2

Author: Technical Specifier marwoodsafety.co.uk MG366/0920

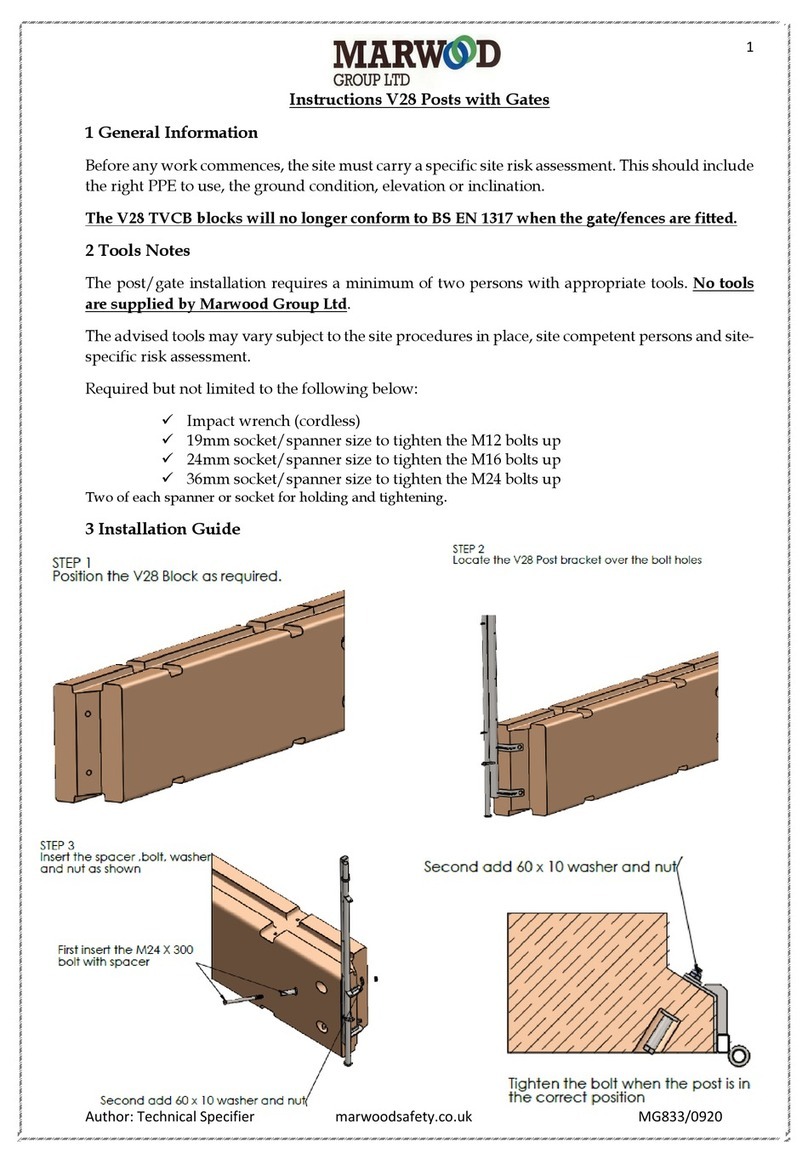

6. Fit the steel plates each side of the barrier, hand screwing the bolts with washer into

the brass inserts located in the recessed areas. Note: layout of hole slots on the plates

are not mirrored so will only fit one-way dependant on insert layout.

7. Hand tighten each bolt with 10mm allen key (do not over tighten).

8. All barriers must be fitted with the steel hinge pin and side plates, all bolts must be

tightened before filling with water.

9. Water filling fill each barrier by placing water hose in top centre hole, ensure all

drain bungs are fitted and tightened accordingly.

Once filled, replace white cap in hole

Press the cap carefully. Make sure a small cable tie is present so the cap does not

fall into the barrier. As this may result in blocking the drain hole and may result in

customers being charged for missing caps or caps that are inside barriers.

10. Once all barriers are water filled to the top of each, the assembly is complete. Moving

the barriers and pushing the tops into the barrier at this point may cause

irreparable damage.

NO TESTS HAVE BEEN CARRIED OUT ON THE BARRIERS WITH THE PEDESTRIAN

AND VEHCILE GATES INSTALLED, SO THE BS EN1317-N1 IS NOT APPLICABLE

Dismantling

1. For dismantling the barriers, firstly undo and take out the drain bung situated at the

bottom of each barrier with T bar tool.

Note: all bungs are to be kept and screwed back into the barrier once emptying is

complete.

2. Once barriers are empty of water, undo and take off steel side plates. Finally, remove

steel hinge pin.

Note: all parts can be re-used, not to be thrown away.

Daily Checks

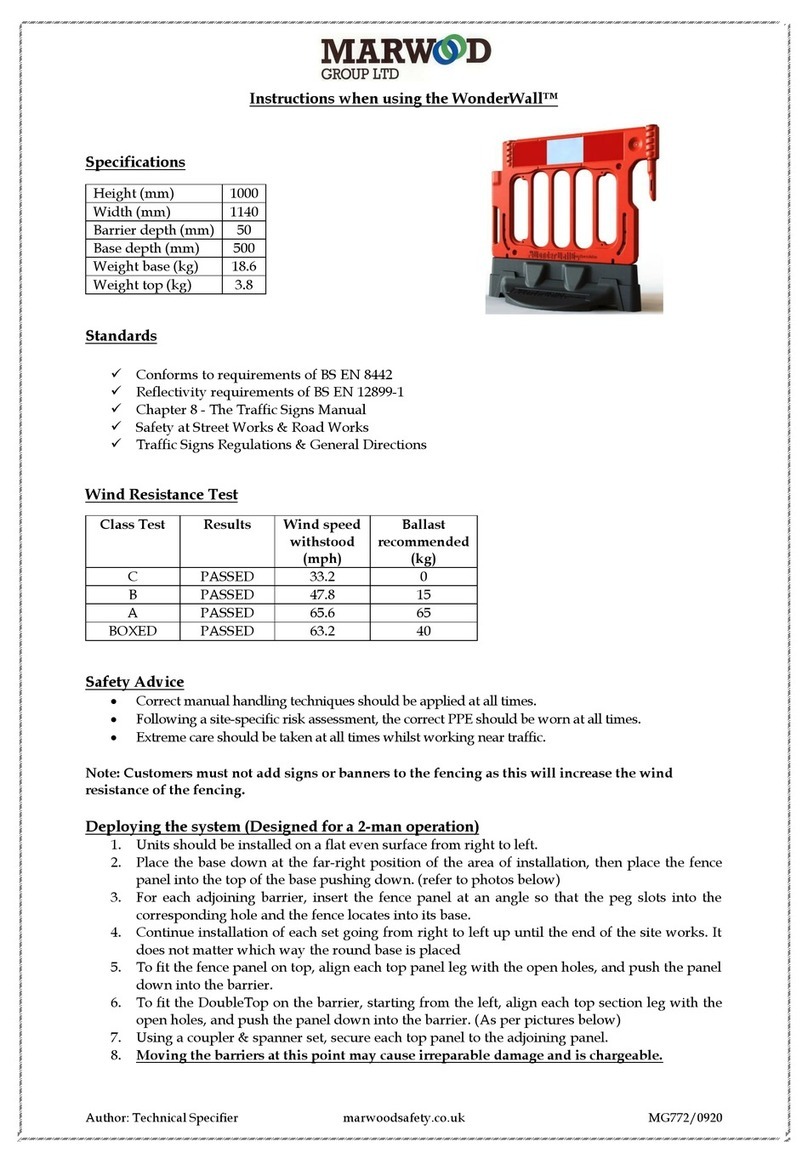

•The barrier system should be inspected daily checking to ensure:

•Each barrier is retaining water and is full with the filler cap in position.

•That all connecting pins and side plates are fitted.

•Inspect all barriers for damage caused by any unreported impacts.

Impacts

Following an impact, all barriers must be inspected for any signs of damage all barriers must

retain water. Barriers with not capable of holding water or where the captive nuts pulled

from the body of the barrier must be replaced.

Should the barriers require moving back into their position must be drained of all water; this

will enable the barriers to be moved without causing damage. Loosen the side plates to

allow the barriers to be returned to their operating position, all hinge pins and side plates

must be tightened. The barrier can then be refilled with water and the white filler caps

replaced.

Additional information

Each barrier has 3 raised spigots on the top of each long side. This is for stacking purpose,

and will locate into female sections at the bottom of each barrier. To ensure safe stacking,

each location point must be interlocked into the bottom of the above barrier.

GUIDE TO INSTALL PEDESTRIAN AND VEHICLE GATES ARE ATTACHED BELOW