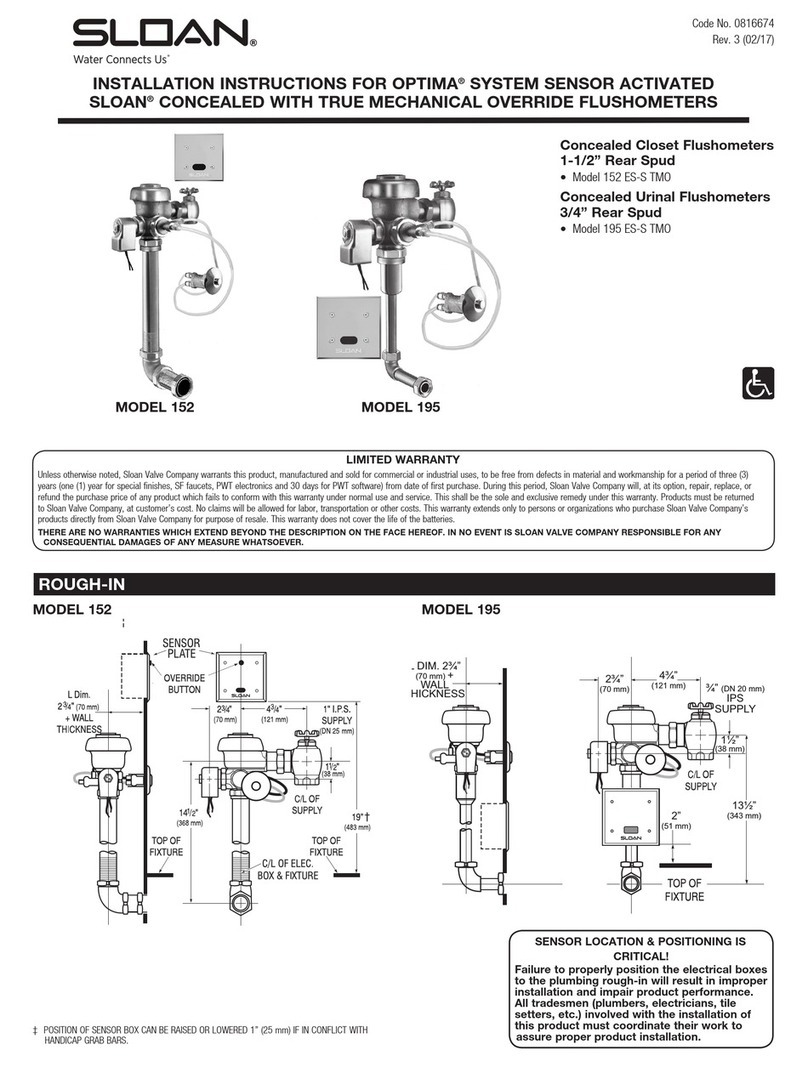

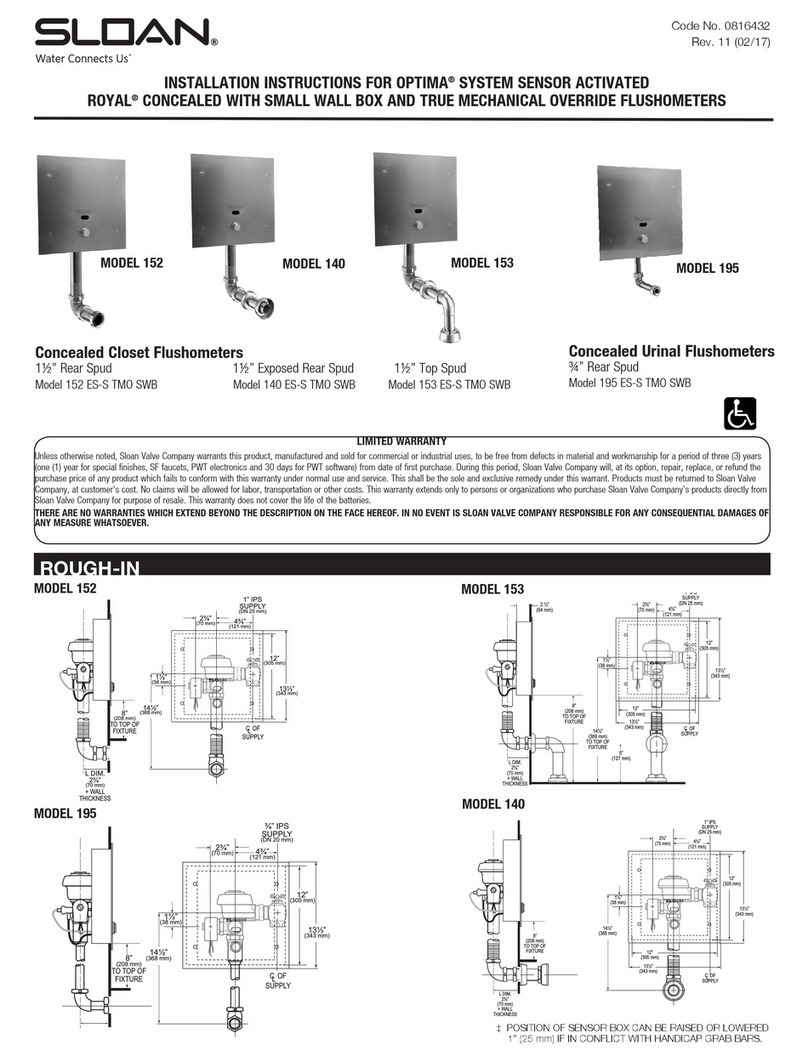

Sloan G2 Optima Plus Operating manual

FOR USE WITH SLOAN’S ORIGINAL OPTIMA®PLUS

FLUSHOMETER PRODUCED FROM 1992 - 2003

AND REGAL PRO®OPTIMA PLUS PRODUCED AFTER MAY, 2003

LIMITED WARRANTY

Sloan Valve Company warrants its Flushometer Products to be made of first

class materials, free from defects of material or workmanship under normal

use and to perform the service for which they are intended in a thoroughly

reliable and efficient manner when properly installed and serviced, for a period

of three years (one year for special finishes) from date of purchase. During

this period, Sloan Valve Company will, at its option, repair or replace any part

or parts which prove to be thus defective if returned to Sloan Valve Company,

at customer’s cost, and this shall be the sole remedy available under this

warranty. No claims will be allowed for labor, transportation or other incidental

costs. This warranty extends only to persons or organizations who purchase

Sloan Valve Company’s products directly from Sloan Valve Company for

purpose of resale.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION

ON THE FACE HEREOF. IN NO EVENT IS SLOAN VALVE COMPANY

RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY MEASURE

WHATSOEVER.

Maintenance Guide •SENSOR OPERATED VALVES

OPTIMA PLUS M.G. – Rev. 2 (09/03) Code No. 0816193

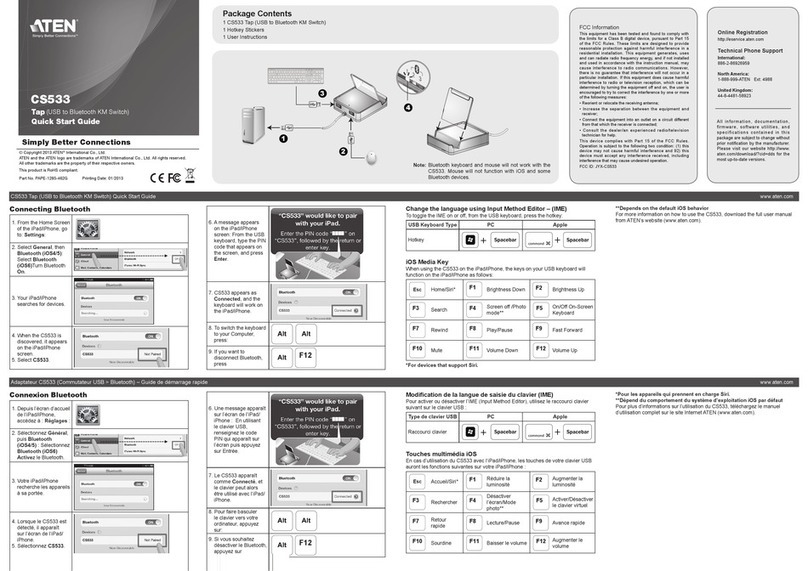

The Sloan Valve Company introduced its OPTIMA Plus Battery Operated

Sensor Flushometer in 1992 revolutionizing the flushing of water closets

and urinals. In both new construction and retrofit applications the use of the

OPTIMA Plus has become the standard method for many facilities to

improve restroom hygiene and ensure handicap accessibility compliance.

In May, 2003 Sloan introduced the G2®OPTIMA Plus.

The G2 OPTIMA Plus builds on the success of the original product and

offers many technological advancements to further improve on

performance and reliability expected of sensor operated plumbing. In

addition to a new aesthetic design, the G2 OPTIMA Plus features a new

state-of-the-art electronic and optical package and a unique Solenoid

Operator that keeps the moving components of the Solenoid completely

isolated from the water supply. This ensures long life and low maintenance

regardless of local water conditions.

The G2 OPTIMA Plus replaces the original OPTIMA Plus product, which

was phased out of production in mid 2003. Regal Pro OPTIMA Plus Valves

produced after May, 2003 include G2 Interior Components with the old

style OPTIMA Plus Cover.

Many of the new technologies developed for the G2 have been integrated

into the repair parts available for the older OPTIMA Plus product. This

Maintenance & Repair Guide reflects these new components and includes

crossover information for the old components.

Use this Maintenance & Repair Guide for OPTIMA Plus Valves produced

from 1992 - 2003 and Regal Pro Optima Plus Valves produced after

May, 2003 only.

For the G2 OPTIMA Plus, use Maintenance & Repair Guide #0816456.

If further assistance is required, please contact the Sloan Valve Company

Installation Engineering Department at:

Phone: 1-888-SLOAN-14 (1-888-756-2614)

Email: productsuppor[email protected]

The Sloan OPTIMA Plus automatic battery powered Flushometer relies on

an infrared sensor to detect a user and activate a flushing cycle. No

physical contact with the Flushometer surface is necessary, assuring

sanitary protection. OPTIMA Plus Flushometers are ADA compliant devices

and are available in both Royal®and Regal®Flushometer models.

The Flushometer is triggered by means of an active infrared Sensor. The

OPTIMA Plus Sensor emits a continuous invisible light beam. When a user

enters the beam’s effective range, the beam is reflected into the OPTIMA

Plus Scanner Window. The user is now detected. After the user moves out

of the effective range of the Sensor, a signal is sent to the Flushometer

Solenoid and, after appropriate arming and/or flush delays, the flush cycle

is initiated.

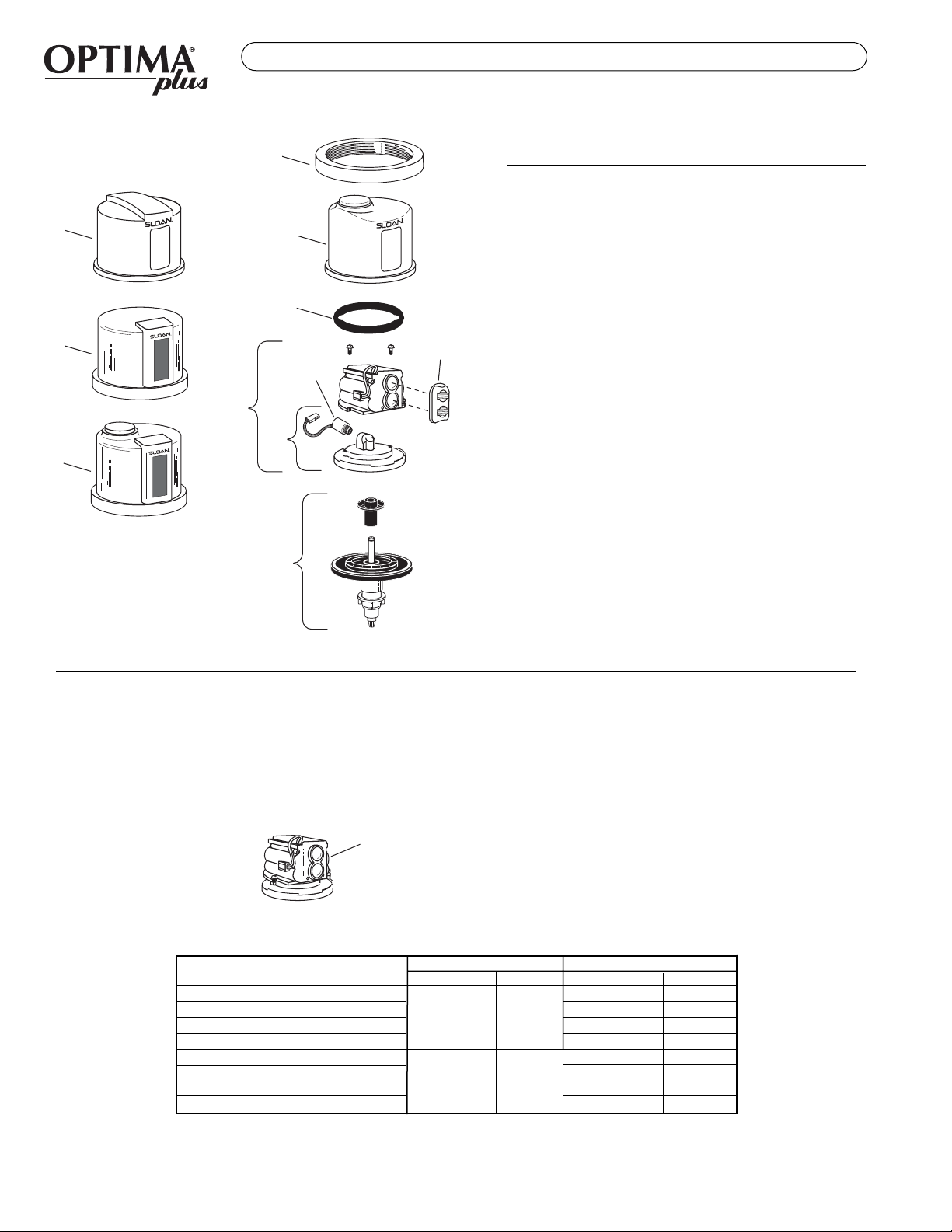

G2®OPTIMA PLUS

FLUSHOMETER

ORIGINAL

OPTIMA PLUS

FLUSHOMETER

AND REGAL PRO®

OPTIMA PLUS

2

SENSOR OPERATED FLUSHOMETERS

For all Optima Plus produced from 1992 - 2003

And Regal Pro Optima Plus produced after May, 2003

3

8

7

2C

2D

1

2B

2A

4

5

6

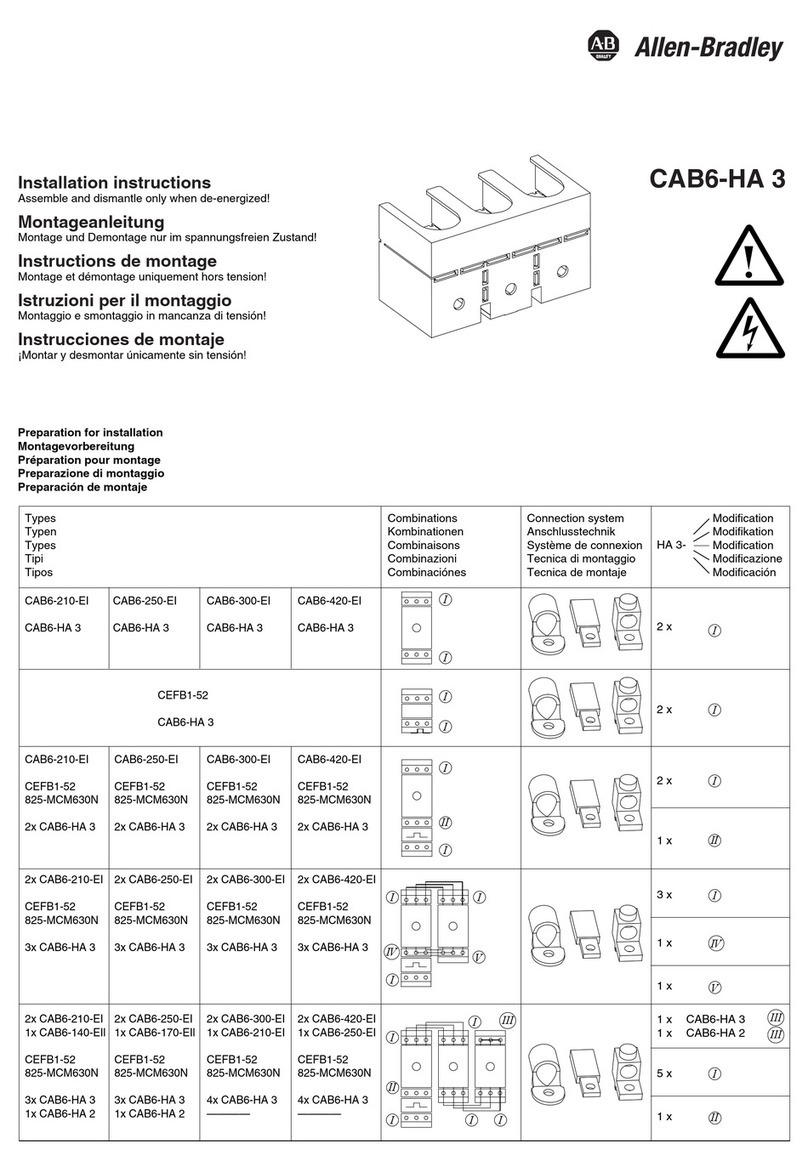

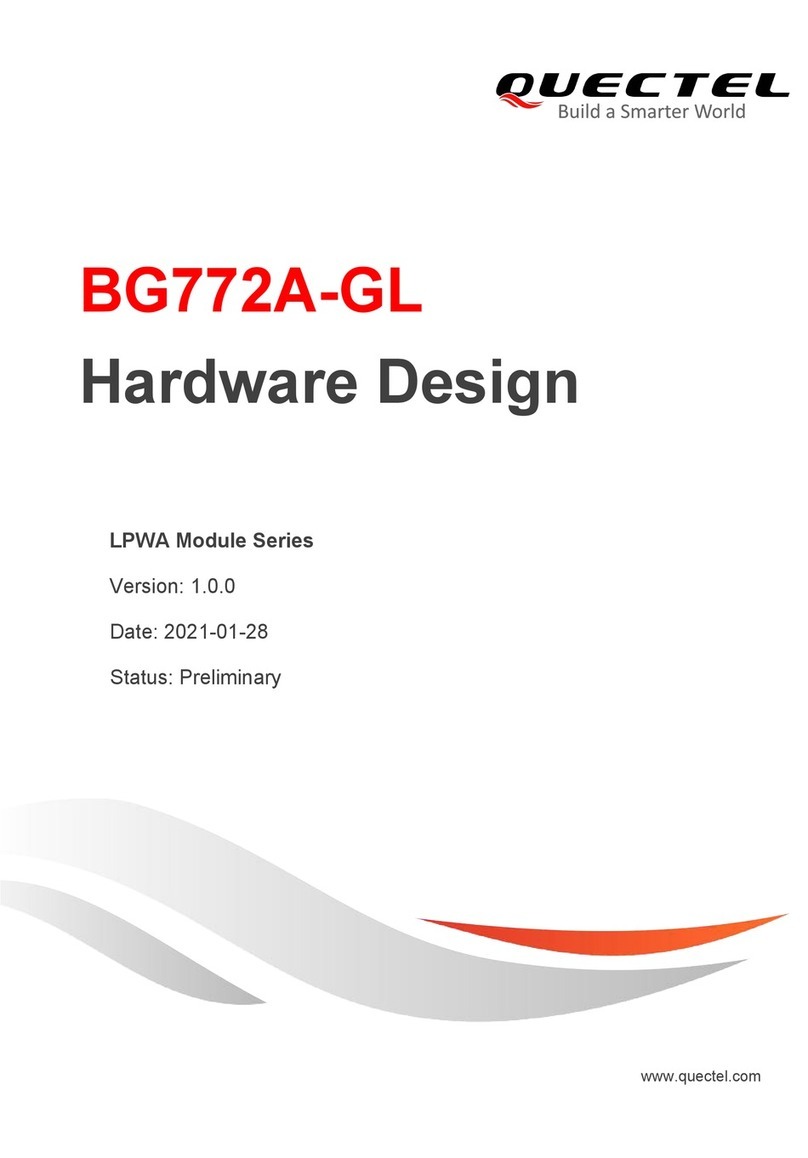

SENSOR MODULE COMPONENT PARTS

Item Code Part

No. No. No. Description

1. 0325804 EBV-14 Locking Ring

3325524 EBV-31-A Locking Ring for Zurn Valve Bodies

2A. 0325806 EBV-11 Cover (Urinal)

2B. 3325538 EBV-38-A Cover w/Override Button (Water Closet)

2C.3325012 EBV-55-A Metal Cover Assembly (Urinal)

3325017 EBV-1034-A Metal Cover Assembly for Zurn Valve

Body (Urinal)

2D. 3325013 EBV-60-A Metal Cover Assembly with

Override Button (Water Closet)

3325016 EBV-1033-A Metal Cover Assembly w/Override Button

for Zurn Valve Body (Water Closet)

3. 5325011 EBV-67 Cover Gasket — 12 per package

4. SEE CHART BELOW — ELECTRONIC MODULE

5. 0325814 EBV-21-A Inside Cover Assembly

(Includes Solenoid)

6. 3325462 EBV-144-A Isolated Solenoid Operator †

7. SEE CHART on PAGE 3 — Flex Tube Diaphragm Kit

8. 3325537 EBV-46-A Beam Deflector ‡

† The new EBV-144-A Isolated Solenoid replaces the Solenoid used with

the old style Black EBV-26-A Modules only.

For Blue EBV-146-A G2 Modules, use the EBV-136-A (code #3325453)

Isolated Solenoid Operator.

Refer to Page 4 for instructions regarding Solenoid replacement.

‡ Beam deflectors are for use on Black, old style Modules. They are not

required (and will not work) on Blue G2 Modules.

ELECTRONIC MODULE ASSEMBLY CHART

The electronic and optical improvements of the G2 OPTIMA Plus have been

incorporated into the Electronic Modules for use with older OPTIMA Plus

products.

ELECTRONIC

SENSOR

MODULE

There are now only two Electronic Module Assembly variations for

use with older OPTIMA Plus valves:

• EBV-146-A-U Urinal

• EBV-146-A-C Water Closet

This chart cross references the part numbers and code numbers of

our new Electronic Modules over from our old Module numbers.

The EBV-146-A Modules include the Isolated Solenoid, Inner Cover

and Electronic Module.

These Modules are for use with older OPTIMA Plus and Regal Pro

OPTIMA Plus Valves only. Consult Maintenance & Repair Guide

#0816456 for G2 OPTIMA Plus Electronic Modules.

USE TO RREPLACE

New PPart NNo. Code NNo. Old PPart NNo. Code NNo.

Electronic Module — 0.5 gpf/1.9 Lpf Urinal EBV-26-A-U-0.5 3325039

Electronic Module — 1.0 gpf/3.8 Lpf Urinal EBV-26-A-U-1.0 3325540

Electronic Module — 1.5 gpf/5.7 Lpf Urinal EBV-26-A-U-1.5 3325541

Electronic Module — 3.5 gpf/13.2 Lpf Urinal EBV-26-A-U-3.5 3325543

Electronic Module — 1.6 gpf/6.0 Lpf Closet EBV-26-A-C-1.6 3325542

Electronic Module — 2.4 gpf/9.0 Lpf Closet EBV-26-A-C-2.4 3325643

Electronic Module — 3.5 gpf/13.2 Lpf Closet EBV-26-A-C-3.5 3325544

Electronic Module — 4.5 gpf/17.0 Lpf Closet EBV-26-A-C-4.5 3325545

Optima Plus Modules can be identified

by color.

Old style Modules are Black and have a

wire that runs along the side of the unit.

G2 Modules are Blue and have a wire

only on the back of the unit.

Description

Note: EBV-26-A Modules are no longer available. Use the EBV-146-A Module shown.

EBV-146-A-U 0325177

EBV-146-A-C 0325176

3

SENSOR OPERATED FLUSHOMETERS

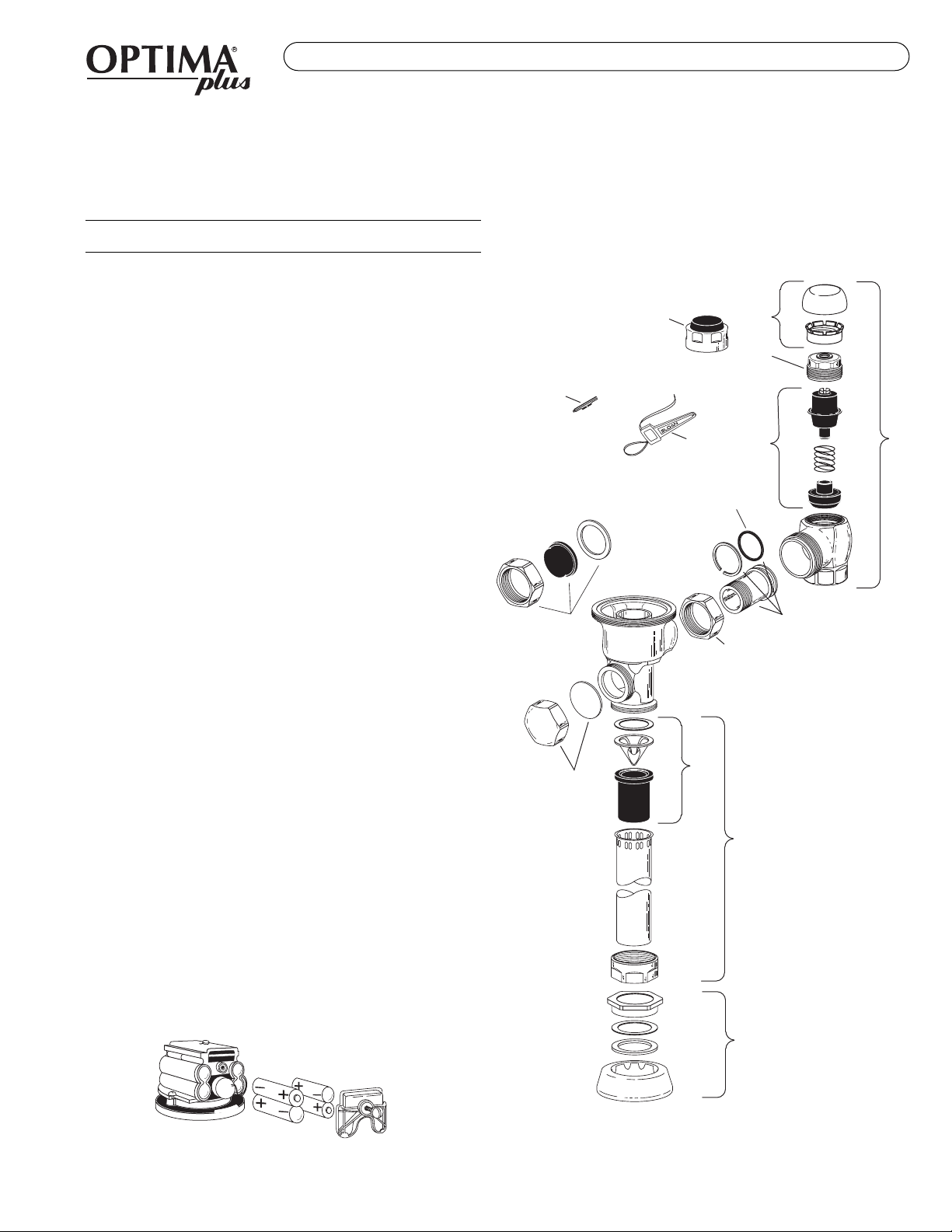

DIAPHRAGM INSIDE PARTS KITS

FLEX TUBE DIAPHRAGM ASSEMBLY

In early 2003 Sloan introduced the Flex Tube Diaphragm kit into the OPTIMA

Plus. This design completely replaced the old OPTIMA Plus Diaphragm Kit

that featured the metal shaft with the Quad Ring. This change further

improved the reliability of the OPTIMA Plus as it replaced a wearable

dynamic seal (the Quad Ring) with a non-moving static O-ring seal.

The Flex Tube Diaphragm Kit also features Sloan's exclusive Dual Filter

Diaphragm. The Dual Filter Diaphragm helps to protect the valve from water

bourn sediment that can cause the valve to stick open and run on. The Dual

Filter diaphragm is also made from Sloan's Permex Synthetic Rubber

material for resistance against chloramines and other water treatment

chemicals.

FLEX TUBE DIAPHRAGM KITS

5325056 EBV-83 O-ring — 6 per package

REGULATORS

The flush volume of the Flex Tube

Diaphragm Kit is control by the

Regulator. Regulators are identified

by color. Some Flex Tube Diaphragm

Kits are supplied with multiple

Regulators. The installer must make

sure the proper regulator is used

when installing the Flex Tube

Diaphragm Kit.

OLD STYLE DIAPHRAGM INSIDE PARTS

The EBF-18 Quad Ring is still available.

5325813 EBV-18 Quad Ring — 12 per package

† The EBV-1020-A and EBV-1022-A Kits are supplied with multiple Regulators.

‡ A 0.5 gpf (1.9 Lpf) Urinal kit can be converted to a 1.0 gpf (3.8 Lpf) by cutting and removing

the smooth A-164 Flow Ring from the Guide.

§ For a 4.5 gpf (17.0 Lpf) Water Closet flush, use the EBV-1020-A Kit with the White Regulator,

and cut and remove the A-164 Flow Ring from the Guide.

Color of Regulator to be used with Flex Tube Diaphragm to obtain the listed flush volume.

KIT NO. COLORCODE NO. KIT NO. CODE NO.

URINAL-0.5 gpf/1.9 Lpf EBV-1023-A GREEN 3325003 EBV-32-A-U-0.5 3325038

URINAL-1.0 gpf/3.8 Lpf ‡ EBV-1022-A GREEN 3325000 EBV-32-A-U-1.0 3325851

URINAL-1.5 gpf/5.7 Lpf EBV-1022-A BLACK 3325000 EBV-32-A-U-1.5 3325818

URINAL-3.5 gpf/13.2 Lpf EBV-1020-A WHITE 3325001 EBV-10-A-U-3.5 3325841

CLOSET-1.6 gpf/6.0 Lpf EBV-1020-A GREEN 3325001 EBV-10-A-C-1.6 3325850

CLOSET-2.4 gpf/9.0 Lpf EBV-1021-A BLUE 3325014 EBV-10-A-C-2.4 3325033

CLOSET-3.5 gpf/13.2 Lpf EBV-1020-A WHITE 3325001 EBV-10-A-C-3.5 3325841

CLOSET-4.5 gpf/17.0 Lpf § EBV-1020-A WHITE 3325001 EBV-10-A-C-4.5 3325842

REGULATOR (Sold 6 per package)

The EBV-1020-A and EBV-1022-A Kits are supplied with multiple Flush Volume Regulators. The

Installer must use the correct Regulator when installing the kit.

ADJUSTING THE OLD STYLE INSIDE DIAPHRAGM ASSEMBLY

The Inside Diaphragm Assembly was set at the factory to ensure an

accurate flush cycle over a range of water pressures.

If adjustment is required, remove the Inside Diaphragm Assembly and turn

it upside down. Inside the Assembly Guide is an Adjustment Screw. Insert

a slotted screwdriver and turn the Adjustment Screw according to the

Conversion Guidelines.

Turning the Adjustment Screw

clockwise DECREASES the flush

volume.

Turning the Adjustment Screw

counterclockwise INCREASES

the flush volume.

For full adjustment procedures,

see OPTIMA Plus Conversion

Guide #0816511.

FLUSH VOLUME REGULATOR PART CODE

AND FIXTURE COLOR NO. NO

URINAL-0.5 gpf/1.9 Lpf GREEN EBV-95 5325122

URINAL-1.0 gpf/3.8 Lpf GREEN EBV-95 5325122

URINAL-1.5 gpf/5.7 Lpf BLACK EBV-102-2 5325129

URINAL-3.5 gpf/13.2 Lpf WHITE EBV-102-1 5325130

CLOSET-1.6 gpf/6.0 Lpf GREEN EBV-95 5325122

CLOSET-3.5 gpf/13.2 Lpf WHITE EBV-102-1 5325130

CLOSET-2.4 gpf/9.0 Lpf BLUE EBV-101 5325128

QUAD RING

FLEX TUBE

DIAPHRAGM

KIT

REGULATOR

FLEX TUBE DIAPHRAGM

The Flex Tube Diaphragm can be used to replace all generations of Sloan

OPTIMA Plus Diaphragm Kits. The same Flex Tube Diaphragm kits are used

in the G2 OPTIMA Plus valve.

FLEX TUBE DIAPHRAGM INSIDE

PARTS KIT (INTRODUCED FEB., 2003)

O-RING (Part # EBV-83)

OLD STYLE KITS ARE

OBSOLETE. SEE CHART

FOR REPLACEMENT.

USE TO RREPLACE

0-RING

REGULATOR

(MUST BE INSTALLED

PAST 0-RING)

FLEX TUBE

DIAPHRAGM

FLEX TTUBE DIAPHRAGM KKIT WW/

DIAPHRAGM KKIT ††QUAD RRING ((OBSOLETE)

APPLICATION

4

SENSOR OPERATED FLUSHOMETERS

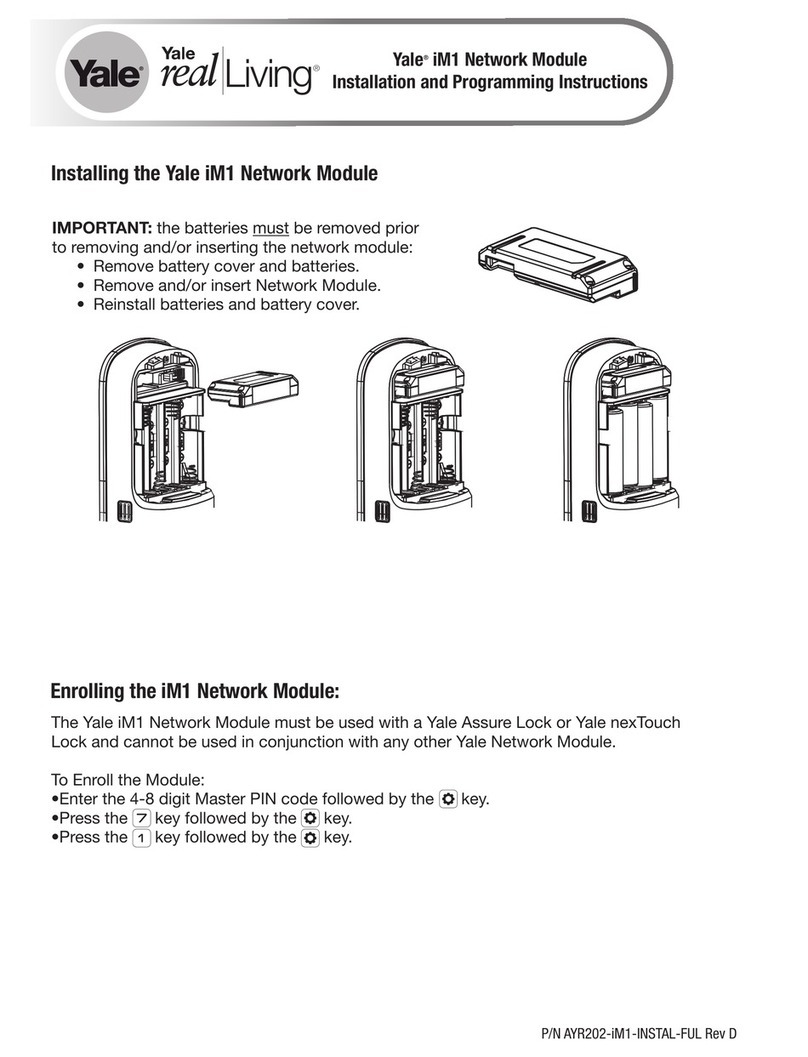

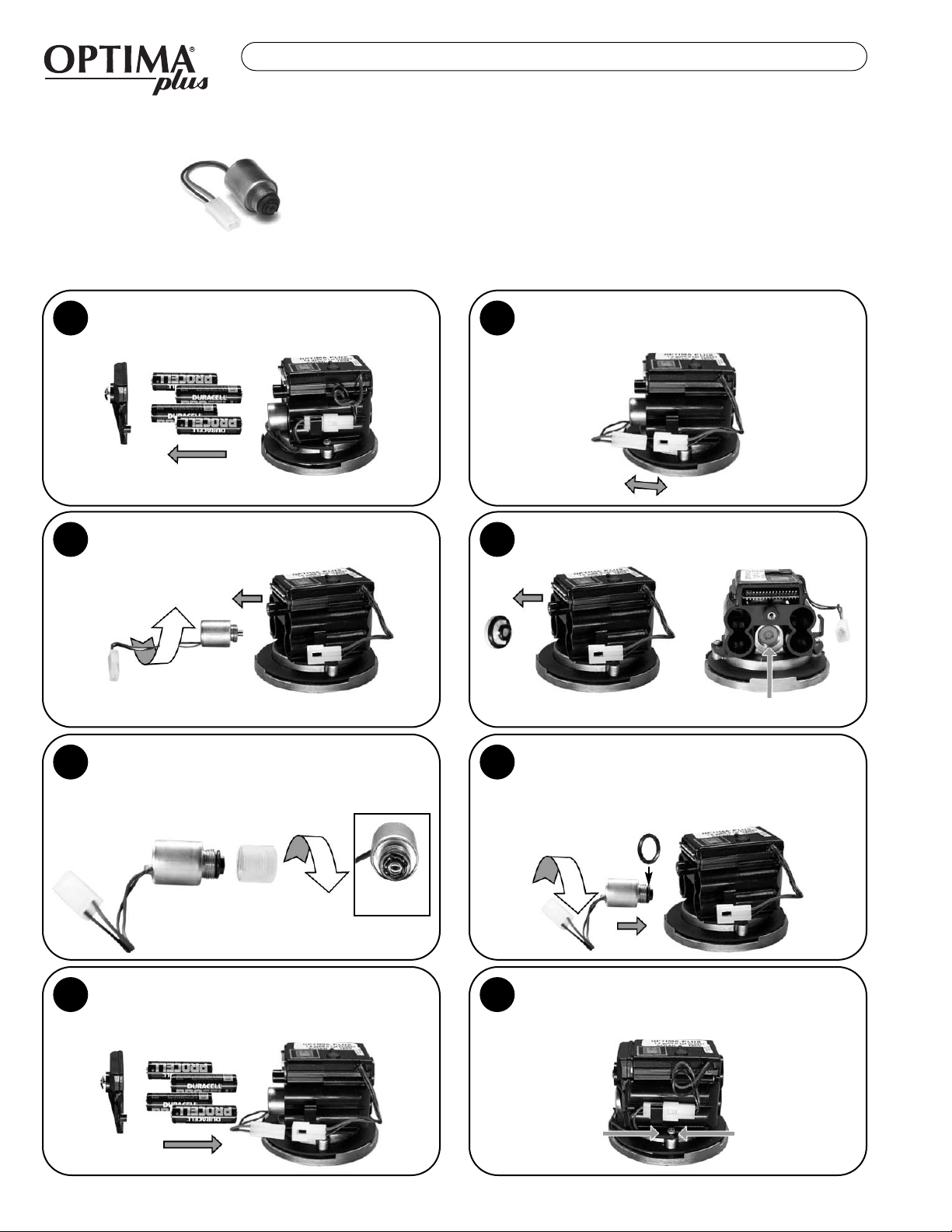

Remove Battery Cover and Batteries from existing

Sensor Module.

12

Unscrew (counterclockwise) the existing

Solenoid Valve from the Base Plate.

3Remove White Plastic Seat and O-rings that are

located inside the Housing.

4

Back View

Remove Clear Plastic Housing from the threaded

end of new Isolated Operator by unscrewing

(counterclockwise). It is normal to find water

inside this housing.

56

Reconnect the White Plastic Connectors on the

side of the Module. Slide the White Connector

into the Clip to secure. Tuck Wiring in close to

Module.

8

Reinstall batteries in the correct position and

reattach Battery Door.

7

Front View

Make sure O-ring is installed on the Black

Housing of the new Isolated Operator. Install

Isolated Operator by threading it (clockwise) into

the Housing. Tighten with fingers beyond just

snug.

For use with Black Optima Plus EBV-26-A Modules only (produced 1992-2003)

For G2 Optima Plus Modules (identified by a Blue Module) use the EBV-136-A Solenoid

Disconnect the White Plastic Connector that

connects the Black and Red Wires on the side of

the Module.

EEBBVV--114444--AACCOODDEE##33332255446622

IISSOOLLAATTEEDDSSOOLLEENNOOIIDDOOPPEERRAATTOORR

SOLENOID REPLACEMENT

5

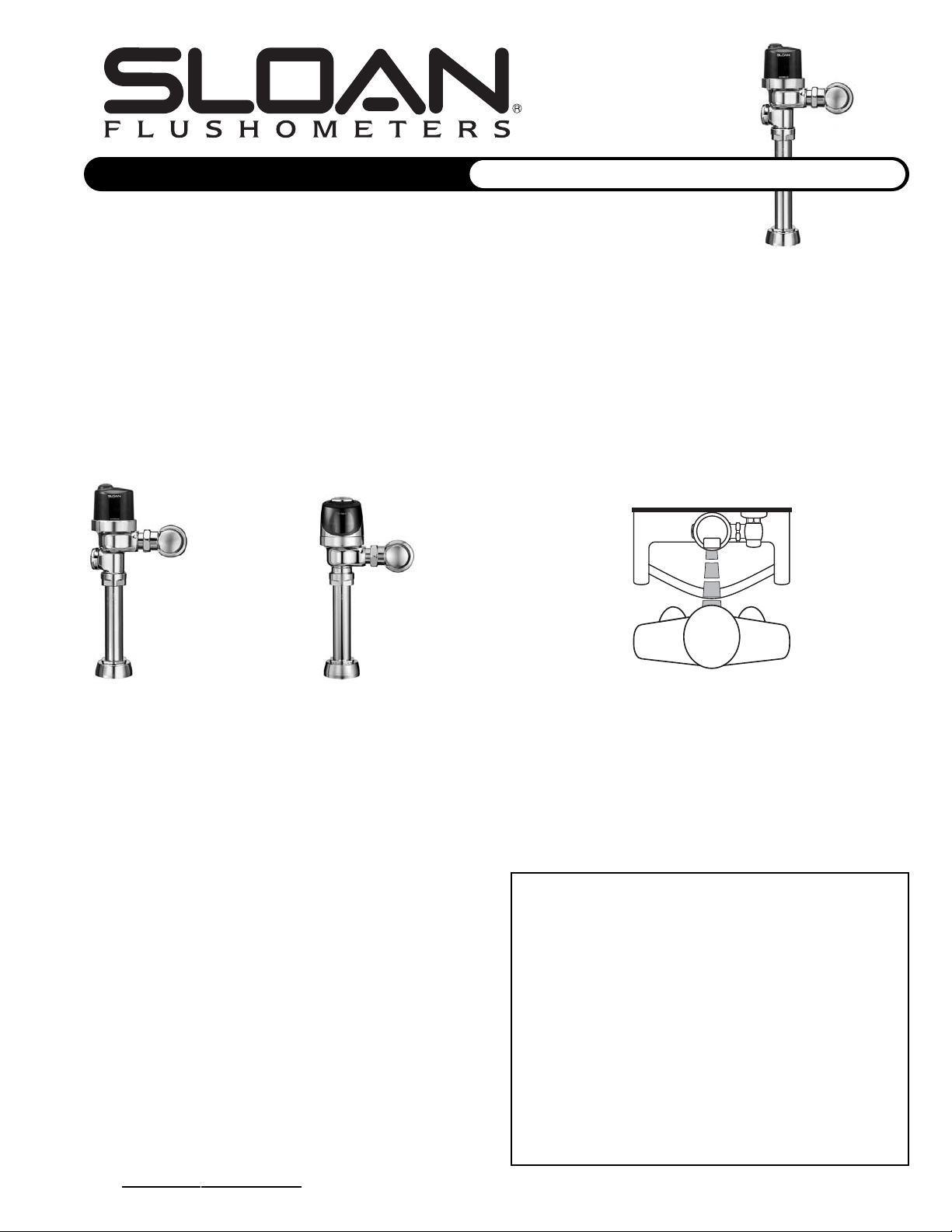

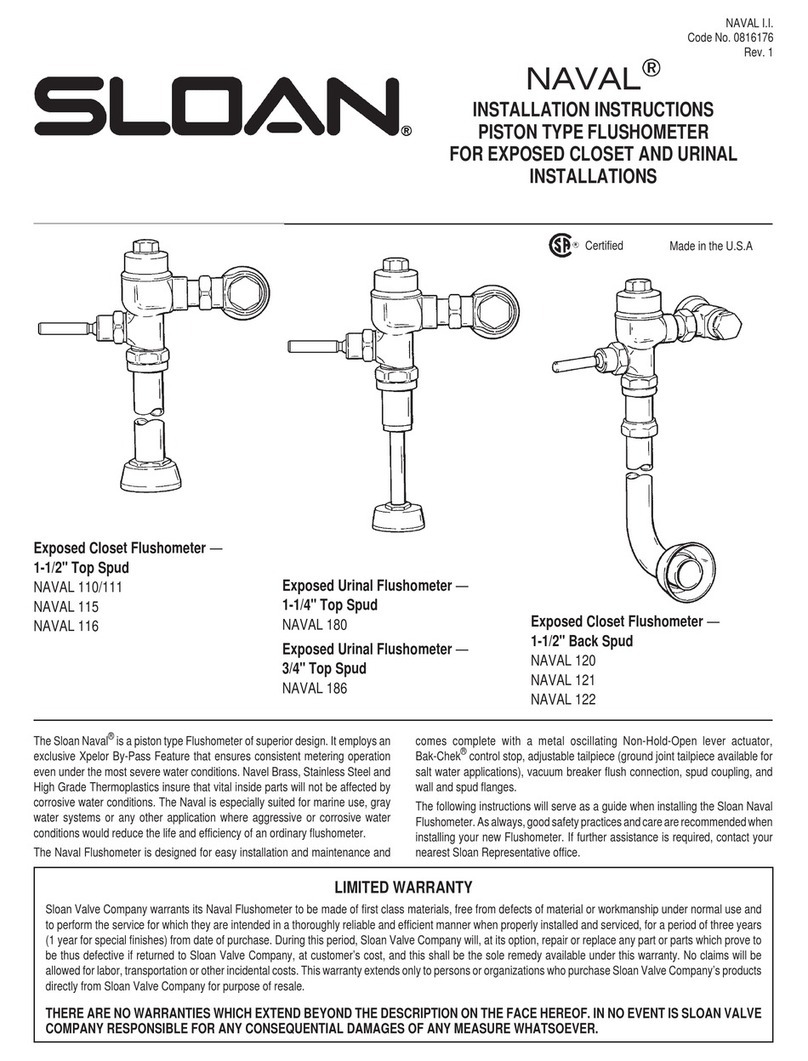

OTHER VALVE COMPONENT PARTS

Item Code Part

No. No. No. Description

9. 3325814 EBV-1017-A Handle Cap — Metal

10. 3325815 EBV-1018-A Handle Cap — Decorative

11. 3323182 V-651-A Vacuum Breaker Repair Kit

12. 0393004 V-600-A ¾'' (19 mm) x 9'' (229 mm) CP Vacuum Breaker

0393006 V-600-A 1¼'' (32 mm) x 9'' (229 mm) CP Vacuum

Breaker

0393007 V-600-A 1½'' (38 mm) x 9'' (229 mm) CP Vacuum

Breaker

13. 0306125 F-5-A ¾'' (19 mm) CP Spud Coupling

0306140 F-5-A 1¼'' (32 mm) CP Spud Coupling

0306146 F-5-A 1½'' (38 mm) CP Spud Coupling

14. 0308676 H-550 CP Stop Coupling

15. 0308801 H-551-A CP Adjustable Tailpiece 2-1/16'' (52 mm) long

16. 5308696 H-553 O-ring — 24 per package

17. 3308386 H-700-A 1'' (25 mm) Screwdriver Bak-Chek®Stop CP —

complete

3308384 H-700-A ¾'' (19 mm) Screwdriver Bak-Chek®Stop CP —

complete

18. 3308853 H-541-A Control Stop Repair Kit †

3308856 H-543-A Control Stop Repair Kit ‡

19. 0308612 H-622 CP Bonnet †

0308843 H-577 CP Bonnet ‡

20. 3308791 H-1010-A Vandal Resistant Control Stop Cap Assembly †

3308790 H-1009-A Vandal Resistant Control Stop Cap Assembly ‡

21. 3325816 EBV-1019-A ¾'' (19 mm) Decorative Stop Cap

3308866 H-574 1'' (25 mm) Decorative Stop Cap

Accessories

22. 0325107 EBV-91 Trimpot Adjustment Screwdriver

23. 0325823 EBV-22 Disposable Strap Wrench

† For use w/H-700-A 1'' & ¾'' and H-600-A 1'' Screwdriver Bak-Chek®Control Stops.

‡ For use w/H-600-A ¾'' Screwdriver Bak-Chek®Control Stops.

18 17

21

16

20

19

15

14

10

9

12

11

13

SENSOR OPERATED FLUSHOMETERS

Battery Replacement

When OPTIMA Plus has approximately 4,000 flushes left, the same red

light that appears at start-up will flash four (4) times quickly whenever an

object is detected. When this occurs, we recommend changing the

batteries.

Separate Locking Ring, Cover and Flex Tube Diaphragm from Electronic

Sensor Module.

Loosen Retaining Screw on Battery Compartment Door and remove Battery

Compartment Door. Install four (4) Alkaline, AA Batteries exactly as

illustrated. Install Battery Compartment Door and secure with Retaining

Screw. Make certain that Battery Compartment Door is fully compressed

against Gasket to provide a seal; Do Not overtighten.

For all Optima Plus produced from 1992 - 2003

And Regal Pro Optima Plus produced after May, 2003

22

23

II..SSeennssoorrFFllaasshheessCCoonnttiinnuuoouussllyyOOnnllyyWWhheennUUsseerrSStteeppssWWiitthhiinnRRaannggee..

A. Unit in Start-Up mode; no problem. This feature is active for the first 10

minutes of operation.

IIII..VVaallvveeDDooeessNNoottFFlluusshh;;SSeennssoorrNNoottPPiicckkiinnggUUppUUsseerr..

A. Range too short; increase the range.

B. OPTIMA Plus installed on a high rough-in fixture (beam is shooting over

the user's head). Install the Sloan EBV-46-A Beam Deflector (black

modules only).

IIIIII..VVaallvveeDDooeessNNoottFFlluusshh;;SSeennssoorrPPiicckkiinnggUUppOOppppoossiitteeWWaalllloorrSSuurrffaaccee,,oorr

OOnnllyyFFlluusshheessWWhheennSSoommeeoonneeWWaallkkssBByy..RReeddLLiigghhttFFllaasshheess

CCoonnttiinnuuoouussllyyffoorrFFiirrsstt1100MMiinnuutteessEEvveennwwiitthhNNooOOnneeiinnFFrroonnttoofftthhee

SSeennssoorr..

A. Range too long; shorten range.

B. Sensor is picking up mirror or highly reflective wall or surface in front of

fixture. Install OPTIMA Plus slightly "off-center" (2 to 5 degrees) to

eliminate direct reflection off of mirror or opposite wall or surface.

IIVV..VVaallvveeDDooeessNNoottFFlluusshhEEvveennAAfftteerrAAddjjuussttmmeenntt..

A. Range Adjustment Potentiometer set at full "max" or full "min" setting.

Readjust Potentiometer away from full "max" or "min" setting.

B. Batteries completely used up; replace batteries.

C. Problem with Electronic Sensor Module; replace Electronic Sensor

Module.

VV..UUnniittFFllaasshheess44QQuuiicckkTTiimmeessWWhheennUUsseerrSStteeppssWWiitthhiinnRRaannggee..

A. Batteries low; replace batteries.

VVII..VVaallvveeDDooeessNNoottSShhuuttooffff..

A. Bypass orifice in diaphragm is clogged with dirt or debris, or bypass is

clogged by an invisible gelatinous film due to "over-treated" water.

Remove Flex Tube Diaphragm and wash under running water.

Note: Size of orifice in the Bypass is of utmost importance for the proper

metering of water by the valve. DO NNOT EENLARGE OORDDAMAGE TTHIS

ORIFICE. Replace Flex Tube Diaphragm if cleaning does not correct the

problem.

B. Dirt or debris fouling Stem or Flex Tube Diaphragm. Remove Flex Tube

Diaphragm and wash under running water.

C. Problem with Solenoid. If cleaning does not correct the problem, replace

with new Isolated Solenoid Operator.

VVIIII..NNoottEEnnoouugghhWWaatteerrttooFFiixxttuurree..

A. Wrong OPTIMA Plus Flex Tube Diaphragm installed; i.e., 1.0 gpf urinal

installed on 3.5 gpf closet fixture. Replace with proper Diaphragm

Assembly.

B. Enlarged Bypass in Diaphragm. Replace with Flex Tube Diaphragm Kit.

C. Control Stop not adjusted properly. Readjust Control Stop.

D. Inadequate volume or pressure at supply. Increase water pressure or

supply (flow) to valve. Consult factory for assistance.

VVIIIIII..TTooooMMuucchhWWaatteerrttooFFiixxttuurree..

A. Control Stop not adjusted properly. Readjust Control Stop.

B. Wrong OPTIMA Plus Flex Tube Diaphragm installed; i.e., 3.0 gpf model

installed on 1.0 or 1.5 gpf urinal fixture. Replace with proper OPTIMA Plus

Diaphragm Assembly.

C. Dirt in Diaphragm Bypass. Clean under running water or replace with new

Flex Tube Diaphragm.

IIXX..MMeenn''ssRRoooommCClloosseettBBoowwllssUUnnfflluusshheedd..

A. Closet being used as urinal. Angle Sensor slightly off fixture centerline to

detect standing person in front of fixture.

XX..HHiigghhVVaaccuuuummBBrreeaakkeerrIInnssttaallllaattiioonn

((MMooddeell88111155//88111166))——UUnniittNNoottFFlluusshhiinngg..

A. EBV-46-A Beam Deflector not installed. Install EBV-46-A Beam Deflector

(black modules only) to divert Sensor beams.

XXII..EElleemmeennttaarryySScchhoooollUUrriinnaallssNNoottFFlluusshhiinngg..

A. Unusually short users not being detected. Install EBV-46-A Beam

Deflector (black modules only) to divert Sensor beams.

† Note: Use on Black Modules Only.

BATTERIES

When required, replace batteries with four (4) Alkaline Type AA batteries.

For information and instructions on field converting OPTIMA Plus Module

settings or to activate the Stadium Flush™ Feature in urinal models, see the

Sloan OPTIMA Plus Conversion Guide (0816511).

This manual and the OPTIMA Plus Repair and Maintenance Guide are

available at www.sloanvalve.com

CARE AND CLEANING OF CHROME AND SPECIAL FINISHES

DO NOT use abrasive or chemical cleaners to clean Flushometers as they

may dull the luster and attack the chrome or special decorative finishes.

Use ONLY soap and water, then wipe dry with clean cloth or towel.

While cleaning the bathroom tile, the Flushometer should be protected from

any splattering of cleaner. Acids and cleaning fluids can discolor or remove

chrome plating.

Refer to the OPTIMA Plus Flushometer Maintenance Guide for additional

Troubleshooting and Repair Part information.

If further assistance is required, please contact the Sloan Valve

Company Installation Engineering Department at 1-888-SLOAN-14

(1-888-756-2614).

Manufactured in the U.S.A. by Sloan Valve Company under one or more

of the following patents: U.S. Patents: 4,893,039; 5,169,118; 5,244,179;

5,295,655; Des. 345,113; Des. 355,478. Other Patents Pending. BAK-

CHEK®, PARA-FLO®, PERMEX®, TURBO-FLO®.

Troubleshooting and Maintaining the Sloan OPTIMA Plus Flushometer

SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131

Phone: 1-800-9-VALVE-9 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380 • www.sloanvalve.com

Copyright © 2003 Sloan Valve Company Printed in the U.S.A. Made in the U.S.A. OPTIMA PLUS M.G. — Rev. 2 (09/03) Code No. 0816193

SENSOR OPERATED FLUSHOMETERS

FOR USE WITH SLOAN’S ORIGINAL OPTIMA PLUS

FLUSHOMETER PRODUCED FROM 1992 - 2003

COUNTERCLOCKWISE CLOCKWISE

Decreases

Range Increases

Range

EBV-46-A BEAM

DEFLECTOR †

Other manuals for G2 Optima Plus

6

This manual suits for next models

2

Table of contents

Other Sloan Control Unit manuals

Sloan

Sloan SOLIS 8100 Series User manual

Sloan

Sloan NAVAL 110 User manual

Sloan

Sloan Optima ETF-80 User manual

Sloan

Sloan 152 ES-S TMO SWB User manual

Sloan

Sloan 152 ES-S TMO SWB User manual

Sloan

Sloan Optima Plus EBV-500-A User manual

Sloan

Sloan G2 Optima Plus Operating manual

Sloan

Sloan TRUFLUSH TRF 8900-CP User manual