Ref No.: m92A/om/101

Issue No.: 15

2 | P a g e

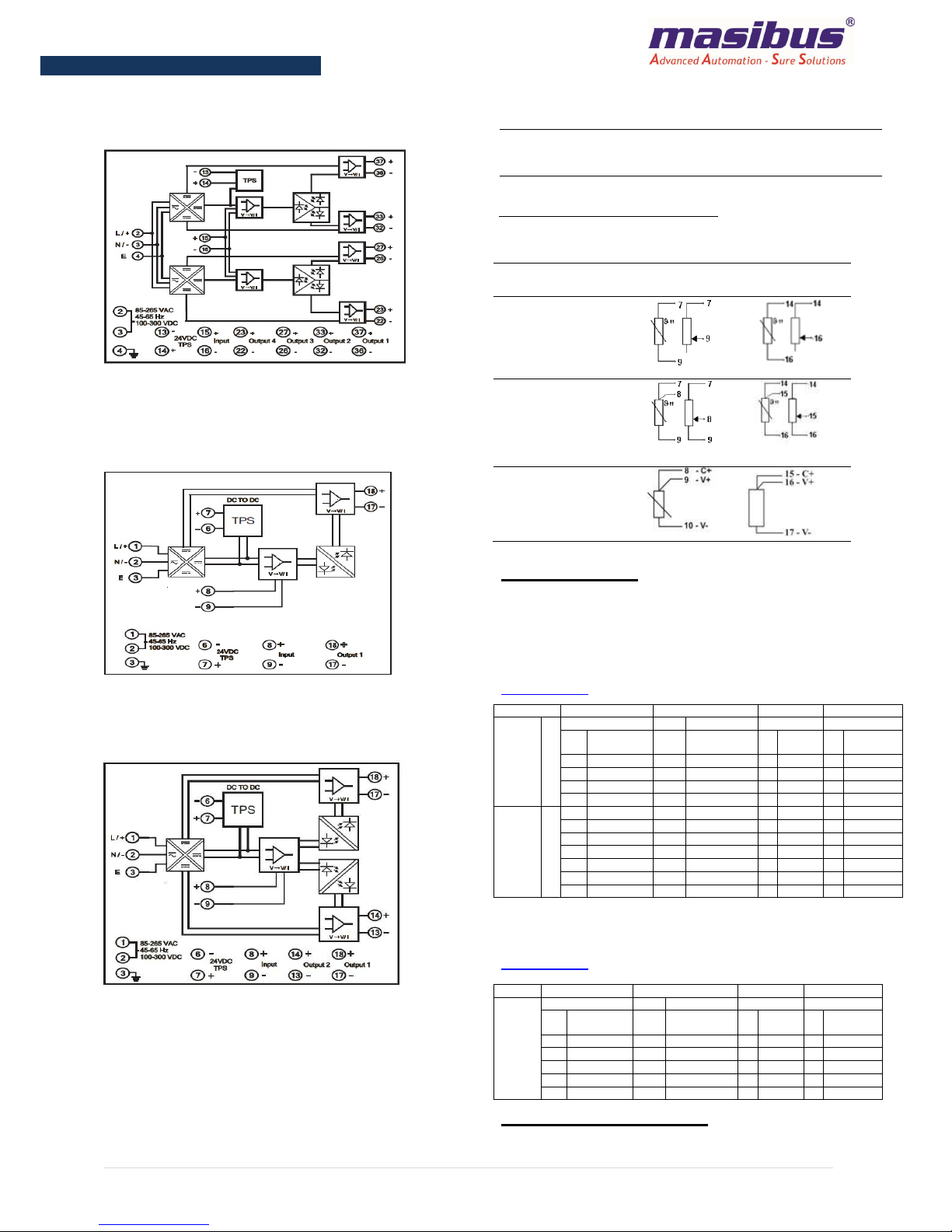

9000U Series are rugged 4 wire isolator designed to accept custom-built and

wide range of voltage and current input signals.

Signal is then isolated and

converted to standard instrumentation signals, acceptable to commercially off the

shelf (COTS) automation products.

•9000U Series offer a wide range of input / output signal types like mA, mV,

VDC which are factory settable as per customer requirements.

•Built in transmitter power supply (TPS) can drive filed transmitters in case of 4-

20mA DC input signal.

•9000U Series act as signal distributor when used with more number of outputs.

•9000U Series are flexible for DIN rail mounting and easily installable.

ISOLATED CONVERTER

9000

U SERIES

Three pot Isolation

Mains / DC operated

DIN Rail / Back panel mounted

Built in transmitter powering

Accepts non-std. signal input

option

Up to four isolated outputs of

different types available

D

IMENSION

F

OR

SOP/

DOP

55mm x 75mm x 110mm

85V-265VAC

45-65Hz

100-300VDC

F

OR

TOP/

FOP

100mm x 75mm x 110mm

S

PECIFICATION

Input

Input Type Voltage/ Current/ Potentiometric/ RTD(PT100)

Input Range

For Voltage : Min: 0 to ±10mV, Max: 0 to ±600VDC

For Current : Min: 0 to ±1mA, Max: 0 to ±100mA

For Potentiometric : 0 to 10K Ω

For RTD(PT100): Zero range:-200˚C to 0˚C,

Span range:100˚C to 850˚C

Input Impedance For Current I/

P

< 51 Ω; For Voltage I/P > 1 MΩ

Output

Output Type Voltage/ Current (Reverse range in output is supported with 9000U)

Output Range For Voltage : Min: 0 to ±100mV, Max: 0 to ±10VDC

For Current : Min: 0 to ±1mA, Max: 0 to ±10mA/+20mA

Response Time < 50 ms

Accuracy ± 0.1% of FS / 0.25% of FS in RTD I/P

Output Load resistance

For 0/4mA to 20mA : ≤750 Ω

For -10mA to +10mA : ≤910 Ω

For -1mA to +1mA and 0 to 1mA : ≤9.1K Ω

For 0 to ±1V : ≥200 Ω

For 0 to ±5V : ≥1K Ω

For 0 to ±10V : ≥2.7 KΩ

Auxiliary Output

Transmitter Power Supply 24VDC

Max current Limit: 26mA

Power Supply

Power Supply 85-265VAC 45Hz to 65Hz,100-300VDC / 18-36VDC on request.

Power Consumption Less than 10VA

CMRR >100dB

NMRR >70dB

Isolation Power to Input / Output, Input to Output, Output to Output –

2.0KV AC for 1 minute

Environmental

Operating temperature 0 to 55ºC

Temp. Co-efficient ≤100 PPM

Relative humidity 30 to 95% RH (Non-Condensing)

Protection Conformal Coating on PCB

Physical

Mounting Type DIN RAIL (35 mm) Mounting

Dimensions 55mm x 75mm x 110mm [For SOP/DOP]

100mm x 75mm x 110mm [For TOP/FOP]

Weight

Less than 450 gm [For TOP/FOP]

Terminal

Terminal Block UL,CSA standard

Terminal Cable Size 2.5mm

Isolated Convertor