2

NOTE

!CAUTION

Welcome to the Marvel Experience

Thank you for choosing our quality American-built product

to add to your home. We are thrilled to welcome you to

our growing community of Marvel owners, who trust in our

products and our support.

The information in this guide is intended to help you install

and maintain your new Marvel undercounter model to pro-

tect and prolong its lifetime. We encourage you to contact

our Technical Support team at (616) 754-5601 with any

questions.

Got a Marvelous Design?

We would love to see how your Marvel product looks in its

new home. Send us photos at marketing@marvelrefriger-

ation.com, and we might feature your Marvel home design

on our website and social media!

Thank you again for investing in Marvel for your home!

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situa-

tions that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operat-

ing this appliance.

Recognize Safety Symbols,

Words, and Labels.

CAUTION-Hazards or unsafe practices which could re-

sult in personal injury or property / product damage.

NOTE-Important information to help assure a problem

free installation and operation.

CONTENTS

!WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

!WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm.

!WARNING

WARNING - This unit contains R600a (Isobutane)

which is a flammable hydrocarbon. It is safe for regular

use. Do not use sharp objects to expedite defrosting.

Do not damage refrigerant circuit.

Contents:

Safety information ...............................................................2

Unpacking Your Appliance ................................................. 3

Installing your appliance ......................................................4

Electrical ..............................................................................5

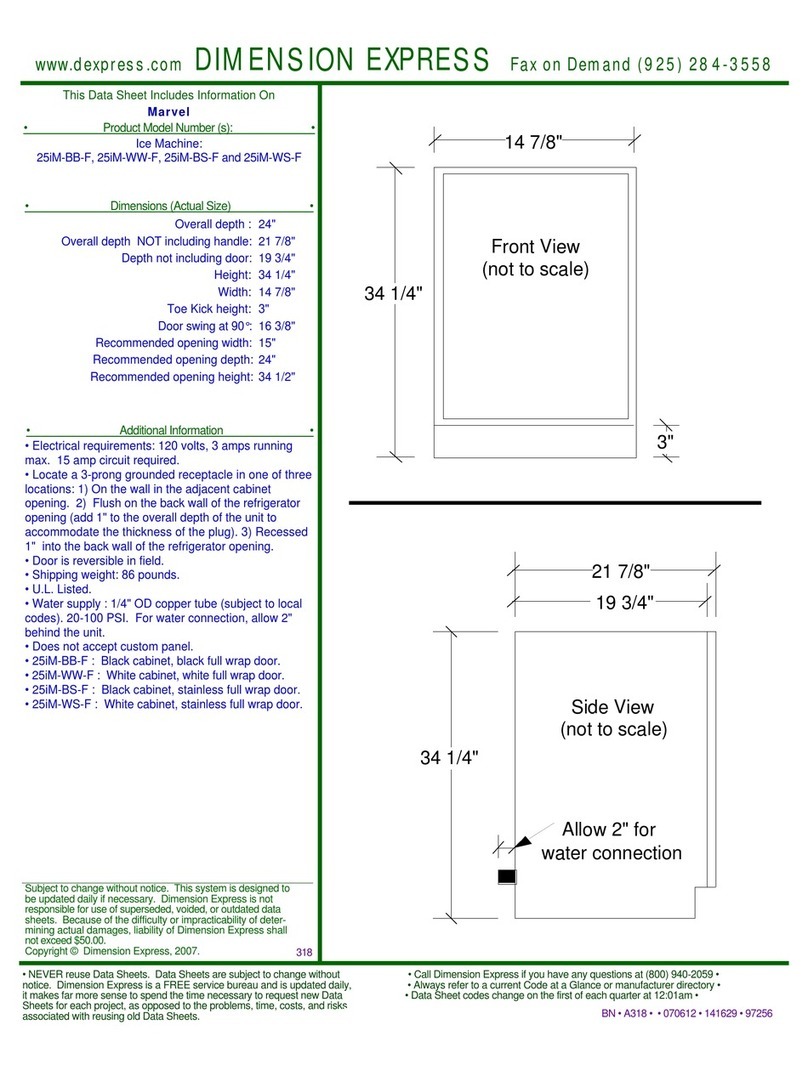

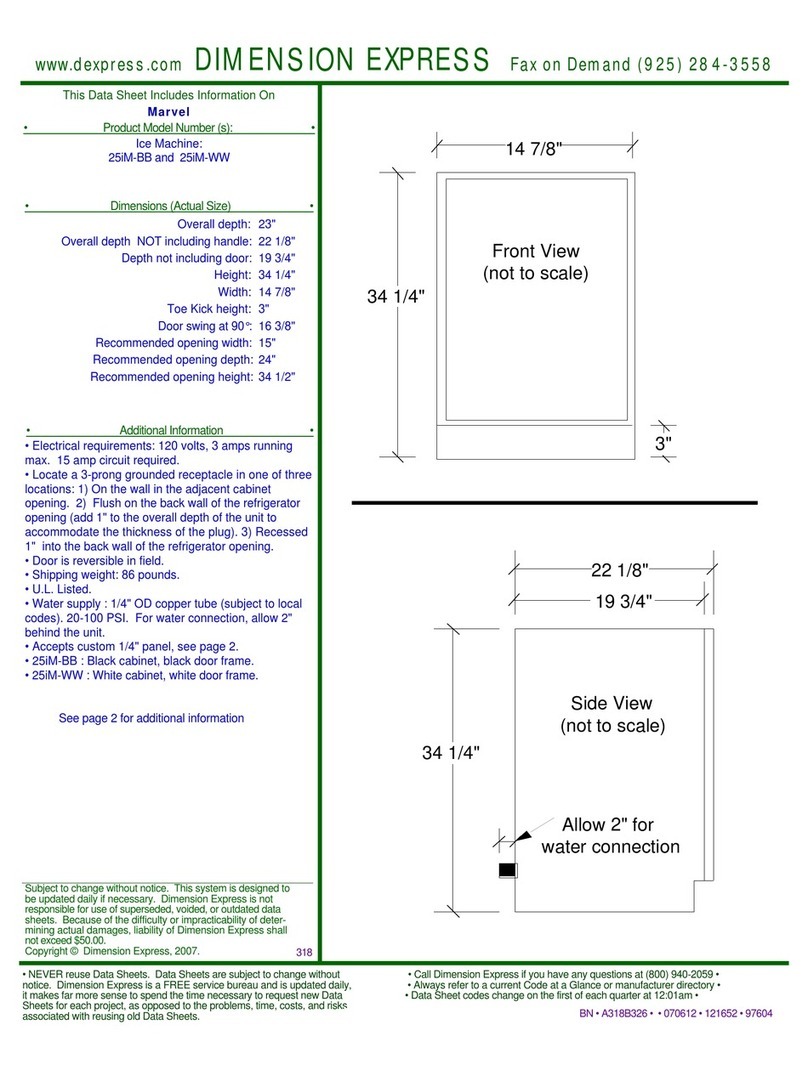

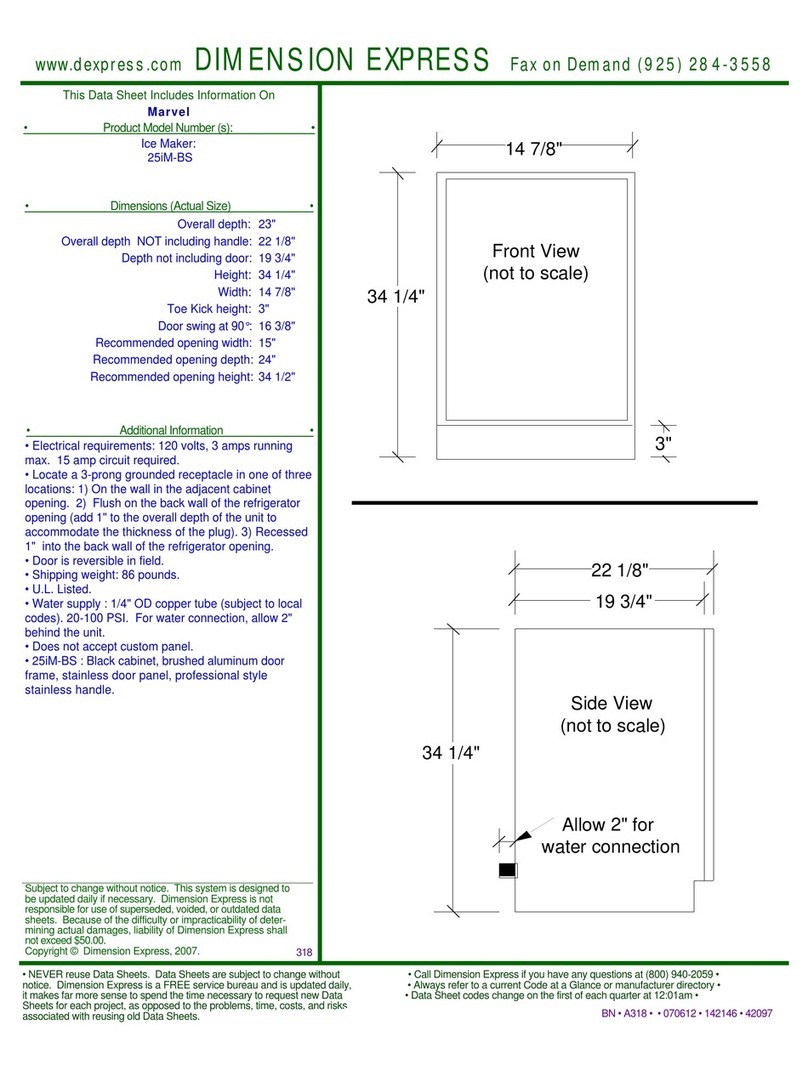

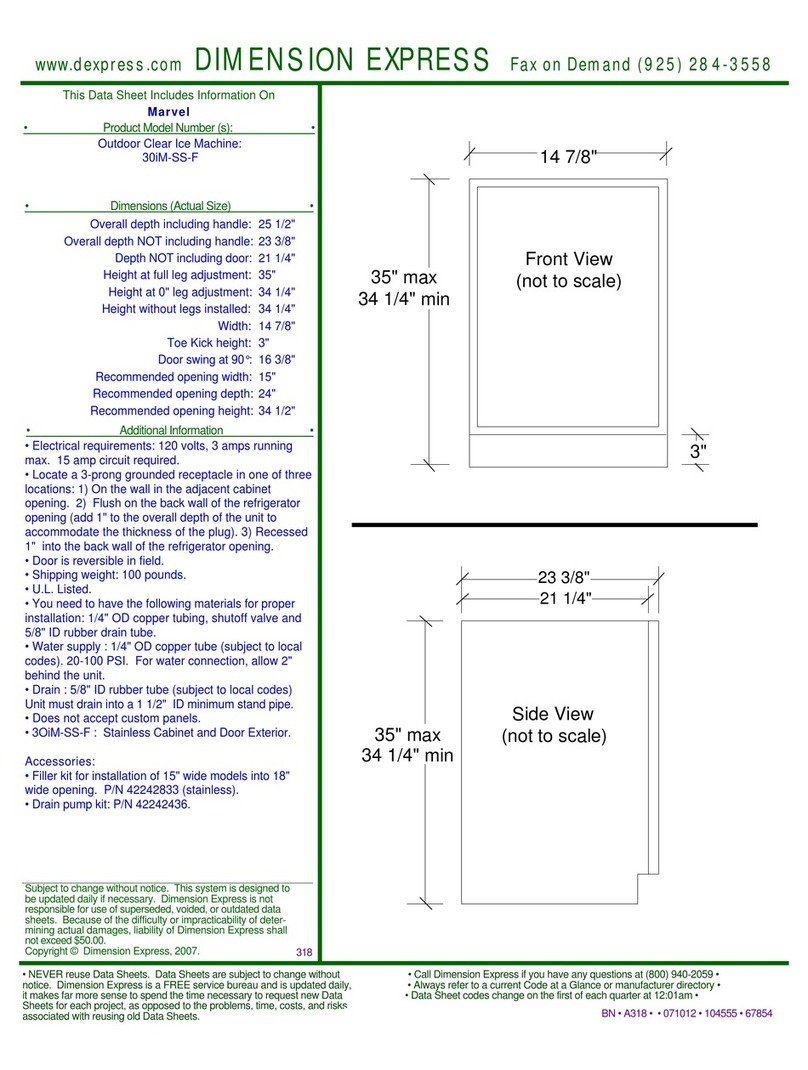

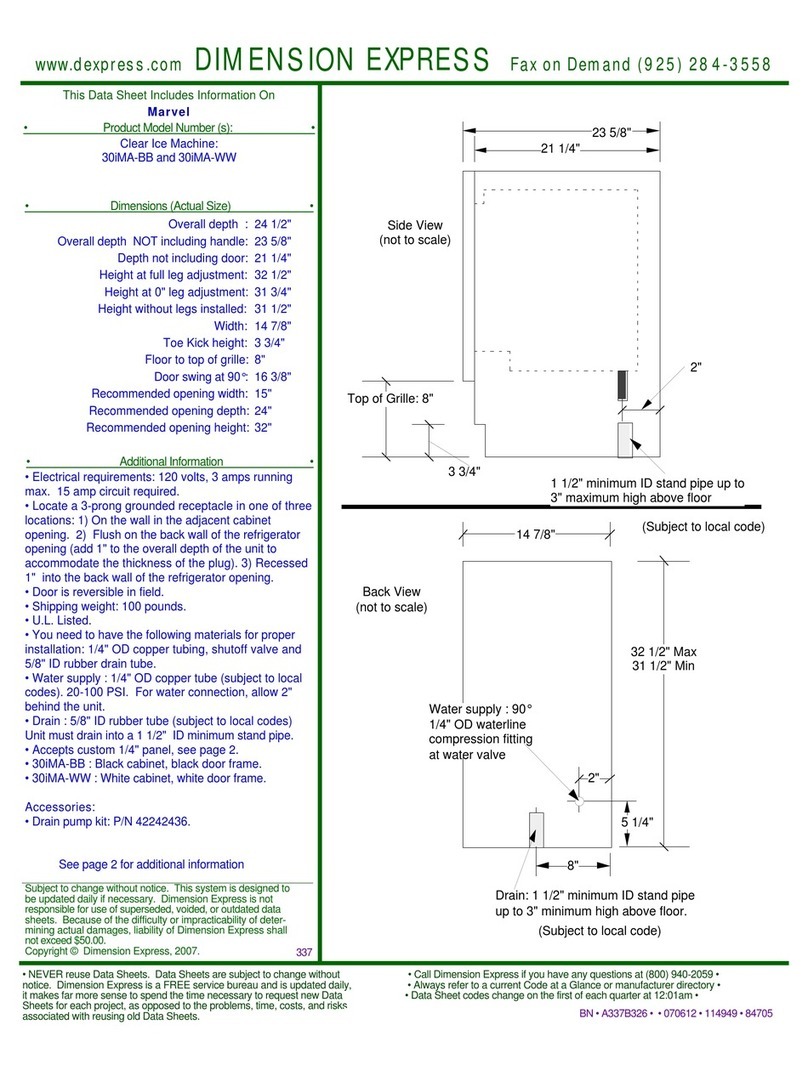

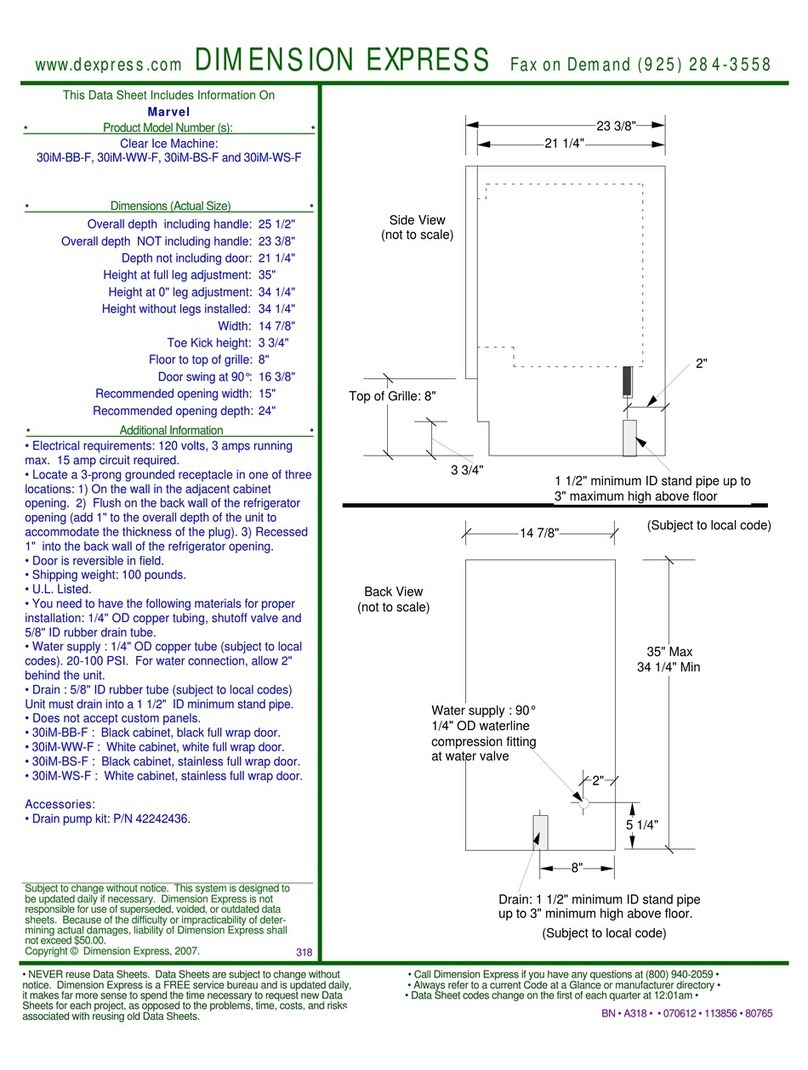

Cutout and product dimensions ..........................................6

Door adjustments ...............................................................8

Door reversal ....................................................................11

Installing the anti-tip device ...............................................12

Integrated panel installation .............................................13

Installing the drain plumbing .............................................14

Installing the water supply ................................................15

Operation of ice machine .................................................16

Using your Electronic Controls ........................................17

Cleaning your ice machine ...............................................21

Care and cleaning .............................................................24

Obtaining service ..............................................................25

Warranty ............................................................................26