Elmi CM-50M User manual

USER MANUAL

elminorthamerica.com

Centrifuge-Mixer CM-50M

USER MANUAL

Centrifuge-Mixer CM-50M

2

Content

Introduction .................................3

General information ..........................3

Technical specications........................3

Delivery package .............................3

General safety................................4

Electrical safety...............................4

During operation .............................4

Biological safety ..............................4

Preparation for use ...........................4

CarbonSpinTM ................................6

Control panel ................................7

Control keys .................................7

Additional commands of the buttons ...........8

Operating fugamix in centrifugation mode “CN” ..9

Operating fugamix in “SP” mode...............10

Operating fugamix in “Miniprep 1” and “Miniprep

2” modes Advantages of the Fugamix 3.........10

Operating fugamix in “Miniprep” mode

Understanding the interface ..................11

Operating fugamix in “Miniprep 1” mode .......12

Operating fugamix in “Miniprep 2” mode .......14

Operating fugamix in “Custom” mode

Understanding the interface ..................16

Operating fugamix in “Custom” mode

Creating a program ..........................17

Operating fugamix in “Custom” mode

Running a program ..........................18

Operating fugamix in “Mixer” mode ...........19

Error codes and solutions ....................20

Emergency opening of the lid .................20

Restoring factory settings using special

“TO” menu ..................................21

Understanding the screen readouts............21

Safety features ..............................22

Disinfection and cleaning .....................22

Transportation and storage ...................22

Warranty statements.........................22

Certicate of approval........................23

3

USER MANUAL

Centrifuge-Mixer CM-50M

Dear user!

Centrifuge-mixer Fugamix CM-50M is easy to use

and reliable in operation.We ask you to carefully

read the user manual and follow the instructions

for proper operation and maintenance of the CM-

50MP. This will insure excellent results and endur-

ing performance.

General information

The Fugamix CM-50M can be used with a range of ro-

tor options, including for 12 x 1.5/2ml tubes, as well

as PCR Strips and tubes. This microprocessor-con-

trolled system provides smooth rotor acceleration

and braking during all segments of the operation.

A big graphical display oers instant readout of all

the relevant parameters, including time, braking

level, mixing level and rotor speed (simultaneous

RPM and RCF). The centrifuge lid locks during rota-

tion and unlocks at the end of each run. Adjustable

sound alarm , brightness and sleep mode are also

standard. Imbalance detection and a temperature

sensor protect the unit from imbalancing and over-

heating.

Technical specication Rotors: 50.01(50.02/50.03)

Rotor rotation speed, RPM...........................................................15000 (12500)

Speed step selection, RPM .................................................................... 100

Centrifugal force, RCF ...............................................................15294 (10621)

Centrifugal force step selection, RCF ............................................................ 10

Timer settings, Min ........................................................................0.1-99

Number of braking levels ........................................................................5

Number of mixing levels....................................................................... 12

Total possible imbalance of test tubes: ................................................15294 (10621)

Environmental temperature,°C ..............................................................10 - 40

Relative air moisture at 20°C,% ................................................................. 80

Power supply adapter..................................................................... 24V-5A

Max power consumption, W .....................................................not more than 120

Size of the device (length x width x height), mm .........................................200х180х145

Weight ......................................................................................3.1

Delivery Package

Item Quantity

Centrifuge .....................................................................................1

Rotor nut ......................................................................................1

Rotor key ......................................................................................1

Power supply adapter 24V- 5A 120W ..............................................................1

Power cord ....................................................................................1

User manual ...................................................................................1

Packaging material .............................................................................1

ATTENTION! Type and quantity of rotors are determined by customer)

USER MANUAL

Centrifuge-Mixer CM-50M

4

General safety

•Use only as specied in the operating instruc-

tions provided.

•The unit should not be used if it has encoun-

tered a physical shock or has been dropped.

•The unit must be stored and transported in a

horizontal position (see package label).

•After transport or storage, allow the unit to dry

out (2-3 hrs) before connecting to mains power.

•It is necessary to observe the safety area of 300

mm around the centrifuge in accordance with

EN-61010-2-20. Persons and hazardous materi-

als must not be located in the safety area whilst

the centrifuge is in operation.

•Use only original accessories (rotors, adaptors,

etc.) provided by the manufacturer and ordered

specically for this model.

Electrical safety

•Connect to the mains only with a voltage cor-

responding to that on the serial number label.

•Ensure that the switch and plug are easily ac-

cessible during use.

•Do not plug the unit into the main outlet with-

out grounding, and do not use extension lead

without grounding.

•Before moving the unit, disconnect it from the

mains. To turn o the unit, disconnect the pow-

er plug from the mains outlet.

•It is the user’s responsibility to carry out appro-

priate decontamination if hazardous material is

spilt on or inside the equipment. If liquid is split

inside the unit, disconnect it from the mains

and have it checked by a competent person.

During operation

•Do not centrifuge ammable or chemically vig-

orously reactive materials. If such liquids are

spilled in the rotor or rotor chamber, the centri-

fuge must be cleaned with a moist cloth and a

mild soap solution.

•Do not use rotors with visible signs of corrosion,

wear or mechanical damage.

•Do not ll in the containers after they are insert-

ed in the rotor.

•Do not leave the operating unit unattended.

•Do not operate the unit in environments with

aggressive or explosive chemical mixtures.

•Do not operate the unit if it is faulty or has been

incorrectly installed.

•For indoor use only.

•Do not use outside laboratory rooms.

•Before using any cleaning or decontamination

method except those recommended by the

manufacturer, check with the manufacturer

that the proposed method will not damage the

equipment.

•Do not make modications to the unit.

Biological safety

•Without bioseal, the centrifuge is not a biosafe-

ty system in accordance with EN61010-2-20 and

cannot be used for centrifuging hazardous ma-

terials contaminated with toxic, radioactive or

pathogenic microorganisms.

•It is the user’s responsibility to carry out appro-

priate decontamination if hazardous material is

spilt on or inside the equipment.

Preparation for use

•Unpack the device.

•Inspect the appearance of the device, the adapt-

er and the power cord for damage.

•Open the lid of the CM-50M with the emergen-

cy lid opening lever and remove the packaging

material.( see emergency opening of the centri-

fuge lid p.8).

•In the cold season keep centrifuge at room tem-

perature for at least 2 hours.

•Assembly the rotor.

•Rotor must rotate freely without jamming.

•Centrifuge it self determines and congures to

the installed rotor.

•Connect the centrifuge to the adapter and the

adapter to the socket.

•Thus the light indicators will light up.

•In the absence of faults or damage the centri-

fuge can be considered ready to work.

•In the presence of faults and damage, do not

use the centrifuge without consulting a special-

ist.

ATTENTION! Automatic rotor detection system seamlessly detect a type of rotor installed and reprogram the pa-

rameters of the operation accordingly.

ATTENTION! Network socket must correspond to the adapter plug. In case of non compliance with this condition

the rules of electrical safety are violated.

5

USER MANUAL

Centrifuge-Mixer CM-50M

Casing Control panel

Lid

Network switch

Power plug

USER MANUAL

Centrifuge-Mixer CM-50M

6

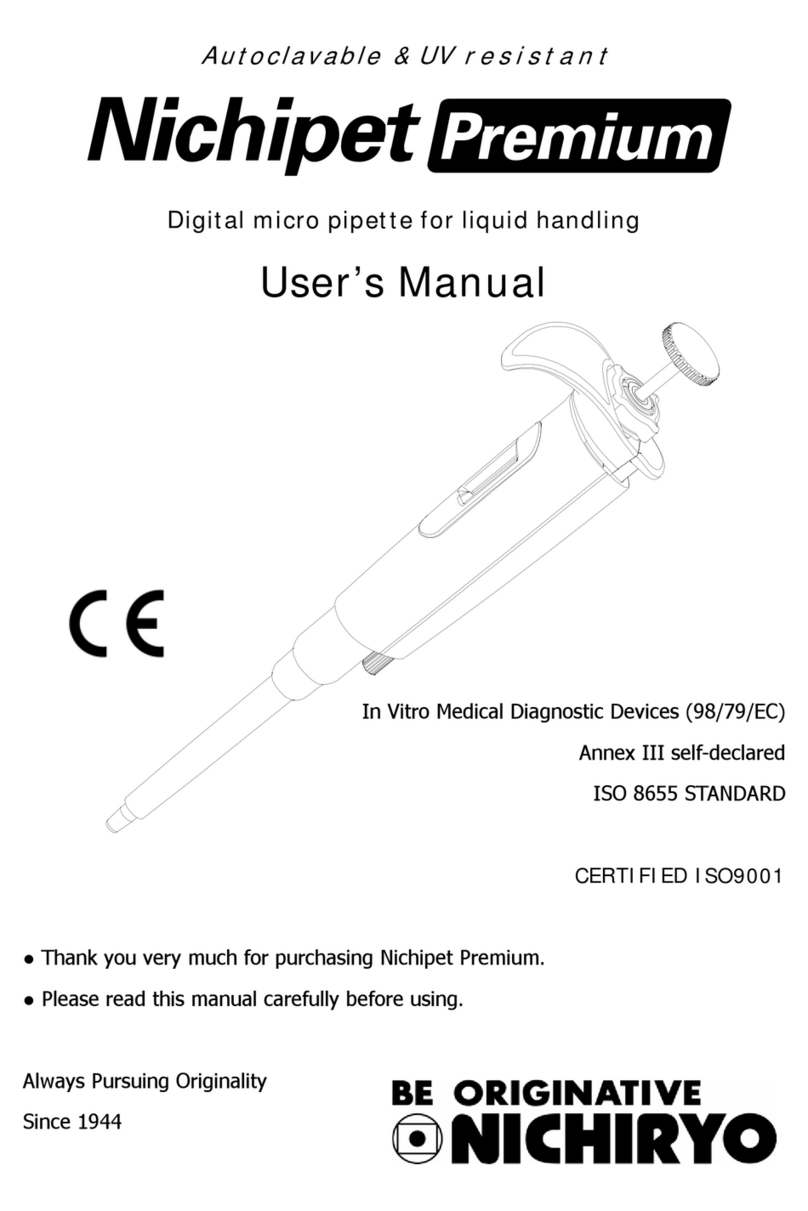

Rotor assembly and usage

Assembly: Put the rotor on the shaft rst and then

tighten the nut with a provided hand driven key.

Usage: always load the rotor symmetrically. By

minimizing the dierence of weight between the

lled test tubes, you reduce the wear of mechani-

cal parts of the centrifuge. If the overall imbalance

of test tubes exceeds 1gram, centrifuge will stop

and the display will show DISBALANCE error code.

Always apply the accessories for the rotor:

Rotor 50.01 must be used with the aerodynamic

lid which seals the contents of the rotor, reduces

noise level and heating of test tubes.

Rotors 50.02 and 50.03 must be used with the

aerodynamic housing which reduces noise level

and heating of the tubes.

ATTENTION! It is prohibited to apply the aerodynamic housing with the rotor 50.01.

Rotor 50.01

Highspeed rotor 50.01 for 12 test tubes

with aerodynamic, hermetic lid.

Maximal rotation speed 15 000 RPM.

Maximal centrifugation force 15 294 RCF.

5 braking levels.

Short run mode.

Rotor 50.02

MIX rotor 50.02 for 12 test tubes with

aerodynamic housing.

Maximal rotation speed 12 500 RPM.

Maximal centrifugation force 10 621 RCF.

12 mixing levels.

Full range of available modes.

Rotor 50.03

Strip rotor 50.03 for 2 strips with aerody-

namic housing.

Maximal rotation speed 12 500 RPM.

Maximal centrifugation force 10 621 RCF.

12 mixing levels.

Full range of available modes.

7

USER MANUAL

Centrifuge-Mixer CM-50M

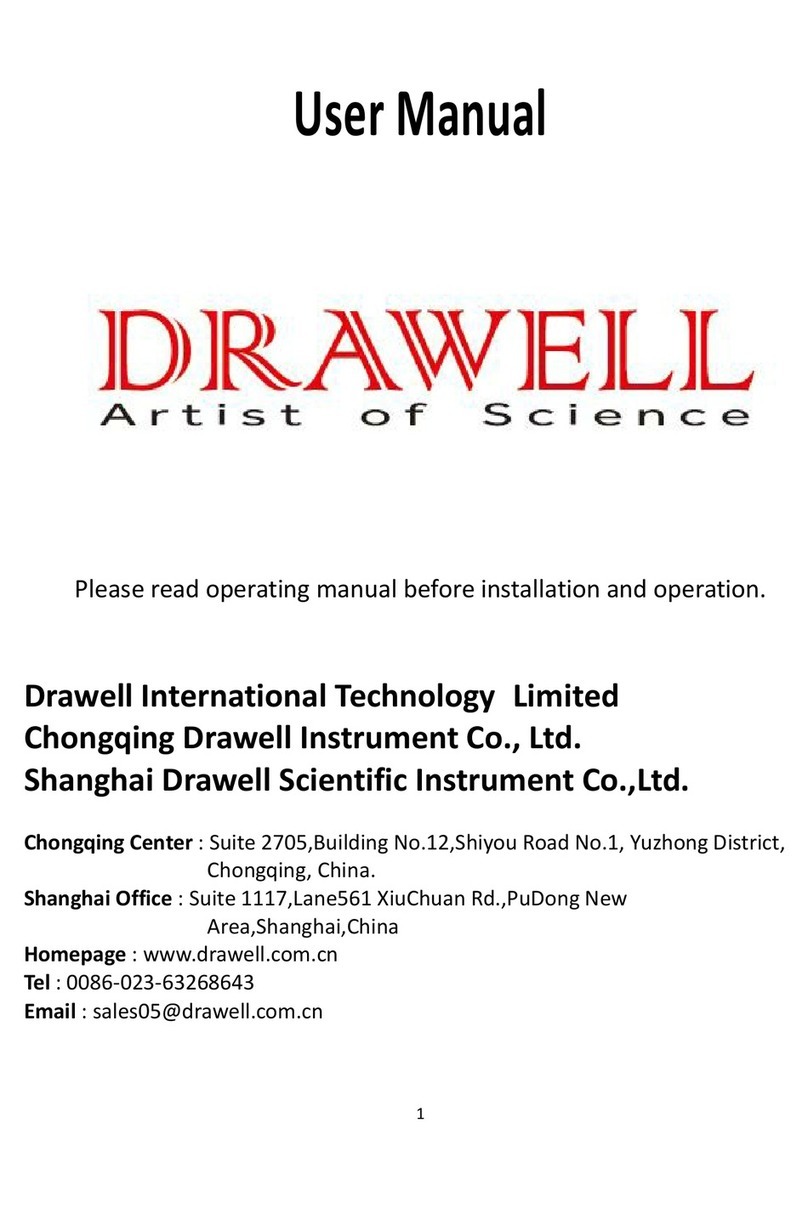

Lid opening. Mode selection.

Start/stop and custom

program launch.

“Custom” mode view and

conguration.

Up and Down menu scroll

and parameter change. Mixer start/stop.

Control keys

Control panel

USER MANUAL

Centrifuge-Mixer CM-50M

8

Additional commands of the buttons

By pressing and holding down “MODE” for 3 sec-

onds you enter “Options” menu to adjust screen

brightness, beeper volume and more.

When timer is set to “Short run” you can push and

spin the centrifuge. Operation will stop when but-

ton released.

When timer is set to “Short run” you can push and

mix. Operation will stop when button released.

Use “START/STOP” and “MIX/STOP” buttons to

switch between centrifugation “CN” and vortexing

“Mixer” modes swiftly. One single click takes to the

given mode immediately.

9

USER MANUAL

Centrifuge-Mixer CM-50M

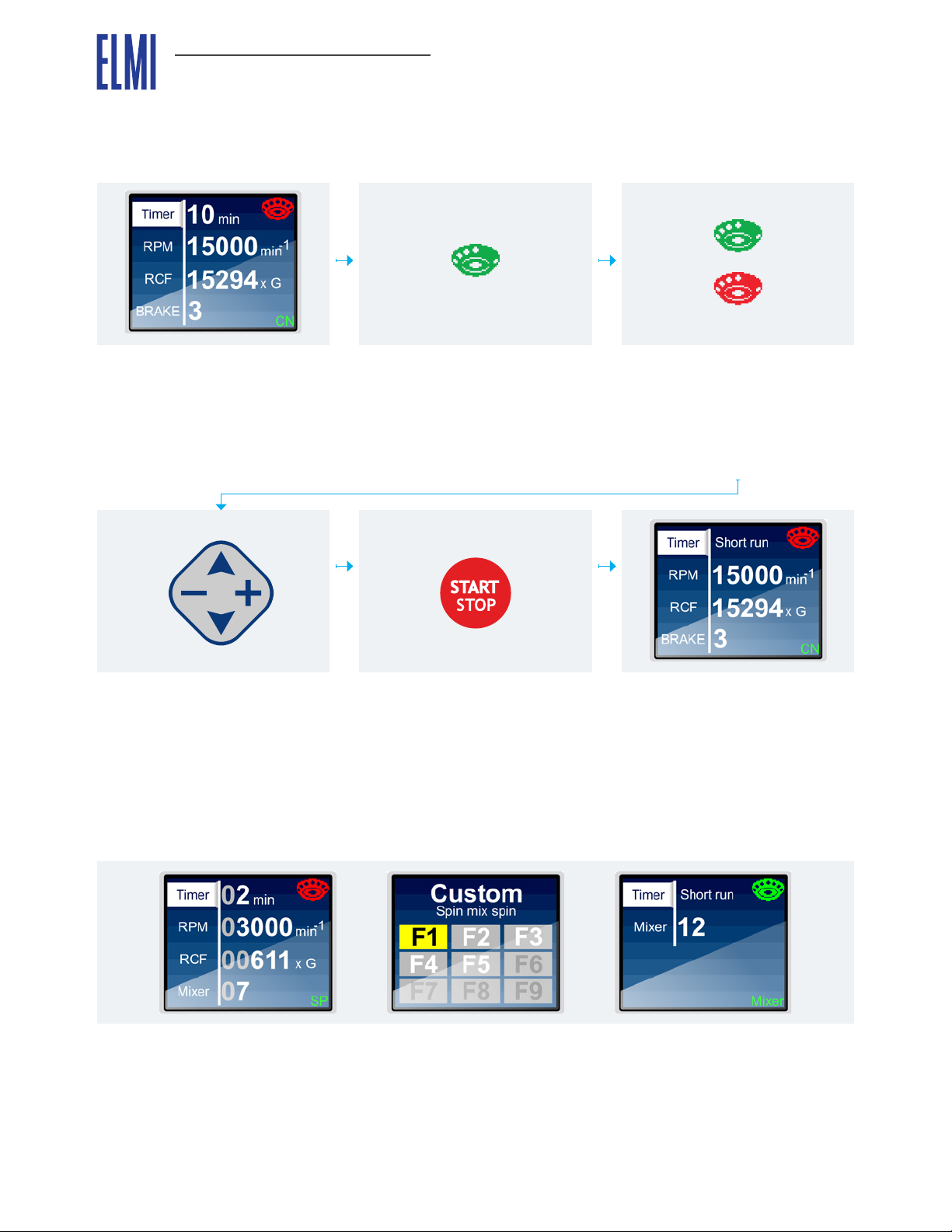

Automatic rotor recognition dis-

plays an icon of a rotor currently

installed.

Rotor icon also has a color code.

Green color means that the lid is

opened.

Red color means the lid is closed

and you can now run the centri-

fuge.

To run centrifugation just press

START/STOP button.

When rotor 50.01 is installed sys-

tem will automatically reprogram

itself to allow maximum speed

15000 RPM. Also all the other

operation modes will be hidden

away, allowing user to use the

centrifuge in “CN” mode only.

Settings adjustments are made

using the +/- up/down key-

board. Parameters can only be

changed while the centrifuge is

not running.

By reducing the timer to the min-

imum you will reach a “Short run”

mode. This mode allows using

START/STOP button to manage

the duration of the spindown.

Centrifuge will run while the but-

ton is depressed and will stop

automatically when released.

Braking levels (15000 rpm, full rotor)

Level Seconds

1........................................................................................... 28

2........................................................................................... 20

3........................................................................................... 15

4........................................................................................... 13

5........................................................................................... 11

ATTENTION! DO NOT use the Aerodynamic housing with the rotor 50.01.

Operating centrifuge with a rotor 50.01

USER MANUAL

Centrifuge-Mixer CM-50M

10

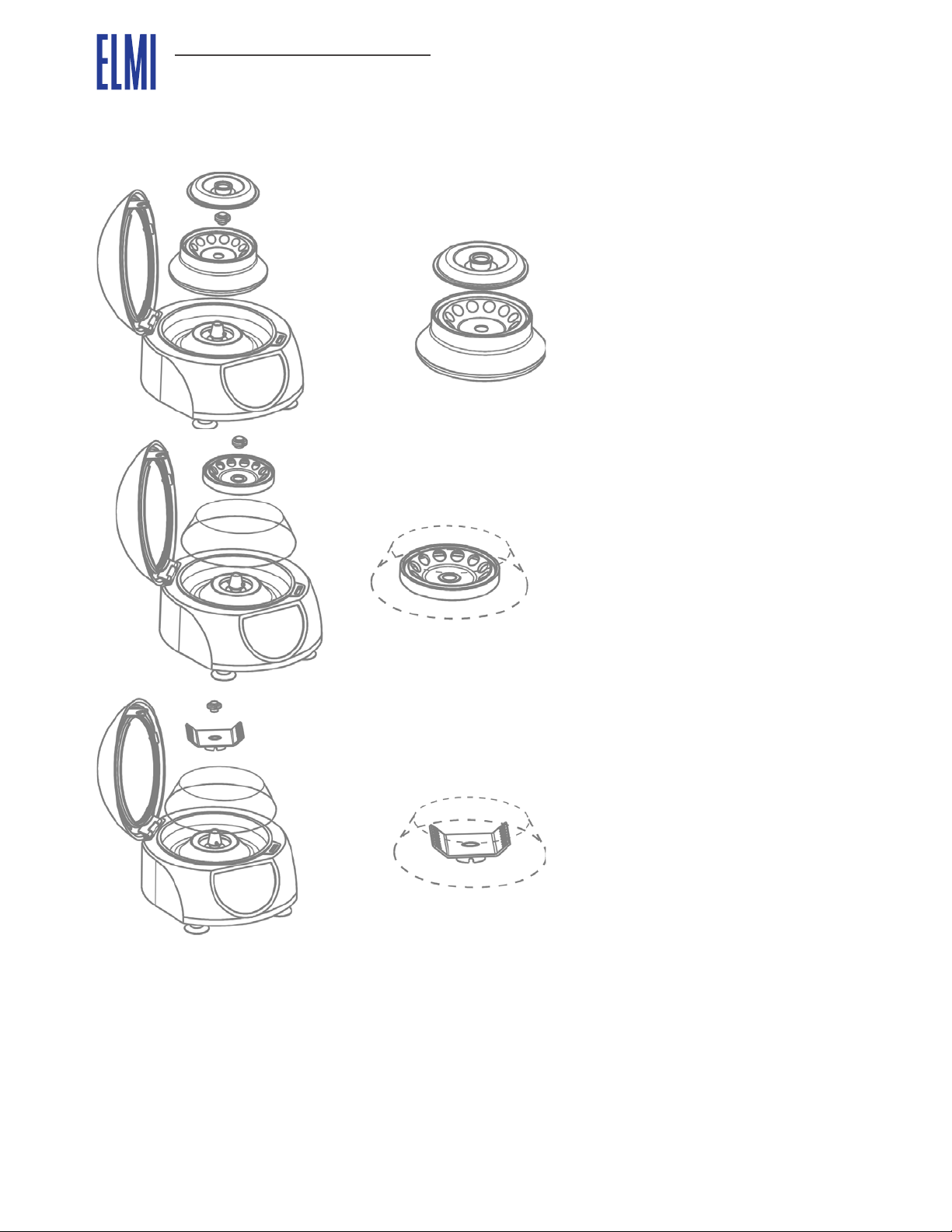

Automatic rotor recognition dis-

plays an icon of a rotor currently

installed.

Rotor icon also has a color code.

Green color means that the lid is

opened.

Red color means the lid is closed

and you can now run the centri-

fuge.

To run centrifugation just press

START/STOP button.

When rotor 50.02/50.03 is in-

stalled system will automatically

reprogram itself to allow mix-

ing functions and limit speed to

12500 RPM.

Settings adjustments are made

using the +/- up/down key-

board. Parameters can only be

changed while the centrifuge is

not running.

By reducing the timer to the min-

imum you will reach a “Short run”

mode. This mode allows using

START/STOP button to manage

the duration of the spindown.

Centrifuge will run while the but-

ton is depressed and will stop

automatically when released.

In addition to “CN” mode 3 modes become available:

• SP - sample preparation.

• Custom - Spin mix spin programmable mode.

• Mixer - Vortexer mode.

ATTENTION! Use the Aerodynamic housing with rotors 50.02 and 50.03.

Operating centrifuge with rotors 50.02 and 50.03

11

USER MANUAL

Centrifuge-Mixer CM-50M

ATTENTION! Use the Aerodynamic housing with rotors 50.02 and 50.03.

“Timer” Controls the overall

duration of the procedure.

“RPM / RCF” - Variable spin

down speed.

“Mixer” - Vortexing speed.

When timer is done operation

will stop and automatically

open up the lid. Rotor indica-

tor will change from Red to

Green and a sound notica-

tion will beep.

When all the setting are made,

just press “START/STOP” to

start the program.

Operating fugamix in “SP” mode

Sample preparation is a programmable sequence

of mixing and spin down that allows eectively mix

small volumes of reagents and collect them on the

bottom of a test tube.

USER MANUAL

Centrifuge-Mixer CM-50M

12

Fully programmed both Mix-

ing and RPM part of a step.

This step will do 12 second

mixing with a level 9 speed

and then do 30 sec spin down

with 12500 RPM speed.

This step has both parts di-

sactivated “O” and will ap-

pear on a main screen as a

grey cell with grey number

“Empty”. Programm will just

skip this step.

This step is programmed to

do only the spin down and

skip the mixing part. It will do

30 sec spin down with 12500

RPM speed. Same way you

can disable the spin down

part and do only the Mixing.

Operating fugamix in “Custom” mode Understanding the interface

Way to program individual steps.

Custom mode is a step by step program with 9 inde-

pendently programmable steps F1-F9.

Understanding the color code for program steps.

F3 Yellow eld: selection marker. This step is

currently selected for editing or running.

F9 Grey eld, grey letters: this step is empty and

has no user settings.

F5 Grey eld, white letters: this step contains

user created program.

F2 Grey eld, black letters: this step contains

user created program and it has already

been executed.

Every step has two parts :

• Mixer: Variable speed vortexing

• RPM: Spin down with an optional speed.

Mixer

RPM

ATTENTION! Use the Aerodynamic housing with rotors 50.02 and 50.03.

13

USER MANUAL

Centrifuge-Mixer CM-50M

ATTENTION! Use the Aerodynamic housing with rotors 50.02 and 50.03.

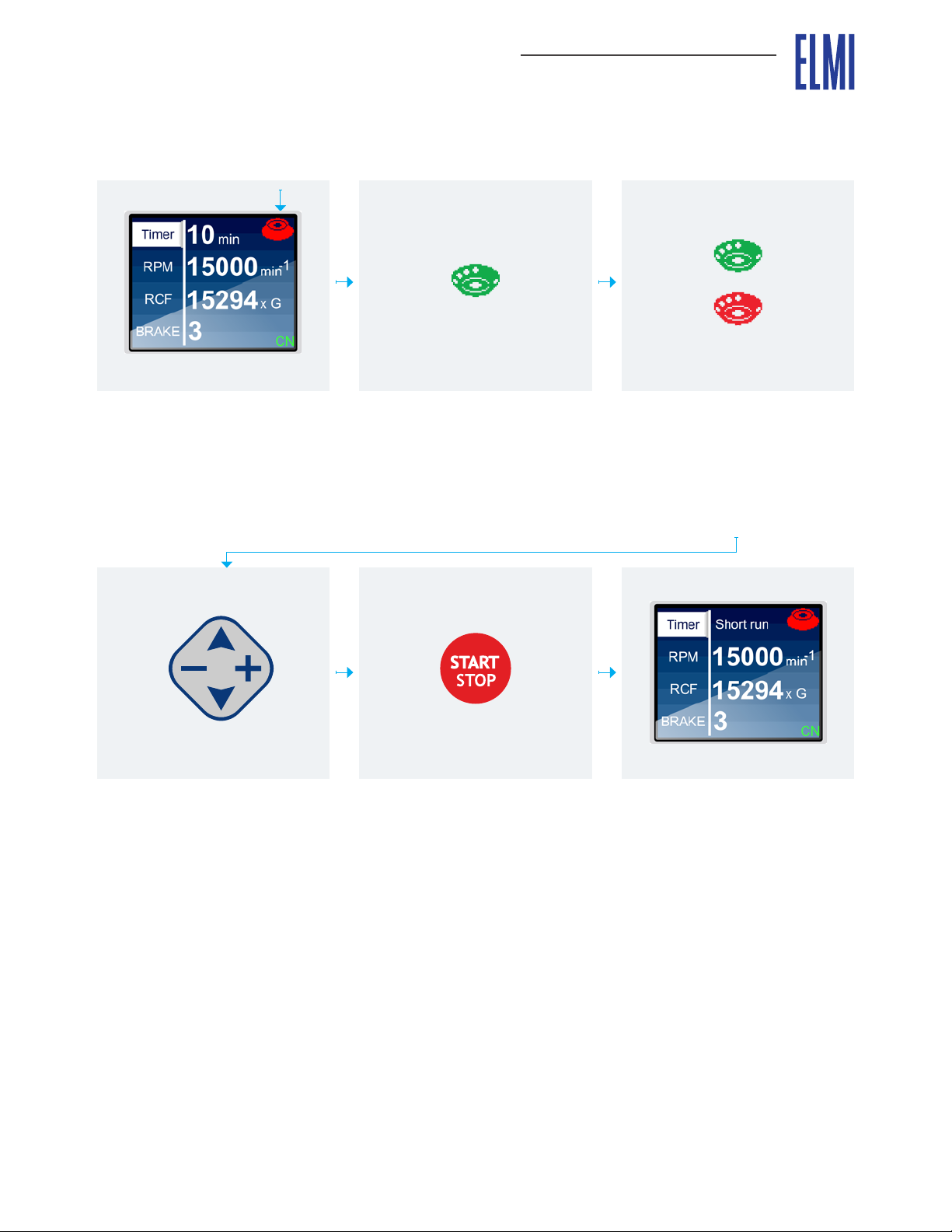

Operating fugamix in “Custom” mode Creating a program

Find mode “Custom” in a mode list by pressing

“MODE” button.

Cell editing screen will open up. Here you can mod-

ify the settings of Mixer and RPM by using “+/- up/

down” keyboard.

When all the steps are edited press “SET” and return

to main screen of the “Custom” mode. You will see

your edited steps as a grey cells with white letters.

In order to start programming steps of the program

press “SET”.

When the rst F1 step editing is nished press

“MODE” to proceed to step F2 then F3 and so on.

You can also move between steps by pushing “up

and down” buttons on the control keyboard.

USER MANUAL

Centrifuge-Mixer CM-50M

14

Operating fugamix in “Custom” mode Running a program

Selector is automatically placed at the beginning of

the program to the st step F1.

Upon completion of every step centrifuge will stop,

open the lid and wait to proceed to the next step F2.

Steps that are already completed are marked black

color.

If needed you can move selector from one step to

another to change the sequence using the “+/- up/

down” keyboard.

Press START/STOP to run the program.

To proceed to step two F2 press START/STOP.

When all the steps are completed the system will

return to main screen of the “Custom” mode. You

can now repeat the program again.

ATTENTION! Use the Aerodynamic housing with rotors 50.02 and 50.03.

15

USER MANUAL

Centrifuge-Mixer CM-50M

Operating fugamix in “Mixer” mode

Mixer mode is a fully functional vortexer. Easy to set vibration speed from 1 to 12.

Settings adjustments are made using the “+/- up/

down” keyboard. Parameters can also be change

while the centrifuge is running.

Vortexing level RPM

1105

2375

3525

4575

5732

6945

71082

81220

91332

10 1400

11 1540

12 1620

By reducing the timer to the minimum you will reach

a “Short run” mode. This mode allows using “MIX/

STOP” button to manage the duration of vortexing.

Vortexer will run while the button is depressed and

will stop automatically when released.

To run vortexing just press “MIX/STOP” button.

Centrifuge lid can be either open or shut while vor-

texer is running.

Vortexing mode 1 is a Smart function which resem-

bles hand shaking motion!

Relative speed in rounds per minute from level 2 to

lever 12.

Vortexing levels explained.

USER MANUAL

Centrifuge-Mixer CM-50M

16

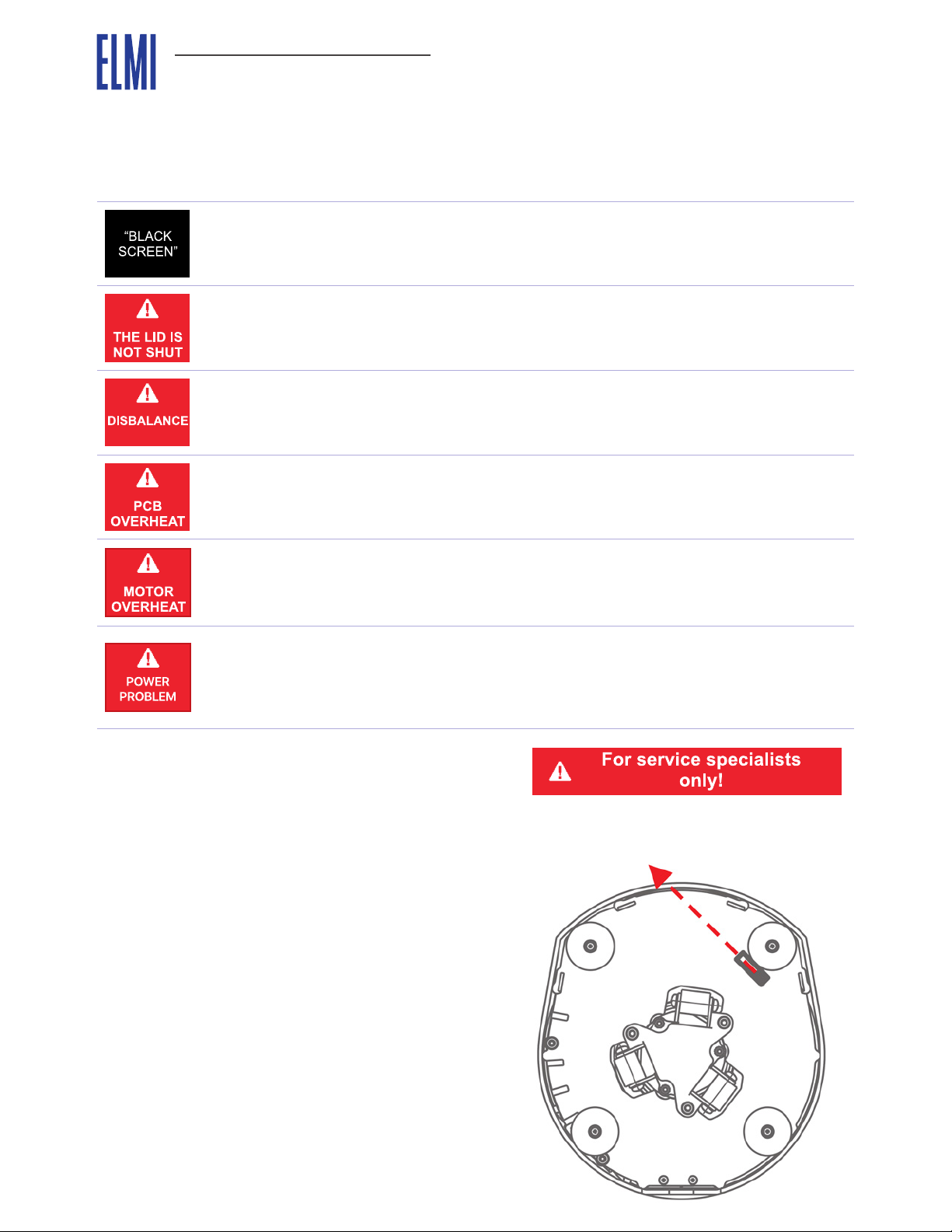

Error codes and solutions

Error code Cause Solution

No main power connection.

Power failure

Check connection of the power cable.

Check if the power supply adapter is func-

tioning.

Centrifuge lid is left open. Close and press on the lid till you hear a

click.

Total imbalance of test tubes

is more than 7 gram. Load rotor symmetrically.

Processor Control Board is

overheated.

Give a little time and centrifuge will cool

down automatically.

Motor is overheated. Give a little time and centrifuge will cool

down automatically.

Bad connection of power

supple to device / to power

socket. Power supply failure.

Turn on and o the device with mains For

service specialists switch, check the power

supply only! connections from device up to

the socket. Check the condition of power

supply, if necessary replace the unit.

Rotor detection fails.

Centrifuge does not

start. Power supply

cuts o. Disbalance

detection failure.

Controller factory settings

mismatch.

Go to “TO” special menu.

Emergency opening of the lid

To open the lid of centrifuge in case of power failure

or lock damage of the lid it is necessary to raise the

centrifuge and move the lever, which is located on

the bottom of a centrifuge under the control panel,

to the side as it is shown on the gure.

17

USER MANUAL

Centrifuge-Mixer CM-50M

Restoring factory settings using special “TO” menu

Understanding the screen readouts:

When in “CN” mode turn the

centrifuge o by clicking the

main power switch to “o”

position.

Centrifuge will enter to a spe-

cial service menu “TO”.

Press and hold down both

buttons (-) and (+).

While holding down the but-

tons click the power switch to

“on” position.

Compare the “modiable parameter” gures with corresponding

factory default gures that you can nd on the “centicates” page in

the end of this manual.

If gures does not match - correct them manually using “up/down

+/-” keyboard.

Parameter Actual parameter

Modiable parameter

USER MANUAL

Centrifuge-Mixer CM-50M

18

Safety features

Service personnel are prohibited to:

• Plug the devie in to a power outlet with cong-

uration that diers from the power adapters

conguration.

• Use the device with damaged adapter, power

cord, rotor aerodynamic lid or housing.

• Move the device during centrifugation.

• Run the unit without rotor aerodynamic lid or

housing.

• Load the rotor asymmetry.

• Use damaged tubes.

ATTENTION! Studied Samples may contain pathological material, including pathogens of serious diseases.

Disinfection and cleaning

Before you start disinfection or cleaning make sure

the power adapter is unplugged. It is recommend-

ed to perform cleaning with water and universal

washing liquids. Afterwards the machine should be

carefully dried. Do not let the water get inside the

centriguge-mixer.

Transportation and storage

To insure safety during the transportation, trans-

ported equipment should be packed in the original

manufacturers packaging or similar packaging sub-

stitute.

Equipment can be transported by any kind of closed

transport make sure that equipment is tightly xed

and transportation runs accordingly to regulations

applied to this way of transport. Equipment should

be stored in original manufacturers packaging in

dry room with humidity not more then 80% and

temperature range from +10 C up to +40 C. It is not

recommended to store the equipment more then

36 month.

Warranty statements

• Warranty applies to 24 month period from the

date of purchasing.

• Malfunctions arisen by the fault of manufactur-

er during warranty period, are removed free of

charge.

• Warranty is is not valid in the following cases:

If the serial number label of the manufac-

turer is damaged.

If damages appears as a result of the incor-

rect operation, transportation or storage.

• These documents are necessary if applying for

warranty repair:

User manual with serial number of the ma-

chine.

Ocially signed report, describing the rea-

sons and conditions of equipment malfunc-

tion.

• Warranty repair could be performed only if the

equipment is delivered in the original manu-

facturers packaging or equally safe packaging.

Therefore please save the packaging after un-

packing the device.

• If the above warranty requirements are dis-

turbed, repair charges are applied to the con-

sumer.

• For all further questions concerning exploita-

tion and maintenance please contact manufac-

turer or product vendor.

19

USER MANUAL

Centrifuge-Mixer CM-50M

Certicate of approval

Fugamix CM-50M___

N0 __________________________________________

has been inspected for the technical conditions

and meets all regulations necessary for this class

of device.

Quality control person _____________________________

(name) (signature)

Date of manufacture ______________________________

PLACE FOR STAMP

Certicate of sale Organization_____________________

Address 1 line _____________________________________

Address 2 line _____________________________________

Phone _____________________________________________

Vendor ________________________ (name) (signature).

Date of sale ________________________________________

USER MANUAL

Centrifuge-Mixer CM-50M

20

Phone:

(805) 375-0060

3483 Old Conejo Rd., STE 206

Newbury Park, CA 91320

elminorthamerica.com

North America

Phone:

(371) 6755-8743

21-133 Aizkraukles Str., Riga LV-1006

Fax: (+371) 6755 1934

E-mail: [email protected]

www.elmi-tech.com

Europe

© ELMI North America, Inc. 2021

Table of contents

Other Elmi Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

ThermoFisher Scientific

ThermoFisher Scientific HERASAFE 2025 operating instructions

cytiva

cytiva AKTA flux 6 operating instructions

Klein Tools

Klein Tools TI220 instruction manual

Thermo

Thermo 2210 Instrument manual

Protecto

Protecto F-SAFE SST 12/20 Series Installation and operating manual

cytiva

cytiva Xuri W25 operating instructions