www.mc-techgroup.com ECS-SS HF EX2 | 1.00.003

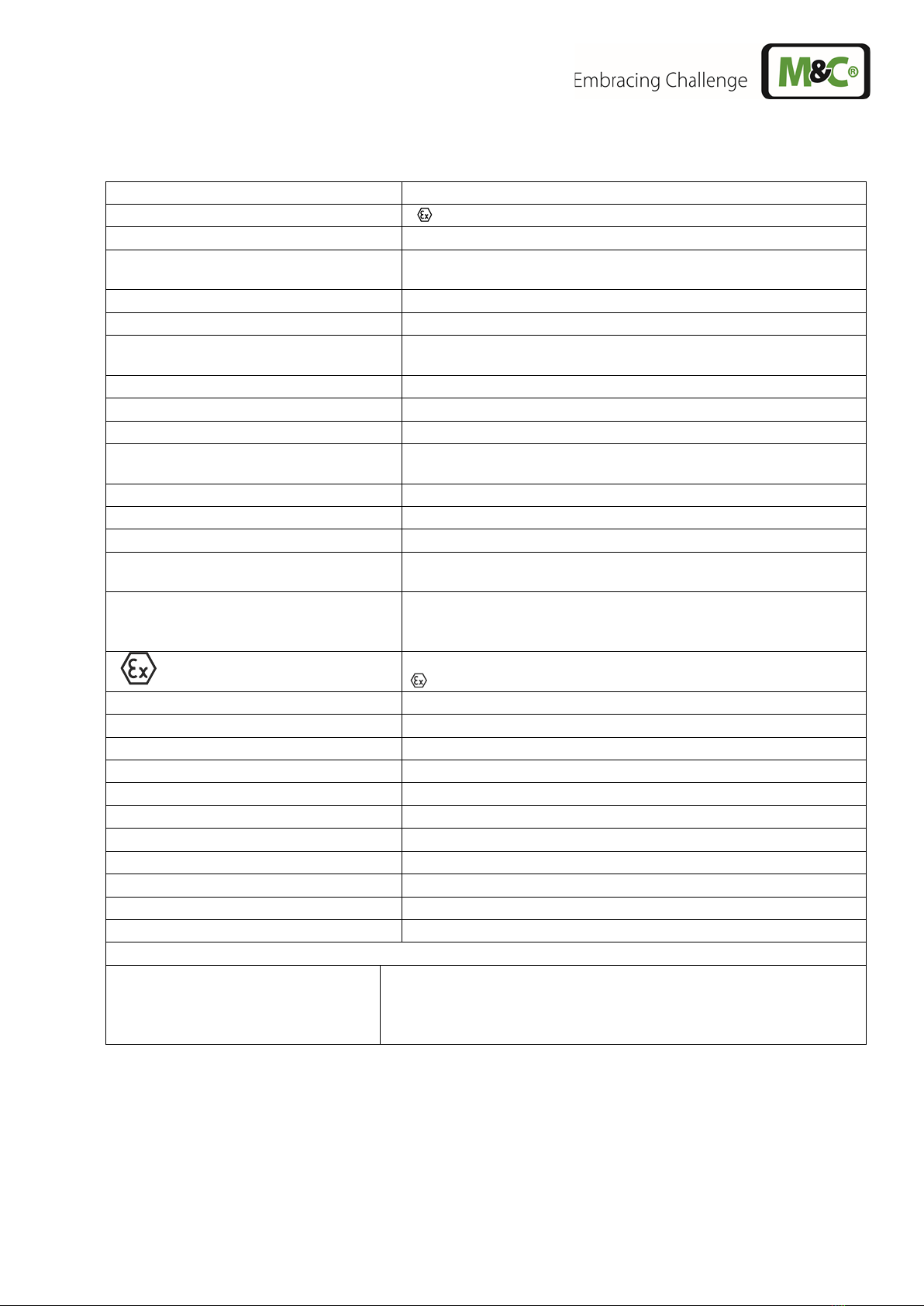

List of Contents

1General information ................................................................................................................ 4

2Declaration of conformity....................................................................................................... 4

3Safety instructions.................................................................................................................. 5

4Information and safety instructions for using the cooler in hazardous areas.................... 5

5Warranty .................................................................................................................................. 6

6Used terms and signal indications ........................................................................................ 6

7Introduction ............................................................................................................................. 8

8Application .............................................................................................................................. 8

9Technical data ......................................................................................................................... 9

10 Description ............................................................................................................................ 10

11 Function................................................................................................................................. 11

12 Reception and storage.......................................................................................................... 12

13 Installation instructions........................................................................................................ 12

14 Supply connections .............................................................................................................. 13

14.1 Hose connections .......................................................................................................... 13

14.2 Electrical connections .................................................................................................... 13

15 Start-up .................................................................................................................................. 15

16 Closing down......................................................................................................................... 16

17 Maintenance .......................................................................................................................... 17

17.1 Cleaning the fins of the condenser ................................................................................. 17

17.2 Maintenance of the optional mounted peristaltic pump, type SR25.6 ............................. 18

17.2.1 Changing the pump tubing....................................................................................... 19

17.2.2 Changing contact pulleys and springs...................................................................... 20

17.2.3 Reassembly of the driver ......................................................................................... 21

17.2.4 Cleaning the pump head.......................................................................................... 22

18 Operating of the built-in electronic temperature controller ............................................... 23

18.1 Changing the set value .................................................................................................. 23

18.2 Changing the temperature alarm window ....................................................................... 23

19 Trouble shooting................................................................................................................... 24

20 Spare parts list ...................................................................................................................... 25

21 Appendix................................................................................................................................ 26

List of Illustrations

Figure 1 Example of application of ECS-SS HF ............................................................................ 8

Figure 2 ECS-SS HF EX2 ............................................................................................................10

Figure 3 Electrical connection ECS-SS HF EX2...........................................................................14

Figure 4 Changing the pump tubing .............................................................................................19

Figure 5 Different pump tube sizes...............................................................................................19

Figure 6 Disassembly of pump head and driver ...........................................................................20

Figure 7 Check of axes and rolls..................................................................................................21

Figure 8 Front view of the temperature controller

.........................................................................23

Figure 9 Sample gas outlet dew point characteristics...................................................................27

Figure 10 Circuit diagram ECS-SS HF EX2 ...................................................................................28

Figure 11 EC declaration of conformity ..........................................................................................29