Manusa Op. Visio L1H User manual

Table of contents

Other Manusa Door Opening System manuals

Popular Door Opening System manuals by other brands

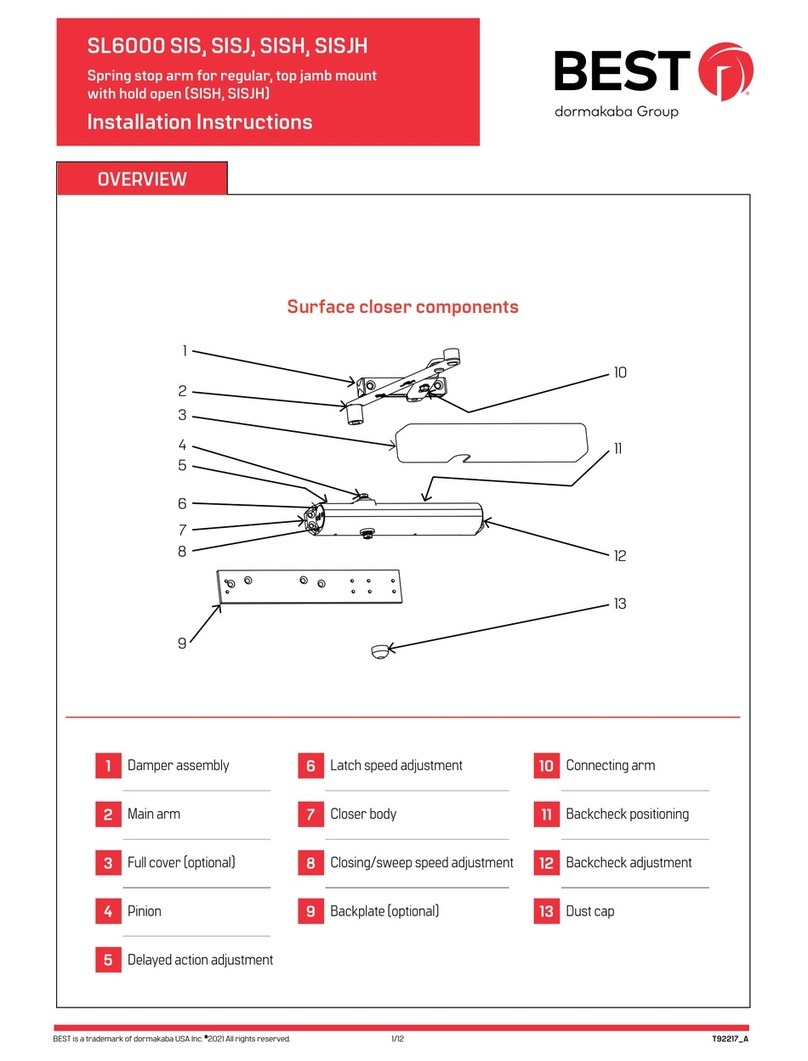

Dormakaba

Dormakaba Best SL6000 SIS installation instructions

CAMDEN

CAMDEN CM-550SK-V2 installation instructions

Assa Abloy

Assa Abloy Yale 6000 Series parts manual

GEZE

GEZE TSA 325 NT Translation of the original instructions

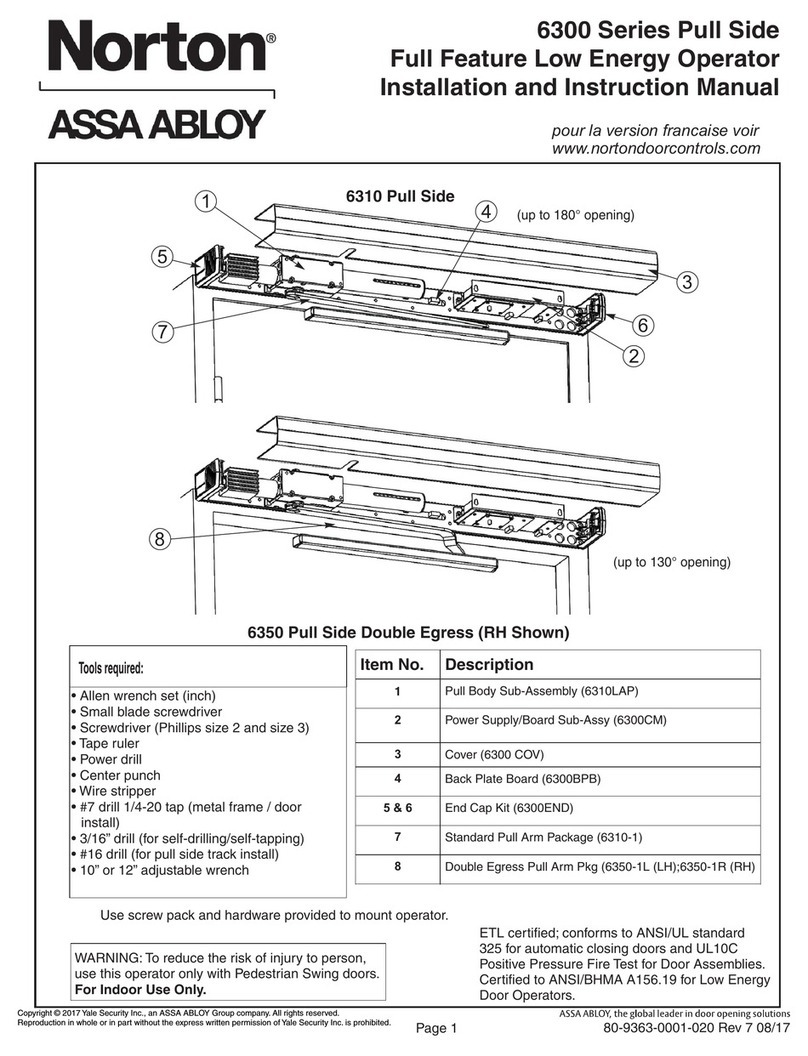

Assa Abloy

Assa Abloy Norton 6300 Series Installation and instruction manual

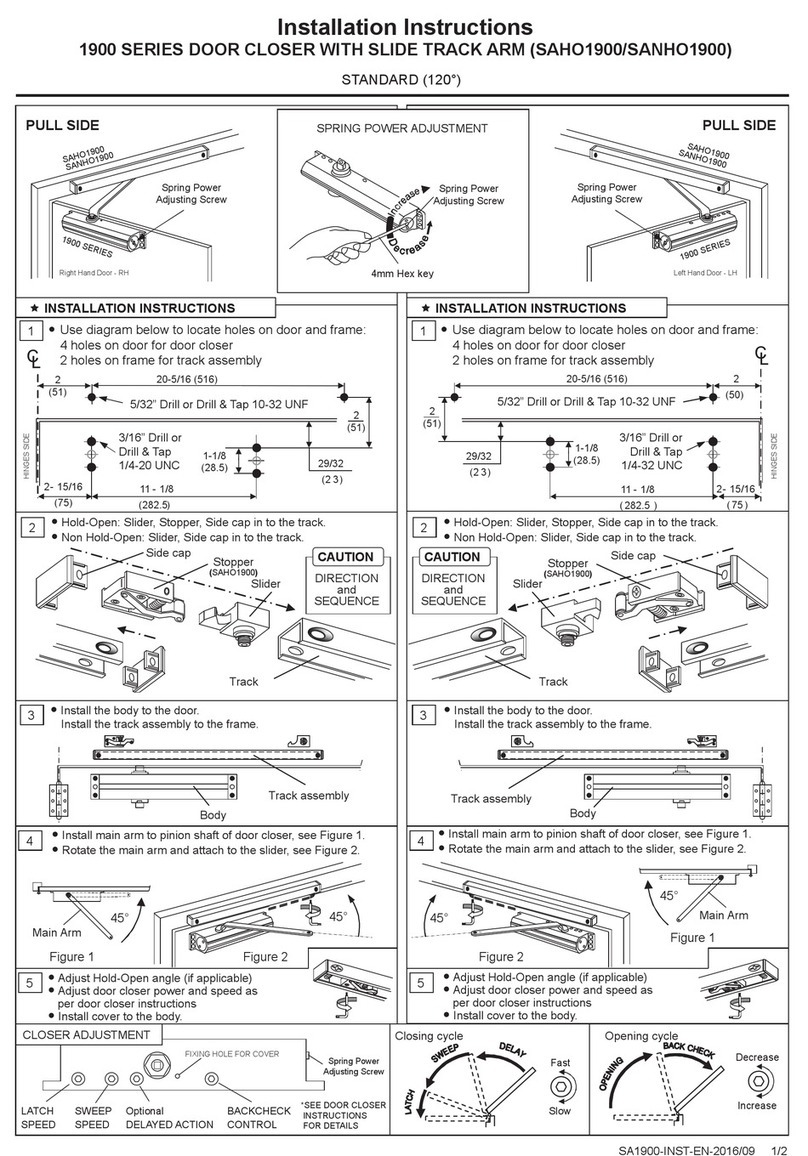

Canaropa

Canaropa 1900 Series installation instructions

DITEC

DITEC DAS107 Technical manual

SEA

SEA Saturn 600 Mounting and Connecting Instructions

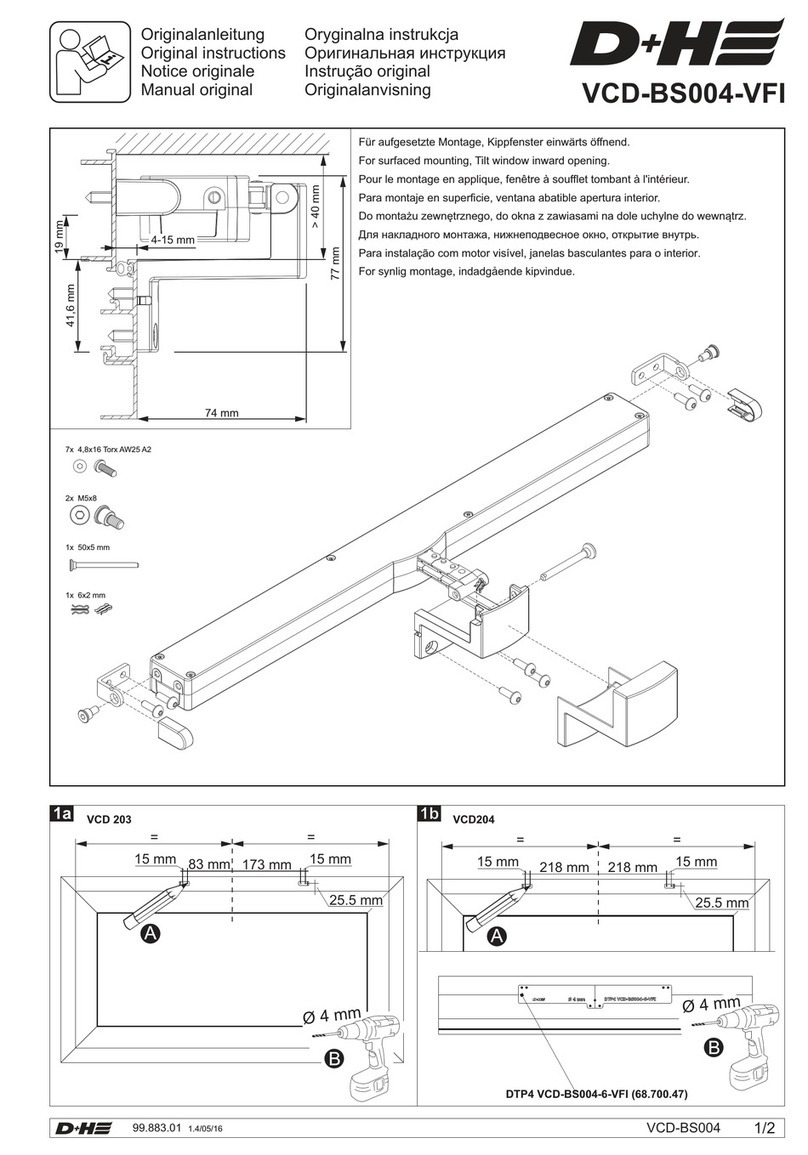

D+H

D+H VCD-BS004-VFI Original instructions

hager

hager 5400 Series installation instructions

MEILLER

MEILLER MiDRIVE twinCAN Installation instruction

Assa Abloy

Assa Abloy Norton 6300 Pull Side Series Installation and instruction manual

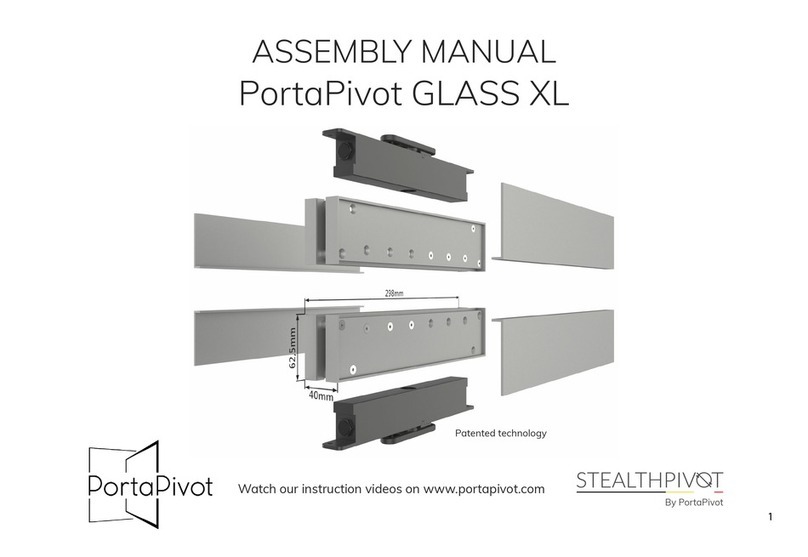

PortaPivot

PortaPivot StealthPivot XL Assembly manual

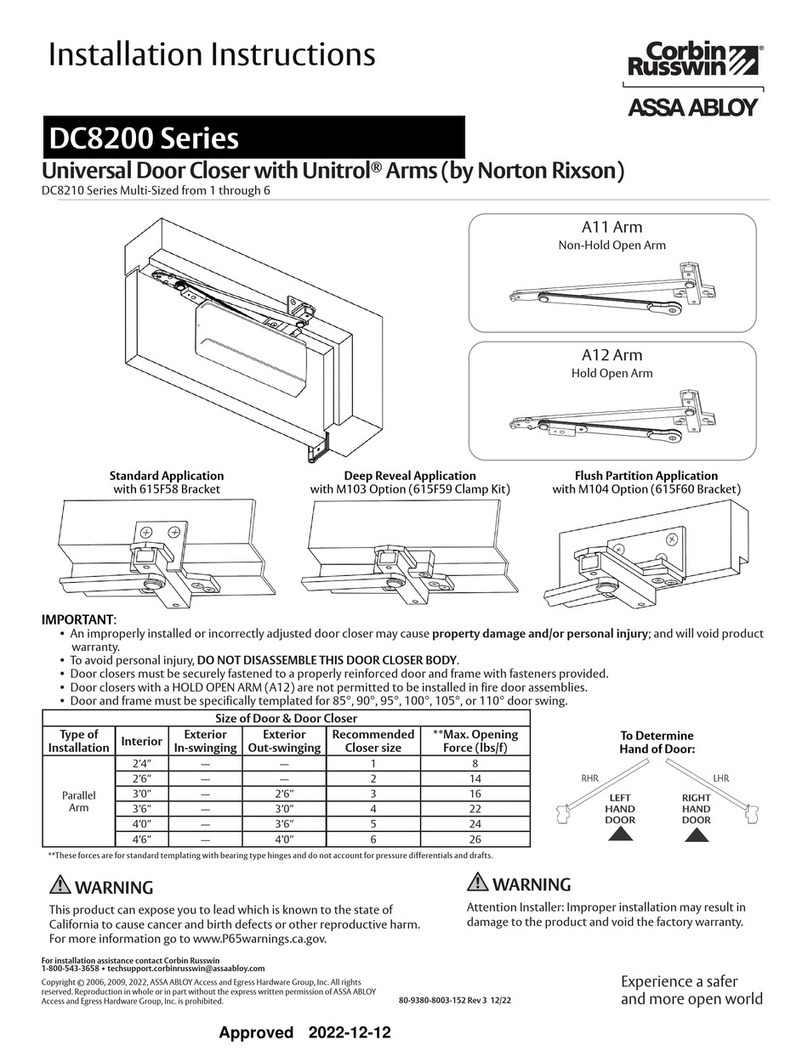

Assa Abloy

Assa Abloy Corbin Russwin DC8200 Series installation instructions

Verkada

Verkada AC62 install guide

Automatic Technology

Automatic Technology GDO-8 ShedMaster instruction manual

Ingersoll-Rand

Ingersoll-Rand Von Duprin XP98 Series installation instructions

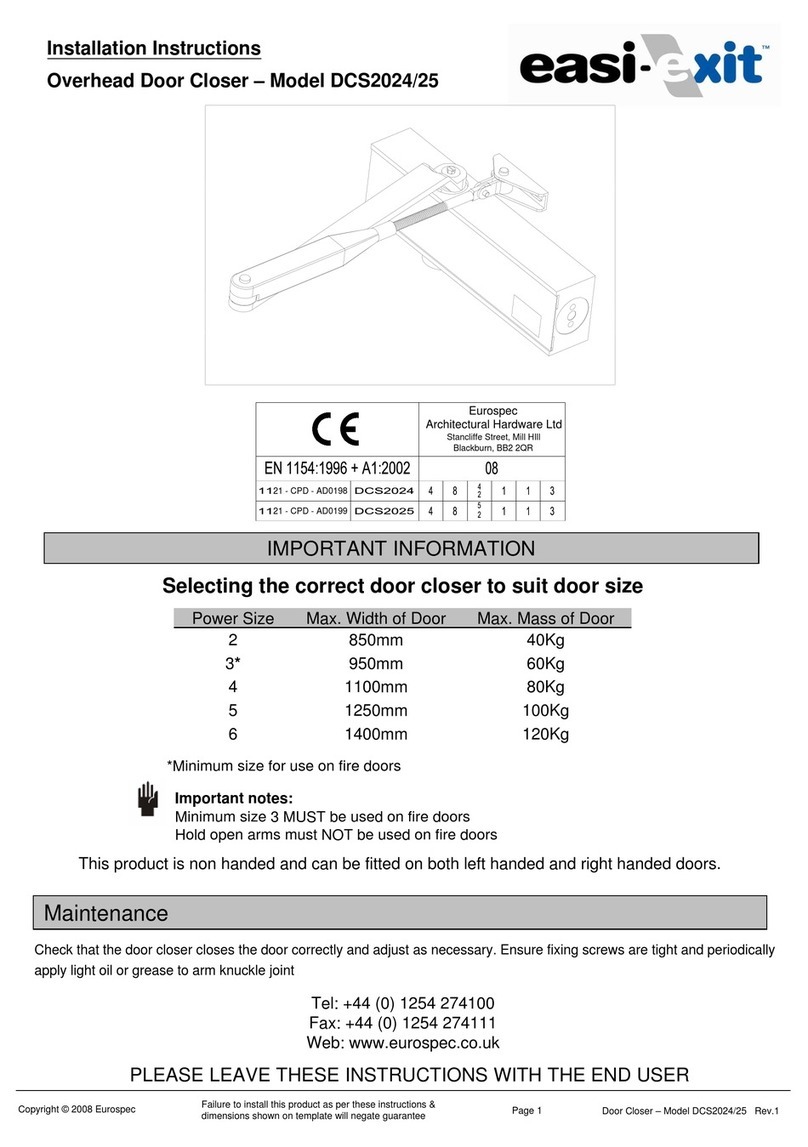

Easi-Exit

Easi-Exit DCS2024 installation instructions