Manusa Visio C2H User manual

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

1

Installation manual

Op. Visio C2H

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

2

INSTALLATION MANUAL

VISIO C2H OPERATOR

TRANSLATED DOCUMENT

Read thoroughly all of these instructions before using

the unit.

This manual includes all the necessary information

required to install the product.

Keep this manual in a safe place for future reference.

0. INDEX

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

3

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

4

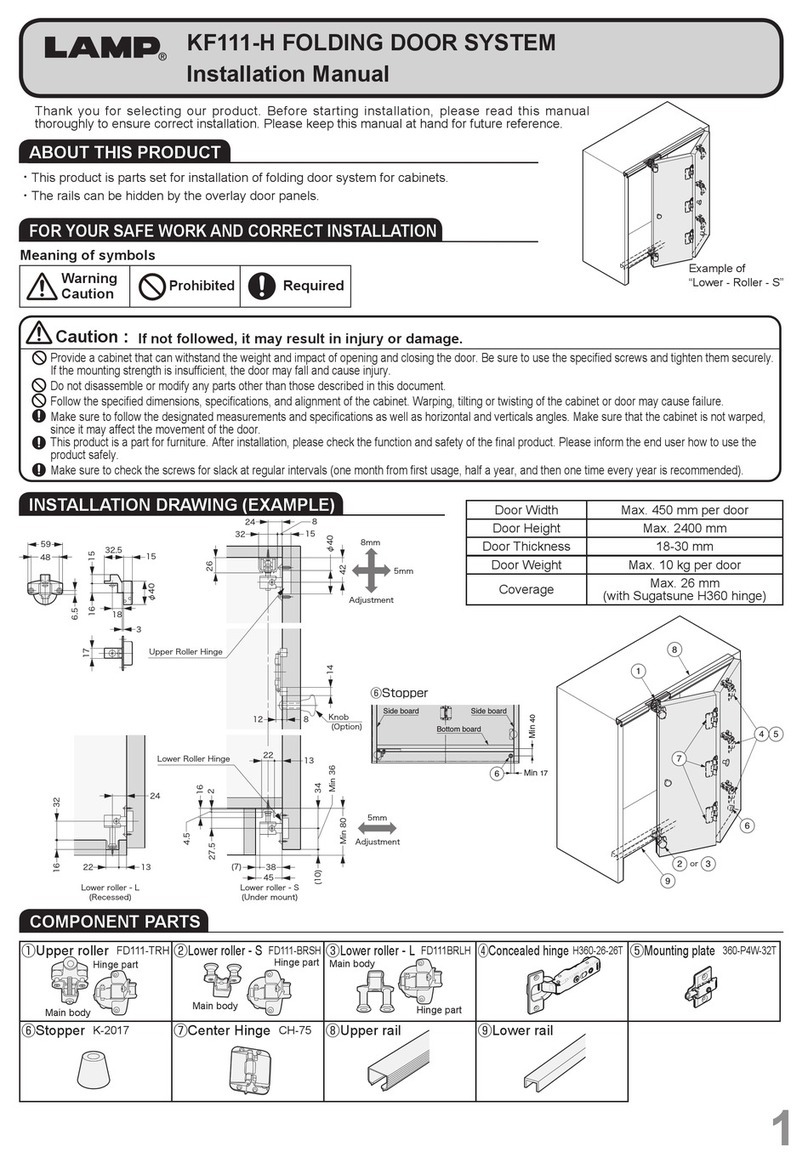

Fig. 1.1

i

Check that the dimensions correspond to the order.

(See delivery note.) AT x HL ; PL

AH, Opening Width =

HV, Beam Height =

Fig. 1.1

1.2 INSTALLATION DIMENSIONS

i

Sp* Overlap between door leaves depending on

frame:

Frame 20,30,35,40 = 40

Frame 44 = 95

i

Dop * Operator deduction depending on frame:

Frame 20,30,35,40 = 100

Frame 44 = 200

Frame SOS 44 = 300

Abr DESCRIPTION FORMULA

HL DOOR CLEAR HEIGHT

PL DOOR CLEAR WIDTH

AT OVERALL OPERATOR WIDTH

HM SLIDING LEAF HEIGHT HM=HL

HF FIXED LEAF HEIGHT HF=HL

AM SLIDING LEAF WIDTH AM=PL/2+Sp

AF FIXED LEAF WIDTH AF=(AH-PL)/2

HV BEAM HEIGHT HV=HL+28

HT OVERALL DOOR HEIGHT HT=HL+125

HR MINIMUM CEILING HEIGHT HR=HT+(5 min)

Dt TOTAL DOOR DEDUCTION Dt=Dop+S1+S2dch+S2izq

S2izq MINIMUM SAFETY DISTANCE HEAD AND BODY AS PER DET 2.4.1

S2dch MINIMUM SAFETY DISTANCE HEAD AND BODY AS PER DET 2.4.1

S1 MINIMUM SAFETY DISTANCE HANDS AND FINGERS AS PER DET 2.4.2

Sp* OVERLAP FIXED LEAF / SLIDING LEAF DEP. ON FRAME

Dop * OPERATOR DEDUCTION DEP. ON FRAME

1.1 LEGEND AND FORMULAE

1. INSTALLATION DIMENSIONS AND CHECKS

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

5

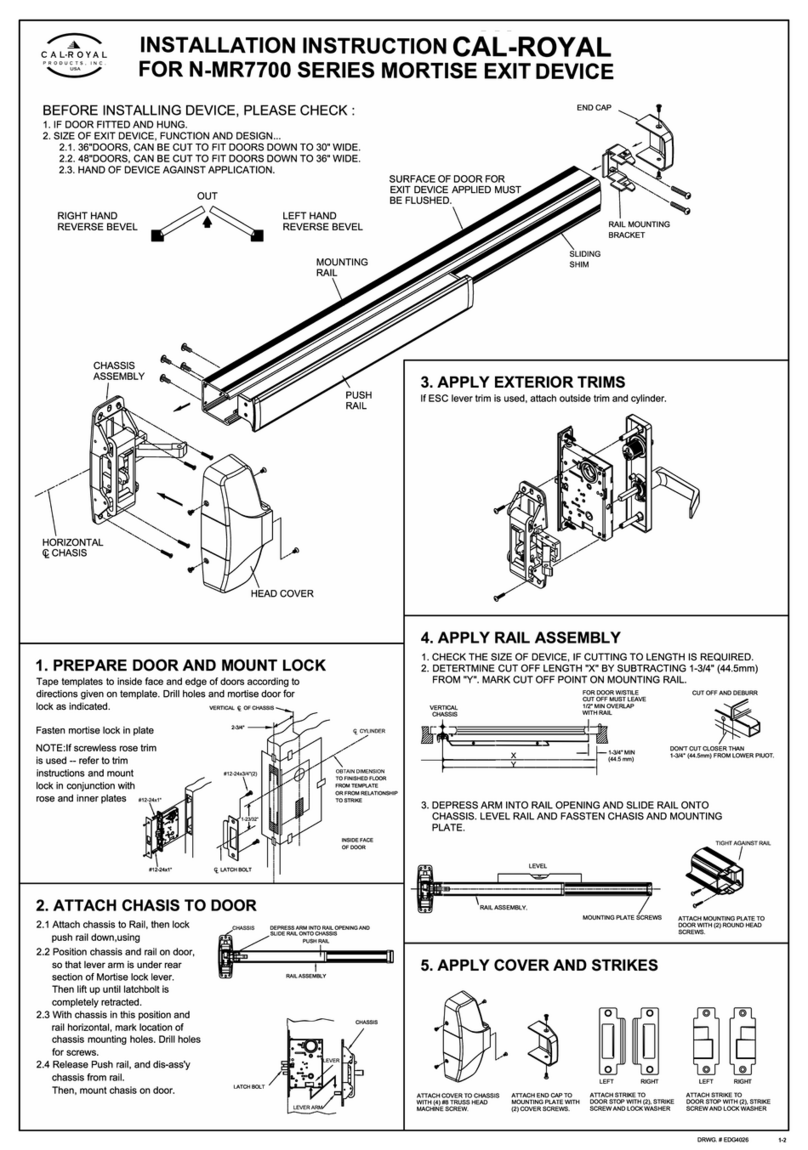

1.4.2

DET

1.2

i

AH Opening width

PL = (AH-Dt)/2 Clear width

AT = PL/2+Dt Overall operator width

AM = PL/2+Sp Sliding leaf width

AF = (AH-PL)/2 Fixed leaf width

1.3

1.4.1

1.4.2

1.4

S2right

S2left

1.4.1

i

S1* Safety distances depending on Frame:

i

S2* Safety distance depends on S as follows: For D20,T20,F20,R20,T35,D35 S1 = 0mm

For E20 S1 = 50mm

For I30 S1 = 55mm

For C44 S1 = 105mm

For S44 S1 = 105mm

If S <250 S2 = 200 mm

If S ≥250 S2 = 500 mm

DET

Fig.

DET

DET

Fig.

Fig.

Fig.

1.3 DOOR DIMENSIONS

1.2

1.3.1 Door width.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

6

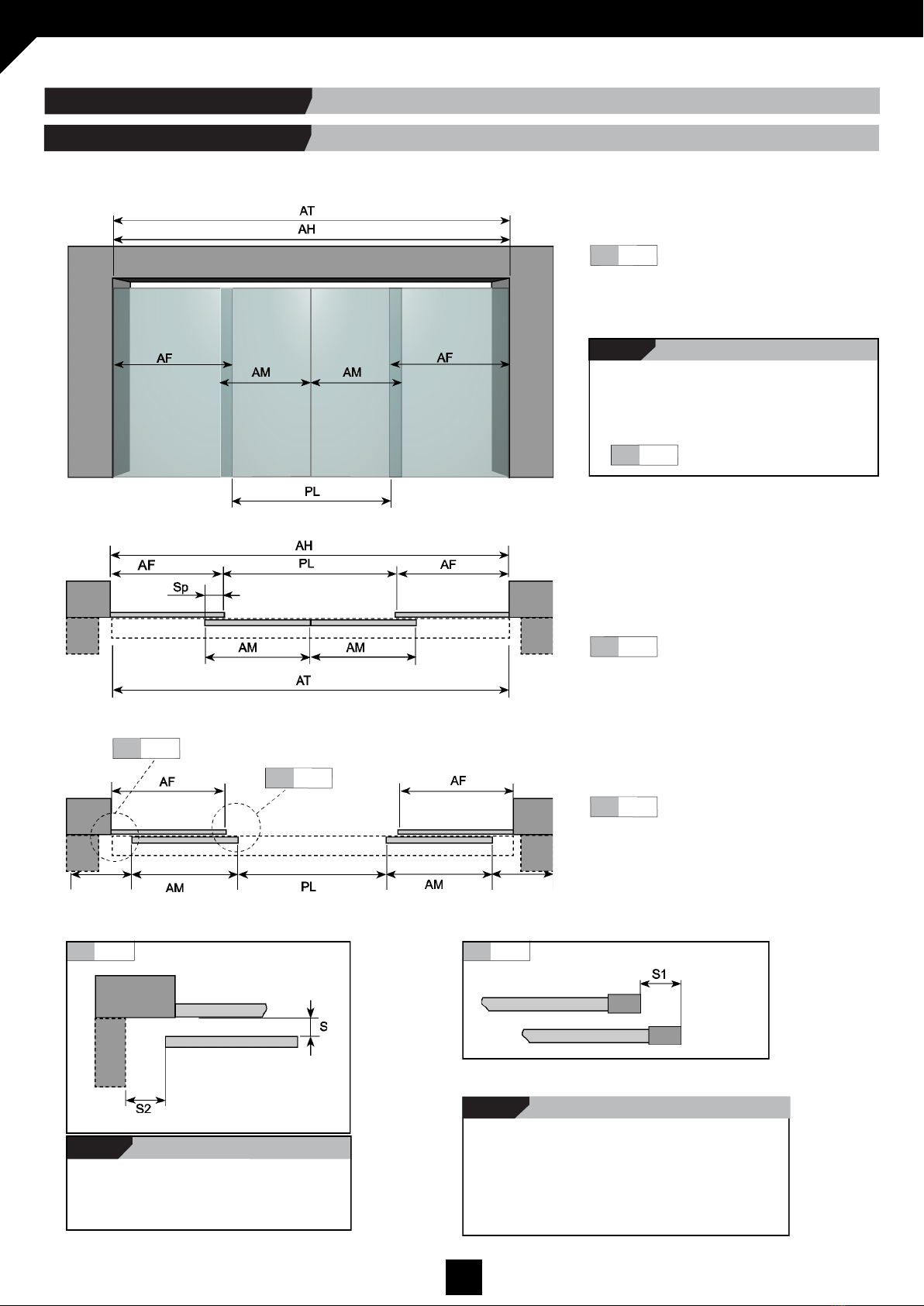

1.6.1

1.5 1.6

Ceiling line

i

HL Door clear height

HT = HL + 125 Overall door height

HR = HT + (5min) Minimum ceiling height

HV = HL + 28 Beam height

1.5 1.6

1.6.1

i

Check the floor level, beam and walls overhang.

FIG 1.7

Check AH for the whole opening as per Fig 2

Check that minimum HV = HL+28 for the whole

opening

1.7

1.8

1.9

5 min

Fig.

Fig.

Fig.

Fig.

Fig.

Fig.

1.4 CHECKS

DET

Fig.Fig.

Fig.

Fig.

DET

1.8

1.9

1.3.2 Door height.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

7

10 mm approx.

i

Keep a distance of 10mm to the right and left of the

main profile.

Fig. 2.5

i

1. Track profile Length = AT-20mm

2. Insulation profile Length = AT-20mm

Fig. 2.4

Fig. 2.5

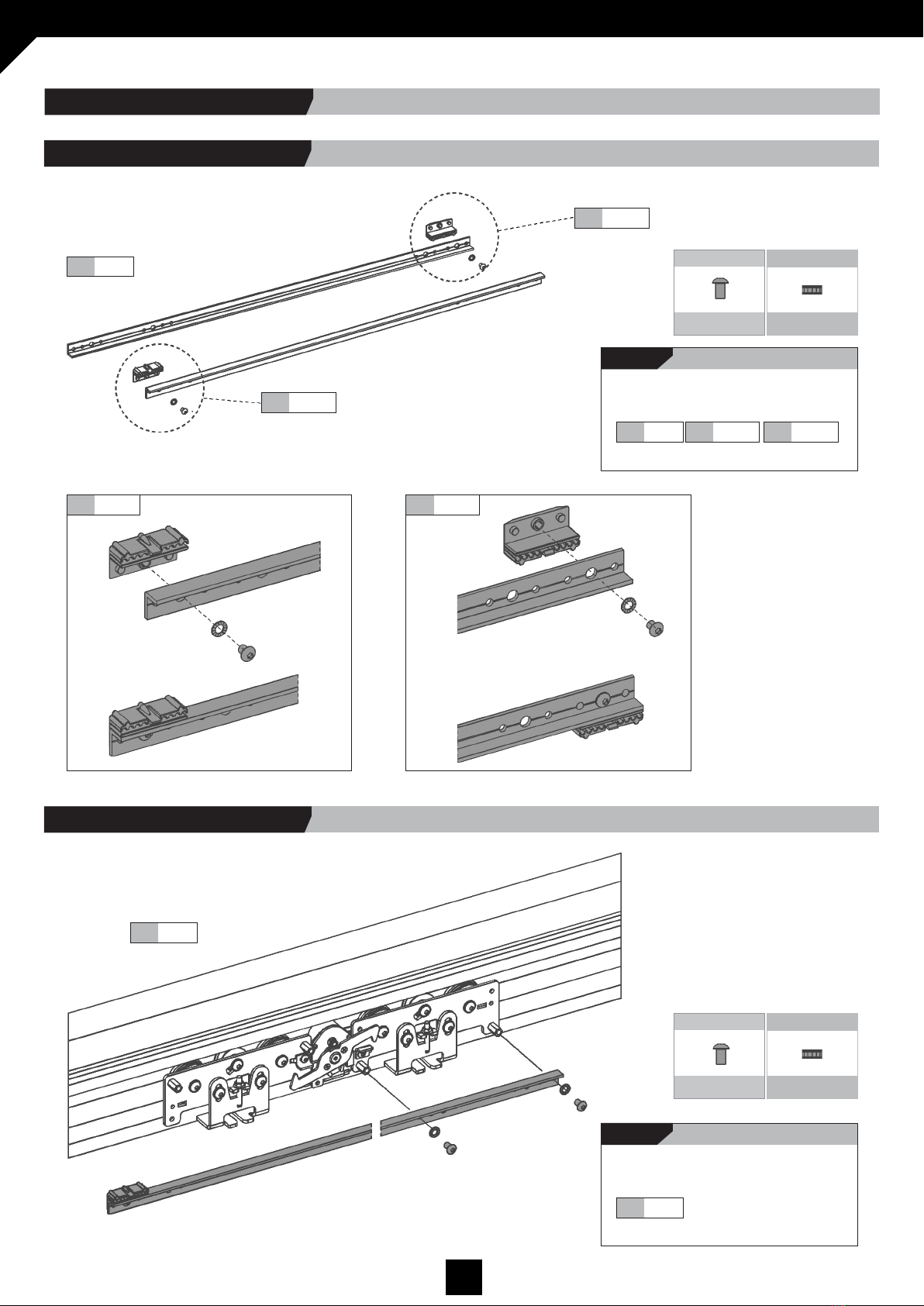

Fig. 2.4

2.2.2 Position.2.2.1 Introduce.

2.2 TARCK PROFILE ASSEMBLY

i

Drill hole size Ø9 along main profile as shown in

diagrams.

Fig. 2.2Fig. 2.1

Tools

Drill bit no.9

Fig. 2.3

Fig. 2.2

Fig. 2.1

Space drill holes

2. PREPARE MAIN PROFILE

2.1 DRILLING

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

8

Fig. 2.8

Fig. 2.7

i

Use a previously assembled trolley as

shown in the diagram.

Adjust the top wheel as shown in diagram.

Introduce the trolley on the top stile as

shown in diagram.

Slide the trolley along the whole length of

the main profile as shown in the diagrams.

Use a hand to help position the track rail.

Fig. 2.8

Fig. 2.7

Fig. 2.6

Fig. 2.6

Fig. 2.6

2.3 ADJUST TRACK PROFILE

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

9

Reference vertical

Nuts & bolts

DIN7504N

i

Make marks in the top lintel as shown in

the diagram.

Self thread top lintel to the UPN beam x10

self-threading screws placed at equal

intervals along the length of the beam, as

shown in the diagrams.

Fig. 3.3Fig. 3.3

Fig. 3.2

Fig. 3.4

Fig. 3.3Fig. 3.2

Fig. 3.1

i

Set out the sections as shown in the diagram.

Fig. 3.1

3.1 PROFILES LAYOUT

3. MAIN PROFILE AND TOP LINTEL ASSEMBLY

3.2 TOP LINTEL ASSEMBLY

3.2.1 Mark and screw.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

10

Reference vertical

Fig. 3.10Fig. 3.9

i

Screw main profile to the UPN as shown in the

diagrams.

Fig. 3.10Fig. 3.9

Nuts & bolts Nuts & bolts

DIN6923 M8 SO7380 M8×20

i

Drill where marked along the length of the UPN at Ø8,

as shown in the diagrams.

Fig. 3.8Fig. 3.7

Herrramientas

Drill Ø8

Fig. 3.8Fig. 3.7

Fig. 3.5

i

Drill holes in the beam using the main profile

as template, as shown in the diagrams.

Fig. 3.6Fig. 3.5

Fig. 3.6

3.3.2 Drill.

3.3.1 Introduce and mark.

3.3.3 Screw.

3.3 MAIN PROFILE ASSEMBLY

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

11

Woodw. E20 Woodw. D35 Woodw. 40 Woodw. I30 Woodw. 44

i

Drill sections A,A’, as shown in the

diagram.

See table for different frame

dimensions.

Fig. 4.3

Fig. 4.3

Tools

Drill bit no. 8’5/5

i

Cut the bottom lintel as shown in the diagram.

Fig. 4.2

Fig. 4.1

Fig. 4.2

4.1 MOUNT LOWER LINTEL

4. BOTTOM LINTEL PREPARATION

4.1.1 Cut.

4.1.2 Drill.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

12

Woodw. E20 Woodw. D35 Woodw. I30 Woodw. 40 Woodw. 44

Nuts & bolts

DIN6923 M8

i

Screw the bottom lintel to the fixed leaves as shown in the diagrams.

Leave 40mm in the PL part of the door leaves.

Check table for different frame dimensions.

Fig. 4.4

Fig. 4.4

4.1.3 Screw.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

13

Variable depending on

frame dimensions

Reference vertical

Reference vertical

Reference vertical

Reference vertical

Reference vertical

Reference vertical

Woodw. E20 Woodw. D35 Woodw. I30 Woodw. 40 Woodw. 44

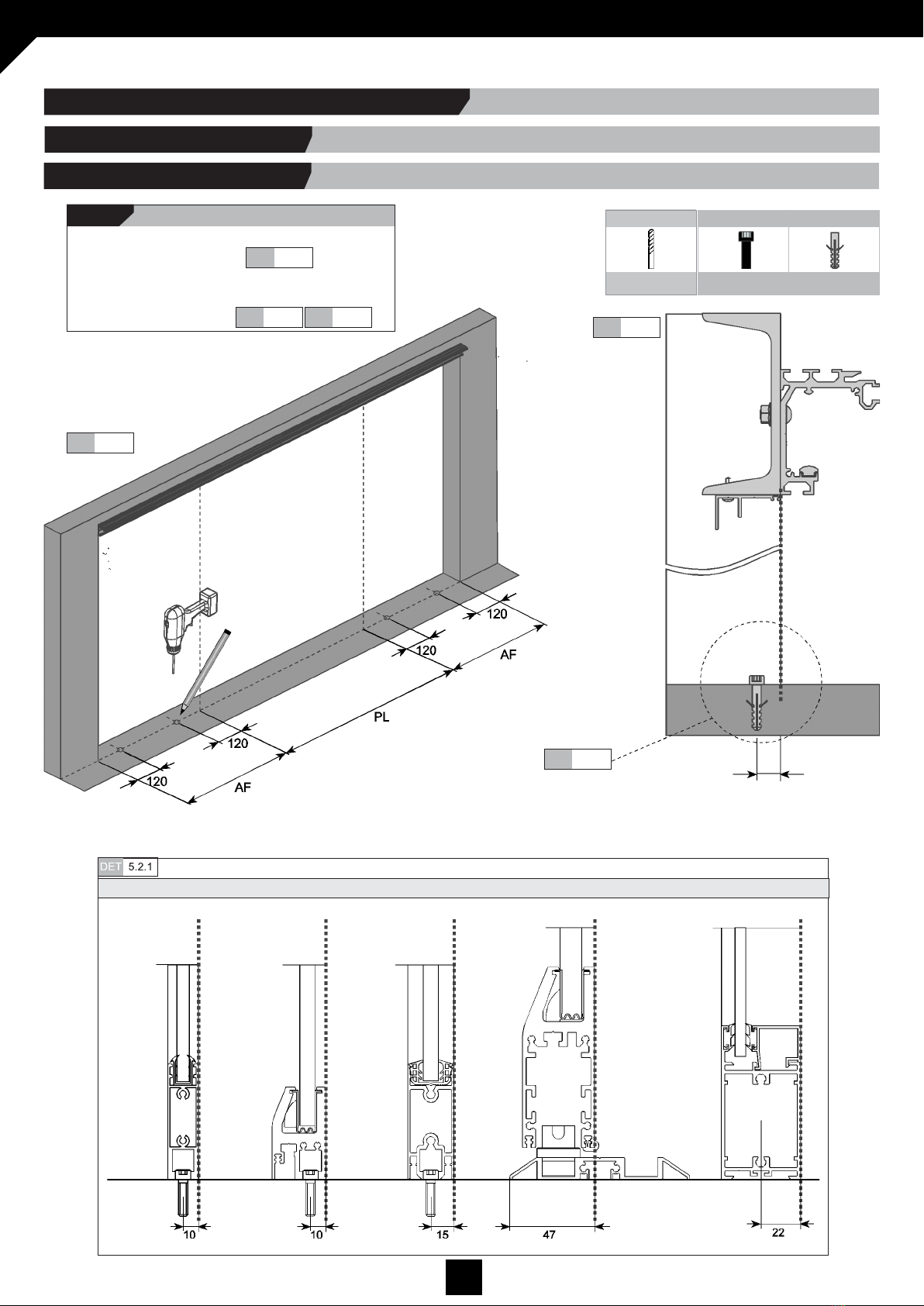

DET 5.2.1

Fig. 5.1

Fig. 5.2

i

Mark and drill the floor on the inside of the AT in

accordance with dimensions.

Mark and drill with respect to the reference vertical,

according to frame dimensions.

Fig. 5.2 DET 5.2.1

Fig. 5.1

Tools Nuts & bolts Nuts & bolts

Drill bit no. 6 DIN912 6x20 Rawlplug S-6

5.1 MOUNT FIXED LEAVES

5. FIXED LEAVES / BOTTOM LINTEL (PL) ASSEMBLY

5.1.1 Drill.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

14

Fig. 5.6

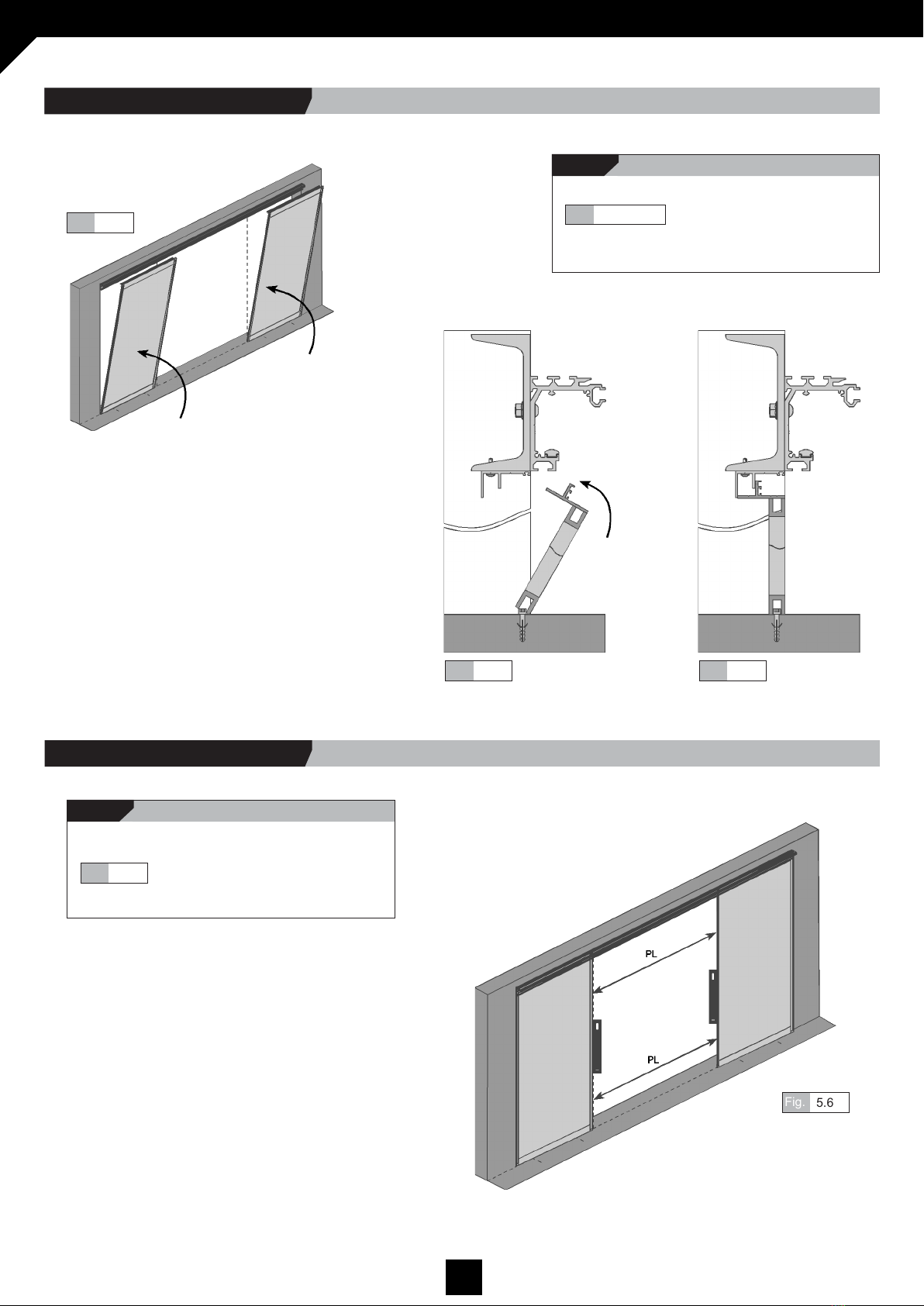

i

Check door leaves (PL) are parallel throughout the

clear height.

Fig. 5.6

Fig. 5.5

Fig. 5.4

Fig. 5.3

i

Position the fi xed leaves as shown in the diagrams.

Fig. 5.3/5.4/5.5

5.1.2 Position fixed leaves.

5.1.3 Check for plumb.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

15

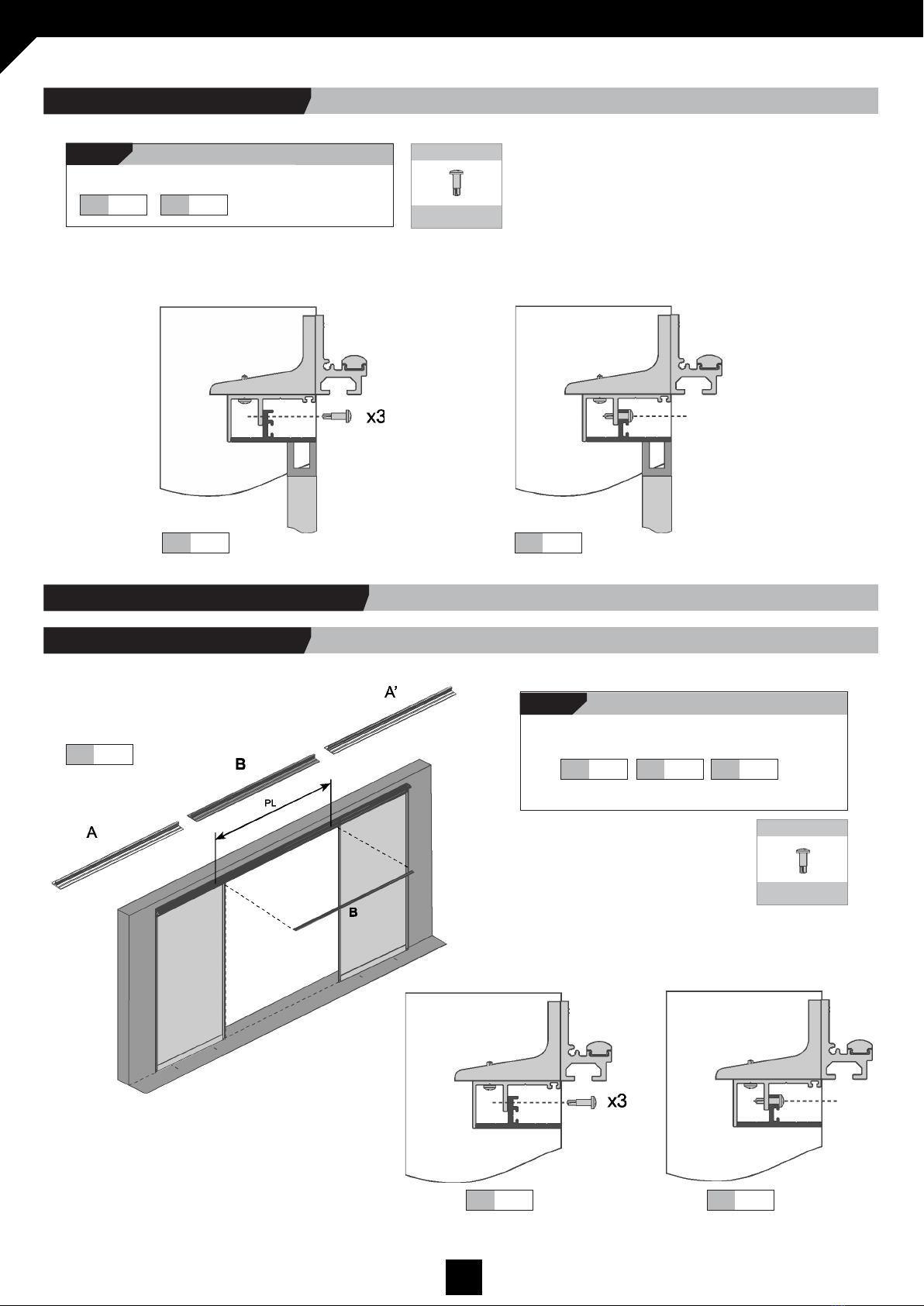

Fig. 5.11

Fig. 5.10

Nuts & bolts

D-7504N 4,2x16

Fig. 5.9 Fig. 5.11

Fig. 5.10

Fig. 5.9

Fig. 5.8

Fig. 5.7

Nuts & bolts

D-7504N 4,2x16

i

Screw (x3) fi xed leaves to top lintel.

Fig. 5.8

Fig. 5.7

i

Screw (x3) bottom lintel (PL) to top lintel.

5.2 BOTTOM LINTEL (PL) ASSEMBLY

5.1.4 Screw.

5.2.1 Screw.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

16

i

Insert 4 nuts distributed in the AT as shown in

the diagram.

Insert the nuts in the bottom channel of the main

profile.

6.2

6.1

6.3 6.4

i

Introduce lateral end stops and screws/nuts

into main profile. 6.3

Position stops at the two ends of the main

profile. 6.4

Screw to the nut inside the channel, and tighten

the screw over the track rail.

6.5

6.6

DIN7380 6x10 DIN6798 M-6DIN933 6x12

Fig.

Nuts & bolts Nuts & bolts Nuts & bolts

Fig.

Fig.

Fig.

Fig.Fig.Fig.

Fig.

Fig.

Fig.

Fig. 6.1

6.2

6.5

6.1 LATERAL STOPS ASSEMBLY

6. LATERAL STOPS / LOCK ASSEMBLY

6.1.1 Insert nuts into beam.

6.1.2 Lateral stops assembly.

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

17

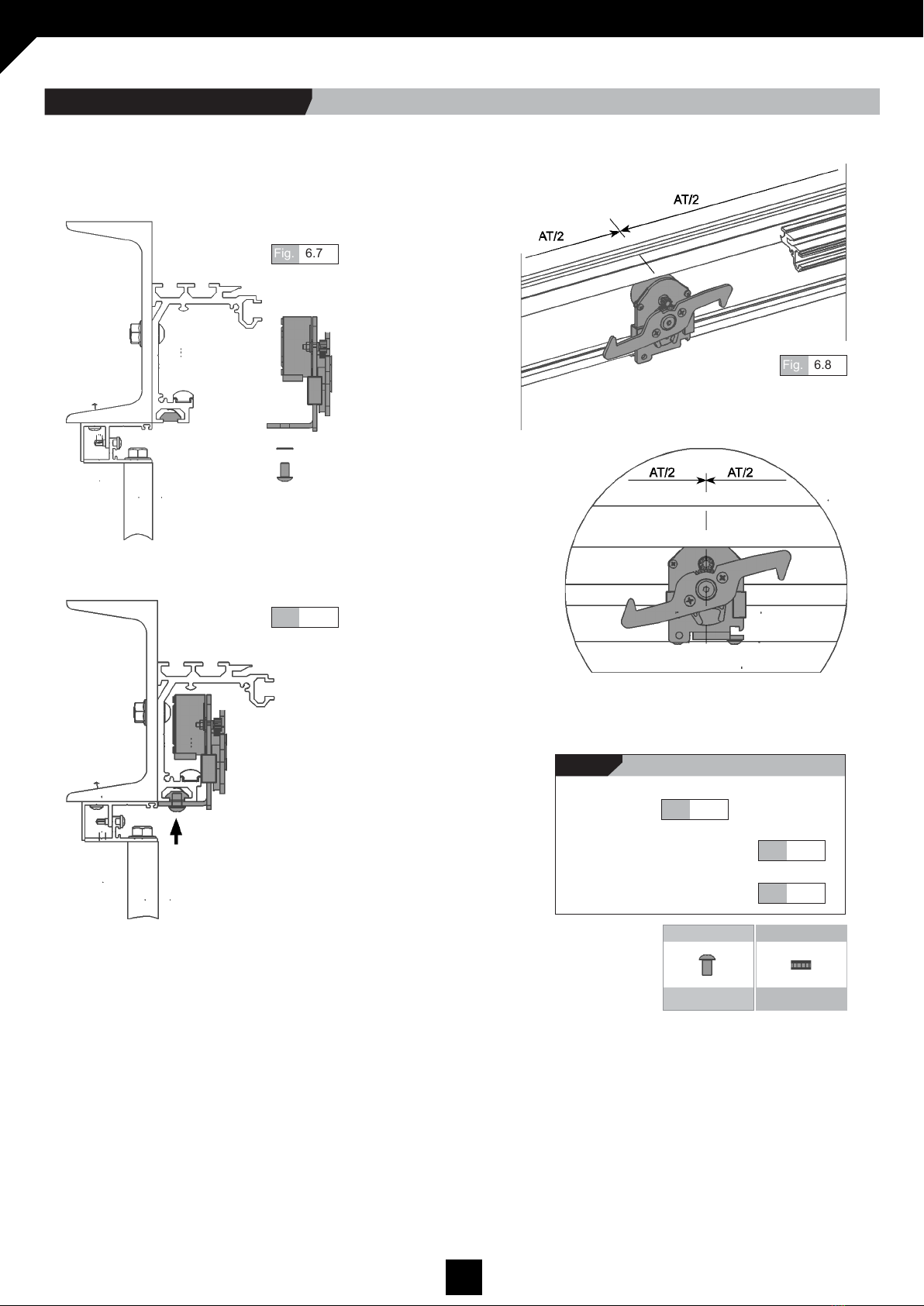

Nuts & bolts Nuts & bolts

DIN7380 6x10 DIN6798 M-6

Fig. 6.9

Fig. 6.8

Fig. 6.7

Fig. 6.9

Fig. 6.8

Fig. 6.7

i

Introduce lock and screws/nuts into centre of

main profile.

Position the lock at AT/2.

Screw nuts inside channel.

6.2 CENTRAL LOCK ASSEMBLY

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

18

i

Screw separators to trolleys 2-3 accor-

ding to the layout shown in the diagrams.

Fig. 7.3 Fig. 7.4

Fig. 7.4 Nuts & bolts

D6334 M6x18

Nuts & bolts

PFH M6x10

Fig. 7.3

i

See the distribution of trolleys as per the scheme shown in

the diagram.

For ease of assembly number them 1 to 4. Fig. 7.2

Fig. 7.1

Fig. 7.2

Fig. 7.1

7.1.1 Distribute the trolleys in the operator

7. DRAGGING TROLLEYS / ARMS ASSEMBLY

7.1 TROLLEYS ASSEMBLY

7.1.2 Separators on trolleys assembly

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

19

Fig. 7.9

DET 7.9.1

DET 7.9.1

Fig. 7.8

Fig. 7.7

i

Introduce the 4 trolleys into the main

profile as shown in the diagrams.

Adjust the top wheel in the 4 trolleys

as shown in the diagrams.

Fig. 7.9 DET 7.9.1

Fig. 7.7 Fig. 7.8

i

Attach lock hooks to trolleys 2-3 as

shown in the diagrams.

Fig. 7.5 Fig. 7.6

Fig. 7.6

Tools Nuts & bolts

DIN7380 6x10 DIN6798 M-6

Fig. 7.5

7.1.3 Lock hooks assembly.

7.2 INTRODUCE TROLLEYS INTO MAIN PROFILE

DMJOIC201EN - v2 VISIO C2H OPERATOR - INSTALLATION MANUAL

20

i

Screw right hand arm to right hand

trolley (3) as shown in the diagram.

Fig. 7.11

Nuts & bolts Nuts & bolts

DIN7380 6x10 DIN6798 M-6

Fig. 7.11

DET 7.10.1DET 7.10.2

DET 7.10.2

i

Screw anchors to arms as shown

in diagram.

Fig. 7.10 DET 7.10.1 DET 7.10.2

Fig. 7.10 Nuts & bolts Nuts & bolts

DIN7380 6x8 DIN6798 M-6

DET 7.10.1

7.3 DRAGGING ARMS ASSEMBLY

7.3.1 Anchors and arms assembly.

7.3.2 Arms on trolleys assembly.

Table of contents

Other Manusa Door Opening System manuals