Maple Systems Silver Plus Series User manual

Installation and

Operation Manual

1010-1007 Rev. 05

808 134th Street SW, Suite 120

Everett, WA 98204, USA

Phone: 425.745.3229

Fax: 425.745.3429

Email:

Web:

www.maplesystems.com

COPYRIGHT NOTICE

This manual is a publication of Maple Systems, Inc., and is provided for use by its customers only. The contents of the

manual are copyrighted by Maple Systems, Inc.; reproduction in whole or in part, for use other than in support of Maple

Systems equipment, is prohibited without the specific written permission of Maple Systems.

WARRANTY

Maple Systems warrants each product to be free from electrical and mechanical defects in materials and workmanship for a

period of two years from the date of shipment. This warranty does not apply to defects in the Products caused by abuse,

misuse, accident, casualty, alteration, negligence, repair not authorized by Maple Systems, use on current or voltages other

than specified by Maple Systems, or application or installation not in accordance with published instruction manuals. This

warranty is in lieu of any other warranty either expressed or implied.

Maple Systems’ liability is limited to the repair or replacement of the Product only, and not costs of installation, removal, or

damage to user’s property or other liabilities. If Maple Systems is unable to repair or replace a nonconforming Product, it

may offer a refund of the amount paid to Maple Systems for such Product in full satisfaction of its warranty obligation.

Maximum liability of Maple Systems is the cost of the Product.

Information furnished by Maple Systems, Inc., is believed to be accurate and reliable. However, no responsibility is assumed

by Maple Systems for the use of this information nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication, or otherwise, under any patent or patent rights of Maple

Systems, Inc. Maple Systems retains the right to revise or change its products and documentation at any time without notice.

IF SERVICE IS REQUIRED

Package the unit in its original packaging container or, if unavailable, any suitable rigid container. If a substitute container is

used, surround the unit with shock absorbing material; damage in shipment is not covered by the warranty. Include a letter

with the unit describing the difficulty and designating a contact person. Send to the following address: Maple Systems, Inc.,

808 134th Street SW, Suite 120, Everett, WA 98204-7333.

Only Products that have been issued a Return Material Authorization (RMA) number from Maple Systems may be returned.

All RMAs must be accompanied with a written purchase order for tracking purposes or, in the case of out-of-warranty

repairs, for repair charges on a time and material basis.

All returns will be tested to verify customer claims of noncompliance with the product warranty. Improper return packaging,

which makes verification impossible, will void the warranty. Products passing the tests will be returned “AS IS” to the

customer.

If noncompliance is verified and is not due to customer abuse or the other exceptions described with product warranty, Maple

Systems will, at its option, repair or replace the Product returned to it, freight prepaid, which fail to comply with the

foregoing warranty, provided Maple Systems is notified of such noncompliance within the two-year warranty period.

APPLICATIONS ASSISTANCE

This manual is designed to provide the necessary information for trouble-free installation and operation of your new Operator

Interface Terminal (OIT). However, if you need assistance, please call Maple Systems at 425-745-3229 or visit our web site

at www.maplesystems.com.

Table of Contents

EZware-5000 Support ..............1

OIT Models Supported ...........1

PLCs Supported ................1

About Your Documentation ..........1

Conventions...................1

What You Need ................2

OIT Basics .......................2

What is a Silver Plus Series OIT? ...4

List of Features.................5

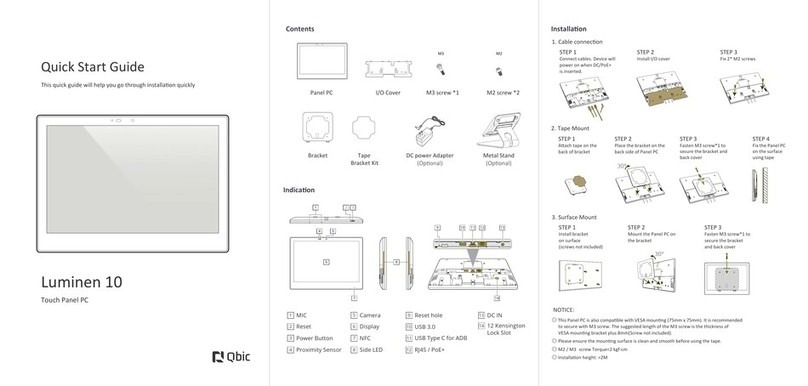

Chapter 1 - Installation of OITs ............7

Unpacking the Unit .............7

Managing Electrostatic Discharge ...7

CE Compliance ................7

NEMA Rating ..................7

Environmental Considerations .....7

Safety Precautions ..............8

Control Panel Design Guidelines ......8

Control Panel Grounding .........9

Connect OIT Chassis Ground to Control

Panel ........................9

Power Supply Selection ..........11

Cable Routing and Noise Immunity .11

Installation.......................12

Connect the OIT to Power ........12

Panel Preparation ..............14

Mount the OIT to the Panel .......14

Configuration Wiring ...............15

Connect the OIT to the PC for

Configuration..................15

Chapter 2 - OIT Local Setup...............17

Factory Configuration...............17

Calibrating the Touchscreen.......17

Getting into Local Setup ..........17

Changing the System Settings .....18

Viewing System Information ....22

Transferring Projects and Data from

USB/CompactFlash .............23

Chapter 3 - Connect the OIT to the PLC or

Controller ............................25

COM Ports for the

HMI5080/HMI5104/HMI5121 .....26

COM Ports for the HMI5056.......27

Connecting to COM1 and COM3 on

Port A .......................28

Connecting to COM1 and COM2 on

Port B........................32

Connecting multiple PLC/controllers

serially using daisy chaining .......33

Connecting one or more PLC/controllers

via Ethernet ...................33

Chapter 4 - Creating Your First Project ......35

Before You Begin ..................35

Connecting OIT to Computer .........35

Starting EZware-5000 ..............35

Creating a Sample Project ...........36

Setting the System Parameters .....36

Creating a Popup Window ........40

Creating a Startup Window .......48

Finishing Up......................54

Chapter 5 - Simulator Mode ..............57

The Simulation Screen ..............57

Chapter 6 - Using EZware-5000 ...........59

Overview ........................59

The Project Manager ...............59

Communications & Password Settings60

Editor Settings .................61

Transfer Settings ...............61

Simulation Settings .............61

The EasyBuilder Application ..........63

Managing Projects ..............64

Editing and Creating Screen Objects 67

General Settings ...............85

The EasyPrinter Utility............98

Automatically Reboot OIT............98

Save and Compile the Project.........99

Chapter 7 - Creating Windows ............101

Window Fundamentals..............101

Opening a Window .............101

Creating a New Window .........102

Assigning Underlay Windows ......106

How to Display Underlay Windows..107

Rules That Apply to Underlay

Windows .....................107

Deleting a Window .............108

Using Base Windows ...............108

How to Display Base Windows .....108

Using the Common Window..........114

Changing the Active Common

Window ......................117

Using the Fast Selection Window ......118

Using the Fast Selection Key.......120

Changing screens using the Fast

Selection window ...............121

System Message Window .........123

Chapter 8 - Creating Graphic Objects .......125

Drawing Objects ..................125

Using the Drawing Tools .........125

Using Text ....................129

Predefined Shapes and Pictures .......131

Using a Predefined Shape ........131

Using a Predefined Picture ........133

Graphics Libraries .................135

What are ‘states’? ..............135

Using Shape Libraries ...........135

Using Picture Libraries ...........139

Using Group Libraries ...........142

Using Sound Libraries ...........145

Chapter 9 - Creating and Using Databases and

Languages ............................149

Creating and Using the Tag Library ....149

Importing and Exporting the Tag

Library ....................150

Using the Tag Library .........150

Creating the Label Library ...........151

Setting Different Fonts for Different

Languages .................153

Importing and Exporting the Label

Library ....................154

Using the Label Library..............154

Using Languages with the Label

Library ....................155

Chapter 10 - Representing Data with Graphics

Objects...............................157

Using Internal Data Memory of OIT ....157

Representing PLC Coil Registers .......165

The Bit Lamp Object..........165

The Set Bit Object ...........169

The Toggle Switch Object ......170

Representing PLC Data Registers ......172

The Word Lamp Object .......172

The Set Word Object .........175

The Slider Object ............176

The MultiState Switch Object ...179

The Numeric Display Object ....181

The Numeric Input Object .....184

The ASCII Display Object ......188

The ASCII Input Object........189

The Moving Shape Object .....190

The Data Block Display Object ..193

The Animation Object ........197

The XY Plot Object ...........199

Chapter 11 - Using and Creating Keypads ...205

How to Create a Keypad ............205

Displaying and Using a Keypad .......206

Chapter 12 - Bar Graphs, Meters and Trends . 209

Creating Bar Graphs ...............209

Creating Meter Displays .............211

Creating Trend Displays & Data Sampling

Objects .........................214

History Data Display Part ......218

Chapter 13 - Capturing Alarms and Events ...223

Using Alarms .....................223

Monitoring Alarms with the Alarm/Event

Log ............................223

Displaying Alarms using the Alarm Display

Object ..........................225

Displaying Alarms using the Alarm Bar

Object ....................226

Using Events ...............227

Monitoring Events With the Event Log

Object ....................227

Displaying Events Using the Event

Display Object ..............228

Chapter 14 - Data and Recipe Transfer Objects231

Using the Data Transfer Object .......231

Using the Recipe Transfer (Data Transfer, Trig-

ger Based) Object .................232

Creating a Recipe............233

Backup Part ................234

Chapter 15 - Macros ....................237

Using Macros ....................237

Macro Sample and

Implementation ............237

Variables, Declarations and Memory

Usage ..........................239

Memory Usage: ............239

Variable Declarations.........240

Variable Initialization .........240

Array initialization ...........241

Reserved Words .............241

Operator ..................241

Order of Precedence .........242

Main Functions and Sub-

functions ..................242

Local and Global Variables ....242

Creating Variable Arrays ......243

Using Macros Within Recipes ...243

Statements, Conditions &

Expressions ................244

Function Calls and Passing Parame-

ters ......................246

Reading & Writing External Registers

in a Macro .................246

Precautions, Tips & Tricks when Using

Macros ...................248

Compiler Errors & Error Codes ........248

1010-1007, Rev 05

ii Silver Plus Series Installation & Operation Manual

Introduction - Welcome

Welcome to the Maple Systems’ Silver Plus Series Operator Interface Terminals (OITs). Using graphic OITs has never been

easier. This powerful family of graphics operator interface terminals connects to programmable logic controllers (PLCs) to

provide the human-machine interface in industrial applications. The Silver Plus Series has several features not found in other

graphic OITs. This manual explains the operation of the Silver Plus Series OITs and how to implement the many available

features using the EZware-5000 Configuration Software.

EZware-5000 Support

OIT Models Supported

For the latest list of Silver Plus Series Models supported by EZware-5000, please visit our website at

www.maplesystems.com.

PLCs Supported

For the latest list of PLCs and controllers supported by the Silver Plus Series OITs, please visit our website.

About Your Documentation

Maple Systems provides many resources to allow you to get the most out of your Silver Plus Series OIT.

·Silver Plus Series Operation Manual (shipped with EZware-5000 as a PDF file) - describes installation, general

operation and features of the Silver Plus Series using EZware-5000 configuration software.

·Controller Information Sheets - important information specific to each supported protocol.

·EZware-5000 On-line Help - covers the operation of EZware-5000. Always available by clicking HelpTopics from

the Help menu in EasyBuilder, or press F1 from any dialog.

For more information about these and other training sources, visit the Maple Systems website.

Conventions

When using EZware-5000, there are usually several ways to perform a task. For example, if you want to copy a graphics

object, you can:

·Click the Copy command on the Edit menu.

·Click the Copy button on the Standard toolbar.

·Press the CTRL + C keys on your computer.

1010-1007, Rev 05

Introduction 1

In most cases, we will describe each method when the task is first discussed. The menu method is then used whenever the

task is used in later procedures. Other conventions used in this manual are listed in the following table.

Convention Meaning

Bold Characters that you must type exactly as they appear. For example, if you are directed to type a:\setup,

you should type all the bold characters exactly as they are printed.

Italic

Placeholders for information you must provide. For example, if you are directed to type filename, you

should type the actual name for a file instead of the word shown in italic type. Italics are also used to

indicate a glossary term.

ALL CAPITALS Directory names, file names, key names, and acronyms

KEY1+KEY2 A plus sign (+) between key names means to press and hold down the first key while you press the second

key.

click Refers to clicking the primary mouse button (usually the left mouse button) once.

Double-click Refers to quickly clicking the primary mouse button (usually the left mouse button) twice.

Right-click Refers to clicking the secondary mouse button (usually the right mouse button) once. Right-clicking

usually opens shortcut menus.

The following table identifies symbols and margin icons.

Icon Meaning

4Identifies a procedure.

4Indicates a reference to additional information.

Indicates an important note.

What You Need

The following items are needed to configure and operate your OIT.

Configuration Software EZware -5000

Configuration Cable17431-0104

Personal Computer2User Provided

Power Cable 6030-0009

24VDC Power Supply User Provided

PLC User Provided

Controller Information Sheet Maple Systems provides Controller Information Sheets which contain important information specific to each

PLC. Please locate the sheet that corresponds to your PLC on our website.

Communication Cable

(HMI to PLC) Refer to our web site (www. maple-systems.com) for a list of available cables.

Ethernet Crossover Cable

1Allows you to connect OIT directly to PC Ethernet port.

2Computer requirements include a Pentium 1.7 GH or higher processor, 512 MB RAM, 200 MB available Hard Disk Space,

VGA or higher resolution monitor, Keyboard and Mouse, available Ethernet port, at least one RS232 port for online

simulation, Windows XP, 2000 or Vista.

OIT Basics

Operator Interface Terminals (OITs) provide much more versatility than traditional mechanical control panels. An OIT

allows a plant floor operator to monitor current conditions of a control system and, if necessary, to initiate a change in the

operation of the system. OITs connect to programmable logic controllers (PLCs) typically through the PLC’s serial

communications port. The OIT can be programmed to monitor and/or change current values stored in the data memory of the

PLC.

OITs can have either text-based or graphics-based displays. A text-based OIT can display printable text characters but no

graphics. Some text-based OITs can display text characters in various sizes. A graphics-based OIT can display printable text

characters of varying fonts and sizes and graphics shapes such as icons, bitmaps, or pictures. Using pictures instead of words

or characters often greatly simplifies the operation of the OIT, making the OIT much more intuitive to use.

1010-1007, Rev 05

2 Silver Plus Series Installation & Operation Manual

Some OITs use touchscreen displays while others use a membrane-style keypad. Membrane-style keyboards are best used in

applications in which the keypad is likely to become dirty. Touchscreen displays are placed over the OIT screen thus

providing much more flexibility than typical membrane-style keypads. Because of this, switches can be created on a

touchscreen that appear only when needed.

The Maple Systems Silver Plus Series OITs are graphics-based touchscreen OITs. Before we get any further into the

operation of these OITs, it is necessary to define some terms that will be used throughout this manual.

Projects

The OIT has two basic segments of internal memory. The code memory contains the information required by the OIT that

controls how it operates such as the features supported and how it communicates to a PLC. The OIT programmer does not

have the ability to change code memory. The project memory pertains to all of the window screens created and any other

features that the OIT programmer can create using the EZware-5000 configuration software. Therefore, the term project is

used to designate the file that is sent to the OIT from the EZware-5000 software.

Objects

An object is any action that the OIT performs while it is communicating to the PLC. In order to get the operator interface

terminal to ‘do anything’, you must program the OIT with objects. Objects perform actions such as display text or graphics,

write a value to a PLC register, or display an alarm. Objects most often are graphics shapes that are to be displayed on the

OIT screen. For example, a Text Object is used to display text on the OIT. But objects are also used to configure the OIT to

perform some action. For example, a PLC Control Object tells the OIT to continuously monitor a PLC register that is used

by the PLC to request a new window. Some objects can display a graphics shape on the OIT screen and perform some

action. For example, a Toggle Switch Object creates a graphic object on the OIT that when pressed, activates a bit in the

PLC.

Graphics Object

A graphics object is any text, icon, or picture that can be displayed on the OIT. Graphics objects are further defined by how

they are composed or created. A Text Object is a graphics object that displays text on the OIT screen. A Bitmap Object is a

graphics object that displays a bitmap on the OIT screen. Bitmaps are files stored in the OIT to display pictures. A Shape

Object is a graphics object that displays a shape on the OIT screen. Shapes are also files stored in the OIT to display

pictures. Shapes differ from bitmaps in that shapes are stored using a vector-based file format whereas bitmaps use a

pixel-based file format. Each format has its advantages and disadvantages. We will not go into any more detail about bitmap

objects and shape objects until later in this manual. For now, think of them as objects used to display pictures on the OIT

screen. Finally, a Group Object is the most complex type of graphics object. It is a combination of other objects. Briefly, a

group object consists of one or more objects that are ‘grouped’ together and stored as one object. A good example is a

keypad, which is really a combination of several keys each designed to perform a specific task. When grouped together, a

keypad can be stored as a group object for use in other projects or windows.

Windows

A window is a screen that can be displayed on the OIT. Windows can be full-sized to completely cover the OIT display or

partially sized. Any partially sized window is usually referred to as a popup window. Windows can appear on the OIT

display by a request from the PLC or by a press from the touchscreen. Windows can be configured to any size. Once a

window is displayed, it can be moved around the OIT display, removed from the display, or minimized to an icon. Windows

can even overlap each other. Each window can display graphics objects and there is no limit to the number of graphics

objects that can be placed on each window. The Silver Plus Series is capable of storing up to 1999 windows , but the actual

limit is determined by the total amount of memory used for the application. A more in-depth discussion of windows is

covered in later chapters. For now, think of windows as screens that can be displayed on the OIT.

1010-1007, Rev 05

Introduction 3

What is a Silver Plus Series OIT?

The Silver Plus Series OITs by Maple Systems are graphics operator interfaces designed to connect to PLCs in an industrial

environment. The displays are covered with analog resistive touchscreens designed for harsh industrial environments. The

touchscreens use the latest in touchscreen technology enabling the OIT programmer to create switches that are very fine in

resolution. Unlike many other touchscreen OITs on the market, the Silver Plus Series OITs are not limited to a fixed number

of cells in which switches can be created. The OIT programmer can create as many switches of varying sizes and shapes as

he wishes, limited only by the total amount of memory available for the project.

Three LED indicators are provided on the face of the Silver Plus Series OITs to provide instant feedback to the OIT operator

of the current operating condition of the OIT.

LED Indicator Purpose

PWR LED (yellow) indicates if power is applied to the OIT

CPU LED (green) indicates if the OIT is operating correctly

COM LED (red) indicates communications activity on PLC port

The Silver Plus Series OITs have three serial ports, which provide a connection to a PLC using RS-232 or

RS-485 communications and an Ethernet connection for PLC communication and project upload and download. The serial

ports also provide the ability to use the EZware-5000 configuration software in Simulation Mode enabling the OIT

programmer to test his project on the PC instead of downloading the project to the OIT.

The Silver Plus Series is powered using +24VDC. The viewing level of the OIT display can be adjusted using a contrast

switch located on the back of the unit, or using Local Bits LB9040 and LB9041 for Contrast Up/Down. Finally, a reset

switch is provided on the back of the OIT to reinitialize the OIT if an operational failure occurs. The Silver Plus Series is

designed for industrial environments and carries a NEMA 4 rating as well as CE compliance for noise immunity and

emissions.

There are currently EIGHT models in the Silver Plus Series:

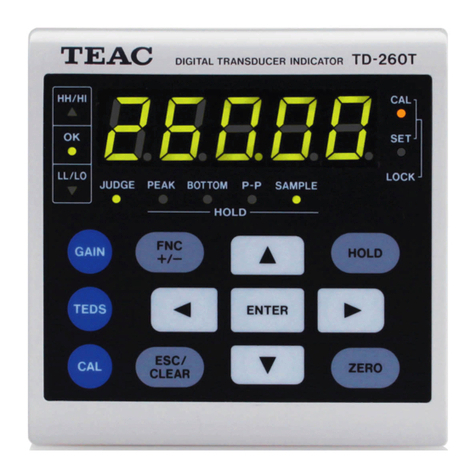

Model Display size Resolution

(pixels) LCD Type Brightness

(cdm2)

Contrast Recipe/RTC

Module

Ethernet &

Compact

Flash

HMI5056T 5.6” 320 x 234 65K color

TFT 500 250:1 Standard Yes

HMI5070T 7.0" 480 x 234 65K color

TFT 350 200:1 Standard Yes

HMI5080T 8.0" 640 x 480 65K color

TFT 400 250:1 Standard Yes

HMI5104T 10.4" 640 x 480 65K color

TFT 400 300:1 Standard Yes

HMI5104X 10.4" 640 x 480 65K color

TFT 400 300:1 Standard Yes

HMI5121T 12.1" 800 x 600 65K-color

TFT 300 200:1 Standard Yes

HMI5121X 12.1" 800 x 600 65K-color

TFT 450 600:1 Standard Yes

HMI5150X 15.0" 1024 x 768 65K color

TFT 350 700:1 Standard

Ethernet -

Yes

Compact

F lash - No

The primary difference between Silver Plus Series models (those with a part number ending in T) and Silver Plus Series X

models (those with a part number ending in X) is in the memory and processor speed. X models have higher speed

processors and more memory than standard models.

Finally, the Silver Plus Series OITs are powered by a 200 MHz Intel XScale processor and the Silver Plus Series X models

are powered by an AMD Geode LX800 500 MhZ fanless CPU, making them some of the fastest OITs available on the

market. Even the most complicated graphics can be displayed quickly on the OIT screen. In addition, the OIT uses a

proprietary algorithm to find the most efficient means of extracting data from the PLC. This lowers the amount of

‘bottleneck’ time due to the relatively slow communications baud rate of most PLCs. Therefore, the update rate to gather

information from the PLC is very fast.

1010-1007, Rev 05

4Silver Plus Series Installation & Operation Manual

List of Features

The next chapter will guide you through the creation of your first project. Before you proceed, you may wish to read this

brief list of some of the features offered in the Silver Plus Series OIT.

Icon Name Description

Bit Lamp Creates a graphics object to reflect the current status of a PLC bit.

Word Lamp Creates a graphics object to reflect the current state of a multi-state PLC data register.

Set Bit

Creates a touchscreen graphics object that represents a two-state switch. When pressed it

sets/resets a PLC bit.

Set Word Creates a touchscreen graphics object that represents a multi-state switch. When pressed it can

place a constant value in a PLC register or jog the value.

Toggle Switch Creates a touchscreen graphics object that represents a two-state switch changing state

(picture) based upon a PLC bit. When pressed, it can control another PLC bit.

Slider Object Creates a touchscreen graphics object that changes the state according to the position of a

slider switch.

Multi-State

Switch

Creates a multi-state touchscreen graphics object that changes state (picture) according to the

value in a PLC data register. When pressed, it sends a value(s) to another PLC register.

Function Key Creates a touchscreen graphics object or runs a macro.

Numeric Input Displays a number stored in a PLC register. The number can be changed using a numeric

keypad.

Numeric Data Displays a number stored in a PLC register.

ASCII Input Displays ASCII characters stored in a PLC register. Characters can be changed using an

alphanumeric keypad.

ASCII Data Displays ASCII characters stored in a PLC register.

Moving Shapes Creates a multi-state graphics object, which changes state (picture) and position on the screen

according to a value in a PLC register.

Animation Creates a multi-state graphics object, which changes state (picture) on the screen according to a

value in a PLC register. The positions on the screen are predefined.

Indirect Window Configures the OIT to monitor PLC data registers to display for a specific window popup by a

PLC word address

Direct Window Displays a Window based on a bit in a PLC register.

Alarm Displays Creates alarms to display alarms sent from the Alarm/Event Log Object.

Alarm Bar Displays alarms detected by the Alarm/Event Log Object on a single horizontal scrolling line.

1010-1007, Rev 05

Introduction 5

Data Transfer

(triggered)

Transfers data to the specified PLC registers based on a touch or PLC bit status.

Data Transferred

(time-based)

Transfers data to the specified PLC registers on a timed basis.

Event Displays Displays messages detected in the Alarm/Event Log and can acknowledge the message(s).

Data Sampling

(Data Logging) Stores data for trending and archiving.

Alarm/Event Log Contains the data for detecting alarm conditions.

Trend Displays Creates a trend graph. Samples data in a single or multiple 16-bit PLC register and plots the

data on a time graph.

Bar Graph

Displays Creates a bar graph with alarm monitoring.

Meter Displays Creates a scale meter.

Recipe Transfer Transfers data to the specified PLC registers.

Event Displays Displays messages according to ‘events’ that occur in the PLC.

Alarm Scan Contains the data for detecting alarm conditions.

System

Message Customizes the content of system-generated messages.

PLC Control Configures the OIT to monitor PLC data registers to display full window screens.

History Data

Display Displays historical data in a tabular format.

Backup Copies recipe, event or historical data to one of the USB memory devices.

Data Block

Display Displays the data in a series of registers as a line graph.

1010-1007, Rev 05

6 Silver Plus Series Installation & Operation Manual

Chapter 1 - Installation of OITs

Before You Begin

Please read the following for proper handling of your new OIT.

Unpacking the Unit

Carefully unpack the OIT. Please read any instructions or cautions that appear on the shipping container. Check all

material in the container against the enclosed packing list. Maple Systems, Inc. will not accept responsibility for

shortages against the packing list unless notified within 30 days. The equipment and its accessories were inspected

and tested by Maple Systems before shipment; all of the equipment should be in good working order. Examine the

equipment carefully; if any shipping damage is evident, notify the carrier immediately. You are responsible for

claim negotiations with the carrier. Save the shipping container and packing material in case the equipment needs to

be stored, returned to Maple Systems, or transported for any reason.

Managing Electrostatic Discharge

It is best NOT to remove the rear enclosure of the OIT. When the rear part of the enclosure is removed, the circuitry

inside is exposed to possible damage by electrostatic discharge during handling. Minimize the possibility of

electrostatic discharge by:

•Discharging personal static by grounding yourself prior to handling the OIT

•Handling the OIT at a static-free grounded workstation

•Connecting the frame ground (FG) connector of the OIT to a clean earth ground

•Placing the OIT in an anti-static bag during transport

CE Compliance

The Silver Plus Series OITs have been tested to conform to European CE requirements per Council Directive

89/336/EEC. The European Union created these requirements to ensure conformity among products traded in those

countries. Specifically, the Silver Plus Series OITs meet or exceed the noise emissions and immunity requirements

as set forth in the EN50081 (Emissions) and EN50082 (Immunity) standards. These products are designed to

withstand electrical noise in harsh industrial environments. They also conform to requirements that limit electrical

emissions. However, this does not guarantee that the products will be totally immune from possible malfunction in

cases where severe electrical noise occurs. Therefore, we strongly recommend that you follow the guidelines

outlined in this chapter for proper wire routing and grounding to insure the proper operation of the Silver Plus Series

OIT.

NEMA Rating

The Silver Plus Series OITs are rated for NEMA 4/12 (indoor) or IP65 installations. This means that when the OIT

is properly mounted to a panel or other enclosure, the front enclosure of the OIT will provide protection to the inside

of the panel from splashing water, wind blown dust, rain, or hose-directed water. The OIT must be installed

according to the instructions in this chapter to be properly sealed.

Environmental Considerations

The Silver Plus Series is designed to operate in temperatures from 0-45° C. It is intended for indoor installations

and not designed for outdoor applications. Avoid installing the Silver Plus Series in environments with severe

mechanical vibration or shocks. Do not install the OIT in enclosures with rapid temperature variations or high

humidity. Either will cause condensation of water inside the device and eventual damage to the OIT.

1010-1007, Rev 05

Installation of OITs 7

Safety Precautions

Please observe the following precautions when installing the Silver Plus Series OIT. Failure to comply with these

restrictions could result in loss of life, serious personal injury, or equipment damage.

Warning: Do not operate the OIT in areas subject to explosion due to flammable gases,

vapors, or dusts.

Warning: Do not connect the OIT to an AC power source. You will cause permanent damage

to the OIT.

Warning: Do not attempt to use a DC power supply that does not meet OIT power

requirements. You may cause malfunction or permanent damage to the OIT.

Warning: Do not power the OIT with a DC power supply used for inductive loads or for input

circuitry to the programmable logic controller. Severe voltage spikes caused by these devices may

damage the OIT.

Control Panel Design Guidelines

Pay careful attention to the placement of system components and associated cable routing. These items can

significantly enhance the performance and integrity of your control application.

1010-1007, Rev 05

8Silver Plus Series Installation & Operation Manual

I / O control lines

PLC/Host

Ground wires

(rear side)

OIT is

grounded to

control panel

Ground

strap

Power

line

filter

Quiet ground

(isolated)

Quiet ground

Line

Filter

OIT

Power

Supply

Shielded power cable

Shielded

communication

cable

Control panel is

tied to a reliable

earth ground

Silver Series

Plus OIT

24V

GND

COM1 [RS-485 2/4W]

PLC [RS-232]

COM3 [RS-485]

COM3 [RS-232]

COM1 [RS-232]

COM2 [RS-232]

Control Panel Example

Control Panel Grounding

The control panel should be connected to a good, high-integrity earth ground both for safety considerations and

shielding purposes. Maple Systems cannot overemphasize the importance of good grounding. If you fail to use

good grounding procedures during installation, sporadic malfunction of the OIT may occur:

·Connect the OIT’s chassis ground terminal to a reliable earth ground with a low-resistance path.

·Route all earth ground wires that lead from the OIT, the PLC, the power supply, and the line filter to a

central earth ground point such as a barrier strip. This will ensure that no ground current from one device

influences the operation of the other devices.

·Connect the OIT chassis ground terminal to the control panel door using a heavy-gauge short braided cable

or ground wire to minimize resistance.

·Connect the power cable’s shield wire to the OIT’s chassis ground terminal.

·Connect the control panel to earth ground using a copper grounding rod close to the OIT and control panel.

Hinged doors on control panels do not provide a long-term electrical connection to the rest of the enclosure.

Corrosion develops over time and prevents good electrical contract. For this reason, a separate wire braid should be

installed from the hinged control panel to the rest of the enclosure.

For a more in-depth overview of ground wiring techniques, refer to technical note #1027, “OIT Ground Wiring and

Electrical Noise Reduction,” which you can find on our web site.

Connect OIT Chassis Ground to Control Panel

To reduce the possibility of electrical interference, connect the chassis ground terminal of the OIT to a clean earth

ground. If the control panel is metal, make sure it is properly grounded. Then connect a short heavy-gauge wire

(#18 AWG) from the chassis ground terminal of the OIT to a mounting bolt on the control panel door. The

mounting bolt must have good electrical contact to the control panel; scrape away any paint that may be covering

the panel to provide a good connection.

If the control panel is made of a non-conductive material, it is essential that you connect the chassis ground terminal

of the OIT to a clean earth ground point located close to the panel.

1010-1007, Rev 05

Installation of OITs 9

Frame ground (marked FG)

Stud or screw

Area on panel free of paint

Control panel

(connected to earth ground)

HMI5056/HMI5070 Chassis Connection

Power Supply Selection

The power supply used to power the OIT should provide an output of +24 VDC 5% measured at the OIT power

terminal block. A 24VDC regulated power supply dedicated to the OIT is required. Use a power supply with a 1.1

Amp output rating for the HMI5056/5070 models and a 2.5 Amp output rating for all other models.

The power cable for the OIT should be 18AWG, 2-conductor wire with a shield drain wire and protective shield

(foil or braid). The shield drain wire must be connected to earth ground at both ends of the cable. Please refer to the

“Connect the OIT to Power” section for more information.

A power line filter installed at the AC input to the OIT power supply is highly recommended as a safeguard against

conducted RF noise, which is often present on factory power lines. The wires connecting the output of the power

line filter to the power supply should be kept as short as possible to minimize any additional noise pickup. The case

of the power line filter should be connected to a quiet earth ground. The power line filter should have a current

rating of at least 3 Amps with common mode and differential mode attenuation.

1010-1007, Rev 05

10 Silver Plus Series Installation & Operation Manual

Frame ground (marked FG)

Stud or screw

Area on panel free of paint

Control panel

(connected to earth ground)

HMI5080/HMI5104/HMI5121/HMI5150 Chassis Ground Connection

Do not use the power supply used to provide power to the OIT to power switching relays, solenoids, or other active

devices.

Cable Routing and Noise Immunity

Follow these guidelines when routing cable to the OIT:

·Always route the OIT communication cable and the power cable away from any AC voltage or rapidly

switching DC control lines.

·Never bundle the OIT cables together with 120VAC power wires or with relay wiring.

·Try to keep at least 8 inches (20 cm) of separation between the OIT cables and other power wiring. If

voltages greater than 120VAC are used in the system, greater separation is required.

·If the OIT cables must come near AC wiring, make sure they cross at 90 degrees.

·Run AC power wires in a separate grounded conduit to reduce electrical noise interference.

·Keep the cable lengths for the OIT as short as possible. Do not coil excess cable and place it next to AC

powered equipment.

·Cover any equipment used in the enclosure that operates at high frequency or high current levels with a

grounded metal shield.

Installation

It is necessary to follow all installation procedures described in this chapter for electrical noise immunity and CE

compliance.

Your Maple Systems OIT is designed to connect easily to your PLC. External rear connectors provide quick

connections for power, communications and programming wiring.

There are two connectors for serial communications on the rear of the OIT. Both of these are D-subminiature 9-pin

connectors.

Use the supplied separate 3-position terminal block to provide power to the OIT.

Connect the OIT to Power

The power cable for the OIT should be 18AWG, 2-conductor wire with a shield drain wire and protective shield

foil. You may buy cable P/N 6030-0009 by the foot from Maple Systems to make these.

1010-1007, Rev 05

Installation of OITs 11

Power Line Filter Connection

Always run the DC ground wire directly back to the signal return of the power supply. Do not use the chassis

ground wire as your signal return.

4To connect the OIT to power:

1. Connect the power cable to the OIT

a. Strip the power cable shield to expose 2” of the black and red wires.

b. Strip about ¼” of insulation from the black and red wires.

c. Thread the black and red wires through the ferrite core. The shield wire must be outside.

d. Connect the red wire to the DC positive (+) input of the OIT power terminal.

e. Connect the black wire to the DC negative (-) input of the OIT power terminal.

f. Connect the power cable shield wire to the OIT power terminal’s chassis ground input.

2. Route the power cable to the OIT power supply. The power cable should not be any longer

than necessary.

3. Install the power supply wires as follows (with colors shown for Maple Systems cable P/N

6030-0009):

Color Power Supply OIT

Red +Output/+24 Vdc +24V

Black -Output/+24 Vdc return GND

Shield Case ground FG

1010-1007, Rev 05

12 Silver Plus Series Installation & Operation Manual

OIT

(rear side)

24Vdc

power supply

Control

panel

Shield wire (bare)

Black wire (-)

Red wire (+)

24V

120Vac

Black

Shield drain

Red

FG

DC Output -V (Gnd)

DC Output +V (+24V)

(+)

GND

(-)

FG

OIT Power Inputs

The power connector on the Silver Plus Series is a terminal block with wire clamps.

Lugs are not required.

Panel Preparation

A metal panel or mounting surface with a minimum thickness of 15 gauge (0.059 inch/3.3mm) if cold-rolled steel or

hardened steel, or 10 gauge (0.101 inch/2.6mm) if aluminum alloy (6061-T6 preferred) is required. Thinner panels

or surfaces may bow between the mounting clamps and not form a seal with the gasket.

The area of the panel or mounting surface where the gasket comes into contact must be flat and free of scratches,

pits, and other features that prevent the gasket from sealing properly. If the panel or mounting surface is not

uniform, thick, flat, stiff, or smooth enough, then a sealant such as silicone may be required.

WARNING: The OIT requires a stiff, flat, smooth mounting surface free of blemishes

to seal properly to NEMA 4.

1010-1007, Rev 05

Installation of OITs 13

Shielded Power Cable,

Maple P/N 6030-0009

HMI Power Supply

Output

FG

DC Output -V (Gnd)

DC Output +V (+24V)

Control

Panel

Power

Connector

+24V

0V FG

HMI5080/HMI5104/HMI5121/HMI5150 Power Wiring

HMI5056/HMI5070 Power Wiring

Clean and deburr the panel cutout before the OIT is installed.

Mount the OIT to the Panel

1010-1007, Rev 05

14 Silver Plus Series Installation & Operation Manual

Screw clamp locking

tabs go through the

slots

Tighten all screw clamps until

they are uniformly snug

Ends of screws must not

protrude from the clamp

Screw Clamp Placement Clamps Tightened

Hold the OIT against

the panel until all screw

clamps are in position

PanelPanel

Installing Screws on the OIT

Position 4 screw clamps

(2 each side)

Panel

STEPS:

1. Prepare the four screw clamps for the HMI5056/5070/5080 or the six screw clamps for the

HMI5104/5121/5150 by positioning the metal brackets at the midpoints of the screws. Position the screws

so that the ends don’t protrude from the plastic portions.

2. Set the OIT in the panel cutout and hold it in place until all clamps are in position.

3. Tighten the screw clamps until all are uniformly snug.

CAUTION: Do not over-tighten the screws beyond snugness, or you may damage the housing.

REINSTALLATION: Because the gasket will take a “set” to the panel, be sure to reinstall the OIT to the same

panel cutout when a NEMA 4 seal is required. For best results, also replace the gasket itself.

Configuration Wiring

The OIT must be configured for a particular protocol before use. The EZware-5000 software (used on a PC with

Windows XP, 2000 or Vista) is used for configuring the OIT. For detailed instructions on installing and using the

software, please refer to the software documentation section of this manual.

Connect the OIT to the PC for Configuration

To configure the OIT using Maple System’s configuration software, you will need an Ethernet crossover cable,

Maple P/N 7431-0102. If using a switch or router between the PC and the OIT, use a straight-through or crossover

cable as required by the switch or router.

If an Ethernet port is not available on the PC, you may be able to install a USB

Ethernet adapter. You can also transfer the project to the OIT with a Compact Flash or

USB memory device. Refer to Chapter 2, OIT Local Setup.

1010-1007, Rev 05

Installation of OITs 15

Position screw clamps 6 places in slots provided:

2 screw clamps each side and one top and bottom

Panel

Side View

1010-1007, Rev 05

16 Silver Plus Series Installation & Operation Manual

Table of contents

Other Maple Systems Touch Panel manuals

Maple Systems

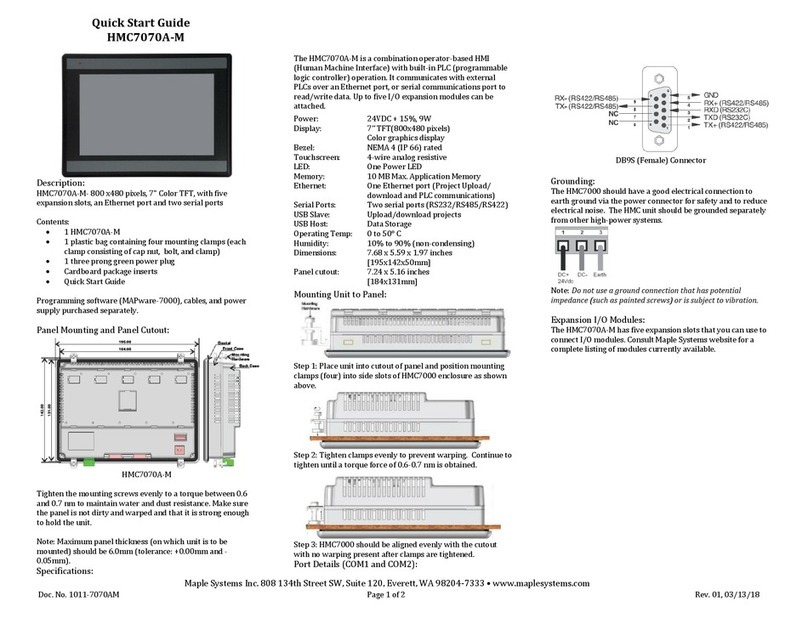

Maple Systems HMC7070A-M User manual

Maple Systems

Maple Systems OMI6912A User manual

Maple Systems

Maple Systems OMI6800 Series User manual

Maple Systems

Maple Systems Ivory Series User manual

Maple Systems

Maple Systems OMI6900BP Series User manual

Maple Systems

Maple Systems PC100 Series User manual

Maple Systems

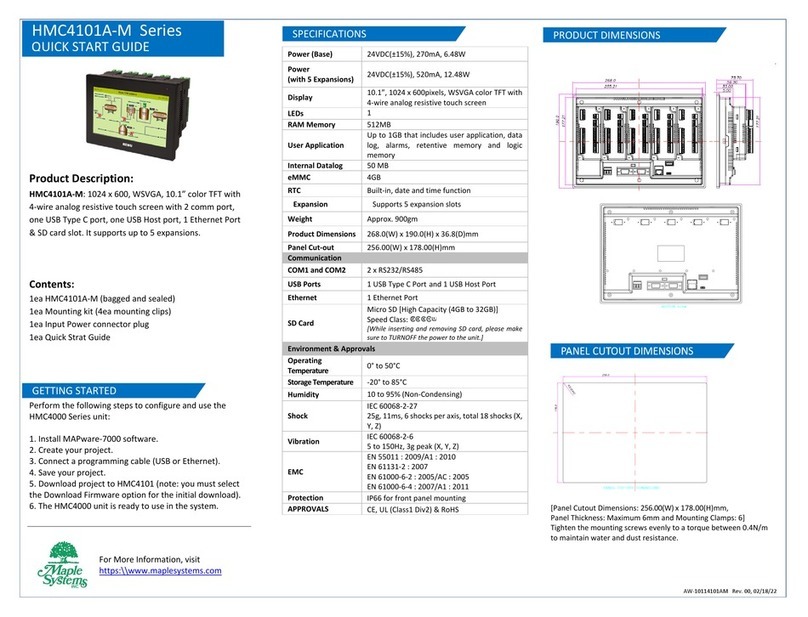

Maple Systems HMC4101A-M Series User manual

Maple Systems

Maple Systems HMC7043A-M User manual

Maple Systems

Maple Systems PC2315A User manual