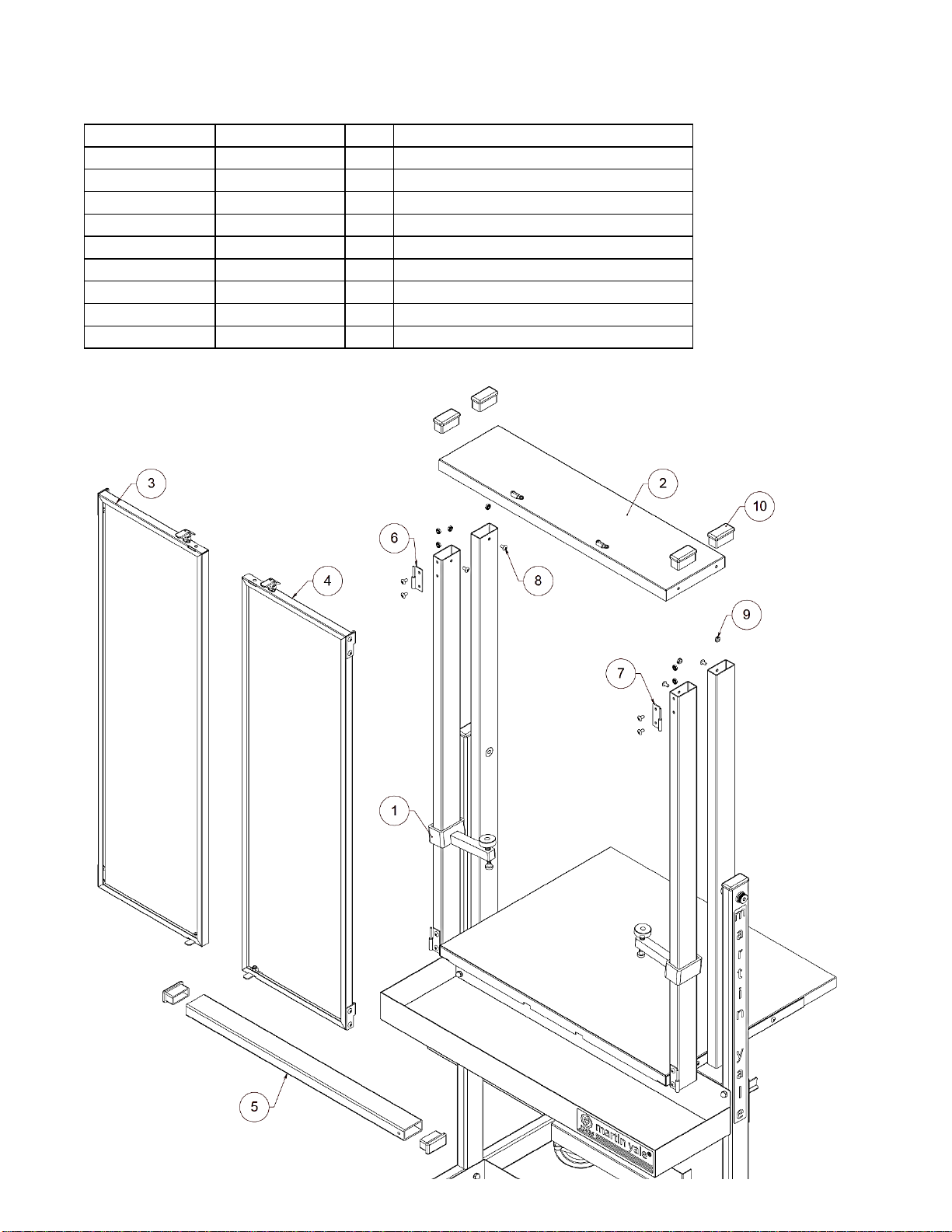

2.2.6 Refer to Parts List C and Diagram C. Locate Top Panel; Doors. Open parts bag C.

2.2.7 Locate hinges in parts bag. Position as shown, ensuring correct hinge is on each

frame, and install using two (2) screws and two (2) keps nuts for each hinge.

2.2.8 Position the Top Panel Assembly as shown and install using four (4) screws and four

(4) keps nuts. Be careful not to bend L-Frames in the process! Tighten screws.

At this point, the Upper Assembly and L-Frames are no longer at risk for bending.

2.2.8 Insert four (4) tubing End Caps into each of the tubing ends near the Top Panel.

2.2.10 Noting orientation of doors, carefully position and slide doors onto Lift Hinge Pins on

Upper Assembly. Close doors and verify they latch into place. Lock doors by hooking

the Draw Latch clasp over the keeper and snapping into place.

Congratulations! Your brand new

Martin Yale Titan –THE Professional Padding Press

is now ready for use!

3.0 Operation

NOTE: For best results, all material should be jogged before padding.

Martin Yale Model 400 or Model 4200 Jogger is recommended.

3.1 Lock casters by pressing down with foot to keep the unit from moving.

3.2 Verify Upper Assembly is locked in the upright position and doors are locked.

3.3 While standing on the left side of the Titan, hold Upper Assembly with left hand while pulling

Tilt Latch up with right hand. When the latch opens, tilt Upper Assembly down and release

latch. Verify the latch has locked the Upper Assembly into place.

3.4 Slide each clamp up to Top Panel and position so that clamp handle rests on Clamp Latch.

3.5 Square the paper into the corner(s) and lightly press against the door(s). Place Clamp Tube

on top of the paper stack(s) and against doors.

3.6 Lower Clamps to Clamp Tube and tighten clamp knobs by hand. Do not use tools such as

wrenches or pliers!

3.4 Unlock and open doors. Apply padding compound to facing edge of paper stack. When dry,

release clamps to remove pad(s).

3.5 For Carbonless Paper

The Titan is constructed so that the Clamp Bar can be set on the edge of the paper for little

penetration or moved away from the edge so that carbonless padding compound can

penetrate further into the sheets. If you are doing snap-outs in carbonless forms, you can

move the Clamp Bar in about 1/4“ and padding compound will penetrate just as well as if

you used a tipping machine.

4.0 Maintenance

Clean unit when needed with warm, soapy water. Doors are installed with Lift Hinges for easy removal and

cleaning; with the Upper Assembly locked in the upright position, unlock and open each door and carefully

pull the door upward and away from the Upper Assembly. Do not use the same brush for regular and

carbonless padding compounds. A paper liner can be used in Drip Tray to minimize clean up.

251 Wedcor Drive • Wabash, IN 46992

Phone (260) 563-0641 • Fax # (260) 563-4575

Website: www.martinyale.com • Email: info@martinyale.com

M-S027946 Rev. 2 8/15/14