Manrose FAN2303 User manual

This manual suits for next models

4

Table of contents

Other Manrose Fan manuals

Manrose

Manrose MANI3000N Assembly instructions

Manrose

Manrose CQF100 User manual

Manrose

Manrose LED Series User manual

Manrose

Manrose FAN0090 User manual

Manrose

Manrose EXTRACT-A-LITE Service manual

Manrose

Manrose FAN0046 User manual

Manrose

Manrose FAN0531 User manual

Manrose

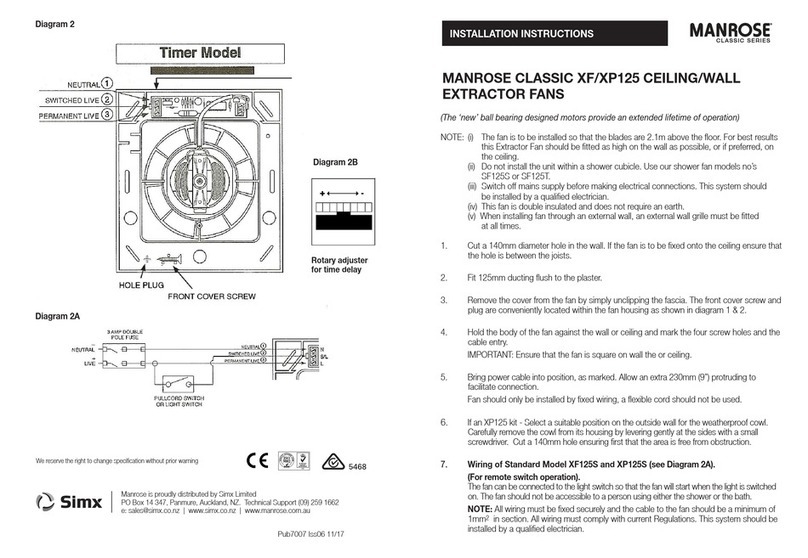

Manrose CLASSIC XF150 User manual

Manrose

Manrose M200P User manual

Manrose

Manrose FAN7180 User manual

Manrose

Manrose CRA100T User manual

Manrose

Manrose MRUF150WH Assembly instructions

Manrose

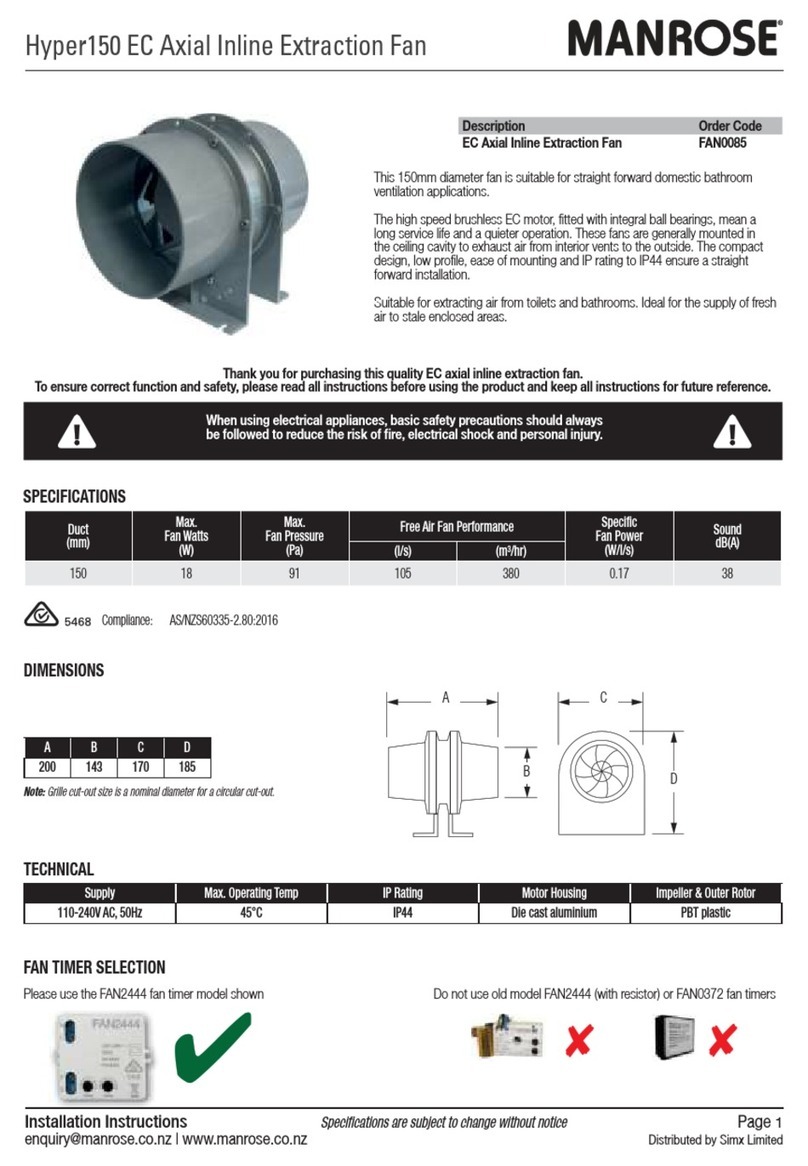

Manrose HYPER150 User manual

Manrose

Manrose FAN0085 User manual

Manrose

Manrose LED Series User manual

Manrose

Manrose LED Series Installation guide

Manrose

Manrose FAN7189 User manual

Manrose

Manrose FAN5375 User manual

Manrose

Manrose MET Series Assembly instructions

Manrose

Manrose COMT Series User manual

Popular Fan manuals by other brands

HAMPTON BAY

HAMPTON BAY Florentine manual

System air

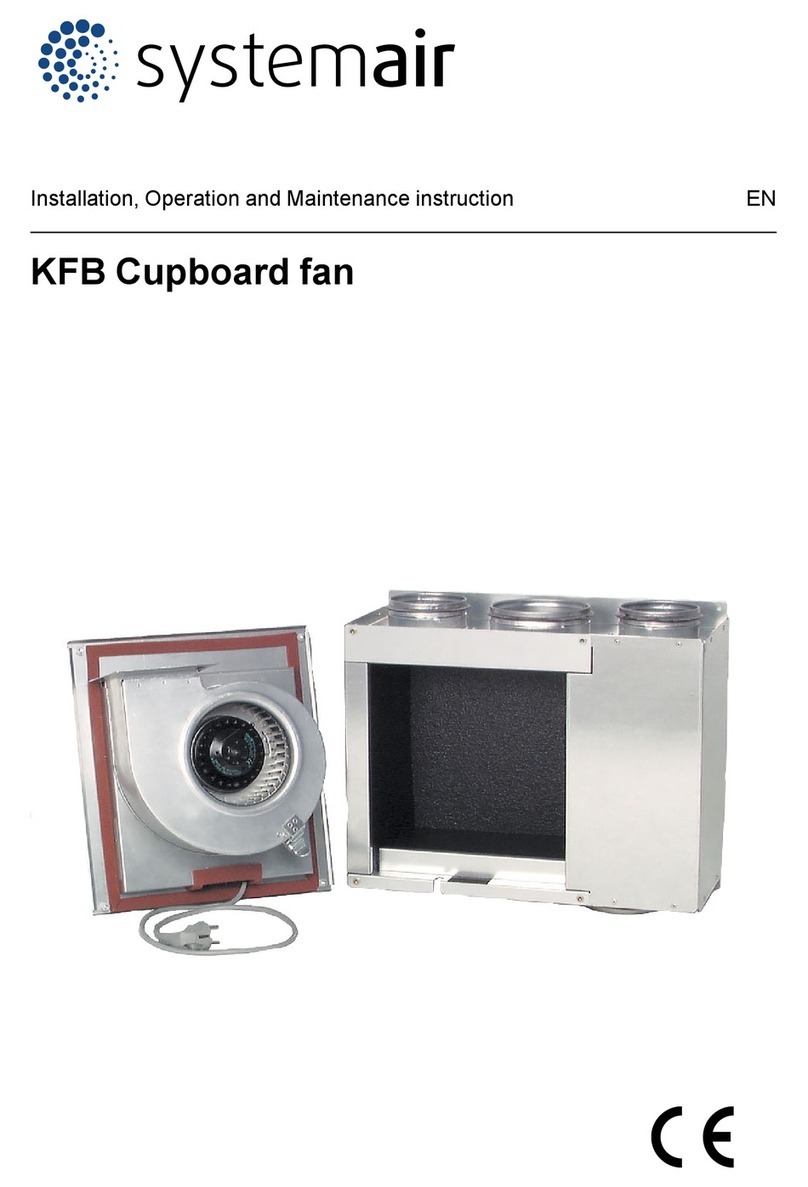

System air KFB Operating and maintenance instructions

System air

System air KFB Installation,operation and maintenance instruction

Ebmpapst

Ebmpapst R2E220-AA40-71 operating instructions

Ebmpapst

Ebmpapst D2E146-HS97-03 operating instructions

Ebmpapst

Ebmpapst S2D200-AH18-01 operating instructions

Air King

Air King 9102 Operating instructions and parts manual

HAMPTON BAY

HAMPTON BAY TY-50-L (HD) Use and care guide

M Confort

M Confort MF60 user manual

Ebmpapst

Ebmpapst M4Q045-BD03-04 operating instructions

Air King

Air King AK150LS Series operating manual

Ebmpapst

Ebmpapst R3G310-AO52-01 operating instructions

Ebmpapst

Ebmpapst A3G710-AU21-01 operating instructions

CO/Tech

CO/Tech FE-23C Original instructions

Oriental motor

Oriental motor MU Series operating manual

Ebmpapst

Ebmpapst W3G400-CC22-51 operating instructions

HAMPTON BAY

HAMPTON BAY VERANDA 499-493 owner's manual

Silvercrest

Silvercrest SBV 50 B1 Operation and safety notes