Mannesmann HYQUIP VT-SWKA-1 Training manual

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

Analog Command Value Card VT-SWKA-1

Product Description and Commissioning Instructions

RE 30 255-B/05.00

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

3

RE 30 255-B/05.00

Product description and commissioning instructions VT-SWKA-1

Table of contents

Table of contents

1. General

1.1 Features 4

1.2 Technical data 5

2. Block circuit diagram 6

3. Functional description / commissioning notes

3.1 General 7

3.2 Command value preselection 7

3.3 Current input 7

3.4 Command value call-ups 7

3.5 External command value potentiometer 7

3.6 Command value inversion 7

3.7 Enable function 7

3.8 Ramp generator 8

3.9 External ramp time adjustment 8

3.10 Ramp status signal 8

3.11 Ramp time selection logic 9

3.12 Characteristic curve generator 9

3.13 Amplitude limiter 10

3.14 Fault recognition 10

3.15 Measuring points 10

4. Indicator / adjustment elements 11

5. Adjustment recommendation 12

6. Pin assignment 13

7. Engineering / maintenance notes / supplem. information 13

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

RE 30 255-B/05.00

4

1. General

1.1 Features – Analog command value card (without power part) for controlling valves with integral

electronics

→For controlling valves without integral electronics, a suitable additional amplifier

is required.

– Suitable for generating, combining and normalizing command value signals

– Configuration and parameterization of the command value card by means of

potentiometers

– Command value inputs:

• Differential input ±10 V

• 4 callable command value inputs ±10 V

• Current input 4 to 20 mA (standard 0 to 100 %; can be changed over ±100 %)

– Control variable output:

• Voltage ±10 V

• Current 4 to 20 mA (standard 0 to 100 %; can be changed over ±100 %)

– Inversion of internal command value signal using 24V input or jumper

– Ramp time selection by quadrant recognition (24V input) or

ramp time call-ups (24V inputs)

– Ramp time range can be changed over by means of jumpers

– Characteristic curve correction by means of separately adjustable step-change heights

and maximum values

– Enable input

– Output signal “ramp ready“ as auxiliary process variable

– Output signal “ready for operation“

– Switchable measuring socket

– Reverse voltage protection for voltage supply

Suitable card holders:

– 19“ rack types VT 19101, VT 19102, VT 19103 and VT 19110 (see RE 29 768)

– Closed card holder VT 12302 (see RE 30 103) with blind plate insert 4TE/3HE

(material no. 00021004)

– Open card holder VT 3002-2X/48 (see RE 29 928)

For control cabinet installation only!

Power supply units:

– Type VT-NE30-1X, see RE 29 929

Compact power supply unit 115/230 VAC →24 VDC, 70 VA

– Type VT-NE31-1X, see RE 29 929

Compact power supply unit 115/230 VAC →24 VDC, 7 VA

– Type VT-NE32-1X, see RE 29 929

Compact power supply unit 115/230 VAC →24 VDC, 60 VA (smoothed) and

24 VDC, 25 VA (regulated)

Product description and commissioning instructions VT-SWKA-1

1. General

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

5

RE 30 255-B/05.00

1.2 Technical data

For applications outside these parameters, please consult us!

Product description and commissioning instructions VT-SWKA-1

1. General

Operating voltage UB24 VDC + 40 % – 20 %

Operating range: – Upper limit value UB(t)max 35 V

– Lower limit value UB(t)min 18 V

Power requirement PS< 7 VA

Current consumption I< 0.3 A

Fuse Thermal overload protection; auto-activating when triggered

Inputs:

– Analog

• command values 1 to 4 (potentiometer inputs) Ue0 to ±10 V; Re= 100 kΩ(reference is M0)

• command value 5 (differential input) Ue0 to ±10 V; Re> 50 kΩ

• command value 6 (current input) Ie4 to 20 mA; load RB= 100 Ω(zero point can be changed over)

• ramp time external Ue0 to +10 V; Re= 10 kΩ

(internally raised to +15 V; reference is M0)

– Digital

• command value call-ups U8.5 V to UB→call-up activated

U0 to 6.5 V →no call-up

• ramp call-ups U8.5 V to UB→call-up activated

U0 to 6.5 V →no call-up

• quadrant recognition U8.5 V to UB→ON

U0 to 6.5 V →OFF

• command value inversion U8.5 V to UB→ON

U0 to 6.5 V →OFF

• enable U8.5 V to UB→ON

U0 to 6.5 V →OFF

Adjustment ranges:

– Zero point adjustment (potentiometer “Zw“) ±30 %

– Command values (potentiometers “w1“ to “w4“) 0 to 110 %

– Ramp times (potentiometers “t1“ to “t5“) 20 ms to 5 s (can be changed over using J3)

– Step-change height (potentiometers “S+“ and “S–“)

0 % to 50 % (step-change height reached at ca. 2 % command value injection)

– Amplitude attenuator (potentiometers “G+“ and “G–“) 0 % to 110 % (valid when step-change height is set to 0 %)

Outputs:

– Analog signals

•

control variable

voltage U±10 V ±2 %; Imax = 2 mA

current I

4 mA to 20 mA ±2 %; R

B

max

= 500 Ω(zero point can be changed over)

• measuring signal U±10 V ±2 %; Imax = 2 mA

– Digital signals

• ramp ready U> 16 V; 50 mA →ready

U< 1 V; Ri= 10 kΩ→ramp active

• ready for operation U> 16 V; 50 mA (in the event of a fault: U< 1 V; Ri= 10 kΩ)

– Regulated voltages U±10 V ±2 %; 25 mA

– Measuring sockets

•

measur. signal “v“ (dep. on position of measur. point selector switch)

U±10 V ±2 %; Imax = 2 mA

Type of connection 48-pin blade connector, DIN 41 612, form F

Card dimensions Euro-card 100 x 160 mm, DIN 41 494

Front panel dimensions: – Height 3 HE (128.4 mm)

– Width soldering side 1 TE (5.08 mm)

– Width component side 3 TE

Permissible operating temperature range

ϑ

0 to + 50 °C

Storage temperature range

ϑ

– 25 °C to + 85 °C

Weight m0.15 kg

Note:

For details regarding environment simulation tests in the fields

of EMC (electromagnetic compatibility), climate and mechanical stress,

see RE 30 255-U (declaration on environmental compatibilty).

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

RE 30 255-B/05.00

6

uu

∑

b20

d10

d12

d14

d16

d24

d28

b14

b16

b22

b24

b8

b6

b4

b2

d2

d4

d6

d8

b10

d18

z30

z32

d26

d30

d32

d22

b32

b30

b26

b28

z20

+15 V

w3

4

L0

J5

5

Zw

– 1

UL

t1 t2

t3 t4

t

7

DC

DC

Gw+

S+ S–

+15 V

+7,5 V

M0

–5 V

–7,5 V

–15 V

v

J7

26

1

1

2

3

4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

15

iu

3

3

w4

w2 2

w1 1

4

+

–

+

–

24 V

0 V

t1

A

t2

B

t3

C

t4

D

t5

E

0123456789A CBDEF

10

4Q

F

7

6J1

v

8

UL

∑

9

J2, J3

Gw–

12

13

J6

ui

UL

14

5

11

1

2

3

4

J4

0

+/–

max

ϑ+100 μF

Product description and commissioning instructions VT-SWKA-1

2. Block circuit diagram

2. Block circuit diagram

Operating

voltage

Inversion

Enable

Com. value 5:

0 to ±

10

V

Quadrant

operation

Contr. variable

0 to ±10 V

Measuring signal

M0

For explanations regarding the jump-

ers as well as the position and assign-

ment of indicator and adjustment

elements, see page 11

1Power supply unit

2Differential amplifier

3Current input

4

Command value selection logic

5Zero point adjustment

Ramp

call-ups

6Command value summation

7Command value inversion

8Enable function

9Ramp generator

10 Ramp time selection logic

11 Ramp status function

12 Characteristic curve generator

13 Amplitude limiter

14 Fault recognition

15 Measuring point changeover

Com. value

call-ups

Ramp time

external

Com. value 6:

4 to 20 mA

Com. value 4

Com. value 3

Com. value 2

Com. value 1

Ramp ready

Control variable

4 to 20 mA

“Ready for

operation“

+ 10 V/25 mA

– 10 V/25 mA

System ground

Measuring points

1)

UP/DOWN

1)

Measuring points 8 and 9

are not assigned.

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

7

RE 30 255-B/05.00

R

5 kΩ< R < 20 kΩ

Product description and commissioning instructions VT-SWKA-1

3. Functional description / commissioning notes

3. Functional description /

commissioning notes

[ ] = Reference to the block circuit diagram

3.1 General

The command value card is designed as printed circuit board in Euro-format 100 x 160 mm

and is suitable for installation in a rack. A power supply unit [1] provides the internally

required positive and negative supply voltages. As soon as the power supply unit is in opera-

tion and no error is present, the green LED on the front panel lights up and the “ready for

operation” signal is set.

3.2 Command value preselection

The internal command value signal is generated from the sum (command value summation

[6]) of the external command value signal applied to differential input [2] and to current

input [3], called-up signal [4] and zero point offset [5] (zero point potentiometer "Zw”).

3.3 Current input [3]

There is no changeover between current and voltage input. Both inputs are permanently

available (see terminal allocation). The input signals are internally normalized and added.

The zero point and the range of values of the current input can be changed over by means of

jumper J5.

3.4 Command value call-ups [4]

Four command value signals, “w1“ to “w4“, can be called up. External command value

voltages (command values 1 to 4) are preselected either directly via the regulated voltage

inputs + 10 V and – 10 V or via external potentiometers. If the command value inputs are

connected directly to the regulated voltages, the command values are adjusted by means of

potentiometers “w1“ to “w4“. If external potentiometers are used, the internal potentiom-

eters act as attenuators or limiters.

Only one call-up is possible at a time. If several call-ups are selected simultaneously, call-up

“1” has lowest priority, call-up “4” highest priority.

A yellow LED on the front panel indicates, which call-up is active.

3.5 External command value potentiometer

3.6 Command value inversion [7]

The command value that is generated internally from input signals, command value call-ups

and zero point offset signals can be inverted by means of an external signal or jumper J1.An

LED (“– 1“) on the front panel signals whether an external inversion signal is applied.

3.7 Enable function [8]

The enable function cuts the enable signal of the ramp generator in or out.When the enable

is cut in or out, the control variable changes at any command value according to the set ramp

time. This prevents a controlled valve from opening or closing suddenly. If an error signal is

present, the input signal of the ramp generator is also set to 0 %.An LED on the front panel

signals that an enable signal is applied.

b2, b4, b6 or b8

b32 b30 b32

(+10V) (–10V) (+10V)

b28 b28 b30

(0V) (0V) (–10V)

Range of command values

0 to 0 to –100% to

+100% –100% +100%

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

RE 30 255-B/05.00

8

d24

d28

+ 15 V

10 k

R

Utest socket "v" (in V) 53210.50.30.20.10.05 0.03 0.02

J3 →connection 2-3 1) t(in ms; ±20 %) 20 33 50 100 200 333 500 1000 2000 3333 5000

J3 →connection 1-2 t(in s; ±20 %) 0.2 0.33 0,50 1 2 3.33 5 10 20 33 50

1) factory setting

3.9 External ramp time adjustment

The internally set ramp time can be extended by means of an external potentiometer. The

setting can be verified with the help of the measuring socket. In the case of a cable break,

the internal presetting will be validated automatically.

The adjustment range depends on "R".

2) The minimum ramp time can only be achieved, if the internally set ramp time is less, i.e.

the relevant potentiometer is turned to the left-hand stop.

3.10 Ramp status signal [11]

The status signal“ramp ready“ indicates that the control variable has reached the requested

final value. This signal (24V output) facilitates the synchronization of higher-level sequence

controls with the valve function or the controlled hydraulic function.

3.8 Ramp generator [9]

The ramp generator limits the increase of the control variable. Downstream step-functions

and amplitude attenuators do not shorten or extend the ramp time.

Jumper J2 can be used to set the ramp time to minimum (< 2 ms) (ramp off).

The minimum/maximum ramp time can be changed between 20 ms/5 s or 0.2 s/50 s by

means of jumper J3.

5 different ramp times can be set and activated. The ramp times can be pre-set or verified

with the help of test socket “v”.

The following is valid (with factory setting of jumper J3 →connection 2-3):

t= (in ms)

100

U

test socket "v"

(in V)

The following is valid (with factory setting of jumper J3 →connection 2-3):

Adjustment range 2)

RMinimum ramp time Maximum ramp time

Potentiometer to left-hand stop Potentiometer angle of rotation = 95 %

1 kΩ80 ms 1 s

0,5 kΩ150 ms 2 s

0,1 kΩ800 ms 10 s

r

l

Product description and commissioning instructions VT-SWKA-1

3. Functional description / commissioning notes

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

9

RE 30 255-B/05.00

+

2

%+

100

%

–

100

%

S–

G–

S+

G+

–

2

%

Product description and commissioning instructions VT-SWKA-1

3. Functional description / commissioning notes

3.11 Ramp time selection logic [10]

a) Operating mode "4-quadrant operation"

When 4-quadrant operation is activated (24V signal “4Q”), the electronics automatically

recognizes the command value polarity and the direction of change of the command value

and assigns a ramp time to the current signal status. Depending on these signal states, one

of the 4 ramp times is selected.

Ramp up, positive →Ramp potentiometer “t1”

Ramp down, positive →Ramp potentiometer “t2”

Ramp up, negative →Ramp potentiometer “t3”

Ramp down, negative →Ramp potentiometer “t4”

4-quadrant operation has a higher priority than all ramp time call-ups. As long as a signal

changes, the LED (on the front panel, directly next to the associated potentiometer) assigned

to the current ramp time lights up.

Note: In the case of very short ramp times, the LEDs' lighting up can no longer be noticed.

LED “4Q” on the front panel is on when quadrant recognition is active.

b) Ramp time call-ups

When operating mode "4-quadrant operation" is deactivated,4 ramp times can be called up

using an optional call-up signal (24V input). Only 1 call-up is possible at a time. If several

call-ups are activated at the same time, call-up “1” has the lowest priority and call-up “4”

has highest priority. Each called-up ramp time is signaled by a yellow LED (on the front panel,

directly next to the associated potentiometer).

c) 5th ramp time

If neither quadrant recognition nor a call-up is activated, ramp time "t5"

is always valid.

3.12 Characteristic curve generator [12]

The adjustable characteristic curve generator can be used to adjust step-change heights and

maximum values separately for positive and negative signals according to the hydraulic re-

quirements. The actual characteristic curve shape through the zero point is not step-like, but

linear.

The step-change height can be adjusted by means of potentiometers "S+" and "S–".

Jumper J4 can be used to activate the step function. For this, the connection 2-3 of jumper J4

must be plugged (factory setting: connection 1-2 →step function OFF). To prevent a re-

sidual step-change (< 1 %) when the step function is deactivated, the potentiometers “S+”

and S–“ must be turned to the left-hand stop and the connection 1-2 of jumper J4 must be

plugged.

The maximum command value can be adjusted by means of potentiometers “Gw+” and

“Gw–”. The adjustment range is between 0 % and 110 %.

3.13 Amplitude limiter [13]

The control variables (current output and voltage output) are limited to approx. ±110 % of

the nominal range.

← Internal command value →

←Command value preselection →

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

RE 30 255-B/05.00

10

3.14 Fault recognition [14]

This features monitors internal operating voltages, voltage outputs and, if jumper J7 (1-2) is

plugged, the current output for cable break. When no fault is present, the green “ready for

operation” LED lights up and the output “ready for operation” is set to 24 V (operating

voltage).

3.15 Measuring points [15]

A measuring socket is provided on the front panel to allow the verification of the settings of

command value call-ups, ramp times and further, internal signals. The measuring points can

be selected using the measuring point selector switch that is also provided on the front

panel. The signal of the measuring socket is also connected to the blade connector (b26).

Switch position Signal

Measuring signal at "v"

0Internal command value ±10 V Ⳏ100 %

1Command value call-up 1 ±10 V Ⳏ100 %

2Command value call-up 2 ±10 V Ⳏ100 %

3Command value call-up 3 ±10 V Ⳏ100 %

4Command value call-up 4 ±10 V Ⳏ100 %

5Zero point offset “Zw” ±3 V Ⳏ±30 %

6

Summated signal of command values

±10 V Ⳏ100 %

7Ramp generator output ±10 V Ⳏ100 %

8free

9free

ARamp time “t1” 10 mV to 10 V

BRamp time “t2” 10 mV to 10 V

CRamp time “t3” 10 mV to 10 V

DRamp time “t4” 10 mV to 10 V

ERamp time “t5” 10 mV to 10 V

FCurrent ramp time “t” 10 mV to 10 V

Product description and commissioning instructions VT-SWKA-1

3. Functional description / commissioning notes

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

11

RE 30 255-B/05.00

Product description and commissioning instructions VT-SWKA-1

4. Indicator / adjustment elements

4. Indicator / adjustment elements

If the sealed potentiometers are misadjusted, the warranty

will become void !

SWKA

-1

4Q

T

v

Zw

w1

w2

w3

w4

t1

t2

t3

t

4

t5

G–

J5

J1

J3 J2

S–

G+

S+

v0

–

vF

4

12 1

J4

J8

J6 J7

1 1

4

12

1

1 1

1

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

• … Connection made

–… Connection broken

… Factory setting of jumpers

Do not change!

(Internal reference voltage)

Do not change!

(Ramp time symmetry)

Measuring point selector

switch

J6 →current output 1-2 2-3

0 % Ⳏ4 mA • –

0 % Ⳏ12 mA – •

J7 →cable break

monitor 1-2 2-3

ON • –

OFF – •

J5

→current input

1-2 2-3

0 % Ⳏ4 mA • –

0 % Ⳏ12 mA – •

No function!

(Reserve)

J4

→step function

1-2 2-3

OFF • –

ON – •

J2 →ramp function 1-2 2-3

OFF • –

ON – •

J3 →ramp time 1-2 2-3

Ten-fold • –

Single – •

LED lamps:

Readiness for operation (green)

Enable (yellow)

–1 External inversion

4Q Quadrant recognition

TReserved

Potentiometers (some with LED lamp):

Zw Zero point adjustment

w1 Command value 1

w2 Command value 2

w3 Command value 3

w4 Command value 4

t1 Ramp time 1

t2 Ramp time 2

t3 Ramp time 3

t4 Ramp time 4

t5 Ramp time 5

Cannot be adjusted on the front panel:

G+ Amplitude attenuator for positive command values

G– Amplitude attenuator for negative command values

S+ Step-change height for positive direction

S– Step-change height for negative direction

Measuring sockets:

vMeasuring signal

⊥Measurement zero

J1

→inversion

1-2 2-3

inverting • –

not inverting – •

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

RE 30 255-B/05.00

12

Product description and commissioning instructions VT-SWKA-1

5. Adjustment recommendation

5. Adjustment recommendation The system-specific circuit must be provided.

Signal Adjustment

Command value call-up – Select the potentiometer to be adjusted using the

measuring point selector switch

–

Adjust the command value call-up and check it on measuring

socket

"

v

"

Command value zero point

– Do not activate a command value call-up!

– Set external command value preselections to zero

– Turn measuring point selector switch to "6"

– Set the measured value to zero using zero point

potentiometer "Zw"

Ramp times – Select the potentiometer to be adjusted using the

measuring point selector switch

–

Adjust the ramp time according to the formula or table (see

"3.8 ramp generator") and check it on measuring socket "v"

External ramp

potentiometer – Do not activate a ramp time call-up!

– Turn ramp potentiometer "t5" to the left-hand stop

– Turn measuring point selector switch to "F"

–

Adjust the ramp time according to the formula or table (see

"3.8 ramp generator") and check it on measuring socket "v"

Step-change height – Apply enable signal

– Turn measuring point selector switch to "7"

– Adjust the measuring signal to + 0.3 V using zero point

potentiometer "Zw" 1)

– Turn measuring point selector switch to "0"

–

Set the required step-change height using potentiometer "S+"

– Turn measuring point selector switch to "7"

– Adjust the measuring signal to – 0.3 V using zero point

potentiometer "Zw" 1)

– Turn measuring point selector switch to "0"

–

Set the required step-change height using potentiometer "S

–"

– Adjust the zero point

1) In the case of external command value preselection, this

must result in at least + 0.3 V / – 0.3 V at measuring

socket "v" (turn measuring point selector switch to "7").

Maximum values Note: Before the maximum values are matched, the zero

point and step-change heights must be correctly set.

– Adjust the step-change heights first; generate command

value ±100 % externally or by means of a command value

call-up

– Turn measuring point selector switch to "7"

– Check measuring signal 10 V ±0.2 V

– Adjust the required maximum control output using

potentiometers "G+"/"G–"

Company Registered in England No: 4167649 VAT Registration No: 732 5692 25 BS EN ISO 9001:2008 No: LRQ 0964389

+44 (0)1204 699959

Hyquip Limited New Brunswick Street Horwich Bolton Lancashire BL6 7JB UK

www.hyquip.co.uk/web/index

13

RE 30 255-B/05.00

7. Engineering / maintenance

notes / supplem. information

– The command value card may only be withdrawn or plugged in when disconnected

from the power supply!

– Never install cables near power cables!

–

The distance to antenna cables, radio equipment and radar systems must be at least 1 m!

– Use relays with gold-plated contacts for switching command values (small voltages,

small currents)!

– Only carry out measurements on the cards with instruments Ri> 100 kΩ!

– Use a screw driver with a blade width of 4 mm for adjusting potentiometers and

turning the measuring point selector switch.

– Always shield command value cables; connect shield to protective earth (PE) on the

card side!

–Caution: When using the differential input, both inputs must always be

switched on or off simultaneously!

If the sealed potentiometers are misadjusted, the warranty will become void !

Pin Row d Row b Row z

2Command call-up 1 Command value 1 Reserved

(24V input)

(Potentiometer connection ±10 V)

4Command call-up 2 Command value 2 Reserved

(24V input)

(Potentiometer connection ±10 V)

6Command call-up 3 Command value 3 Reserved

(24V input)

(Potentiometer connection ±10 V)

8Command call-up 4 Command value 4 Reserved

(24V input)

(Potentiometer connection ±10 V)

10 Ramp call-up 1 Command value inversion Reserved

(24V input) (24V input)

12 Ramp call-up 2 Reserved Reserved

(24V input)

14 Ramp call-up 3 Command value 5 + (+ 10V ) Reserved

(24V input)

16 Ramp call-up 4 Command value 5 – (– 10V ) Reserved

(24V input)

18 Enable Reserved Reserved

(24V input)

20 Reserved 4-quadrant operation System ground

(24V input)

22

Signal "ready for operation"

Command value 6 + Reserved

(24 V, H-active, 50 mA) (4 to 20 mA)

24 Ramp external Command value 6 – Reserved

(4 to 20 mA)

26 Ramp completed Measuring signal Reserved

28 Ramp external / reference Reference potential for Reserved

outputs (M0)

30 Control output ±10 V – 10 V / 25 mA Operating voltage

(24 V)

32 Control output 4 to 20 mA + 10 V / 25 mA L0 (0 V)

6. Pin assignment

Product description and commissioning instructions VT-SWKA-1

6. Pin assignment 7. Engineering / maintenance notes / supplem. information

Table of contents

Popular Computer Hardware manuals by other brands

Anthem

Anthem AVM 90 quick start guide

DPT

DPT SmartRaidV Century Ultra2 SCSI RAID Controller... Features list

Arbor Technology

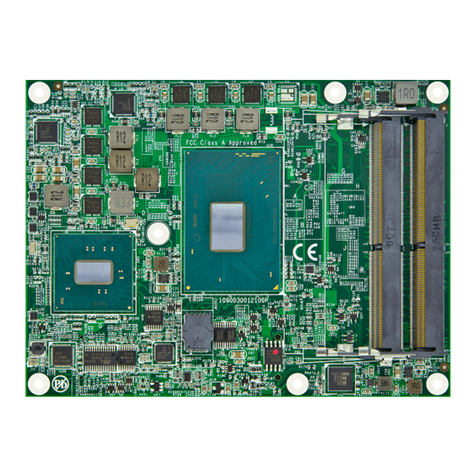

Arbor Technology EmETXe-i90M3 user manual

AV Access

AV Access eShare D10 quick start guide

Digital Equipment

Digital Equipment MS11-BC Maintenance manual

Bitfury

Bitfury B8 quick start guide

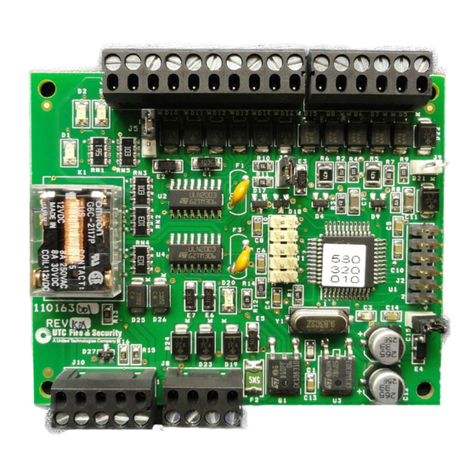

UTC Fire and Security

UTC Fire and Security WIU-4 installation manual

Renesas

Renesas RZ/N1S-DB quick start guide

janitza

janitza Procont LMC-008-IO User manual and technical data

Cebora

Cebora GRV22 instruction manual

Intel

Intel RH80536GC0332M - Pentium M 1.8 GHz Processor datasheet

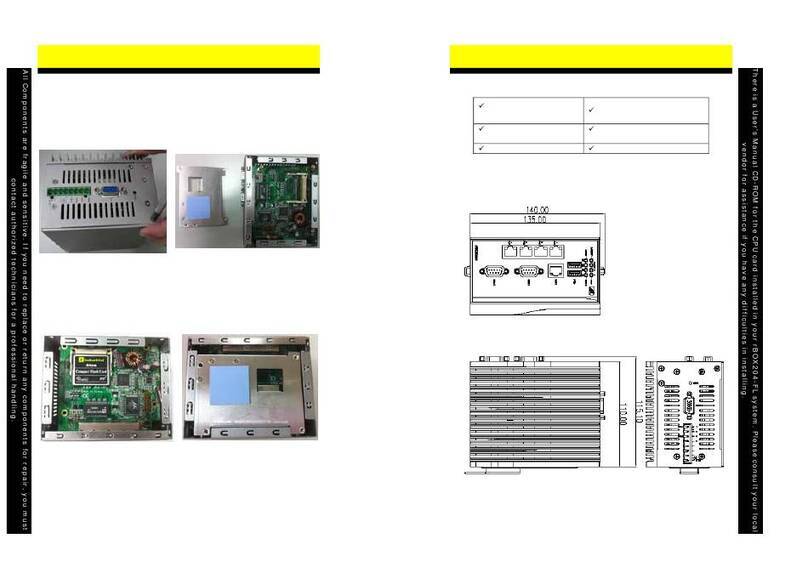

AXIOMTEK

AXIOMTEK rBOX204-FL Quick installation guide