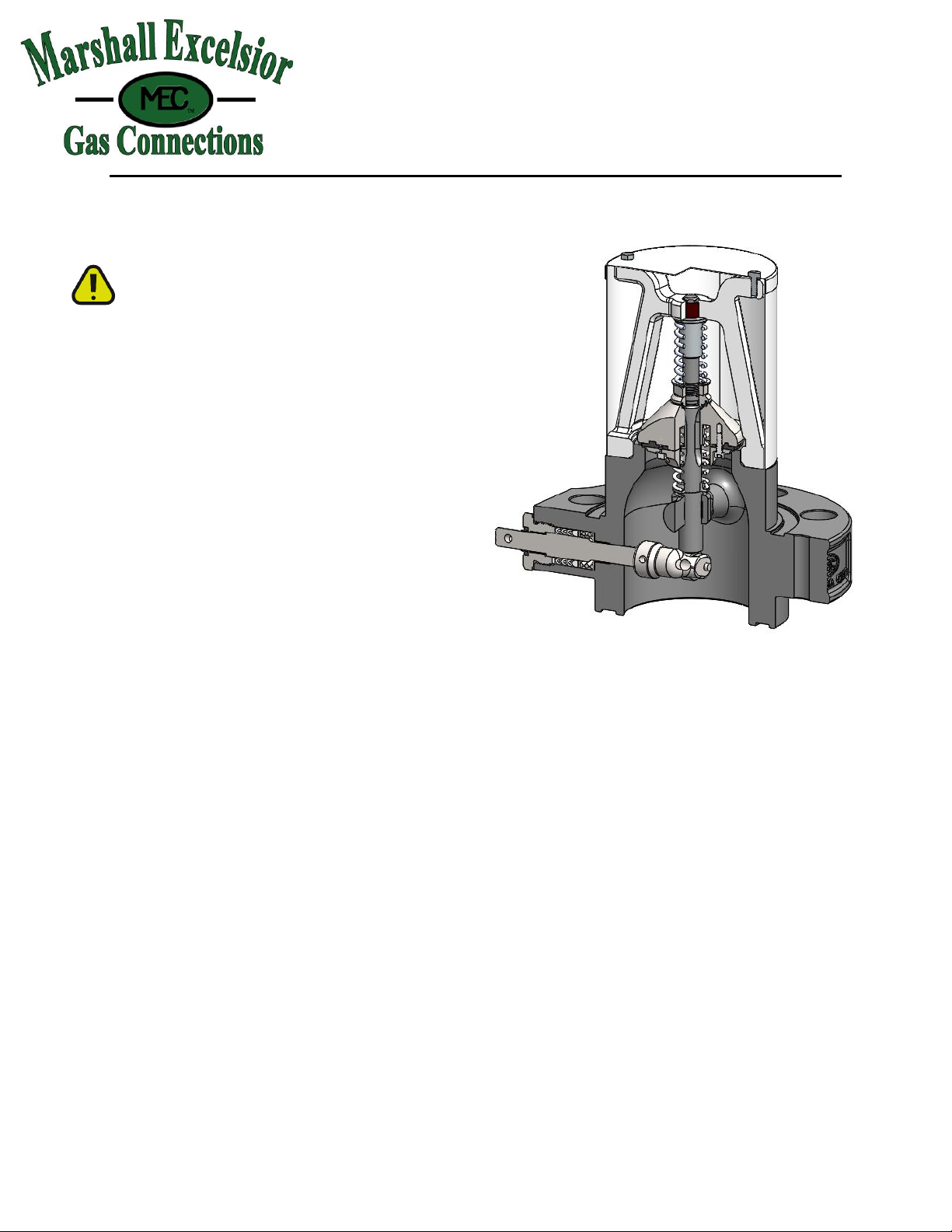

ME990-3F-VRK

COMPLETE VALVE REPAIR KIT

FOR: ME990-3F 3" SINGLE FLANGE

INTERNAL VALVE

Marshall Excelsior Company

1506 George Brown Drive Marshall, MI 49068

Phone (269) 789-6700 Fax (269) 781-8340

www.marshallexcelsior.com

The contents of this publication are for informational purposes only. While every effort has been made to ensure accuracy,

these contents are not to be construed as warranties or guarantees, expressed or implied, regarding the products or services

described herein or for their use or applicability. Marshall Excelsior Co. reserves the right to modify or improve the designs

or specifications of such products at any time without notice. The MEC™ logo is the trademark of Marshall Excelsior Co.

Form #1133 Rev A 3/7/2018

!!!WARNING!!!

READ AND UNDERSTAND ALL INSTRUCTIONS INCLUDED WITH THIS REPAIR KIT

RELIEVE ALL PRESSURE FROM SYSTEM BEFORE REMOVING VALVE FOR SERVICE

NOTE: Numbers in brackets [ ] refer to the number

in the valve component list.

WARNING: These products contain a chemical

known to the state of California to cause cancer and

birth defects or reproductive harm

A. Disassembly

1. EVACUATE ALL PRESSURE FROM

SYSTEM BEFORE ANY DISASSEMBLY

OR REPAIR.

2. Remove (8) Bushings [19] from Valve Body

[1] and discard (not shown).

3. Remove (2) Cap Screws [2] from Screen Cap

[3] and discard.

4. Remove Screen Cap [3] and Screen [4]; retain

components.

5. Remove (4) Cage Screws [5] from Valve

Cage [6] and discard.

6. Remove Valve Cage [6] and Cage Bushing [7]

and discard.

7. Remove Spring Guide [8], Closing Spring [9]

and Spring Washer [10] and discard.

8. Remove Lock Nut [11] and Bleed Disc [12]

and discard.

9. Remove Valve Poppet [13] and discard.

10. Remove Excess Flow Spring [14] and retain.

11. Remove Spring Seat [15] and Stem [16] and

discard.

12. Remove Guide Bearing [17] and discard.

13. Remove Cam Pin [19] and Cam [20] from

Gland Assembly [18] and discard.

14. Remove Gland Assembly [18] and discard.

15. Inspect Valve Body [1] and clean if necessary,

be sure interior is free of dirt, residue and

foreign particles.

B. Reassembly

1. Apply Loctite #242 or equivalent thread

locker to gland threads of Body [1]; install

new Gland Assembly [18]; see recommended

orientation below.

2. Install new Cam [20] and new Cam Pin [19]

onto Gland Assembly [18].

3. Install new Guide Bushing [17] into Body [1]

4. Install new Spring Seat [15], retained Ex-Flow

Spring [14], and new Valve Poppet [13] onto

new Stem [16] in order and orientation shown.

5. Install new Bleed Disc [12] and new Lock Nut

[11] onto Stem [16].

6. Install Stem Assembly [11-16] into Body [1].