DigiConvert Operating Instructions

Copying this document, or disclosing it to third parties is not allowed without our approval. This document must not be used in any abusive way by the receiver or third

parties. Feldbaum + Vogt GmbH

DigiConvert Operating Instructions 2 of 79

Contents

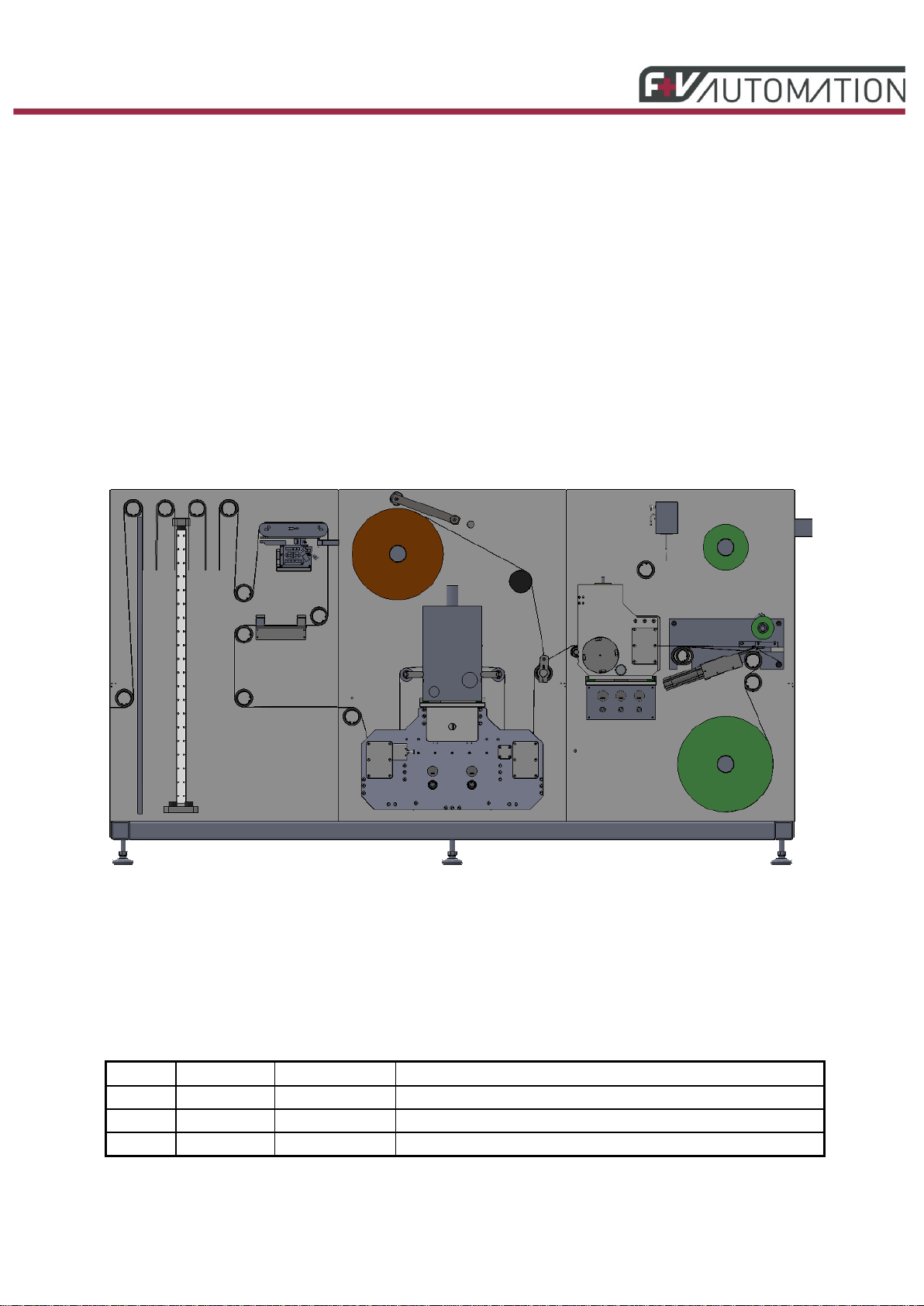

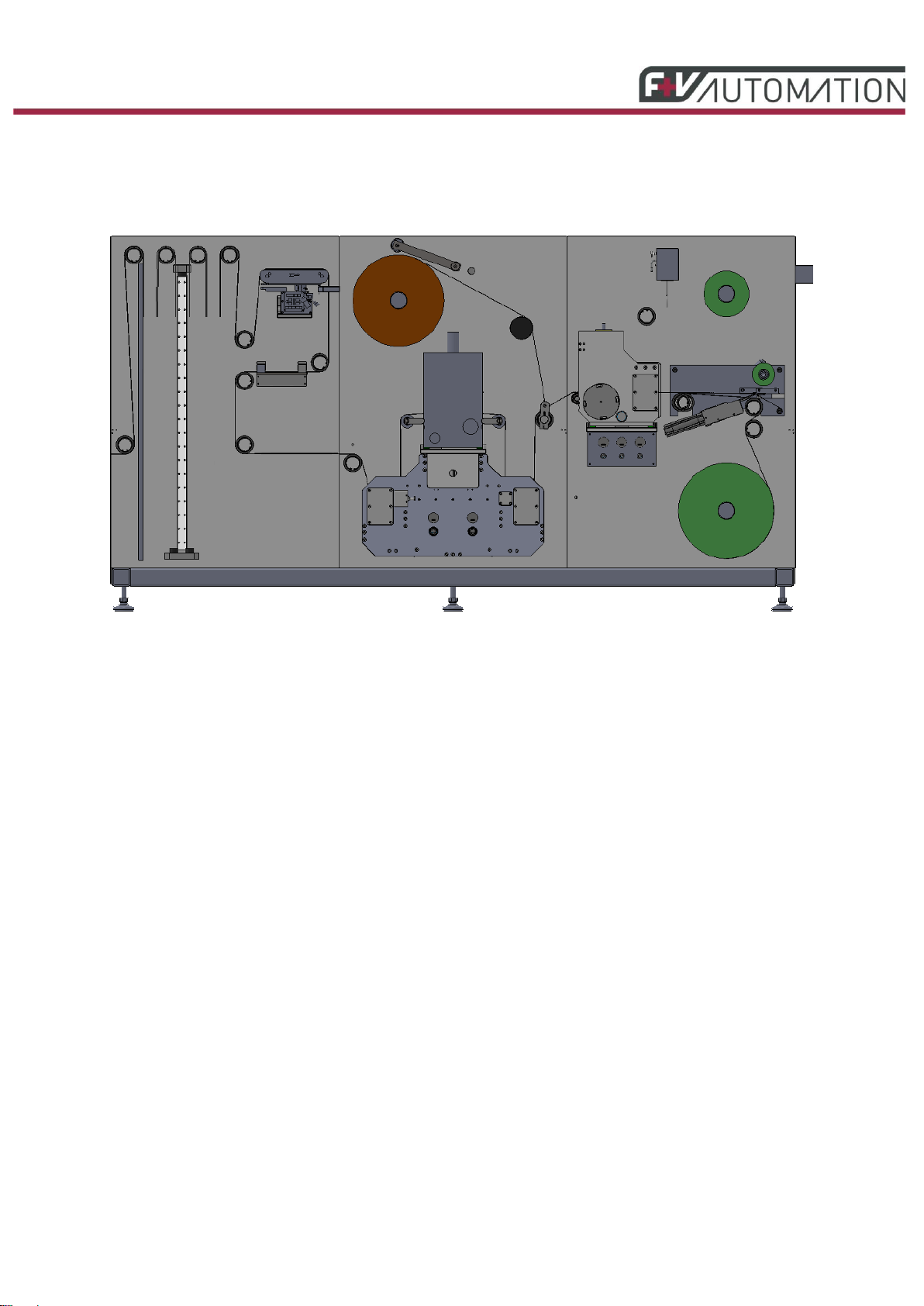

1. MACHINE........................................................................................................................................ 4

2. FIELD OF APPLICATION............................................................................................................... 4

3. MACHINE SPECIFICATION........................................................................................................... 4

4. WARNINGS AND SAFETY INSTRUCTIONS ................................................................................ 5

4.1. GENERAL INFORMATION ................................................................................... 5

4.2. CONTACT FOR SALES,MAINTENANCE AND HELP ............................................... 5

4.3. SKILLED PERSONNEL....................................................................................... 6

4.4. UTILISATION.................................................................................................... 6

4.5. WARNING OF RESIDUAL RISKS .......................................................................... 6

4.6. MAINTENANCE INSTRUCTIONS........................................................................... 7

5. INSTALLATION AND STARTUP ................................................................................................... 7

5.1. INSTALLATION ................................................................................................. 7

5.2. STARTUP ........................................................................................................ 7

6. INTRODUCTION............................................................................................................................. 8

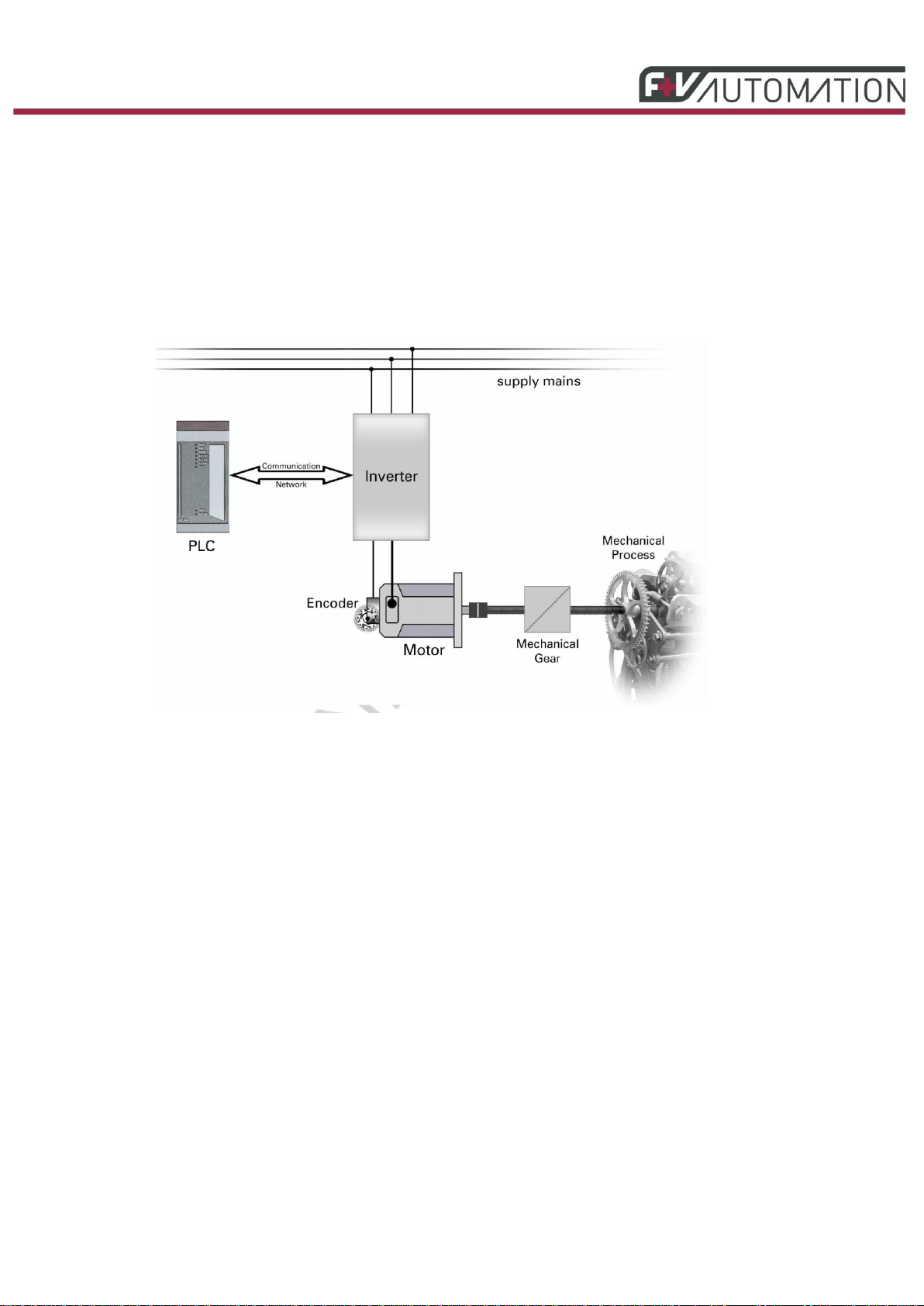

6.1. FUNDAMENTALS OF DRIVE ENGINEERING........................................................... 8

6.2. OPERATOR TERMINAL...................................................................................... 9

6.2.1. MAIN OPERATOR TERMINAL ........................................................................ 9

6.3. WARNING LIGHT SYSTEM FOR THE ENTIRE MACHINE........................................ 10

7. SAFETY FUNCTIONS .................................................................................................................. 11

7.1. SAFETY HOODS............................................................................................. 11

7.2. EMERGENCY STOP FUNCTION......................................................................... 12

7.2.1. TRIGGERING EMERGENCY STOP............................................................... 12

7.2.2. ACKNOWLEDGING EMERGENCY STOP ....................................................... 12

8. OPERATING THE MACHINE....................................................................................................... 13

8.1. SWITCHING ON THE SYSTEM ........................................................................... 13

8.2. OPERATIONAL CONCEPT................................................................................ 13

8.2.1. GENERAL OPERATION.............................................................................. 13

8.2.2. ICONS AND COLOURS............................................................................... 14

8.2.3. LATERAL EDGE CONTROL ........................................................................ 14

8.3. MACHINE CONTROL BUTTONS,MACHINE STATUS............................................ 15

8.4. SWITCHING OFF THE SYSTEM.......................................................................... 17

9. MENU STRUCTURE..................................................................................................................... 18

9.1. WELCOME SCREEN........................................................................................ 18

9.2. MACHINE OVERVIEW...................................................................................... 19

9.3. CHANGE OF OPERATOR.................................................................................. 28

9.4. DRIVE VALUES TREND DIAGRAM ...................................................................... 29

9.5. MACHINE SETTINGS AND JOB MEMORY........................................................... 30

9.6. QUICK OPERATION ........................................................................................ 37

9.7. REGISTER REGULATOR TREND DIAGRAM ........................................................ 39

9.8. ALARMS –HISTORICAL VIEW.......................................................................... 41