MAINTNCE

ADDITION OF HYDRAULIC FLUID

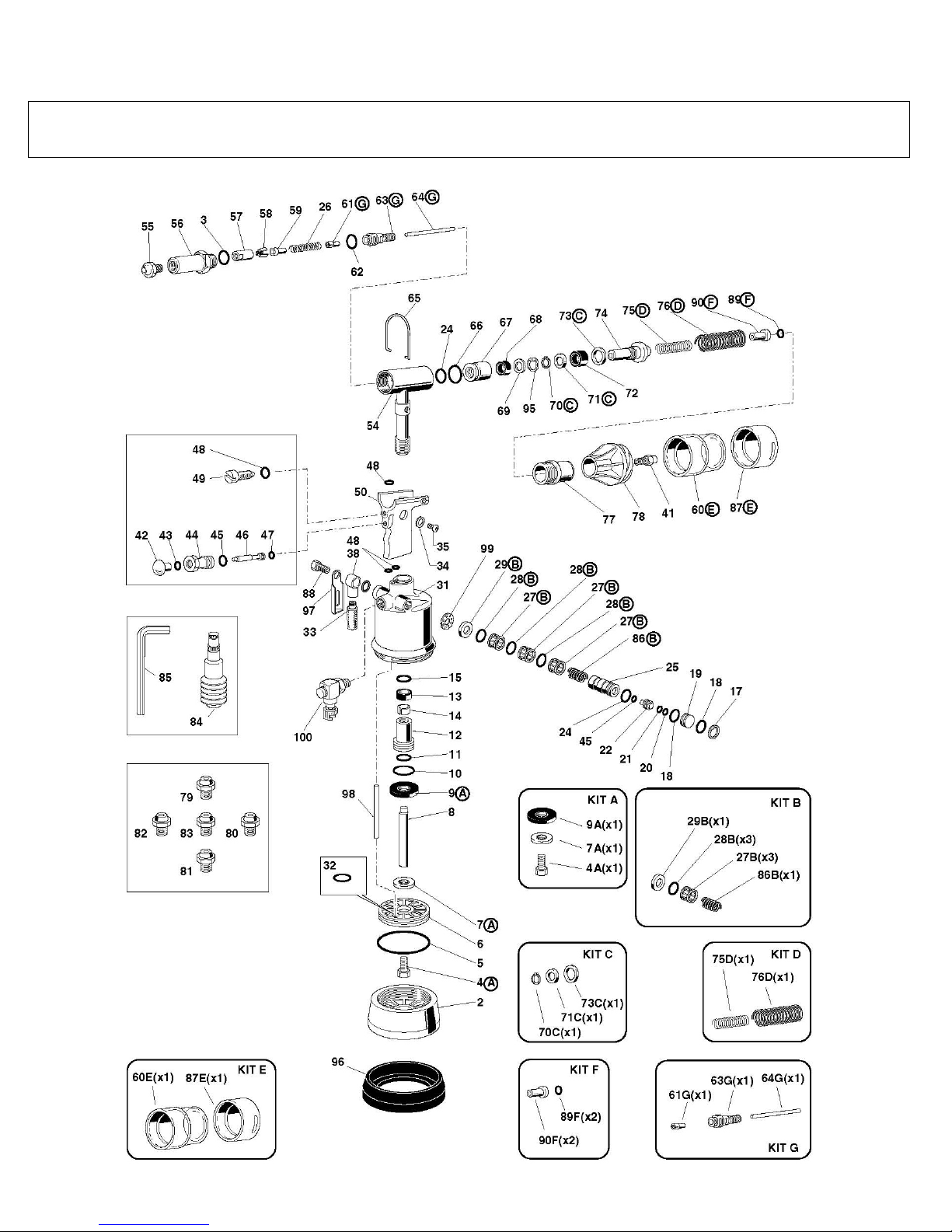

Tool is shipped with oil. If it becomes necessary to add oil, follow this procedure. Put tool

in a horizontal position. Remove plug (35). Pour hydraulic fluid into container (84).

Screw container into fluid plug receptacle. Oil level should reach edge of fill hole. With

container still attached, reconnect to air supply. Actuate trigger button 5 or 6 six times,

or until air bubbles inside the container stop. This releases any entrapped air.

IMPORTANT: Use only Anti-Foam Hydraulic Fluid or equivalent air tool oil.

CHANGING NOSEPIECES

1. Select proper nosepiece

2. Disconnect tool from air supply.

3. Using a wrench unscrew nosepiece from frame head (56) & replace with proper

size nosepiece.

4. Reconnect air supply.

5. Pointing tool away from people & object, push trigger button & hold. Snug down

with wrench. DO NOT OVERTIGHTEN.

Your tool is now ready to work. Insert rivet mandrel into nosepiece. Insert rivet into

predrilled hole in application material, push trigger button (42) & release.

CLEANING & CHANGING OF JAWS

With use, the jaws of the tool may become dirty. This will cause slipping of the rivet

mandrel & and improper setting of the rivet. To clean the jaws follow this procedure.

1. Disconnect air supply

2. Use a suitable wrench, unscrew frame head (56) & remove

3. using a pair of wrenches, disassemble front jaw case (57)

4. To clean jaws, use a stiff dry wire brush.

5. If excessive wear is apparent, replace with new jaws.

6. Reassemble in reverse order.

Further maintenance is beyond the scope of this direction sheet. If the tool fails to

function properly, return to an authorized repair station or the factory for service.