Model: HMC7043A-M

Phone: 425/745-3229 • Fax: 425/745-3429 • Email: maple@maplesystems.com • www.maplesystems.com

.Doc. No. 1011-7043AM Page 2 of 2 Rev. 00, 10/01/2013

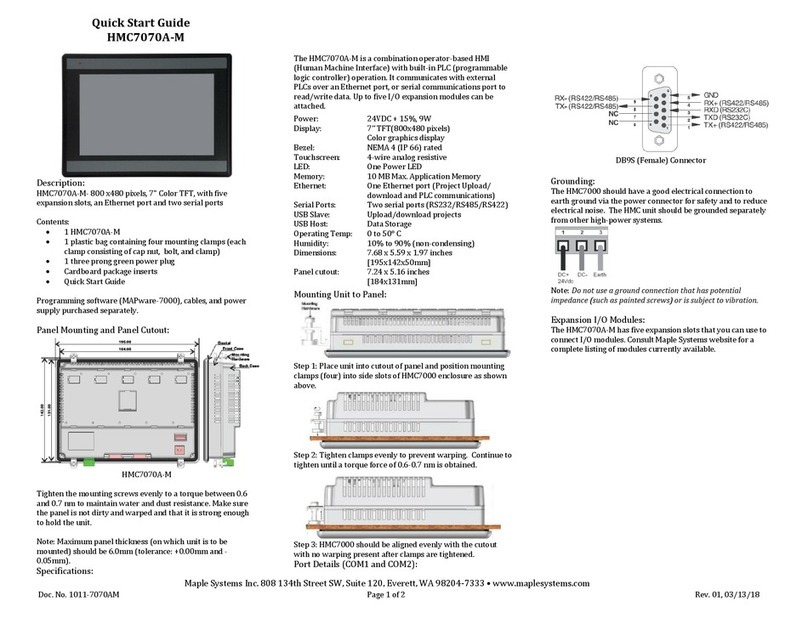

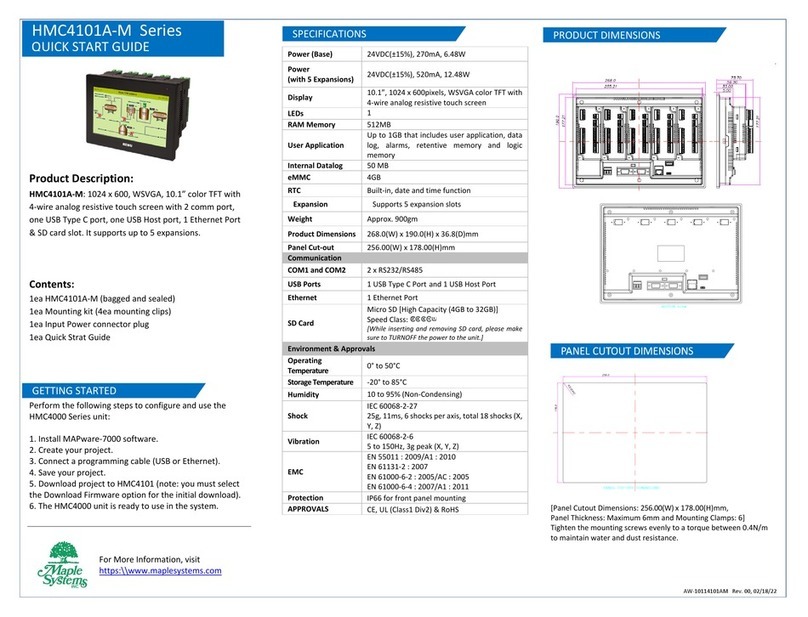

Getting Started:

Perform the following steps to configure and use the HMC7000

Series unit:

1. Install MAPWare-7000 software.

2. Create your project.

3. Connect a programming cable (USB preferred).

4. Save your project.

5. Download project to HMC7000 (note: you must

select the Download Firmware option for the initial

download).

6. The HMC7000 unit is ready to use in the system.

PC Requirements for MAPware-7000:

Processor: 1GHz Pentium-based processor or equivalent

Operating System: Microsoft Windows XP Professional, 2000,

Vista, Windows 7 or Windows 8.

RAM: 1 GB

Hard Disk: 800 MB (including 200MB for the .NET framework

redistributable)

Display: 1024x768 high color 16-bit

Mouse/Keyboard: Required

USB / Ethernet port: for project downloads

Installing the Software:

1. Insert MAPware-7000 CD into CD-ROM drive and

follow instructions.

2. If software installation does not automatically start

click \ SETUP.EXE from CD directory.

PLC Connecting Cables:

Contact Maple Systems to order any PLC Communications

Cables or to download a cable pinout diagram.

Additional Resources:

Detailed instructions on the operation and installation of the

HMC7000 Series are available in the HMC7000 Programming

Manual that is included with the MAPware-7000 configuration

software. MAPware-7000 also includes help files which

provide detailed information on using the configuration

software.

Other Sources (visit Maple Systems Support Center):

Controller Information Sheets- Specific information on

connecting a particular manufacturer's PLC to the

HMC7000

Cable Drawings- wiring diagrams to particular PLCs

Technical Notes- Provides additional information and

examples not covered in the operations manual

Software Upgrades- Upgrades to the MAPware-7000

software

Class I Division 2 Wiring Considerations:

Capacitance and inductance of field wiring from intrinsically

safe equipment to the associated apparatus must be included

in the system calculations as shown in Table 1. Cable

capacitance, Ccable, plus intrinsically safe equipment

capacitance, Ci, must be less than the marked capacitance, Ca

(or Co), shown on any associated apparatus used. The same

applies for inductance (Lcable, Liand Laor Lo, respectively).

Where the cable capacitance and inductance per foot are not

known, the following values shall be used: Ccable = 60 pF/ft,

Lcable = 0.2 μH/ft.

TABLE 1:

Wiring method must be in accordance with ANSI/NFPA70

Associated apparatus may be in a Division 2 or Zone 2 location

if so approved.

Associated apparatus must be installed in accordance with its

manufacturer’s control drawing and National Electrical Code

for installation in the United States and Canadian Electrical

Code for installation in Canada.

WARNING: DO NOT REMOVE OR REPLACE WHILE CIRCUIT

IS LIVE UNLESS THE AREA IS KNOWN TO BE FREE OF

IGNITIBLE CONCENTRATIONS OF FLAMMABLE SUBSTANCES.

This equipment is suitable for use in Class I, Division 2, Groups

A, B, C and D or non-hazardous locations only.

WARNING –EXPLOSION HAZARD –Do not disconnect

equipment unless power has been removed or the area is

known to be non-hazardous.

WARNING –EXPLOSION HAZARD - Substitution of

components may impair suitability for Class I, Division 2.

WARNING - CAUTION, battery may explode if mistreated.

Do not recharge, disassemble or dispose of in fire.

WARNING - Replace battery with Type CR1225FH-LF,

manufactured by Renata SA, only. Use of another battery may

present a risk of fire or explosion. See owner's manual for

safety instructions.

It is recommended that the user periodically inspect the sealed

devices used, check for any degradation of properties, and

replace as necessary.

For Technical Support:

Please contact Maple Systems if you have any questions

regarding this product. We ask that you provide us with the

unit serial number and firmware revision number written on

the product label of the unit. If applicable, please provide us

with the type of PLC used in your application.

Maple Systems Inc.

808 134th St. SW, STE 120

Everett, WA 98204

Tel: 425-745-3229

Fax: 425-745-3429

Email: support@maplesystems.com

Website: www.maplesystems.com

Hazardous Location

Class I Division 2

Groups A, B, C, and D

HMC7043

USB Port

JP9

Vmax=3.3 VDC

Imax=150 mA

Li=0

Ci=9pF

Associated Apparatus

USB Port

Voc<3.3 VDC

Isc<2.2 mA

La>Li+ Lcable

Ca>Ci+ Ccable