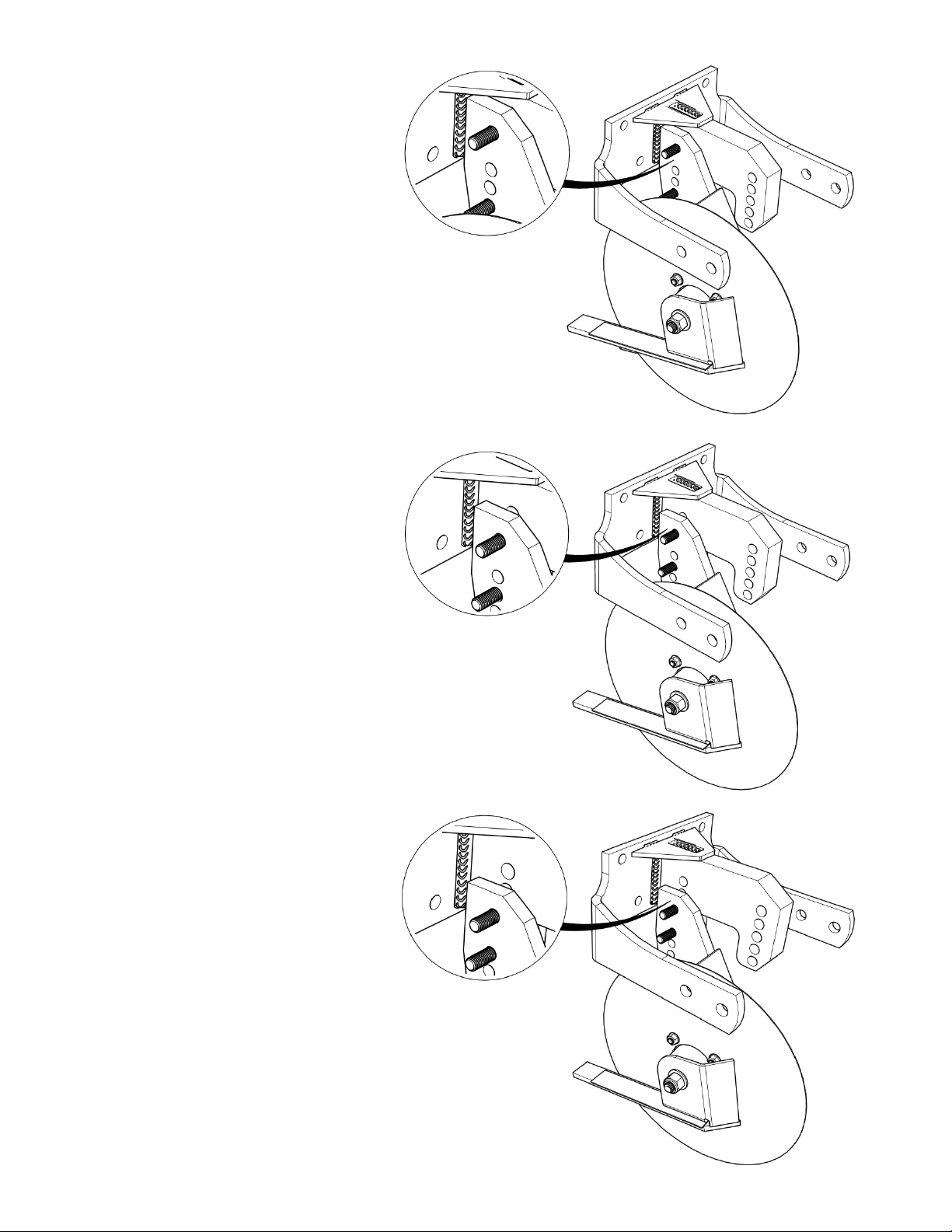

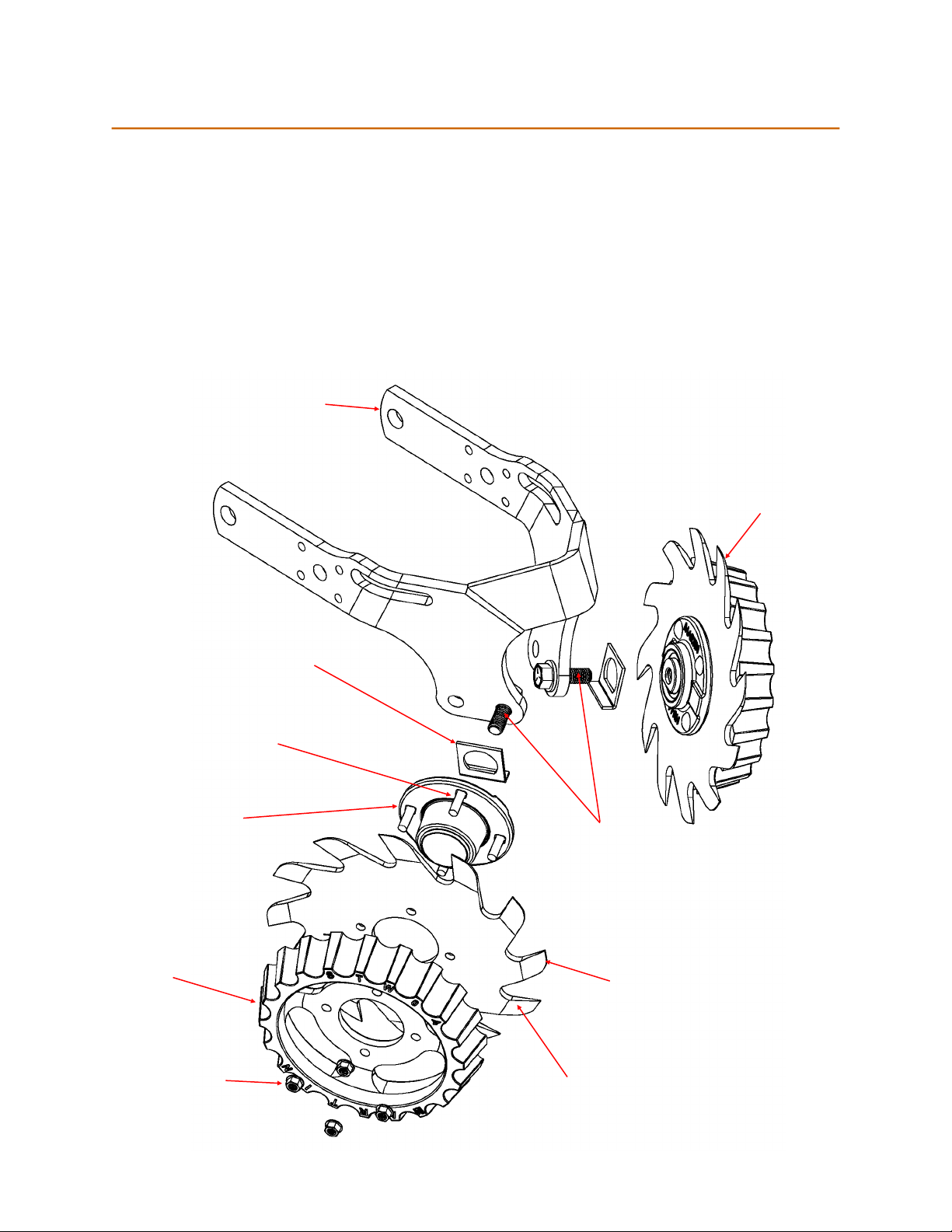

Offset Configuration

1. Place 5/8” x 1 3/4” flange patch bolt through rear hole of frame and torque to 112 ft-lbs, to secure an-

chor and hub axle to frame.

2. Place 5/16” x 1 1/4” BOLT, 5/16’ FLAT WASHER, 5/8” BUSHING, & 5/16” NUT in front hole of frame and

torque to 13 ft-lbs, to prevent anchor from rotating.

5/16” NUT

(N516CH)

5/16” x 1 1/4” BOLT AND FLAT

WASHER(B5m516NC114 &W516)

5/8” BUSHING

(SC-FR-SPACER)

5/16” NUT &

FLAT WASHER

(N516 &W516)

5/8” x 1 3/4” FLANGE

PATCH BOLT

(B5F58NC134)

5/16” x 1/2” BOLT

(B5m516NC12)

Smartclean Anchor

(SC-1360FR-MT-R)

5/16” x 1 1/4” BOLT AND FLAT

WASHER (B5m516NC114 &W516)

5/16” NUT and

Washer(N516

&W516)

5/8” x 1 3/4” FLANGE

PATCH BOLT

(B5F58NC134)

5/8” BUSHING

(SC-FR-SPACER)

Smartclean Anchor

(SC-1360FR-MT-R)

STEP 5: INSTALL SMART CLEAN CYLINDER BOTTOM ANCHOR

IMPORTANT: Skip to Step 6 if optional SmartClean System was not purchased

If the optional SmartClean cylinder was purchased, install the SmartClean cylinder bottom anchor, before in-

stalling the wheels, as shown below. Proper location of the bottom anchor mounting bolts is determined by

the wheel configuration you’ve chosen. The anchor is installed on the right side of the frame.

•

The first picture shows proper anchor mounting for the intersected wheel configuration.

•

The second picture shows proper anchor mounting for the offset wheel configuration.

Intersected Configuration

1. Place 5/8” x 1 3/4” flange patch bolt through front hole of frame and torque to 112 ft-lbs, to secure an-

chor and hub axle to frame.

2. Place 5/16” x 1 1/4 ” BOLT, 5/16” FLAT WASHER , 5/8” BUSHING & 5/16” NUT in rear hole of frame and

torque to 13 ft-lbs, to prevent anchor from rotating.

6