Contents

1 General information .................................................. 4

1.1 Information .......................................................... 4

1.2 Symbols used ...................................................... 4

1.3 Definition of terms .............................................. 4

1.4 Warning notes ..................................................... 4

2 Safety information .................................................... 5

3 Product description ................................................... 5

3.1 Construction ........................................................ 5

3.3 Function ............................................................... 5

4 Correct use ............................................................... 6

5 Order data ................................................................. 7

5.1 Order codes ......................................................... 7

5.2 Order example ..................................................... 8

6 Technical data .......................................................... 9

6.1 Medium ................................................................ 9

6.2 Temperature ........................................................ 9

6.3 Pressure ............................................................... 9

6.4 Product compliance ............................................ 10

6.5 Mechanical data .................................................. 10

7 Dimensions ............................................................... 12

7.1 Actuator dimensions ........................................... 12

7.2 Body dimensions ................................................. 13

7.2.1 Flange EN (code 8) ................................. 13

7.2.2 Flange EN (code 53) .............................. 14

7.2.3 Flange ANSI Class (code 38, 39) ........... 15

7.2.4 Flange ANSI Class (code 56) ................. 16

7.2.5 Flange BS (code 51) ............................... 17

7.2.6 Threaded socket DIN (code 1) .............. 18

8 Manufacturer's information ....................................... 19

8.1 Delivery ................................................................ 19

8.2 Packaging ............................................................ 19

8.3 Transport ............................................................. 19

8.4 Storage ................................................................. 19

9 Installation in piping .................................................. 19

9.1 Preparing for installation .................................... 19

9.2 Installation with flanged connections ................ 20

9.3 Installation with threaded sockets ..................... 20

10 Operation .................................................................. 20

10.1 Optical position indicator .................................... 20

10.2 Lockable handwheel ........................................... 20

11 Commissioning ......................................................... 21

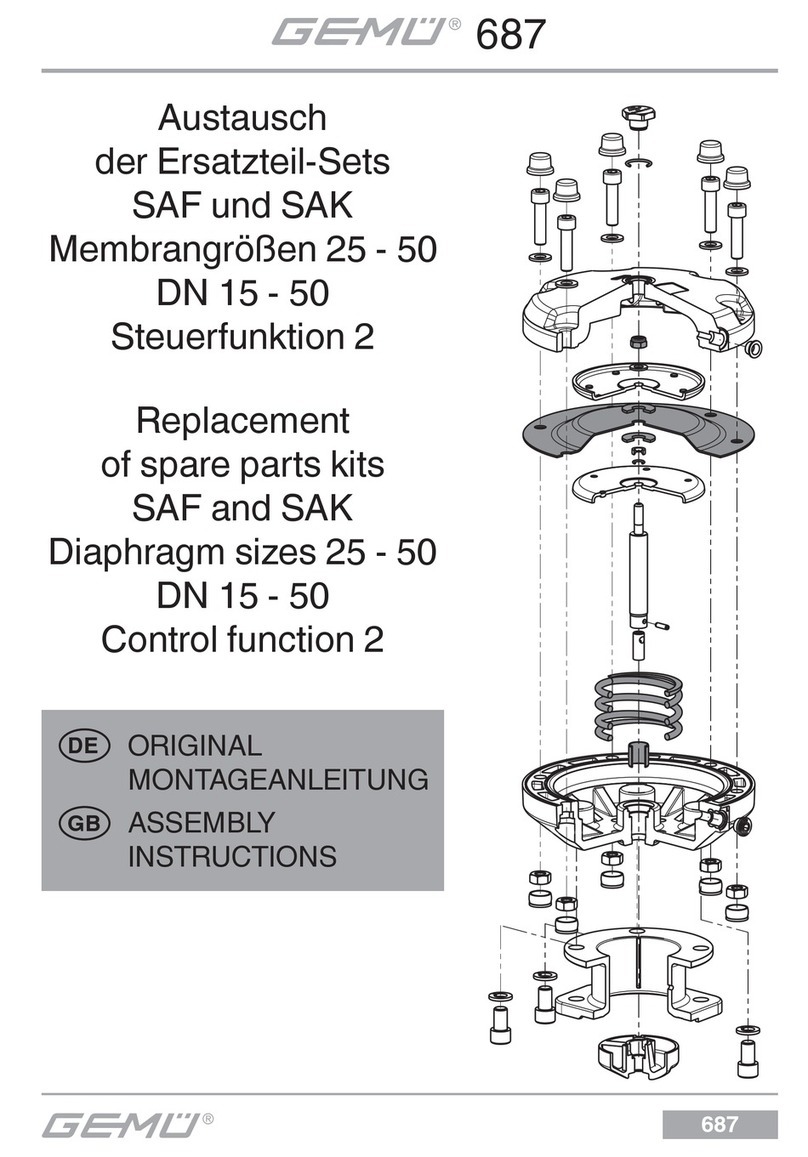

12 Inspection and maintenance ...................................... 21

12.1 Spare parts .......................................................... 21

12.4 Mounting the diaphragm .................................... 22

12.4.1 Mounting the convex diaphragm .......... 22

12.4.2 Mounting the concave diaphragm ........ 23

12.5 Mounting the actuator ........................................ 23

13 Troubleshooting ........................................................ 24

14 Removal from piping ................................................. 25

15 Disposal .................................................................... 25

16 Returns ..................................................................... 25

17 Declaration of conformity according to 2014/68/EU

(Pressure Equipment Directive) ................................. 26

GEMÜ 675www.gemu-group.com 3 / 27