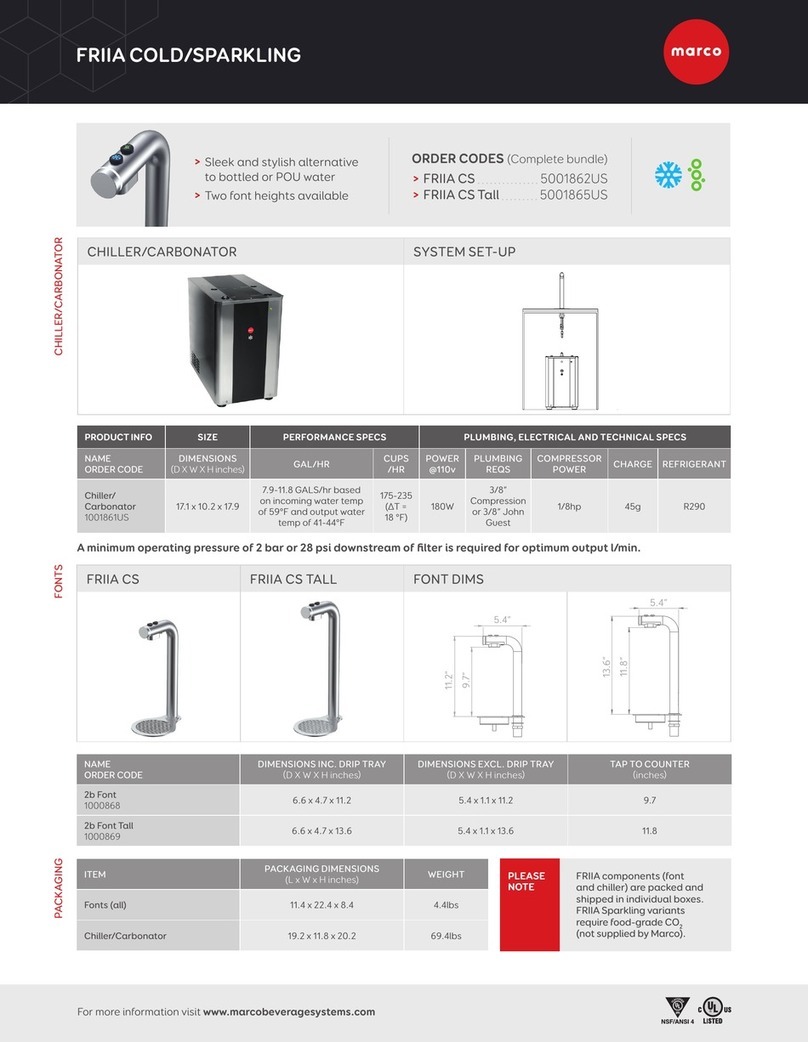

For more information visit www.marcobeveragesystems.com

ÜBER FONT WITH ECOBOILER UC4 / ECOSMART UC4

COUNTER CUT-OUT

ÜBER FONT 1000811

ECOBOILER UC4

1000740

ECOSMART UC4

1000750

VENTILATION REQUIREMENTS

50mm/1.9” clearance required at each side and back of

machine if installed in an enclosed cabinet.

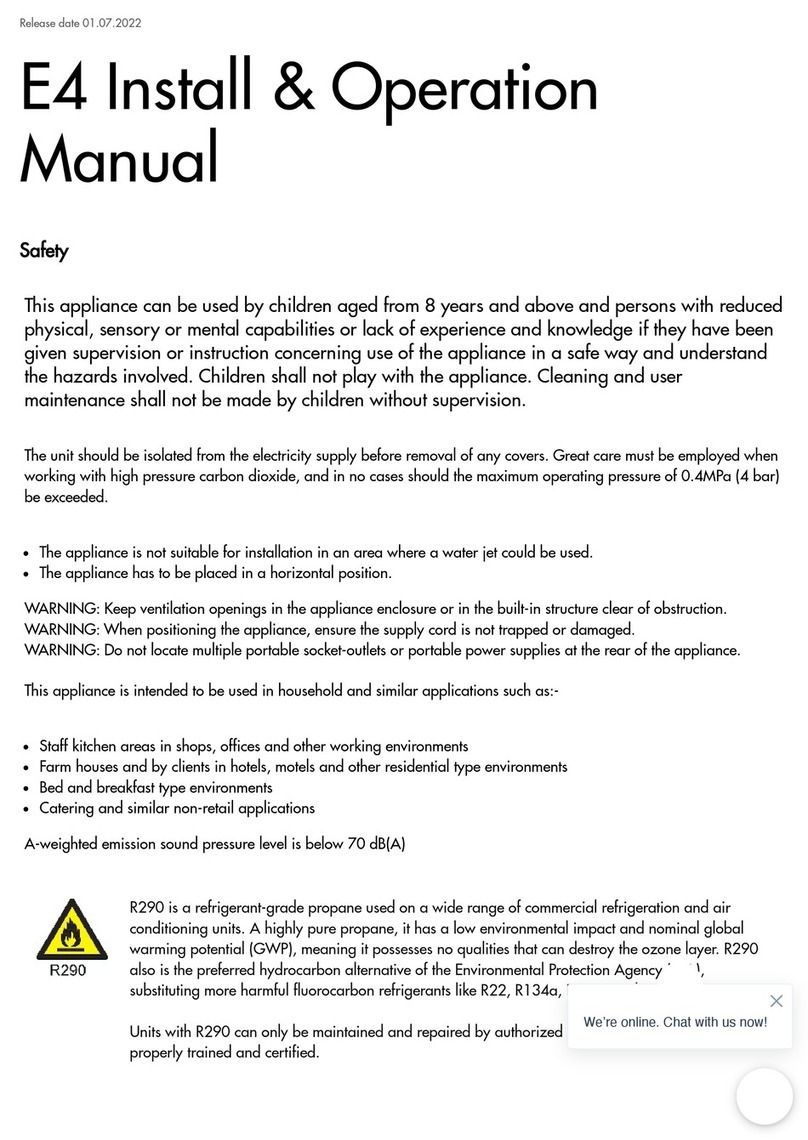

ELECTRICAL INSTALLATION PROCEDURE

When installing the machine, always observe the local

regulations and standards. The standard machine is

supplied with a UK 3-pin plug. For EU models a 2-pin CEE-7

plug will be supplied. US models will be supplied with the

suitable plug. A suitable mains power supply socket should

be available within easy access of the appliance so that it

can be disconnected easily after install. The wires from the

font are terminated in a Mini Fit connector which will plug

into a similar Mini Fit connector mounted on the top lid of

the undercounter boiler.

PLUMBING INSTALLATION PROCEDURE

• Ensure that the equipment is installed according to local

plumbing & water regulations.

• Mains water pressure required (limits): 14.5 - 145psi

(100 - 1000kPa, 0.1 - 1MPa).

• Requires inline water filter within your water

specifications.

• The machine is supplied with a 3/4“ BSP connection.

• Turn on the water to flush any impurities, dust etc

from the inlet hose and water pipe. Allow several litres

through. Especially for new installations. Connect the

hose to the inlet valve of the boiler. Make sure a sealing

washer is fitted.

• Turn on water and check for leaks.

• If the overflow vent is plumbed it must be plumbed with

a tundish device.

• This equipment must be installed with adequate

backflow protection to comply with all applicable

federal, state and local codes.

OPERATING BOILER FOR THE FIRST TIME

• Check that all installation procedures have been

carried out.

• Ensure water valve is on.

• Plug boiler appropriate electrical supply and press

power button on the front of the machine marked

‘Power’.

• The “power on” light will glow green and the machine will

fill to a safe level, above the elements, before heating.

• The “Ready/Status” light will cycle two red flashes while

the machine is filling to the safe level.

• Whilst the machine is above the safe level and filling,

the “Ready/Status” light will remain blank.

• The “Ready/Status” light will glow green when the

machine is both full and up to normal operating

temperature.

• The boiler is now ready for use.

• The font is simply activated by pressing the button on

the top of the font.

NOTE: Because the boiler is electronically controlled no

priming is necessary. The element cannot switch on until

a safe level of water is reached.

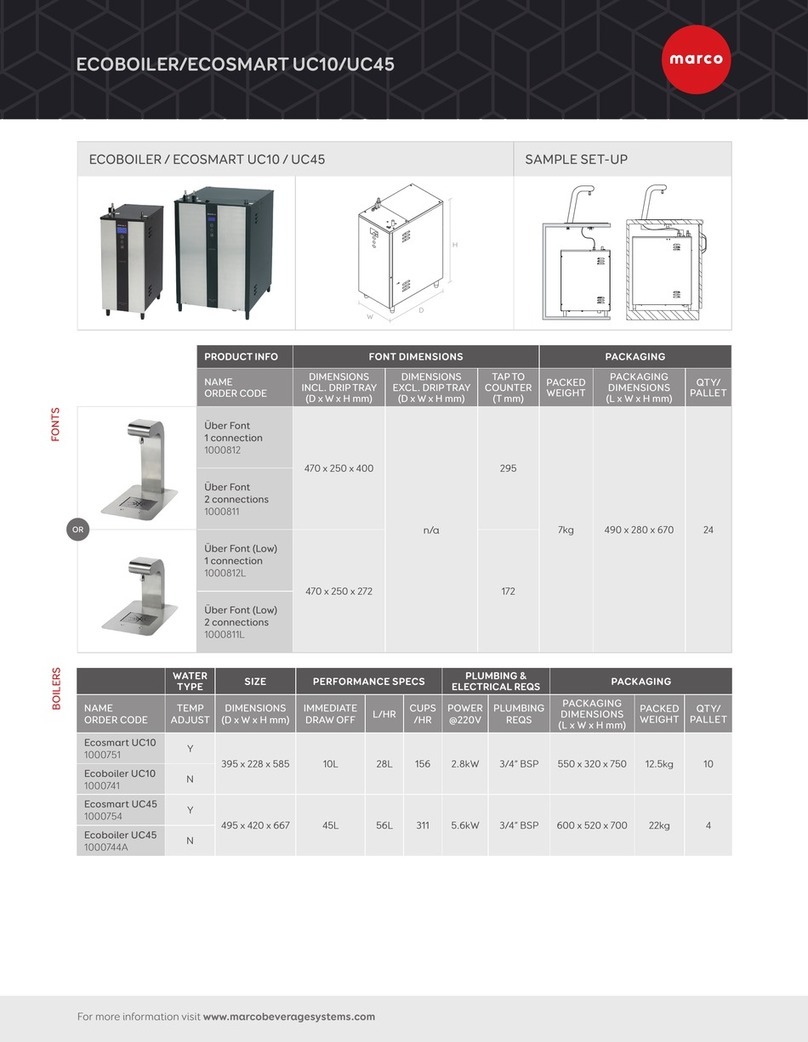

23”/585mm

15.5”/395mm

2”/50mm

11.9”/303mm

* Hosing should

be trimmed to

ensure continuous

drop from font

to boiler

4.5”/114mm

Ø 1.3”/32mm

Boiler Connections to Font

Water

Power Vent

2”/50mm*

2”/50mm

* Required for ventilation

if the machine is installed

in an enclosed cabinet.

>27.6”/700mm

min 5.1”/

130mm*

6.1”/

156mm

23”/585mm

>27.6”/700mm

15.5”/395mm

15.7”/400mm

11.6”/

295mm

18.5”/470mm

Front of Font

14.6”/370mm

6.5”/165mm

Water

Power

Vent

Boiler Connections to Font

min 5.1”/

130mm*

* Hosing should

be trimmed to

ensure continuous

drop from font

to boiler

23”/585mm

>27.6”/700mm

15.5”/395mm

2”/50mm

15.7”/400mm

11.6”/

295mm

18.5”/470mm

Front of Font

14.6”/370mm

6.5”/165mm

Water

Power

Vent

Boiler Connections to Font

min 5.1”/

130mm*

* Hosing should

be trimmed to

ensure continuous

drop from font

to boiler

ECOBOILER/ECOSMART UC4