SEPTEMBER 14, 2017 6 ST-E ELECTRIC PRESSURE COOKER

ADJUSTMENTS & PARTS REPLACEMENT

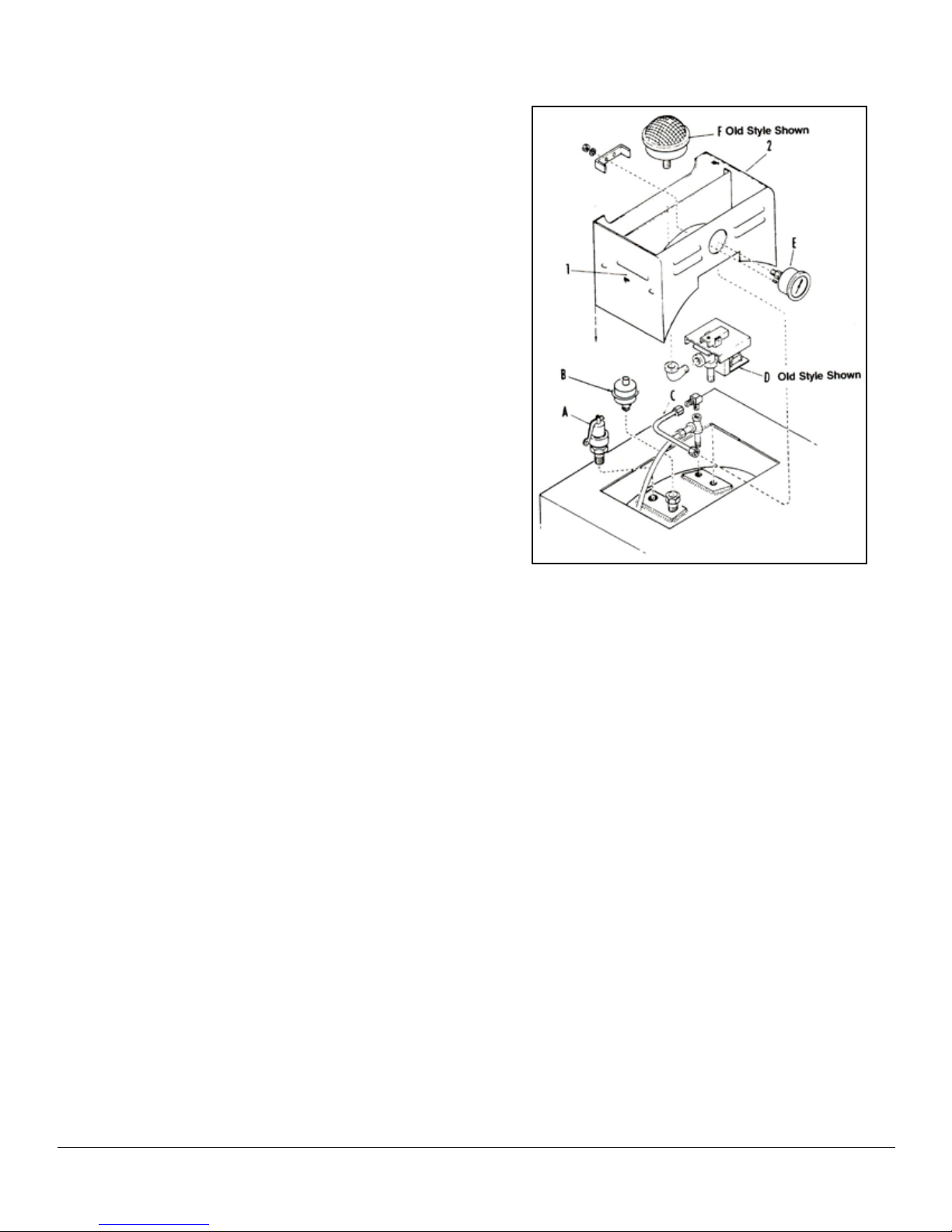

LOW WATER CUT-OFF

The low water cut-off is mounted above the timer assem-

bly under the front lower panel with its thermostat bulb ex-

tending and inserting into a channel provided for it at the

outer edge of the cast-in heating elements. It functions as

a safety feature to shut off the complete unit in the event

the water runs dry.

If the steam-it operated with no water or the water has

evaporated away, the temperature of the cooking cylinder

will rise and by heat inductions effect the thermostat bulb

of the low water cut-off. Electric current ow will b broken

at the low water cut-off and the unit will shut down. With

the replacement of water into the cooking cylinder, the

thermostat bulb will be cooled and the unit will then again

be operative after the reset button has been pressed.

If the unit does not start after pressing the reset button,

more time will have to be allowed for further cooling.

NOTE: Should a cooking cycle be started with insufcient

water and interrupted due to safety action of the

low water cut-off, the food in the process of cook-

ing will be affected. Proper compensation will

have to be made for the cooking performed and

with proper amount of water in the cooking cylin-

der, a new cycle determined and set to complete

the process.

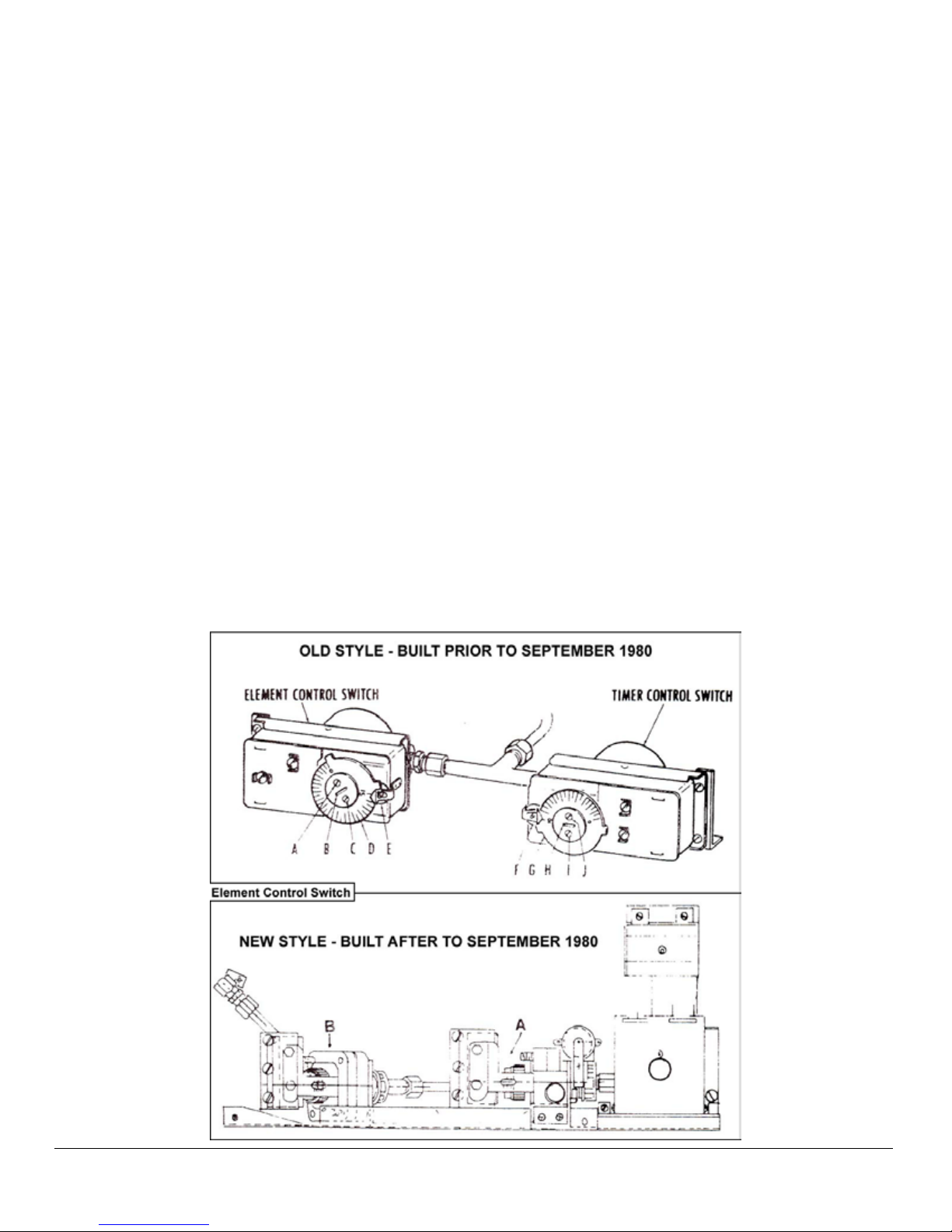

TIMER CONTROL SWITCH

The timer control switch located under the removable

front lower panel just right of center, automatically delays

the timer count-down at the beginning of the cycle until

the Steam-It has fully free-vented out all the cold air from

within the cooking cylinder and pressure has reached 10

PSI. This delay insures the timer to count only that por-

tion of the cycle when cylinder steam pressure is actually

acting on the foods. This, of course, is important when

processing foods which only require very short periods of

cooking time.

The copper tube which extends from the top of the cyl-

inder to the rear portion of the timer control switch con-

stantly reects internal cylinder steam pressure upon the

timer control switches build-up bellows. While cylinder

free-venting is occurring the switch keeps the timer circuit

open. After free-venting has terminated and when the cyl-

inder pressure has built up to approximately 10 PSI, the

contacts will be forces closed by back-pressures working

on the bellows, the timer circuit will be completes and the

timer will then start its countdown.

Adjustments

The cut-in point of the timer control switch has been facto-

ry set at its maximum setting of 10 lbs., and should not be

altered unless its found that the timer does not start until

well after 10 lbs. of steam pressure has been realized on

the pressure gauge. In this case, insert a screw driver into

the center slot (H) of the larger dial (G) and rotate slightly

counterclockwise to adjust timer to start at 10 PSI.

Recalibrating

Should the timer control switch vary through usage from

its original factory setting, it may be restored to proper

working order by recalibrating. A visual check of the timer

control switch during a trial cycle will quickly determine

the need of recalibration. With the timer control switch dial

set at 10 lbs., (fully clockwise) the timer motor should cut-

in when 10 lbs. of steam pressure is registered on the

steam pressure gauge. By watching the smaller dial (F)

on the timer control switch, the cut-in of the switch may

be observed and heard to click forward at the moment the

circuit is made to the timer motor. At that precise moment

the pressure gauge should read 10 lbs.

1. Set the larger dial (G) of the timer control switch to 10

lbs., (fully clockwise).

2. Loosen the two screws (I) and (J) located on either

side of the dial slot (H).

3. First, note the position of the slot (H) in relation to

4. the dial (G). then while holding the dial stationary, in-

sert a screwdriver into the slot and rotate slightly to

adjust (Clockwise- increase pressure, counterclock-

wise-decrease pressure). Tighten the two screws (I)

and (J) to hold this adjustment.

5. Check the unit through a trial cycle and note the pres-

sure gauge reading when the timer control switch is

observed and heard to click forward. Pressure read-

ing should then be at 10 lbs., (check also may be

made by continuity) readjust if necessary.

SAFETY VALVE

The safety valve is set to automatically relieve the cook-

ing compartment of excessive pressure build-up by open-

ing at a point between 15.5 lbs. and 16 lbs. If the safety

valve should leak continually with a pressure build-up, or

should it cause an interruption of the cooking cycle pre-

maturely (less then 15.5 lbs., on steam gauge) it must be

determined to be defective and be replaced. However, the

steam gauge should rst be checked for accuracy before

making this determination. The steam gauge should reg-

ister absolute zero setting with no pressure in the cooking

cylinder. If the normal zero setting has advanced some-

what through usage (a characteristic of steam gauges)

the amount of advancement from absolute zero must be

subtracted from its registered reading to determine the

true steam pressure.