www.mc-techgroup.com PSP4000-H | 1.01.00 3

Contents

1General information.................................................................................................................... 4

2Declaration of conformity........................................................................................................... 4

3Safety instructions...................................................................................................................... 5

4Warranty...................................................................................................................................... 5

5Used terms and signal indications............................................................................................ 6

6Introduction................................................................................................................................. 7

7Serial numbers............................................................................................................................ 7

8Power supply .............................................................................................................................. 7

9Technical Data ............................................................................................................................ 8

9.1 Options.................................................................................................................................. 9

10 Applications.............................................................................................................................. 11

11 Description................................................................................................................................ 11

12 Receipt of goods....................................................................................................................... 12

13 Preparation and installation..................................................................................................... 12

14 Supply connections.................................................................................................................. 13

14.1 Connecting the heated sample line...................................................................................... 13

14.2 Electrical connection............................................................................................................ 14

14.3 Calibration-gas discharge.................................................................................................... 14

14.4 Temperature measurement ................................................................................................. 15

15 Starting...................................................................................................................................... 15

16 Maintenance.............................................................................................................................. 16

16.1 Changing the filter element.................................................................................................. 16

17 Switching off............................................................................................................................. 18

18 Disposal..................................................................................................................................... 18

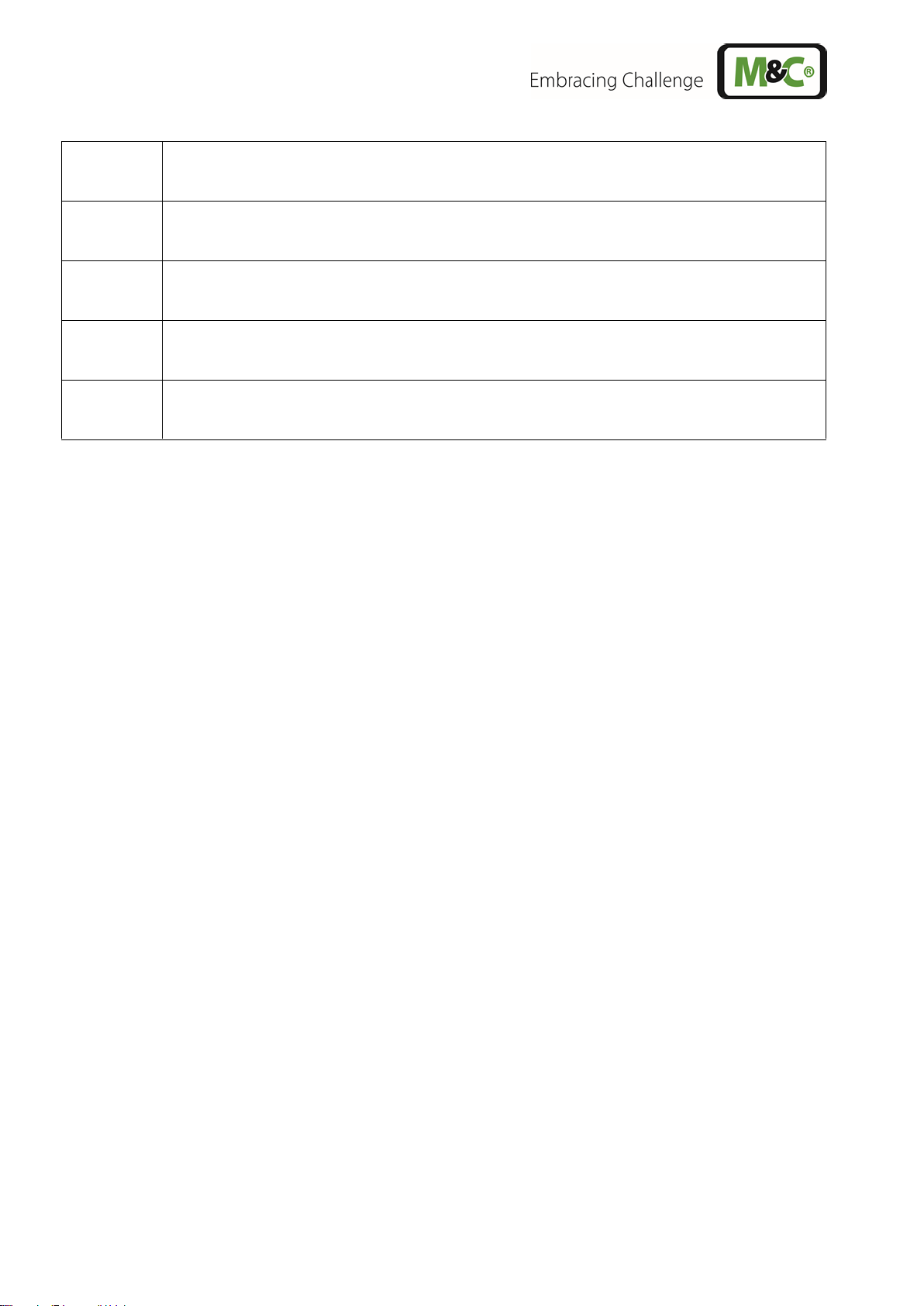

19 Spare parts list.......................................................................................................................... 19

20 Appendix ................................................................................................................................... 20

List of illustrations

Figure 1 Connection of the heated sample line............................................................................... 13

Figure 2 Sample facilities ............................................................................................................... 21

Figure 3 Wiring plan....................................................................................................................... 22

Figure 4 Basic version.................................................................................................................... 23

Figure 5 Carrying case to transport sample probe.......................................................................... 24

Figure 6 Filter unit and connection of the heated sample line......................................................... 25

Figure 7 High temperature sample tube, aluminium oxide.............................................................. 26

Figure 8 Electrically heated sample tube SP34-H........................................................................... 27