www.mc-techgroup.com ECM | 1.01.00 3

Content

1General information................................................................................................................ 4

2Declaration of conformity....................................................................................................... 4

3Safety instructions.................................................................................................................. 5

4Warranty .................................................................................................................................. 5

5Used terms and signal indications ........................................................................................ 6

6Introduction............................................................................................................................. 8

6.1 Serial number ........................................................................................................................ 8

7Application .............................................................................................................................. 8

8Technical Data......................................................................................................................... 9

8.1 For basic cooler ECM without heat exchanger....................................................................... 9

8.2 Options for basic cooler ECM............................................................................................... 10

9Description............................................................................................................................ 10

10 Function................................................................................................................................. 11

11 Reception and storage.......................................................................................................... 12

12 Installation instructions........................................................................................................ 13

13 Supply connections.............................................................................................................. 13

13.1 Hose connections ................................................................................................................ 13

13.2 Electrical connections .......................................................................................................... 15

14 Start-up.................................................................................................................................. 16

15 Closing down......................................................................................................................... 16

16 Maintenance .......................................................................................................................... 17

16.1 Adding and replacing the heat exchangers .......................................................................... 17

16.2 Cleaning the fins of the condenser....................................................................................... 18

16.3 Maintenance of the optional mounted peristaltic pump(s), type SR25.2............................... 18

16.3.1 Mounting instructions for SR25.2 peristaltic pump (optional)......................................... 18

16.3.2 Change of the pump tube.............................................................................................. 19

16.3.3 Change of contact pulleys and springs.......................................................................... 20

16.3.4 Cleaning the pump head............................................................................................... 21

17 Operating of the built-in electronic temperature controller ............................................... 21

17.1 Changing the set value ........................................................................................................ 21

17.2 Changing the temperature alarm range................................................................................ 22

18 Trouble shooting................................................................................................................... 22

19 Spare parts list...................................................................................................................... 23

20 Appendix................................................................................................................................ 24

List of illustrations

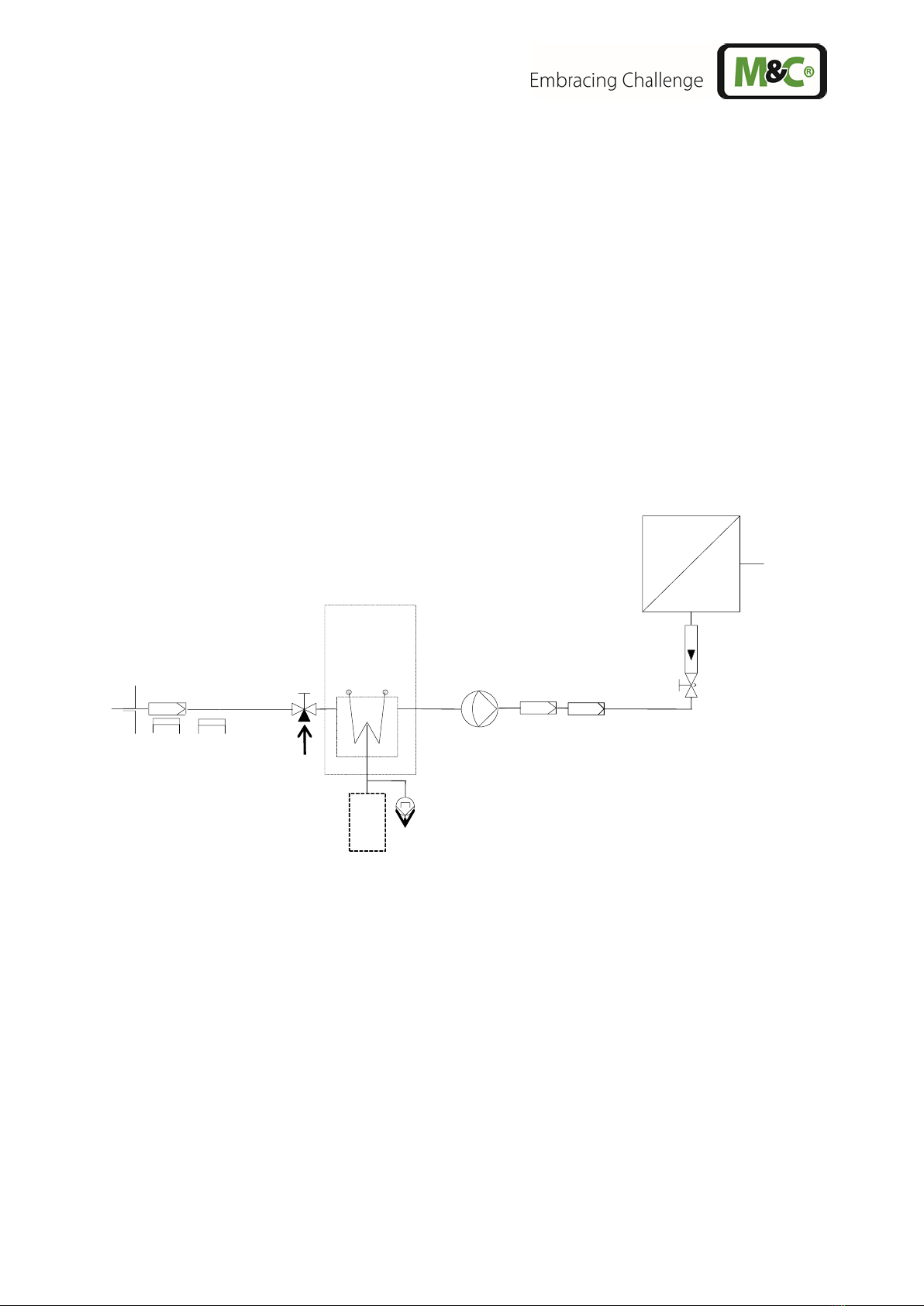

Figure 1 Application example of the ECM..................................................................................... 8

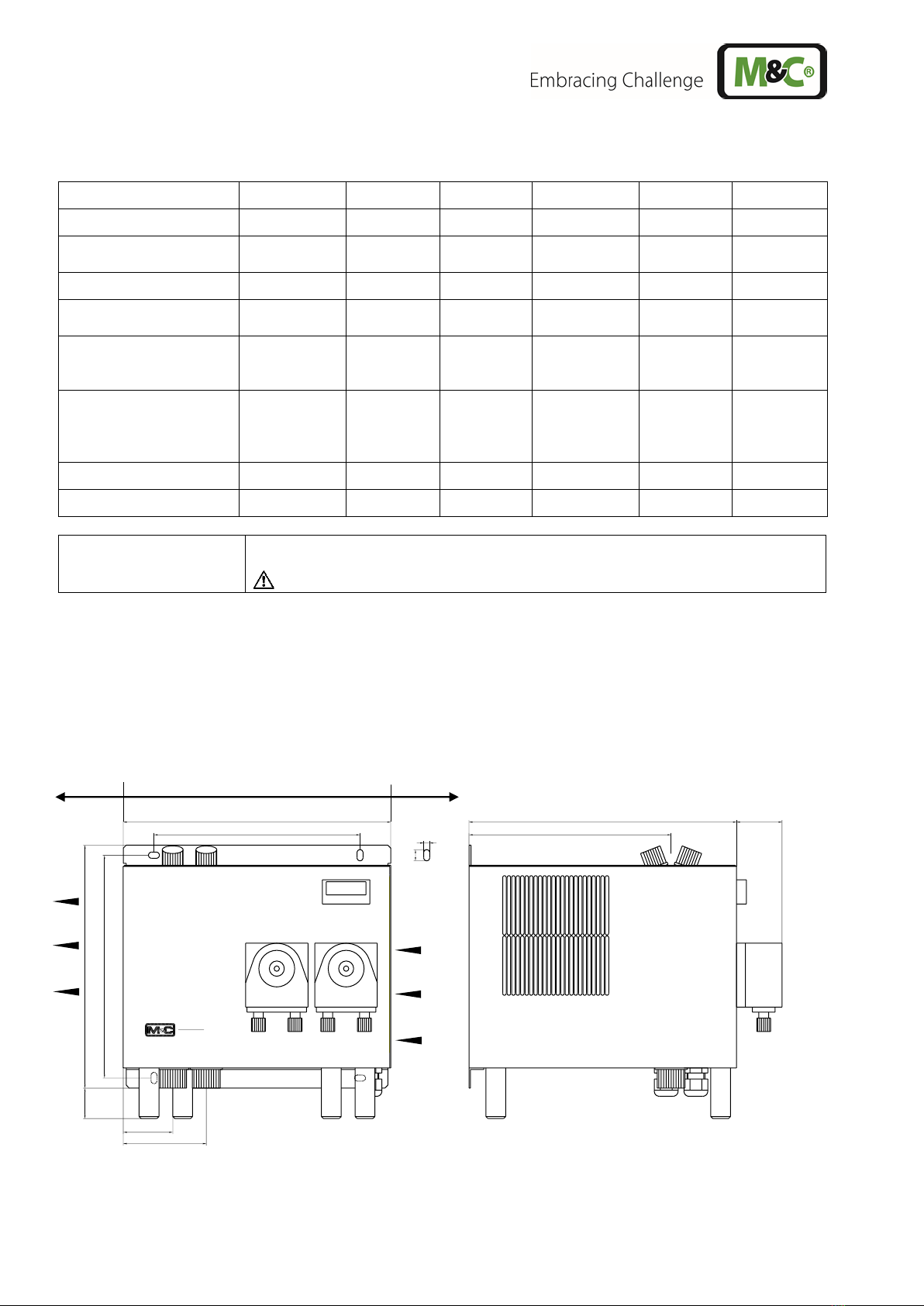

Figure 2 ECM-2G........................................................................................................................ 10

Figure 3 Schematic diagram of the heat exchanger function....................................................... 12

Figure 4 Gas and condensate connections................................................................................. 13

Figure 5 Electrical sockets alarm contact.................................................................................... 15

Figure 6 SR25.2: Mounting distance between front panel and pump motor ................................ 19

Figure 7 Change of the pump tube ............................................................................................. 20

Figure 8 Front view of the temperature controller........................................................................ 21

Figure 9 Dependency of gas outlet dew point at a gas inlet point of 60 °C [140 °F] .................... 24

Figure 10 Circuit diagram ECM (drawing No.: 2456-5.01.0).......................................................... 25

Figure 11 ECM compressor connection........................................................................................ 26