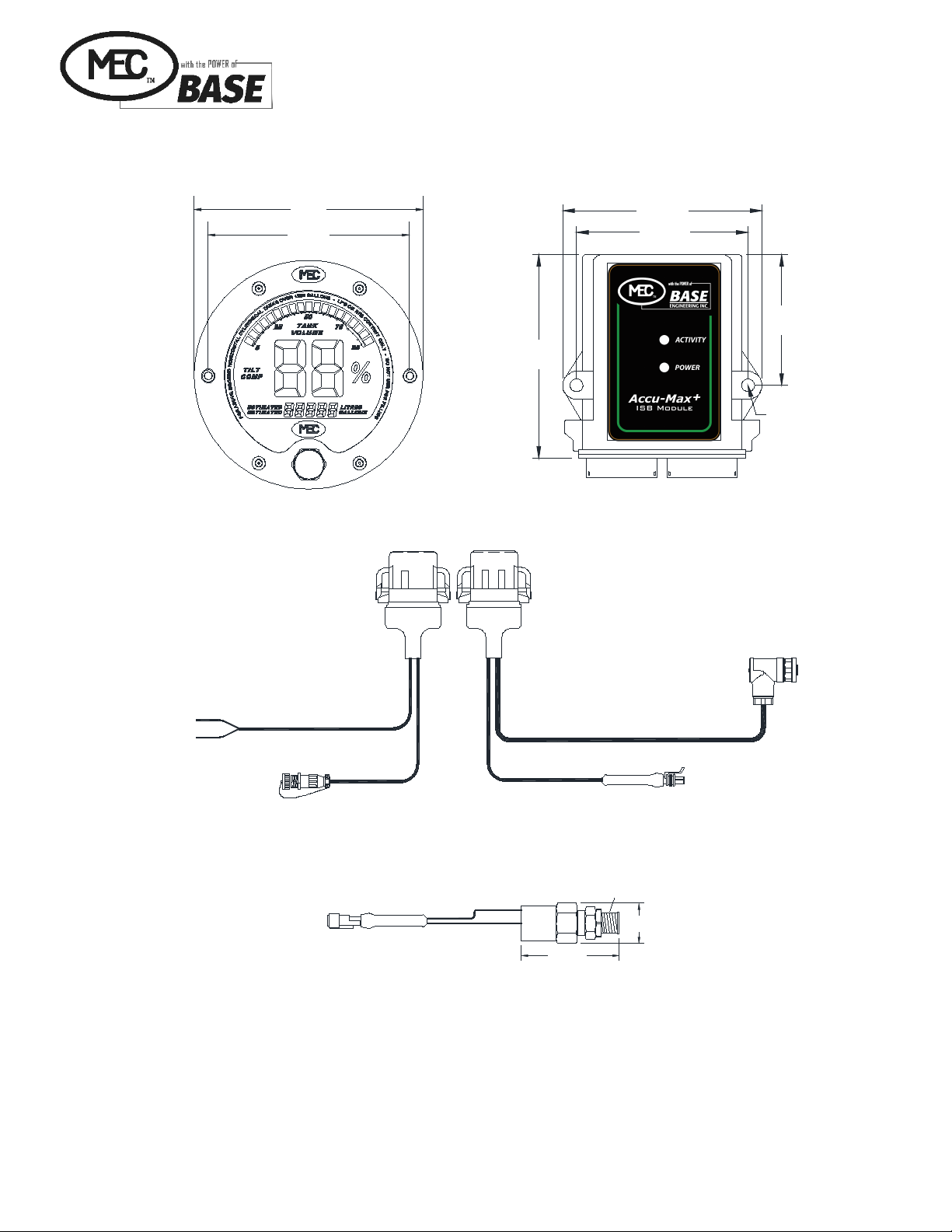

ACCU-MAX+ SERIES

Marshall Excelsior Company Base Engineering

1506 George Brown Drive Marshall, MI 49068 600 Rothesay Ave, Saint John, NB E2H 2H1, Canada

Phone (269) 789-6700 Fax (269) 781-8340 Phone (506) 635-2280 Fax (506) 635-2281

www.marshallexcelsior.com www.baseng.com

The contents of this publication are for informational purposes only. While every effort has been made to ensure accuracy, these contents are not to be construed as warranties or

guarantees, expressed or implied, regarding the products or services described herein or for their use or applicability. Marshall Excelsior Co. and BASE Engineering reserve the right to

modify or improve the designs or specifications of such products at any time without notice. The MEC™/BASE™ logo is the trademark of Marshall Excelsior Co. and BASE Engineering.

FORM #1173 1 REV B 7/13/2021

Installation Information

1Before you Begin & Qualified Installer Requirements

BEFORE YOU BEGIN

•Carefully read this Installation Guide before installing this

product. If anything is unclear, please contact BASE

Engineering for support.

•Ensure that the NEGATIVE battery connection is disconnected

before beginning work.

NOTE: Some components may lose short-term memory (i.e. engine or

transmission adaptive parameters and radio presets) after a prolonged time without battery power.

•Accu-Max+ should be serviced by qualified, trained personnel only. Attempting to remove the

cover or disassemble the device could expose you to dangerous high voltage points.

•Do not attempt to install or operate a damaged device. If the unit has been exposed to excessive

amounts of water, shows evidence of physical damage, or is not operating properly, unplug it

from the power source and contact qualified service personnel.

•Use of thread-locking compounds, such as Loctite, may cause serious damage to plastic

enclosures. Many thread-locking compounds are not compatible with thermoplastics and can lead

to stress-cracking.