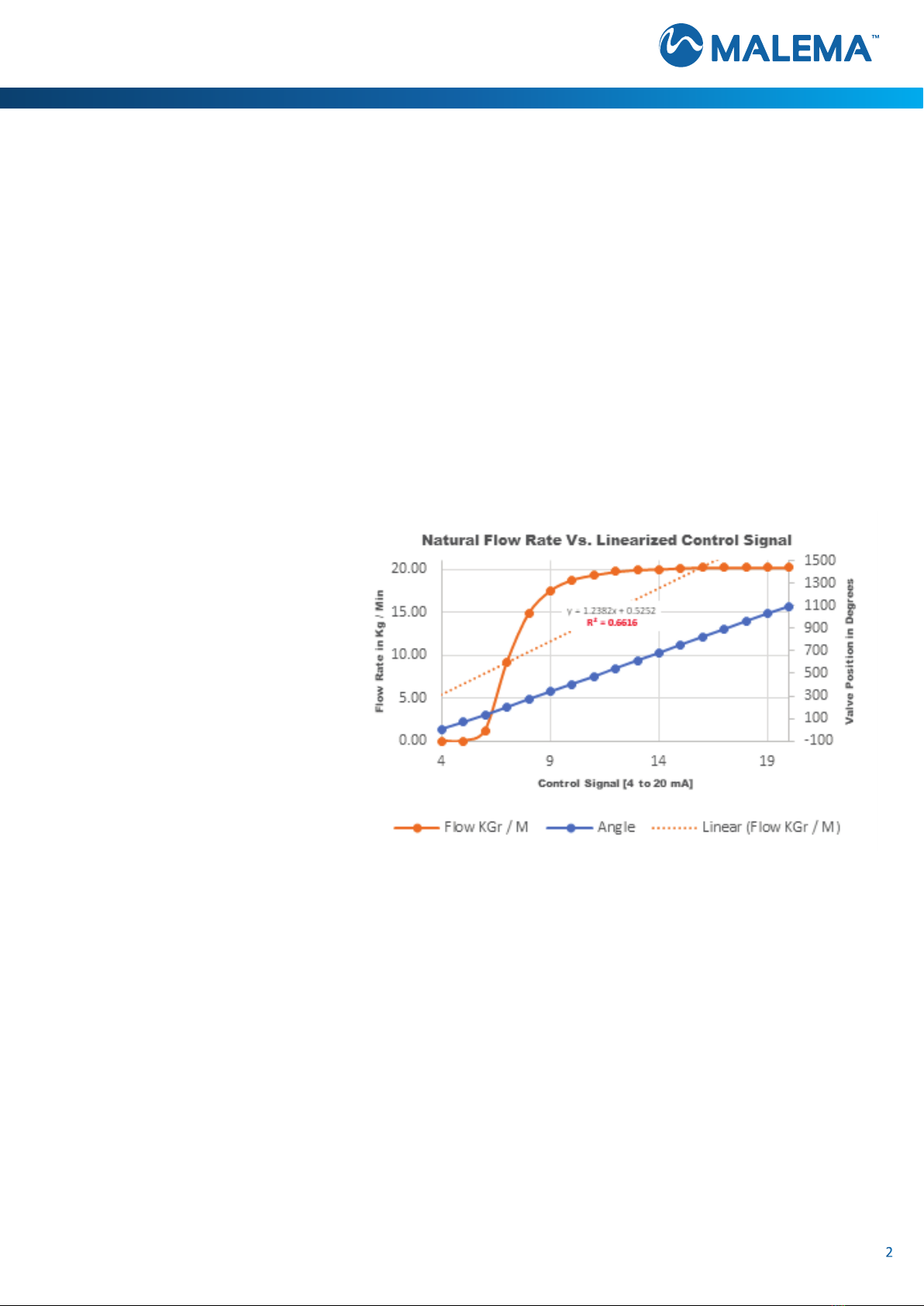

SAFETY CAUTIONS

The BCV-980 is a Pinch Valve: use care keeping ngers, etc. out of the

pinch mechanism! Severe & painful damage is possible.

DIMENSIONAL DRAWINGS: BCV-980

For Reference Only

5

BCV-980; general arrangement

malema.com

6

Performance Specicaons

Fluid Temperature 4° – 60°C *

Ambient: Temperature/Humidity 0° – 40°C / 30% – 80% RH, non-condensing

Maximum Expected Operang Pressure 6 bar (g)

Dierenal Pressure range 0 - 6 bar

Power Supply Input 24 Vdc 10%

Current Consumpon 4 A max, 1A typical

Alarm Signals Max 30 Vdc, 200 mA NPN open collector

Signal Out (Valve Posion) 4 - 20 mA

Weed Parts None

Non Weed Parts, Enclosure Non-magnec 316L Stainless Steel,

Non-magnec Powder-coated Stainless Steel

Mounng Orientaon Performance unaected by mounng orientaon

Fluid Connecons 1/8” – 1” ID exible tube, braided or un-braided

Ingress Rang IP65

Panel Mounng Universal thickness — accommodates any panel thickness

Panel Cutout 1/4 DIN (90mm x 90mm)

Mass 2.6 kg – 3.3 kg

* Consult the factory for higher temperature applicaons

* Up to four external analog signals. Implements standalone TFF control

Electrical Specicaons

Material Specicaons

Physical Specicaons

malema.com

GETTING STARTED

Unpack and mount the BCV-980, using the included Silicon Sponge Gasket, through a standard ¼ DIN panel cut-out [88mm X

88mm]. Panel or surface mounng is essenal to achieve IP65 ingress protecon. The BCV-980 is fully connectorized using

shielded Hirose connectors. [Hirose connectors are readily available from Digikey, Farnell, Mouser, Newark, and others.] Fully

assembled cables are available. Consult Malema factory for details

FINGER GUARD INSTALLATION:

The FINGER GUARD is packaged separately. Using provided 3/16” Allen wrench and provided PIN SCREWS, install the FINGER

GUARD. Finger ght is adequate.

FINGER GUARD INTERLOCK:

The FINGER GUARD is magnecally interlocked with the BCV-980 crush mechanism. The DRAW BAR will not move unl the

FINGER GUARD is replaced. Various FINGER GUARDS are available depending on the tube size in use. Contact Malema for the

FINGER GUARD(s) required for your applicaons.

POWER, CONTROL & SIGNALING

A male, twelve(12) pin, Hirose connector supports device power along with primary signaling. A twelve(12) core, three(3) meter

long, connectorized cable with stripped ends is provided with each BCV-980.

The BCV-980 accepts up to four(4) external analog signals and provides two(2) discrete, OPEN Collector STATUS / ALARM Outputs

[NPN, 30 VDC, <200 mA], one(1) discrete Input along with two(2) analog Output signals. One(1) of these analog outputs is

proporonal to valve posion and provides CLOSED Loop feedback to a remote controller. The other analog output reports μP

temperatures or alternavely, this output can be ulized to drive other components in your system [i.e.: Pump speed(?), consult

Malema factory for details].

The device communicates over [Malema Addressable Sensor Network] MASN (RS-485 serial). Up to two hundred y(250)

devices can be supported by a single RS-485 master controller. MASN supports viewing & seng of device conguraon along

with near real-me data logging on a customer supplied computer or laptop.

GROUNDING

The four(4) rear mounted 4 mm studs provide for a convenient GROUND or EARTHING connecon.

A thumb nut is provided for this essenal electrical connecon. Failure to properly GROUND the

BCV-980 voids the warranty and CE Compliance.

EXTERNAL SENSORS

If ordered separately, Three(3), female, twelve(12) pin connectorized cables support up to three(3) aached, external sensors.

[These are oen pressure transducers, or ow meters monitoring the condions surrounding a TFF module.] The BCV-980

provides +24 VDC, [up to 100 mA] power to these external sensors and accepts Discrete & Analog signals in return. If ulizing

TFF Mode, these external signals are then ulized, internally by the BCV-980, to modulate valve posion. Addionally, these

external sensor interfaces provide:

• A POWER Cycling capability

•A Zero RESET signal

• Discrete signal “Hand Shaking”

• RS-485 Serial Communicaon based on the Malema Addressable Sensor Network Protocol (MASN):

o Baud Rate = 115,200

o Data Bits = 8

o Parity = NONE

o Stop Bits = 1

o Flow Control = NONE

TUBE SIZE SELECTION

The standard BCV-980 ships pre-linearized for several standard tube sizes. These sizes can be selected from a “drop down” menu

accessible from the Malema GUI.

7

malema.com

8

TUBE INSTALLATION

Tubing installaon proceeds from the front of the BCV:

1. Ensure the DRAW BAR is OPEN. A remote panel mounted key switch accomplishes this funcon.

2. OPEN the FINGER GUARD

3. Insert the tube-manifold

4. CLOSE the FINGER GUARD

5. RESTORE the key switch to the normal or operate posion

6. The BCV-980 executes an inializaon roune locang the zero(0) ow locaon

7. The BCV-980 is now ready to operate

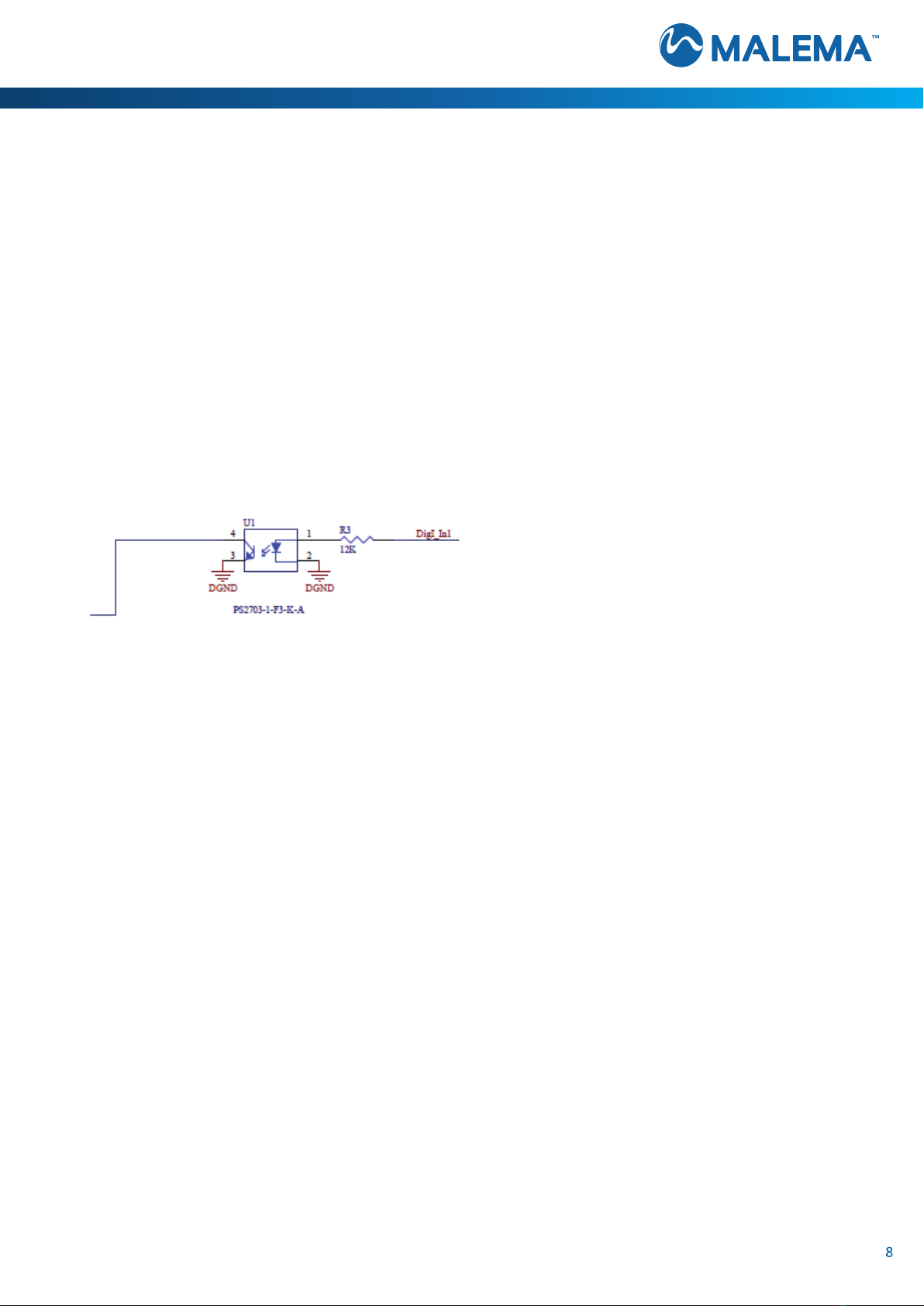

REMOTE MANIFOLD INSTALL COMMAND

This unit is provided with REMOTE MANIFOLD INSTALL COMMAND. An external +24 VDC signal applied to the DI pin [PIN #8,

WHITE/BLACK] on rear panel mounted connector P0 causes the DRAW BAR to fully OPEN so, manifolding can be easily installed

or removed. When this signal is removed the BCV-980 slowly closes under reduced torque unl motor stall occurs. At this point

a new ZERO posion is established and the system returns to Normal operaon.

The internal circuit for this funcon is shown here:

VALVE LINEARIZATION

The BCV-980 ships with Malema’s linearizaon scheme enabled. The feature can be disabled by unchecking the “Enable LIN

funcon” Check Box in the Bio Control Valve sengs Window of the GUI. A Valve Linearizaon Vs. Flow Rate Procedure is

provided [see page 11] should you require a unique linearizaon result

malema.com

9

PANEL MOUNTING

The BCV-980 panel mounts through a standard ¼ DIN panel cutout [88mm X 88mm].

An ORANGE Silicone Rubber sponge gasket is provided with each BCV-980. When properly installed with the gasket the BCV-980

provides IP65 ingress rang; i.e.: protecon against water jets.

CAUTION: [The front of the

BCV-980 provides IP65. IP30 protecon

is provided for the poron behind the

panel or when not panel mounted.]

GROUNDING:

Any of the four(4), 4 mm Rear Mounng

studs can be used for GROUNDING.

[OPTIONAL, BENCH TOP-MOUNTING]

A clear, blue nt, PVC Bench-Top mounng accessory is available. Consult Malema for details.

malema.com

VALVE LINEARIZATION VS. FLOW RATE PROCEDURE

Scope:

To set the BCV angles for minimum and maximum ow rates

Setup requirement:

• PC with GUI to indicate ow rate

• Calibrated Flow meter

• BCV-980 with power/signal cable

• 4-20mA signal generator

• Hose to test

o Use the same tubing / hose that will be used in producon

10

Procedure:

1. Place the tubing into BCV-980 with no pressure and

power-up the unit

a. On inial POWER-UP the BCV-980 slowly

closes while seeking full closure. This is

automac and requires several seconds.

2. Aer the fully closed point is located, set the BCV

to remote mode.

3. Set maximum valve opening of BCV-980 allowing

maximum ow thru the tube.

4. Establish owrate thru the ow meter equal to 110%

of desired owrate:

a. [i.e.: if 2L max desired; set ow to 2.2L]

5. Slowly decrease the maximum valve opening of the

BCV-980 Valve angle unl the ow meter reported

ow rate is 2L/min

6. Enter this angle value in the GUI Maximum open-

ing eld

7. Connue to decrease the angle unl no ow is

observed

8. Enter this angle value in the GUI Deadband eld

9. Set the BCV to remote operaon mode:

a. The Status LED turns BLUE in Remote mode

420 Max opening [degrees]

120 Deadband [degrees]

10. Hook-up a 4-20ma analog signal generator to the the Analog setpoint input of main power cable

11. Set input setpoint signal to 20ma

a. Conrm the BCV-980 opens to the GUI maximum opening angle

b. Conrm ow rate equals the maximum desired owrate

12. Set setpoint to 4ma

a. Conrm the BCV-980 closes to the GUI Deadband angle

b. Conrm minimum ow rate or pressure observed.

Note: The Deadband angle adjustment is an iterave process

13. Power cycle the unit and verify the setpoint and owrates are correct

14. Record owrates for the following setpoints:

a. 4ma __________

b. 5ma __________

c. 8ma __________

d. 12ma __________

e. 16ma __________

f. 20ma __________

malema.com

Typical Linearizaon Results

11

malema.com

12

Connector PINOUTS

Connector FUNCTIONS:

MAIN POWER / CONTROL CONNECTOR [twelve(12) Pin, Male]:

1. RED +24 VDC ±10%; POWER INPUT; 2 AMP

2. BLACK WARNING OUT; OPEN COLLECTOR

3. PINK ALARM OUT; OPEN COLLECTOR; this line shorts to GROUND in the event of drive motor stall.

4. GRAY DIGITAL OUTPUT; FINGER GUARD OPEN

5. BLUE RS485 A+; serial communicaons ulizes Malema Addressable Sensor network protocols;

up to two hundred y(250) devices can be supported on a single channel

6. WHITE RS-485 B-

7. RED / BLACK SETPOINT INPUT; a congurable analog INPUT VIA the Malema

GUI ; could be 4 to 20 mA; 0 to 5 VDC; 0 to 10 VDC or 1 to 5 VDC

8. WHITE / BLACK DIGITAL INPUT 0; A +24 VDC signal applied to this PIN implements the REMOTE MANIFOLD INSTALL

COMMAND [see line 132 on page 7 of this USER GUIDE]

9. YELLOW ANALOG OUT 1; An analog output signal proporonal to valve posion, 4 mA = valve

closed, 20 mA = valve fully opened.

10. BROWN ANALOG OUT 2; Analog output signal proporonal to μP temperature2 ; 4 mA = 0oC,

20 mA = 100o C; could be congured to mirror one(1) of the remote sensor inputs or some calculated value

11. GREEN GROUND

12. VIOLET GROUND

1Congurable VIA the Malema GUI; default is 4 to 20 mA; other opons 0 to 5 VDC; 0 to 10 VDC or 1 to 5 VDC

2This signal can be repurposed – consult Malema for details

malema.com

13

REMOTE SENSOR CONNECTORS [i.e.: RP 1; RP 2 and RP 3] [twelve(12) Pin, Female]:

1. RED +24 VDC ±10%; POWER INPUT; 1 AMP

2. BLACK REMOTE POWER; +24 VDC ±10%; 0.100 AMP; these circuits are

controlled by the BCV-980 allowing interrupon or POWER Cycling of connected sensors

3. PINK DIGITAL OUTPUT 1 thru DIGITAL OUTPUT 3; these are OPEN COLLECTOR circuits enabling the BCV

to send command signal to aached sensors; unimplemented

4. GRAY ZERO 1 thru ZERO 3; these signals allow the BCV-980 to force a ZERO funcon for remote

sensors; these signals are congurable in rmware either supplying +24 VDC or GROUND as required by the

remote sensors

5. BLUE RS485 A+; serial communicaons; ulizes Malema Addressable Sensor network protocols;

up to two hundred y(250) devices can be supported on a single channel

6. WHITE RS-485 B-

7. RED / BLACK ANALOG INPUT 1 thru ANALOG INPUT 3 [or SUPPLY, RETENTATE or PERMEATE]; congurable analog

signal carrying the values generated by the remote sensors

8. WHITE / BLACK DIGITAL INPUT 1 thru DIGITAL INPUT 3; these signals allow the remote sensors to report ALARM

or FAULT condions to the BCV-980

9. YELLOW RESERVED

10. BROWN RESERVED

11. GREEN GROUND

12. VIOLET GROUND

3Requires custom rmware – consult Malema for details

malema.com

14

malema.com

15

CABEL DETAILS

malema.com

FRONT PANEL STATUS DISPLAY

16

The front panel of the BCV-980 supports two(2) LEDs:

•POWER – This LED glows when adequate 24 VDC power is applied.

LED color changes based on currently selected operang mode:

o BLUE – Remote Mode

o GREEN – TFF Mode

•CLAMP – The CLAMP LED glows RED when the FINGER GUARD is OPEN

or missing. At these mes all operang modes are disabled. To restore

funcon replace & CLOSE the FINGER GUARD.

malema.com

17

TYPICAL, STAND-A-LONE, TFF APPLICATION

malema.com

Malema has manufactured Liquid Flow Controllers for many years. Over this me, we have developed sophiscated, propri-

etary, expert, self-learning, rule based, PID control algorithms. These algorithms overcome the shortcomings typically found in

PID process control.

Quick responses to process upsets or changing condions are not followed by overshoot, undershoot and delays associated with

quarter wave decay. Malema ow controllers typically achieve stable control in less than one(1) second aer a process upset

or step change in control setpoint. Systems have normal responses to these events. By observing and recognizing these dis-

rupons as they occur, Malema ow control algorithms take the appropriate steps early on, reestablishing and restoring control

quickly. Just like a truck driver in the mountains knows to conserve his brakes and momentum as he descends so, he’ll need less

addional energy ascending the next hill.

18

CONTROL STRATEGY

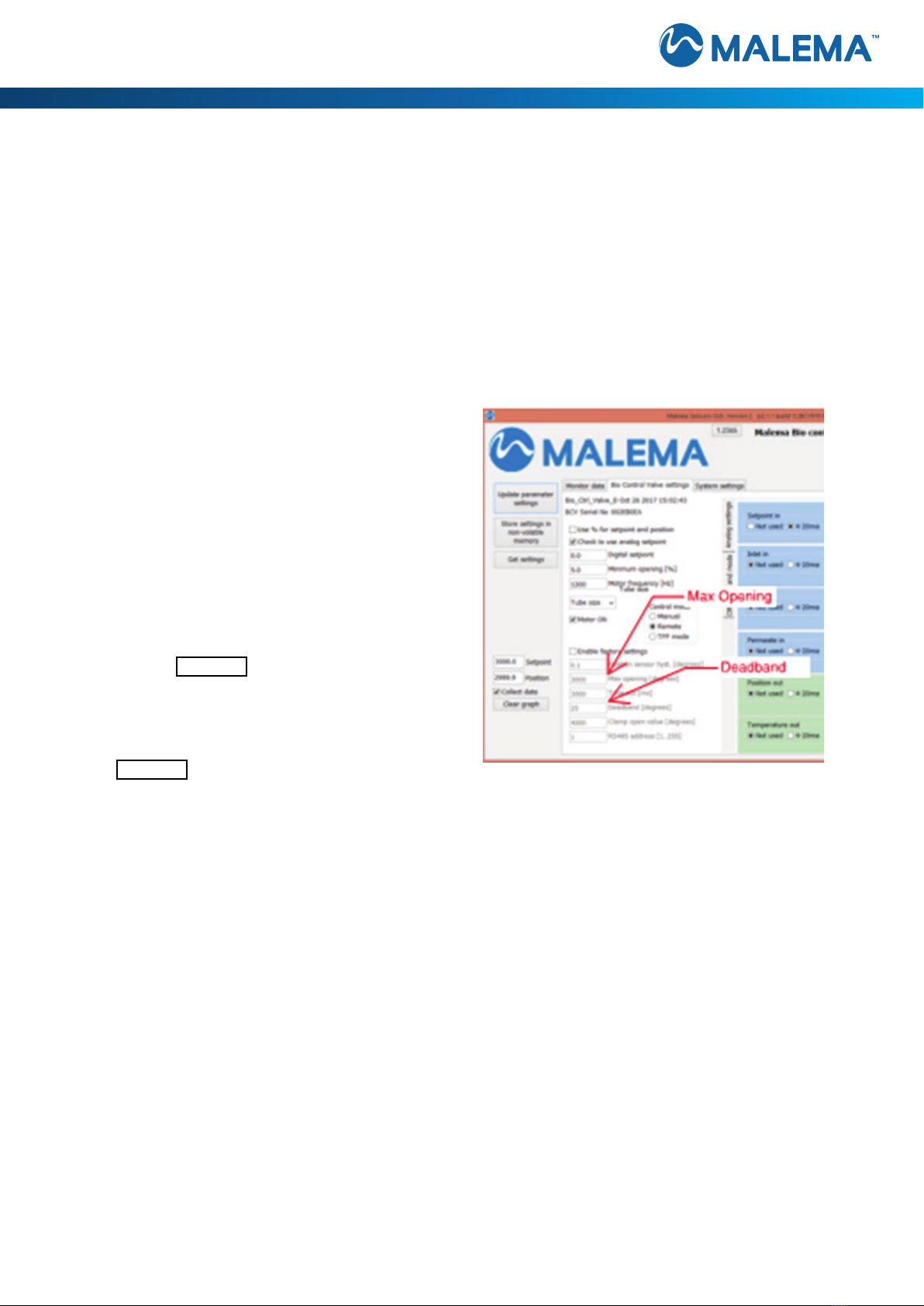

Copy the Malema Sensors applicaon from the CD to a local drive and create shortcut to desktop.

Open the Malema applicaon, click on the text eld labeled with the COM port number to connect PC app to BCV-980 located

in the upper right-hand corner.

To capture a graph, check the Collect data checkbox.

Graph below shows Posion and Setpoint with ramp up/down of 500 deg.

MALEMA GUI

malema.com

Using the GUI to control Digital setpoint:

• Connect the RS485 to the cable.

• Open the Bio Control Valve Sengs tab.

• Set the control mode to Remote.

• Click checkbox “Motor ON”.

• Enter a value in degrees or percent to the Digital setpoint window.

• Click the “Use % for Setpoint and posion” if entering percent valve.

• Click on Update parameter sengs buon.

Note: Update parameter sengs buon must be clicked when any seng has changed.

Controlling the Valve using 4-20mA analog signal:

• Hook up the 4-20mA connecons to the command signals of control cable provided.

• Set the control mode to Remote.

• Click checkbox “Check to use analog setpoint”.

• Select Setpoint input type: 4-20mA, 1,5V, 0-5V, or 0-10V.

Using TTF mode:

• Set the control mode to TFF.

• Connect the other inputs.

• Select the input type for each input: 4-20 mA, 1,5 V, 0-5 V, or 0-10 V.

19

malema.com

20

Bio Control Valve sengs Window

GUI CONTROL WINDOW

Table of contents

Popular Control Unit manuals by other brands

Sloan

Sloan G2 Optima Plus Maintenance Guide

Vega

Vega VEGAFLEX 66 operating instructions

ClimateMaster

ClimateMaster Flow Controller 3 Installation, operation & maintenance instructions

Motorola solutions

Motorola solutions PMLN6827 manual

Victaulic

Victaulic FireLock 912 Installation instructions manual

Blonder tongue

Blonder tongue QTPCM-4 manual

Advantech

Advantech B+B SmartWorx iMcV-Giga-MediaLinX TX/SFP user manual

KWC

KWC AQUAREX WC AQRM550 Installation and operating instructions

COMEPI

COMEPI MS1A31-024 manual

EOS

EOS ECON F1 Assembly and operating instructions

Hach

Hach SC4200c User instructions

Honeywell

Honeywell Silent Knight SK-Monitor Installation and maintenance instructions